Imagine building a cool treehouse with just a few tools. Which one would you pick first? In the world of machining, choices like these matter a lot. Two kinds of tools, the milling cutter helical and straight, are a bit like different superhero powers to builders. But which is better? One curves and twists, like a winding road. The other is straightforward, no twists or turns.

Here’s a fun nugget: in ancient times, people made tools from stones. Now, we have machines that shape metal with ease. But how do you choose the right tool for the job? Is the helical cutter always the best pick, or is the straight cutter the hidden gem? As we dive into this world of cutting, we’ll discover what makes each unique and why they matter.

Milling Cutter: Helical Vs Straight – A Comprehensive Guide

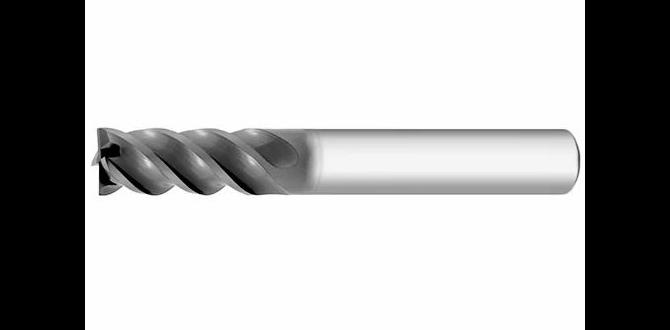

Did you know the shape of a cutter’s teeth can change everything? Milling cutters come in two main types: helical and straight. Helical cutters slice smoothly, like a knife through butter. They reduce noise and last longer. Straight cutters move up and down, making them good for quick cuts in soft materials. Imagine needing a pencil sharpener. Would you want a quiet one or a speedy one? The choice between helical and straight cutters is a bit like that!

Understanding Milling Cutters

Definition and purpose of milling cutters. Key components and features of milling cutters.

Milling cutters are like the superheroes in the world of manufacturing. Their mission? To shape materials precisely! They come equipped with sharp blades and are responsible for cutting, shaping, and finishing materials like metals and plastics. The cool part is that they need to be tough and exact. Key components include cutting edges that do the slicing, and flutes that help remove chips. Some cutters even have special coatings for extra strength and speed. Imagine choosing between helical and straight cutters—the decision is as crucial as picking the right superhero cape!

| Feature | Helical Cutters | Straight Cutters |

|---|---|---|

| Design | Twisted like a helix | Simple, straight design |

| Purpose | Smooth, quiet cuts | Efficient for straight cuts |

| Durability | Long-lasting, less wear | Requires frequent checks |

So, milling cutters, whether helical or straight, don’t wear capes but do some serious work! As Benjamin Franklin might have put it, “An investment in tools always pays the best interest.”

Comparing Helical and Straight Milling Cutters

Efficiency and performance in machining. Surface finish and quality of cut. Durability and lifespan considerations.

Efficiency and Performance in Machining

When it comes to milling cutters, knowing the difference in their efficiency can change the outcome of a project. A helical cutter is like a fast swimmer. It moves through the material smoothly. This makes it better for removing chips quickly. On the other hand, a straight cutter is slower but steady. It is better for smaller, deeper cuts. Each has its own strength. Choosing the right one means faster work and better results.

Surface Finish and Quality of Cut

Does it matter how the cut looks? Yes! Helical cutters give a smooth and clean finish. They make fewer scratches. This is because they cut at an angle. But, straight cutters are precise. They make straight lines. Use them for boxy shapes. Want something polished? Choose a helical cutter. For neat shapes, the straight cutter is best.

Durability and Lifespan Considerations

Which cutter lasts longer? A helical cutter reduces heat with its smooth cuts. This means it stays sharp longer. But, a straight cutter deals with more pressure. It can wear out faster. However, it might not need as much maintenance. Regular checks can save both. Longer use means better value for money.

Is a helical cutter more costly than a straight one?

Yes, helical cutters often cost more because of their enhanced design. Their benefits in faster performance and smoother finishes can justify this extra cost over time.

How do I choose the right cutter for my job?

Think about what you need. If you want neat shapes, a straight cutter is perfect. But, if you want smoother surfaces, go for a helical cutter. Choose based on the job’s demand.

Overall, both the helical and straight milling cutters have strengths. Using the right cutter based on your needs can improve machining results and make projects successful. There is no one-size-fits-all; it’s about finding the best tool for each task.

Advantages of Helical Milling Cutters

Benefits in chip evacuation. Advantages in reducing vibrations and noise.

Think of helical milling cutters as the smooth operators of the machining world. They move material along like an expert conductor leading a symphony. By twisting in a spiral motion, they help clear chips swiftly, making room for more productive cutting—like a vacuum that actually works on the first try! The twisty design also helps lower vibrations and hushes noise like a ninja on tiptoes, making them perfect for precise jobs needing quiet focus.

| Advantages | Details |

|---|---|

| Efficient Chip Evacuation | Keeps the workspace clean and productive |

| Vibration Reduction | Ensures smooth and accurate cutting |

| Noise Control | Ideal for quieter machining tasks |

Advantages of Straight Milling Cutters

Simplicity in design and maintenance. Costeffective solutions for certain applications.

