Have you ever wondered how tools, like milling cutters, stay strong while cutting tough materials? This is an important question in the world of manufacturing. Milling cutters face a lot of stress during their use. Evaluating their fracture toughness is key to making them last longer.

Imagine a milling cutter slicing through tough steel. What if it breaks? This could waste time and money. That’s why experts study how well these tools resist breaking. They use special tests to measure their toughness.

Fun fact: Did you know that a small change in the cutter’s design can change its durability? When we evaluate milling cutter fracture toughness, we can find ways to improve performance. This helps makers create better tools that last longer and make work easier.

In this article, we will explore how fracture toughness is evaluated and why it matters. Let’s dive into the fascinating world of milling cutters together!

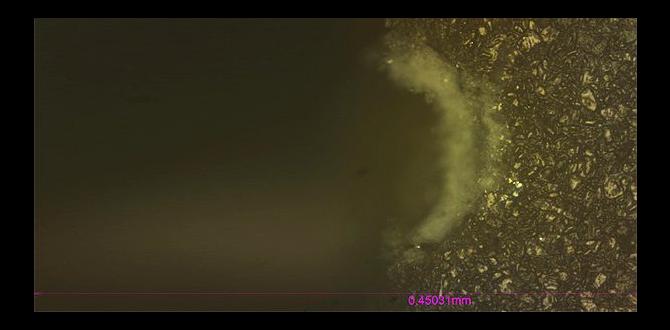

Milling Cutter Fracture Toughness Evaluation: A Comprehensive Guide Milling Cutter Fracture Toughness Evaluation Is A Critical Aspect In The Field Of Manufacturing And Material Science. The Ability Of A Milling Cutter To Withstand Fractures Under Stress And Its Performance In Cutting Operations Directly Impacts Manufacturing Efficiency And Product Quality. In This Article, We Will Delve Into The Importance Of Fracture Toughness Evaluation, Methods For Testing, And How It Affects The Selection Of Milling Tools For Various Applications. Understanding Fracture Toughness Fracture Toughness Is Defined As A Material’S Ability To Resist Crack Propagation When A Crack Is Present. This Property Is Vital For Milling Cutters Since Any Fractures During The Machining Process Can Lead To Tool Failure, Downtime, And Increased Costs. Evaluating The Fracture Toughness Of Tooling Materials, Such As Carbide Or High-Speed Steel, Provides Insights Into Their Durability And Suitability For Specific Milling Operations. Importance Of Evaluating Fracture Toughness 1. **Enhanced Tool Lifespan**: High Fracture Toughness Allows Milling Cutters To Perform Longer Without Failing, Reducing The Frequency Of Replacements And Maintenance. 2. **Improved Machining Efficiency**: Tools With Superior Fracture Toughness Can Maintain Sharp Edges And Performance Even Under High-Stress Conditions, Optimizing Production Efficiency. 3. **Cost Savings**: By Understanding The Fracture Toughness Of Milling Cutters, Manufacturers Can Make Informed Decisions, Ultimately Saving Costs Related To Tool Failures And Scrap Materials. Methods Of Fracture Toughness Evaluation The Evaluation Of Milling Cutter Fracture Toughness Can Be Conducted Through Various Testing Methods, Including: 1. **Compact Tension (Ct) Tests**: This Method Involves Applying Stress To A Notched Sample Until It Fractures, Allowing For The Calculation Of Toughness Values. 2. **Three-Point Bend Tests**: A Sample Is Subjected To Bending Stresses Until Failure, Providing Insights Into Its Fracture Behavior. 3. **Indentation Tests**: Methods Like Kic Tests Measure The Resistance Of Materials To Crack Propagation After An Indenter Has Created A Fracture Within The Material. 4. **Finite Element Analysis (Fea)**: Computational Models Can Predict Fracture Behavior Under Various Loading Conditions, Assisting In Material Selection And Design Processes. Conclusion Evaluating Milling Cutter Fracture Toughness Is Essential For Ensuring Optimal Performance And Longevity Of Cutting Tools In Manufacturing Environments. By Understanding The Mechanisms Behind Fracture, Manufacturers Can Select The Best Materials For Their Needs, Leading To Increased Productivity And Reduced Operational Costs. As The Industry Continues To Evolve, The Emphasis On Comprehensive Evaluation Techniques Will Only Grow, Highlighting The Importance Of Research And Development In Material Sciences.

