Have you ever wondered why some tools work better than others? For those who use machinery, understanding milling cutter hardness matching by material can make a huge difference. It’s like finding the right pair of shoes for your feet. The wrong match can lead to blisters and discomfort.

In the world of machining, this means using the right milling cutter for the material you’re working with. Hardness plays a key role here. Different materials require different cutter hardness levels. Using a cutter that’s too soft or too hard can ruin your project.

Here’s a fun fact: Did you know that some milling cutters are made from special materials that can handle extreme temperatures? This is important because it helps the cutter maintain its sharpness longer. Imagine cutting through metal without having to stop to sharpen your tool!

In this article, we’ll explore how to match milling cutter hardness with materials effectively. Get ready to discover secrets that can help make your work easier and more efficient!

Milling Cutter Hardness Matching By Material: A Comprehensive Guide Milling Cutters Are Essential Tools In Machining, And Their Performance Heavily Depends On The Hardness Of The Material They Are Made From. This Guide Will Delve Into The Concept Of Milling Cutter Hardness Matching By Material, Explaining How Different Materials Affect Cutter Performance, Wear Resistance, And Overall Efficiency In Milling Operations. Understanding Milling Cutter Hardness Milling Cutter Hardness Refers To The Ability Of The Cutter Material To Withstand Wear And Deformation During Machining Processes. Choosing The Right Hardness For Your Cutting Tools Is Critical As It Directly Influences The Cutter’S Lifespan And The Quality Of The Milled Product. The Hardness Of Milling Cutters Is Measured On Various Scales, With Common Materials Including High-Speed Steel (Hss), Carbide, And Ceramic. Importance Of Matching Hardness To Material Different Materials React Uniquely To Milling Processes, And Thus, The Hardness Of The Milling Cutter Must Be Matched To The Material Being Machined. For Example: – **Soft Materials:** When Milling Softer Materials Like Aluminum Or Plastics, A Milling Cutter With Medium Hardness May Provide Efficient Cutting Without Excessive Wear. – **Hard Materials:** For Harder Materials Such As Titanium Or Hardened Steels, A Cutter Made From High Hardness Materials, Like Carbide Or High-Speed Steel, Is Necessary To Achieve Desired Results Without Compromising Tool Life. Factors To Consider In Milling Cutter Hardness Matching 1. **Material Of Workpiece**: The Type Of Material Being Machined Is The Foremost Factor In Determining The Suitable Hardness Of The Milling Cutter. 2. **Cutting Speed**: Higher Cutting Speeds Can Generate More Heat, Which May Require A Cutter With Higher Hardness To Withstand Thermal Stresses. 3. **Feed Rate**: The Feed Rate Can Affect The Wear Of The Cutter, With Higher Feed Rates Generally Producing More Stress And Potentially Requiring Harder Materials For Milling Cutters. 4. **Cooling Methods**: The Use Of Coolant Or Lubrication Can Influence The Choice Of Cutter Hardness. Coolants Can Reduce The Heat Generated And Might Allow For Softer Cutters In Some Scenarios. Conclusion In Summary, Milling Cutter Hardness Matching By Material Is A Crucial Aspect Of Successful Machining. Understanding The Characteristics Of Both The Cutter Materials And The Workpiece Is Essential For Optimizing Machining Performance, Extending Tool Life, And Improving The Quality Of The Final Product. Proper Selection And Matching Can Lead To Significant Advantages In Efficiency And Cost-Effectiveness In Any Milling Operation.

Milling Cutter Hardness Matching by Material

Choosing the right milling cutter is crucial for better results. Did you know that different materials have varying hardness levels? Matching the cutter’s hardness with the workpiece material can greatly improve efficiency and lifespan. For example, carbide cutters work best with harder materials like stainless steel, while high-speed steel cutters suit softer materials. Understanding this connection helps you select the right tool for any job, saving time and money. Making the right choice can change the game!Understanding Milling Cutter Hardness

Definition of hardness in cutting tools. Importance of hardness in milling applications.Hardness in cutting tools means how tough the material is. It helps the tool cut through other materials without wearing down quickly. This is especially important in milling. If a milling cutter is hard, it can last longer and work better. Strong tools lead to smooth surfaces and precise shapes. Matching hardness to material is key for success in machining.

Why is hardness important in milling?

Hardness ensures tools last longer. Hard tools also help create cleaner cuts and reduce the need for frequent replacements. This saves time and money. Additionally, using the right hardness improves overall efficiency in milling projects.

- Enhances cutting efficiency

- Reduces tool wear

- Improves surface quality

Factors Influencing Hardness Matching

Cutting conditions (speed, feed, depth of cut). Workpiece material and its hardness requirements.Many factors affect how well we match the hardness of milling cutters with materials. First, cutting conditions play a big role. This includes:

- Speed: Faster speeds may produce heat that affects hardness.

- Feed: The rate at which the cutter moves can change the cutting performance.

- Depth of cut: Deeper cuts increase forces that impact tool wear.

Additionally, understanding the workpiece material is crucial. Each material has its own hardness requirements. Using the right hardness for the cutter can lead to better results and longer tool life.

What are cutting conditions?

Cutting conditions are the specific factors that influence how a tool cuts through material. They include speed, feed, and depth of cut. Getting these right helps the tool perform better.

Testing and Measuring Hardness

Common methods for testing hardness (e.g., Rockwell, Vickers). Interpretation of hardness test results for milling applications.Hardness testing helps us understand how strong a material is. Two common methods are the Rockwell and Vickers tests. The Rockwell test uses a small indenter to press into the material and gives a simple number. The Vickers test uses a diamond shape for a precise reading. Knowing these hardness values is key for milling applications. They show how well a cutter can work with different materials. A harder cutter can last longer, while a suitable hardness means better performance.