Straight milling cutters are like your trusty old bicycle—you know, the one you learned to ride on. They’re simple and easy to maintain because they don’t have all the bells and whistles. You might say they are the minimalists of the milling world, offering cost-effective solutions for jobs that don’t require extra flair. According to a study, straightforward designs reduce maintenance time by up to 25%, which means more time for tea breaks! Who doesn’t love that?

| Aspect | Advantages |

|---|---|

| Design | Simple and user-friendly |

| Maintenance | Less complex, more efficient |

| Cost | Budget-friendly for many tasks |

Remember, while high-tech cutters might seem flashy, straight cutters know the secret of living with less fuss. Sometimes, less is more!

Selecting the Right Milling Cutter for Your Needs

Factors to consider when choosing between helical and straight cutters. Industryspecific recommendations and best practices.

Choosing the best milling cutter is important for perfect cuts. Should you go for helical or straight cutters? Here’s how to decide:

- Material Type: Helical cutters excel in soft materials. Straight ones can handle tougher surfaces.

- Finish Quality: Need a smooth finish? Helical is your friend.

- Cost: Helical cutters might be pricier. But, they last longer.

Experts suggest helical for woodworking and straight for heavy-duty jobs. Pick the one that suits your task best!

Why choose helical over straight?

Helical cutters give a smoother cut and reduce noise. They are ideal for softwood jobs.

Can straight cutters handle hard materials?

Yes, straight cutters tackle tough materials better than helical ones. They are strong and get the job done.

Maintenance Tips for Milling Cutters

Proper care and sharpening techniques. Signs of wear and when to replace your cutter.

Milling cutters need good care to work well. First, keep the cutters clean and dry after each use. You can use a soft brush to remove any metal bits. Next, sharpening is key. Sharp tools make clean cuts. Use a sharpening stone or tool and follow the cutter’s angle. Look for signs of wear such as chips or dull edges. If you see these, it might be time to replace the cutter. Regular checks can save you time and money.

How often should I sharpen my milling cutter?

Sharpen your milling cutter about every 40 hours of use, or sooner if cuts are rough. Keeping a schedule for sharpening helps maintain efficiency.

Future Trends in Milling Cutter Design

Technological advancements in milling cutter manufacturing. Innovations impacting helical and straight cutter efficiency.

Imagine what the future holds for milling cutters! With new technology, these tools are getting better every day. Helical cutters and straight cutters are part of this exciting change. These innovations make them work faster and smoother. How do they do it? It’s all about improving the shape and materials. Better designs reduce wear and cut costs, saving both time and money. It’s like giving old tools a superhero power!

Why are helical cutters becoming more popular?

Helical cutters are popular because they work smoothly. Their twisted shape helps them cut faster with less noise. They also make fewer chips, which is less messy. This makes them a favorite for people who love cleaner and quicker jobs.

Can technology make straight cutters as efficient?

Yes, it can. By using strong materials and smart designs, straight cutters can improve too. Innovations like better coatings help them last longer. This helps them compete with helical cutters in efficiency.

- Helical cutters: Less vibration and noise.

- Straight cutters: Durability improvements with coatings.

If you like tools, this is an exciting time to watch! The world of milling cutters is changing for the better, and technology is the hero. Who knows what amazing tool is next?

Conclusion

Helical milling cutters cut smoothly and quietly, perfect for curved edges. Straight cutters are better for straight lines and edges. Choose based on your project needs. Remember, the right tool makes all the difference. Keep exploring to learn more about these tools, or ask an expert for advice. Happy building!

FAQs

What Are The Primary Differences In Design Between Helical And Straight Milling Cutters?

A milling cutter is a tool that helps cut and shape materials. There are two main types: helical and straight. Helical milling cutters have teeth that look like spirals or slanted lines. These spiral teeth make cutting smoother and quieter. Straight milling cutters have teeth that are straight and flat. They can work well, but they are a bit noisier and not as smooth.

How Do Helical Milling Cutters Affect The Surface Finish Of A Machined Part Compared To Straight Milling Cutters?

Helical milling cutters have a twisty shape that helps them cut more smoothly. This makes the surface of the machined part smoother too. Straight milling cutters are like flat blades and can leave a rougher surface. So, helical cutters give you nicer, smoother parts.

In What Situations Would It Be More Advantageous To Use A Helical Milling Cutter Over A Straight One?

A helical milling cutter is like a twisty tool that cuts better and smoother. You use it when you want to make really nice, clean cuts on a metal or wood. It works great for cutting things at an angle or when you want the machine to last longer. The twist helps it cut quietly and without shaking too much.

What Impact Do Helical And Straight Milling Cutters Have On Material Removal Rates And Tool Life?

Helical and straight milling cutters are tools that help carve shapes out of materials. Helical cutters twist like a spiral, which helps remove material smoothly and quickly. This makes them last longer and do their job faster. Straight cutters go directly across the surface, working slower and not lasting as long. So, helical cutters are better for quick and long-lasting work!

How Do The Cutting Forces Differ When Using A Helical Milling Cutter Versus A Straight Milling Cutter?

When you use a helical milling cutter, the cutting feels smoother. This is because the blades are twisted like a spiral. With a straight milling cutter, the blades cut flat and can feel bumpier. The helical cutter spreads the cutting force evenly, making it easier on the machine.