Have you ever wondered how important a milling cutter’s impact resistance rating can be? It plays a crucial role in its performance. Imagine trying to cut something tough and the tool just breaks. That wouldn’t be fun, right?

When choosing a milling cutter, we often look at its sharpness. But what about its strength? A milling cutter’s impact resistance rating tells us how well it can handle tough materials.

Surprisingly, not all cutters are made the same. Some can easily chip or break under pressure, while others stand strong and durable. If you need reliability in your work, understanding this rating is essential.

In this article, we’ll explore the world of milling cutters. Let’s dive into why the impact resistance rating matters and how it affects your projects. Your next perfect cut might depend on it!

Milling Cutter Impact Resistance Rating Explained Efficiently

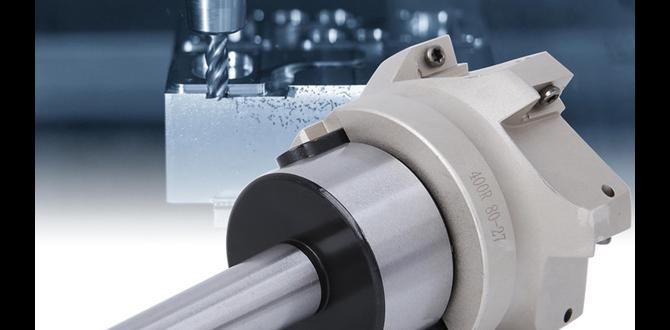

Milling Cutter Impact Resistance Rating

Milling cutter impact resistance rating shows how well a cutting tool can handle hard materials. This rating helps users choose the right cutter for different tasks. Strong cutters last longer and reduce waste. Have you ever wondered why some tools break easily while others endure heavy use? Understanding this rating ensures you pick the best tool for your projects. Choose wisely, and your milling projects will run smoothly!What is Impact Resistance in Milling Cutters?

Definition of impact resistance in the context of milling cutters.. Importance of impact resistance for manufacturing efficiency and tool lifespan..Impact resistance is how well a milling cutter can handle sudden bumps and bangs without breaking. Imagine a superhero that doesn’t flinch when hit! This feature is important. High impact resistance means the tool lasts longer and cuts better. Think of it as the secret sauce for a smooth manufacturing process. Great tools save time and cash. If your cutter can withstand tough jobs, you’ll spend less time fixing and more time creating!

| Feature | Impact Resistance | Benefits |

|---|---|---|

| Durability | High | Longer tool lifespan |

| Efficiency | Improved | Faster production times |

| Cost | Savings | Less downtime |

Common Testing Methods for Impact Resistance Rating

Description of standard testing procedures (e.g., Charpy, Izod).. Significance of testing results in selecting milling cutters..To test milling cutters for impact resistance, two popular methods are used: the Charpy and Izod tests. These tests measure how well materials can handle sudden hits. In the Charpy test, a swinging hammer strikes a notched sample. The force needed to break it is recorded. The Izod test is similar but holds the sample differently. Results help choose the right milling cutters for specific tasks. Think of it like picking the strongest superhero for a mission!

| Test Type | How It Works | Purpose |

|---|---|---|

| Charpy | Swinging hammer hits a notched sample | Measures toughness |

| Izod | Holds sample vertically as it gets struck | Assesses resistance |

Choosing a milling cutter with a good impact resistance rating is vital for durability. A cutter that can withstand more knocks will last longer. So, make sure to pay attention to these tests, or you might end up with the cutting power of a butter knife!

Types of Milling Cutters and Their Impact Resistance Ratings

Classification of milling cutters (e.g., highspeed steel, carbide).. Comparative analysis of impact resistance ratings across different types..Milling cutters come in different types. Each type has unique strengths. The most common ones are high-speed steel and carbide. High-speed steel cutters are less durable but cheaper. Carbide cutters are tougher and can withstand higher forces. Their impact resistance ratings vary between types.

