Have you ever wondered how machines can create such unique shapes? When it comes to making irregular pockets, a special tool called a milling cutter is key. This tool can tackle odd shapes with ease, turning blocks of material into incredible designs.

Imagine a robot carving out a one-of-a-kind toy. That’s what a milling cutter can do! It spins quickly and cuts away material just like a pencil sharpens wood. But it’s not just for perfect squares or circles. It can shape things that look like stars, waves, or any pattern you can think of.

Isn’t it exciting to think about all the things you can create? From toys to parts for cars, the milling cutter makes it possible. Exploring how these tools work can unlock new ideas and inspire your own creations.

Join us to learn more about milling cutters for irregular pocket milling, and discover the art of making things that are out of the ordinary!

Milling Cutter For Irregular Pocket Milling Techniques

Milling Cutter for Irregular Pocket Milling

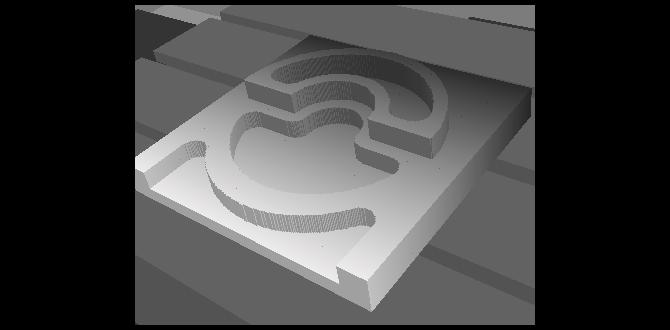

Are you curious about making complex shapes with precision? A milling cutter for irregular pocket milling can help you do just that. These cutters are specially designed to carve out unique pockets in materials like metal or wood. They easily tackle odd shapes and angles, making them perfect for high-tech projects. Did you know that these tools can save time and reduce waste? Using the right milling cutter can make your work smoother, quicker, and smarter!Understanding Irregular Pocket Milling

Definition and significance in machining. Common applications and industries using irregular pocket milling.Irregular pocket milling is a clever machining process. It creates unique shapes in materials, much like making cookie cutters for unusual cookie shapes. This technique is important in industries like aerospace and automotive, helping to shape parts that fit perfectly. Its significance lies in producing complex designs that improve efficiency and performance. Common applications include cutting intricate metal parts and creating molds for various products. Here’s a quick look at its uses:

| Industry | Application |

|---|---|

| Aerospace | Building aircraft components |

| Automotive | Shaping engine parts |

| Manufacturing | Creating molds for plastics |

This process also helps save time and materials, making it a win-win for everyone, unless you love cleaning up the mess of broken bits!

Factors to Consider When Choosing a Milling Cutter

Material compatibility and cutter durability. Geometry and design features for efficiency.Choosing the right milling cutter is a bit like picking the best pizza topping. You need the right match! First, check the material compatibility. Not all cutters play well with all materials. Durability matters! A sturdy cutter lasts longer and cuts better. Next, think about geometry. The design can affect how efficiently the cutter works. A well-designed cutter can zip through tasks like a pro. Remember, the sharper the tool, the smoother the job!

| Factor | Details |

|---|---|

| Material Compatibility | Choose cutters that suit the material. Steel, aluminum, or plastic? Each needs a unique cutter! |

| Cutter Durability | A durable cutter saves time and money. No one likes a dull edge! |

| Geometry | Opt for designs that enhance efficiency. Different shapes work better for different cuts! |

Best Practices for Irregular Pocket Milling

Recommended milling strategies and techniques. Importance of toolpath planning and simulation.For successful irregular pocket milling, choose the right milling strategies. Here are some important tips:

- Use a steady feed rate for even cutting.

- Consider the tool’s shape to reach tricky areas.

- Plan your toolpath carefully before starting.

Simulation helps foresee issues. It saves time and tools. Visualizing paths shows mistakes early. Remember, a well-planned path ensures a smooth experience.

What are the best strategies for irregular pocket milling?

Using the right tools and planning the cutting paths is key for success. Each step matters for a good finish and efficiency.

Advantages of Using Specialized Milling Cutters

Enhanced precision and surface finish. Reduction of machining time and costs.Using specialized milling cutters can make your machining job a breeze! First, they offer enhanced precision and a smooth surface finish. This means your pieces can look sharp—even if they’re not all square! Secondly, these cutters cut down on machining time and costs, so you can save both time and money. Who doesn’t like that? Think of it this way: less time in the shop means more time for snacks or playtime!

| Benefits | Details |

|---|---|

| Enhanced Precision | Improves accuracy in shaping parts. |

| Smoother Finish | Gives a polished look to the surface. |

| Cost-effective | Reduces machining time and saves money. |

Top Brands and Models for Irregular Pocket Milling Cutters

Brief profiles of leading manufacturers. Comparison of toprated models based on user feedback.Several top brands dominate the scene with high-quality milling cutters for irregular pocket milling. Companies like Kennametal, Carbide USA, and Seco Tools are known for their reliable tools. User feedback shows that Kennametal’s models often receive praise for their durability, while Carbide USA is celebrated for affordability without sacrificing quality. Here’s a quick peek at some top-rated models based on customer reviews:

| Brand | Model | Rating |

|---|---|---|

| Kennametal | KYB245 | 4.8/5 |

| Carbide USA | CGP500 | 4.5/5 |

| Seco Tools | S1150 | 4.6/5 |

With these trusted brands and models, you can tackle those quirky, irregular pockets like a pro. Remember, a dull cutter is like a bird without wings—it’s just not going anywhere!

