Have you ever wondered how artists create stunning sculptures with smooth surfaces? The secret often lies in a special tool called a milling cutter for sculpted surfaces. These tools help shape materials like wood, metal, and plastic with amazing precision.

Imagine a sculptor carefully carving a piece of stone. The right milling cutter turns that idea into reality. It removes tiny bits of material to form beautiful patterns and textures. Isn’t it fascinating how a simple tool can transform a block into a masterpiece?

What if you could learn how these milling cutters work? You’ll discover how they make detailed designs much easier. Whether you’re an artist or just curious, this article will take you on a journey through the world of milling cutters and their role in creating stunning sculpted surfaces.

Milling Cutter For Sculpted Surfaces: Enhance Your Craft

Milling Cutter for Sculpted Surfaces

Milling cutters create stunning details on sculpted surfaces. They help craftsmen carve intricate designs in wood, metal, and plastic. Imagine transforming a plain block into a beautiful statue! These tools shape surfaces by removing material precisely. Choosing the right cutter, like a ball nose or a flat end mill, makes a big difference. Did you know that using the wrong cutter can ruin your project? With the right milling cutter, you can unleash your creativity and bring your vision to life!Understanding Milling Cutters

Definition and purpose of milling cutters. Types of milling cutters available in the market.Milling cutters are special tools used to shape materials like metal or wood. Think of them as artists’ brushes, but for manufacturing! Their main purpose is to carve out designs and smooth surfaces. There are several types of milling cutters, each serving a unique role. Here’s a quick overview of some common types:

| Type | Description |

|---|---|

| Flat End Mill | Great for making flat surfaces! |

| Ball Nose Mill | Perfect for curved surfaces; it’s like a ball on a stick! |

| Tapered End Mill | For delicate designs with angled edges. |

Whether you’re sculpting furniture or crafting intricate art, choosing the right milling cutter is key to your masterpiece!

Choosing the Right Milling Cutter for Sculpted Surfaces

Factors to consider when selecting a milling cutter. Material compatibility for sculpted surfaces.Choosing the perfect milling cutter for sculpted surfaces can feel like picking ice cream flavors at a shop with a hundred options! First, think about material compatibility. Not all cutters are friends with every material. Some cutters love wood, while others prefer metal. Next, consider the cutter’s size and shape. A small cutter can dance in tight spots, while a larger one can carve grand designs. Pick wisely so your project turns out as smoothly as a well-churned butter!

| Material | Best Cutter Type |

|---|---|

| Wood | High-Speed Steel (HSS) |

| Aluminum | Cobalt Steel |

| Plastic | Carbide Tipped |

| Steel | Solid Carbide |

With these tips, you’re set to create amazing sculpted surfaces, and your projects will shine like a freshly polished trophy!

Types of Milling Cutters for Sculpted Surfaces

Ball Nose Cutters: Features and benefits. Tapered End Mills: Applications for detailed sculpting.Two common types of milling cutters work well for sculpted surfaces. First, Ball Nose Cutters have rounded ends. They are great for carving smooth curves and details. These cutters help create 3D shapes easily.

Next, Tapered End Mills have a pointed tip. They are perfect for detailed sculpting. The taper allows for precision in tight spots and complex designs. It helps to add depth and texture.

- Ball Nose Cutters: Smooth curves, ideal for 3D shapes.

- Tapered End Mills: Precision in detailed areas, enhances designs.

What are the main benefits of these milling cutters?

Ball Nose Cutters allow for easier carving of smooth curves. Meanwhile, Tapered End Mills offer precision in small, tricky areas of your project.

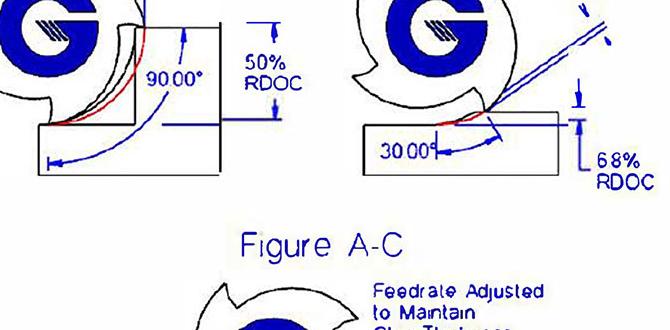

Techniques for Using Milling Cutters on Sculpted Surfaces

Recommended machining strategies for intricate designs. Best practices for achieving precision and fine detail.To create stunning designs on sculpted surfaces, use effective milling cutter techniques. Start with a slow feed rate to avoid mistakes. This helps maintain precision. Remember to choose the right cutter size for your details. Smaller cutters work well for tight spaces. Consider these strategies:

- Use a steady speed during cutting.