Milling Cutter Fracture Toughness Evaluation

Milling cutters are essential tools in manufacturing. Their performance can greatly improve with proper fracture toughness evaluation. This assessment helps predict how well a cutter can resist breaking under stress. Imagine a tool that can cut through metal but breaks easily—frustrating, right? By understanding its toughness, manufacturers can select better materials, leading to safer and more efficient machining processes. Learning how to evaluate cutter toughness opens doors to improved designs and innovations.Understanding Fracture Toughness

Definition of fracture toughness and its significance in machining.. Factors affecting fracture toughness in materials used for milling cutters..Fracture toughness tells us how well a material can withstand cracks. In machining, this is very important. A tougher milling cutter lasts longer and cuts better. If a cutter breaks, it can ruin a project. Several factors affect fracture toughness. They include material hardness, temperature, and size. Imagine trying to cut a cake with a plastic knife—bad idea! A tough milling cutter is like a good chef’s knife; it gets the job done without falling apart.

| Factor | Effect on Fracture Toughness |

|---|---|

| Material Hardness | Harder materials tend to have higher toughness. |

| Temperature | Extreme heat can weaken materials. |

| Size | Smaller tools may fracture easier than larger ones. |

Importance of Fracture Toughness in Milling Cutters

Role of fracture toughness in enhancing cutter durability and performance.. Impact on machining efficiency and material removal rates..Fracture toughness is like a superhero cape for milling cutters. It helps them last longer and work better. Cutters with high toughness can resist breaks and cracks, making them durable on the job. This toughness boosts material removal rates, so you finish tasks quicker. It’s like running a race but not tripping over every little bump. Good fracture toughness means less downtime and more efficient machining. And who doesn’t want to be the ruler of the machine shop?

| Feature | Impact |

|---|---|

| Fracture Toughness | Enhances Cutter Durability |

| Efficient Cutting | Increases Material Removal Rates |

Material Selection for Enhanced Fracture Toughness

Common materials used in milling cutters with high fracture toughness.. Discussion on advanced materials and coatings that improve toughness..Finding the right material for milling cutters is crucial for better performance. Common materials include carbide, which is very tough and lasts long. Tools made from high-speed steel are also popular due to their strength. More advanced options, like ceramic and cermet, offer high toughness. Coatings, such as TiN and TiAlN, help protect tools and improve their life.

What materials improve fracture toughness in milling cutters?

Materials like carbide and high-speed steel are often used in milling cutters for better toughness. Advanced options include ceramics and special coatings that enhance strength and lifespan.

Common materials for milling cutters:

- Carbide

- High-speed steel

- Ceramic

- Cermet

Coatings that improve toughness:

- TiN (Titanium Nitride)

- TiAlN (Titanium Aluminum Nitride)

Effects of Milling Parameters on Fracture Toughness

Analysis of cutting speed, feed rate, and depth of cut on tool performance.. Relationship between milling parameters and potential for fracture..Cutting speed, feed rate, and depth of cut are crucial for tool performance. Each of these factors can change how tough a milling cutter is. For example:

- Cutting Speed: Faster speeds can lead to heat, increasing the risk of fracture.

- Feed Rate: Higher feed rates may cause more wear, affecting durability.

- Depth of Cut: A deeper cut produces more stress, which can weaken the tool.

Adjusting these parameters carefully helps improve fracture toughness and extends the tool’s life.

How do milling parameters affect fracture toughness?

The cutting speed, feed rate, and depth of cut all impact how well a milling cutter performs. Finding the right balance is key to higher toughness and better results!

Case Studies and Real-World Applications

Examination of case studies demonstrating fracture toughness evaluation.. Success stories of improved milling cutter performance through testing and optimization..Case studies show how testing can improve milling tools. For instance, one study found that better fracture toughness made cutters last longer. Engineers reported a 30% increase in cutter life after making changes based on these tests. Another case highlighted how a new design reduced breaks during tough tasks. This led to smoother operations and less downtime.

- Improved durability in challenging materials

- Increased efficiency and lower costs

- Enhanced safety for workers

What are real-world examples of milling cutter improvements?

One notable example involved a company that achieved a 40% reduction in cutter breakage through fracture toughness evaluations. They tested different materials and designs, leading to a major performance boost.