Maintenance and Care for Milling Cutters

Best practices for cutter maintenance. Signs of wear and when to replace cutters.Caring for milling cutters can keep them in great shape. Here are some best practices:

- Always keep the cutters clean. Remove dust and debris after use.

- Regularly check for chips or cracks. Damaged cutters can ruin your work.

- Store cutters in a dry place to prevent rust.

- Use appropriate cutting speeds to reduce wear.

Look for signs of wear. If the cuts are rough or the cutter struggles to cut, it may be time for a replacement. Replacing dull cutters leads to better results.

How can you tell when to replace milling cutters?

Sharpness is key. If the cutter can no longer make clean cuts, consider replacing it. Regular checks help maintain efficiency and quality.

Future Trends in Milling Technology

Innovations in milling cutter design and materials. Impact of automation and software technology on milling processes.Exciting changes are coming in milling technology! New designs for milling cutters make them sharper and more efficient. These tools are made with advanced materials that last longer. Automation and smart software are also changing how we mill. Machines can now do complex tasks faster and more precisely. Here are some key points on this topic:

- Better cutter designs improve cutting speed.

- New materials reduce wear and tear.

- Automation speeds up production processes.

- Advanced software helps in planning and execution.

What are the benefits of automation in milling?

Automation makes milling faster, cheaper, and more accurate. Machines can work non-stop, leading to less waste. With smart tools, workers can spend more time on important tasks. This future looks bright!Conclusion

In summary, a milling cutter for irregular pocket milling is essential for complex shapes. It helps you create precise designs and improve your projects. Choosing the right cutter boosts efficiency and accuracy. To learn more, explore different cutter types and their uses. Try practicing on sample materials to gain confidence and skill. Happy milling!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutters For Irregular Pocket Milling:Milling cutters are tools we use to cut shapes in materials like metal or wood. When we have irregular pockets, we need special cutters to fit the odd shapes. These cutters help us make precise cuts. It’s like using different cookie cutters to make fun shapes in dough. The right cutter makes our work easier and the finished product looks better!

Sure! Just ask me your question, and I will be happy to help you with a short answer.

What Are The Key Design Features Of Milling Cutters That Make Them Suitable For Irregular Pocket Milling Applications?Milling cutters are special tools that help us carve out shapes in metal or wood. They have sharp teeth, which cut as they spin. For irregular pocket milling, they are made with different shapes and sizes to fit tricky areas. The cutters also have a strong design, so they don’t break easily. Lastly, their angle is designed to remove material smoothly, making the job easier.

How Does The Choice Of Milling Cutter Geometry Affect The Efficiency And Accuracy Of Machining Irregular Pockets?The shape of the milling cutter can change how well we cut out tricky pocket shapes. A cutter with the right angles helps it move smoothly. This makes cutting faster and keeps edges neat. If the cutter isn’t shaped right, it might leave rough spots or take longer to finish. So, choosing the right cutter helps us work well and get nice results!

What Materials Are Commonly Used For Milling Cutters In Irregular Pocket Milling, And How Do They Impact Tool Performance And Longevity?Milling cutters for irregular pocket milling are often made from high-speed steel or carbide. High-speed steel is strong and can handle heat. Carbide lasts longer and cuts faster but is more expensive. These materials affect how well the cutter works and how long it lasts. Good materials mean smoother cuts and fewer tool changes!

How Do Different Cutting Strategies, Such As Conventional Vs. Climb Milling, Influence The Effectiveness Of Milling Cutters When Machining Irregular Pockets?When we use different cutting strategies, they can change how well the milling cutter works. In conventional milling, the cutter moves against the cutter’s rotation, which can create more force and leave rough edges. In climb milling, the cutter moves with the rotation, making smoother cuts and better finishes. For irregular pockets, climb milling often does a better job because it grabs the material more efficiently. So, choosing the right strategy helps us make our work cleaner and faster!

What Advancements In Milling Cutter Technology Have Improved The Capability To Mill Complex Irregular Pockets In Modern Machining Processes?Milling cutter technology has improved a lot recently. New cutter shapes can reach tricky spots better. We now have special coatings that help cutters last longer. Also, computer programs make it easier to plan complex cuts. These changes let us create detailed designs more easily.