- Switch to finer cutters for intricate designs.

- Regularly check the surface for errors.

These best practices ensure you achieve fine detail and smooth finishes every time.

What is the best way to ensure precision with a milling cutter?

The best way to ensure precision is by maintaining a steady speed and selecting the right cutter size for the design. Keep checking your work often to catch any mistakes early.

Maintenance and Care of Milling Cutters

Key maintenance tips to extend cutter lifespan. Cleaning and storage best practices.Care for your milling cutters is essential for their lasting performance. Proper maintenance keeps them sharp and working well. Here are some key tips:

- Keep cutters clean from debris after use.

- Store them in a cool, dry place to prevent rust.

- Inspect regularly for any signs of wear.

Following these steps can help your milling cutter for sculpted surfaces last longer. Remember, a well-cared cutter is a happy cutter!

Why is cleaning important?

Cleaning removes dirt and grime that can dull the cutter. This keeps your work smooth and precise.

What are the best storage practices?

- Use a protective case or sheath.

- Avoid stacking them haphazardly.

Proper storage prevents damage and extends the cutter’s life.

Common Mistakes to Avoid When Milling Sculpted Surfaces

Miscalculations and their impact on the final product. Improper feed rates and speeds: Consequences and solutions.Milling sculpted surfaces can be tricky. One common mistake is miscalculating dimensions. This can lead to products that don’t fit—or worse, crash like a car at a bad movie! Improper feed rates and speeds also cause issues. If you’re too fast, your cutter can burn out like a lightbulb. Too slow? You’ll be waiting longer than a kid in a candy store. Let’s break it down:

| Problem | Consequences | Solutions |

|---|---|---|

| Miscalculation | Poor fit | Double-check measurements |

| Improper Speed | Cutter damage | Match speed to material |

| Wrong Feed Rate | Uneven surface | Adjust according to cutter specs |

By avoiding these blunders, you can make sure your sculpted surfaces look fantastic and function well. Remember, it’s all about those right numbers!