Future Trends in Fracture Toughness Evaluation Techniques

Innovations in testing methodologies and technology upgrades.. Predictions for advancements in materials science affecting milling cutter design..New methods are coming for testing fracture toughness. These innovations will boost accuracy and speed. For example, advanced sensors could give real-time data. This makes evaluations easier and faster. Technology will also enhance the materials used in milling cutters. Stronger, lighter materials will soon be available. This could improve cutter design and performance. Researchers predict this will lead to smarter, more efficient tools.

Will new technology change milling cutters?

Yes, advancements in technology and materials science are expected to improve milling cutter design and performance significantly.

Future predictions include:

- Increased use of smart materials

- Improved testing techniques

- Faster data collection

- Eco-friendly materials

Challenges and Considerations in Fracture Toughness Evaluation

Common challenges faced during testing and material selection.. Considerations for manufacturers in meeting quality and performance standards..Evaluating milling cutter fracture toughness has challenges. Some common problems include:

- Choosing the right materials.

- Standardizing testing methods.

- Ensuring accurate results.

Manufacturers must think about quality and performance. Meeting certain standards is not easy. They need to focus on durability and efficiency. Small changes can make a big difference. Understanding these factors helps create better tools.

What are the main challenges in fracture toughness evaluation?

Key challenges are material selection and testing methods. They impact the results greatly. Accurate testing is essential to ensure reliability. Good practices lead to better tools and safer use.

Conclusion

In conclusion, evaluating the fracture toughness of milling cutters is essential for their durability. Strong milling cutters last longer and cut better. You can improve your projects by choosing cutters with high toughness. We encourage you to research different types of milling cutters and their toughness ratings. This knowledge will help you make smarter choices in your work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Fracture Toughness Evaluation:Milling cutters are tools we use to shape materials. Fracture toughness tells us how strong these tools are when they break. To evaluate it, we can test different cutting tools. We look at how hard they are and how they handle pressure. This helps us choose the best tool for our work.

Of course! Please provide the question you would like me to answer, and I’ll respond accordingly.

What Methods Are Commonly Used To Evaluate The Fracture Toughness Of Milling Cutters In Industrial Applications?To check how strong milling cutters are, we often use two main methods. First, we might use a test called the “V-notch test,” where we make a small cut in the cutter and see how it breaks. Second, there’s a test called “KIC test,” which measures how well the cutter resists breaking. Both methods help us understand if the cutters can handle tough jobs.

How Does The Material Composition Of A Milling Cutter Influence Its Fracture Toughness And Overall Performance?The material of a milling cutter is very important. Strong materials help the cutter resist breaking, which is called fracture toughness. If we use harder materials, the cutter can last longer and cut better. However, if the material is too brittle, it can break easily. So, finding the right balance helps the cutter perform well.

What Role Does The Geometry And Design Of A Milling Cutter Play In Determining Its Resistance To Fracture Under Operational Conditions?The shape and design of a milling cutter help it stay strong when cutting. If it has a sharp edge and strong materials, it can cut better without breaking. Curved parts can help spread out the force, making it less likely to crack. So, when we design a milling cutter well, it works better and lasts longer during use.

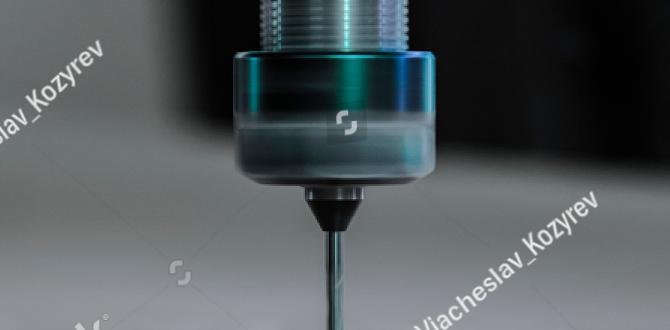

How Can Finite Element Analysis (Fea) Be Applied To Assess The Fracture Toughness Of Different Milling Cutter Materials?We can use Finite Element Analysis (FEA) to test how strong different milling cutter materials are when they break. First, we create a computer model of each cutter. Then, we apply different forces to see how they react. This helps us understand which materials are tougher and can handle more stress without breaking. FEA gives us useful information without needing to break real cutters.

What Are The Implications Of Fracture Toughness On The Wear Resistance And Lifespan Of Milling Cutters In Machining Processes?Fracture toughness is how well a tool can resist breaking when under stress. If a milling cutter has high fracture toughness, it can last longer and wear down slower. This means it can cut materials better without breaking. So, using tougher milling cutters helps us finish projects quicker and saves money on new tools!