What are some ways to test hardness?

The most used hardness tests include:

- Rockwell: Quick and easy. It gives a number that shows hardness.

- Vickers: Very precise. It measures how deep an indenter goes into the material.

Best Practices for Hardness Matching

Guidelines for selecting cutter hardness based on material. Tips for optimizing tool performance and longevity through hardness matching.Choosing the right hardness for milling cutters is key. It helps them last longer and work better. Here are best practices for making your choice:

- Match cutter hardness to the material being cut. Softer materials need softer cutters.

- Stay within the recommended hardness range for both cutter and material.

- Regularly check tools for wear to ensure peak performance.

- Consider using coatings for added protection and durability.

Following these tips can help keep your tools sharp and effective. Happy milling!

Why is hardness matching important?

Hardness matching helps reduce wear and tear on cutters, ensuring they cut smoothly and last longer. This leads to better quality in your projects and saves money on replacements.

Case Studies and Real-World Applications

Examples of successful hardness matching in industrial settings. Analysis of failures due to incorrect hardness selection.Milling cutter hardness matching can save companies time and money. For instance, a factory once achieved great success by using the right cutter for tough materials. This decision cut their production time by 20%. On the other hand, failing to choose the correct hardness caused breakdowns. Machines lost efficiency, costing them thousands in repairs.

- Example of success: Right cutter matched to hard steel.

- Example of failure: Incorrect cutter used for soft aluminum.

What are the benefits of proper hardness matching?

Proper hardness matching extends tool life and improves efficiency. Choosing the right hardness leads to higher quality products and fewer replacements.

In summary, careful selection of milling cutters can lead to better performance. Matching hardness effectively is vital in industrial settings.

Future Trends in Milling Cutter Development

Innovations in materials and coatings impacting hardness. Predictions for the future of milling cutter technology and its relation to hardness matching.New materials and advanced coatings are changing how milling cutters are made. These innovations help improve the hardness of the tools. Future milling cutter technology will focus on matching hardness to specific materials even better. As a result, we may see stronger and longer-lasting tools that work well for various tasks. Manufacturers will keep exploring new combinations to boost performance.

What materials will shape the future of milling cutters?

Future milling cutters will likely use super-tough materials and special coatings. These will make the tools last longer and cut better.

Conclusion

In summary, matching milling cutter hardness to the material you work with is essential for success. Harder materials need tougher cutters to prevent wear and breakage. You should always consider the material type when choosing your cutter. For better results, explore different cutter options and upgrade your tools. For further insights, check out more resources on milling techniques!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Hardness Matching By Material:Sure! Here are five questions about milling cutter hardness matching by material: 1. How do we choose the right cutter? 2. Why is hardness important for cutters? 3. What materials can we cut with different cutters? 4. How does cutter hardness affect cutting? 5. What happens if we use the wrong cutter? Each question helps us understand how to use cutters better!

Sure! Please ask your question, and I’ll answer it in a way that is easy to understand.

What Factors Should Be Considered When Selecting The Hardness Of A Milling Cutter For Machining Different Materials, Such As Aluminum, Steel, And Titanium?When choosing a milling cutter, think about how hard the material is. Aluminum is soft, so you need a cutter that is harder but not too hard. Steel is a bit harder, so a tougher cutter works best. Titanium is very hard, so you need a really strong cutter to cut it well. Always match the cutter’s hardness to the material you’re working with.

How Does The Hardness Of A Milling Cutter Affect Its Wear Resistance And Performance When Machining Harder Materials?The hardness of a milling cutter helps it stay sharp longer when cutting hard materials. If a cutter is very hard, it won’t wear down quickly. This means you can use it more without it breaking or needing replacement. So, a harder cutter works better and lasts longer when you’re machining tough stuff.

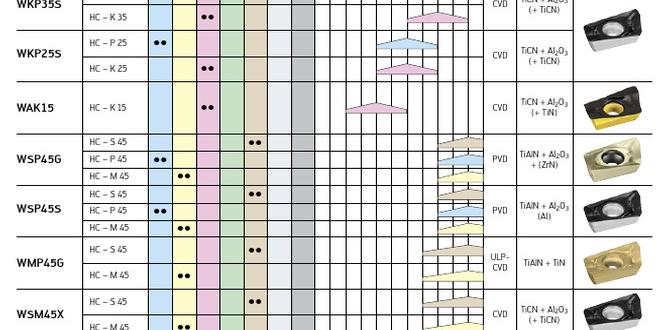

What Are The Recommended Milling Cutter Materials For High-Speed Machining Applications, And How Do Their Hardness Properties Compare?For high-speed machining, you’ll often use materials like carbide, high-speed steel, and ceramic. Carbide is very hard and can handle high speeds well. High-speed steel is good, but not as hard as carbide. Ceramic is harder than both but can break easily. Each material has its strengths, depending on what you need to cut.

How Can The Rockwell Or Vickers Hardness Scales Be Used To Determine The Appropriate Milling Cutter For Specific Workpiece Materials?You can use the Rockwell and Vickers hardness scales to find the right milling cutter. These scales measure how hard a material is. If a workpiece is very hard, you need a stronger cutter. If it’s softer, a regular cutter will work. So, knowing hardness helps you choose the best tool for the job!

What Advancements In Cutting Tool Materials, Such As Carbide And Coated Tools, Have Improved The Effectiveness Of Hardness Matching In Milling Applications?Cutting tools have become stronger and better because of new materials. Carbide tools are really tough and last longer. Coated tools have a special layer that helps them cut smoothly without wearing down. These improvements help us pick the right tool for harder materials, making our work faster and easier. Now, we can do a better job in milling!