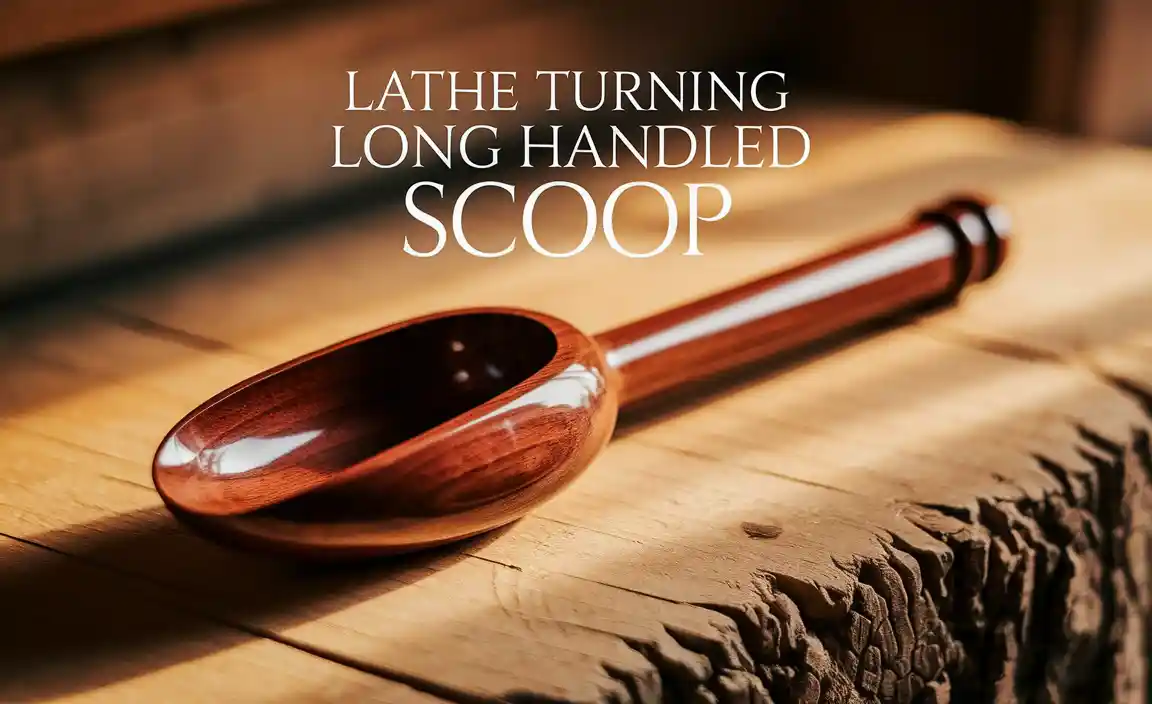

Case Studies and Applications

Examples of successful projects using milling cutters. Insights from industry professionals on sculpted surface milling.Many artists and engineers use milling cutters to create amazing sculptures. For example, a famous project involved carving intricate designs on stone. The result was a stunning fountain that attracted many visitors. Another project used milling cutters to make detailed patterns on metal. Professionals say these tools help save time and improve quality. Here are a few insights:

- Speed: Milling cutters work faster than hand carving.

- Precision: They create exact shapes and details.

- Versatility: Use them for different materials like wood, stone, and metal.

Conclusion

In conclusion, a milling cutter for sculpted surfaces is essential for creating detailed designs. It offers precision and smooth finishes. You can explore different types to find what suits your project best. Experiment with various materials to see how they respond. Remember, practice makes perfect! For more tips, consider researching online or visiting your local workshop. Happy milling!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutters For Sculpted Surfaces:Milling cutters are tools that help shape and smooth surfaces. They can create detailed designs, like patterns and curves. These tools spin very fast to cut through materials like wood or metal. You can use different kinds of milling cutters for different effects. They are important for making things like sculptures and furniture look nice.

Of course! Please provide the question you’d like me to answer.

What Types Of Milling Cutters Are Most Effective For Creating Detailed Sculpted Surfaces In Various Materials?To create detailed sculpted surfaces, we can use ball end mills and flat end mills. Ball end mills have rounded tips, which help us make curved shapes. Flat end mills have straight edges for sharper details. We can use these cutters on wood, metal, or plastic to create nice designs.

How Do The Design And Geometry Of A Milling Cutter Influence The Quality Of Sculpted Surfaces?The design and shape of a milling cutter can change how smooth a surface is. If the cutter has sharp edges and a good shape, it cuts better. This means we get cleaner and smoother surfaces. If the cutter is dull or not shaped well, it can leave bumps and marks. So, the right cutter helps us create nicer-looking shapes.

What Are The Recommended Cutting Speeds And Feeds For Milling Cutters When Working On Intricate Sculpted Designs?When milling intricate designs, you need to use slower cutting speeds. This helps to make smooth edges and details. A good starting point is around 100 to 500 RPM (revolutions per minute). For feeds, aim for about 0.005 to 0.020 inches per tooth. These settings help you make beautiful and clean designs.

How Can The Use Of Multiple Milling Cutters In A Single Machining Operation Improve The Efficiency And Precision Of Sculpted Surfaces?Using multiple milling cutters helps us make sculpted surfaces faster and more accurately. Each cutter can work on different parts at the same time. This means we finish the job quicker. Also, using the right cutter for each detail helps us create smoother and better designs. Overall, we save time and get great results!

What Advancements In Milling Cutter Technology Are Enhancing The Ability To Create Complex Sculpted Surfaces In Today’S Manufacturing Processes?Milling cutter technology has improved a lot recently. New cutters can shape more complicated designs easily. They are sharper and can cut faster. We can also adjust them for different materials. This helps us make detailed and beautiful parts for machines and toys.