- High-Speed Steel: Good for light tasks, lower impact resistance.

- Carbide: Great for heavy tasks, higher impact resistance.

Choosing the right cutter helps improve work quality. Always consider impact resistance for better results in milling tasks.

What is the impact resistance rating for milling cutters?

The impact resistance rating shows how well a cutter handles stress. A higher rating means the cutter is stronger. For example, carbide cutters usually have a better rating than high-speed steel cutters.

Applications Requiring High Impact Resistance Milling Cutters

Industries and scenarios where durability is critical (e.g., aerospace, automotive).. Case studies illustrating the consequences of low impact resistance..High impact resistance milling cutters are like superheroes in tough jobs. They work in industries like aerospace and automotive, where durability is key. Imagine a plane getting built with weak tools—yikes! Case studies show that when impact resistance is low, the results can be disastrous, leading to equipment failure or even safety risks. Durability in cutting tools keeps everything running smoothly and safely.

| Industry | Scenario | Consequence of Low Impact Resistance |

|---|---|---|

| Aerospace | Engine component manufacturing | Flight risks due to tool failure |

| Automotive | Vehicle assembly | Costly recalls and safety hazards |

Improving Impact Resistance in Milling Cutters

Techniques for enhancing impact resistance (e.g., coatings, heat treatment).. Recommendations for selecting milling cutters with optimum impact resistance..To make milling cutters tougher, consider using special coatings. These coatings act like superhero capes, protecting the cutters from damage. Heat treatment is another trick; it’s like giving your cutters a hot bath that strengthens them.

When choosing milling cutters, look for ones with high impact resistance ratings. Check for hard materials and strong design. A little research can save you headaches later. Remember, a good cutter lasts longer, which means less time worrying and more time making cool stuff!

| Technique | Benefits |

|---|---|

| Coatings | Protects against wear and tear |

| Heat Treatment | Enhances strength |

Interpreting Impact Resistance Ratings for Optimal Tool Selection

How to read and evaluate impact resistance ratings from suppliers.. Best practices for matching impact resistance ratings to specific applications..Reading impact resistance ratings is crucial for choosing the right tools. These ratings help people understand how strong a milling cutter is against damage. To pick the best tool, follow these tips:

- Check the rating scale from suppliers.

- Match the rating to your specific task.

- Look for user reviews and ratings for extra insights.

Using tools with the proper rating boosts safety and performance. Remember, the right choice saves time and money! Did you know that a tool with a high impact rating can last twice as long as one with a low rating?

What should I consider when selecting a tool based on impact resistance?

Focus on your specific project needs and the assigned ratings from suppliers. Does your task involve heavy materials or continuous use? If so, a higher resistance rating is better.

Conclusion

In summary, the milling cutter impact resistance rating shows how tough a cutter is. A higher rating means it can handle more stress and last longer. When choosing a cutter, consider this rating for better performance. You can learn more about different types and their uses by exploring additional resources. Let’s make smart choices for our projects!FAQs

What Factors Influence The Impact Resistance Rating Of Milling Cutters?The impact resistance rating of milling cutters depends on a few key factors. First, the material of the cutter affects how strong it is. If we use tougher materials, it can resist impacts better. The design of the cutter also plays a role; a good design helps spread out the force when it hits something. Lastly, the sharpness of the edges matters—sharp cutters can handle impacts without breaking easily.

How Can The Material Composition Of A Milling Cutter Affect Its Overall Impact Resistance?The material of a milling cutter is important for how well it can handle impact. If the cutter is made from strong materials like carbide, it can resist breakage better. We need cutters that are tough, so they don’t chip or crack when we use them. Softer materials might break more easily when they hit hard surfaces. Choosing the right material helps the cutter last longer.

What Testing Methods Are Commonly Used To Evaluate The Impact Resistance Of Milling Cutters?To test how strong milling cutters are, we use a few methods. One way is the drop test. We drop a weight onto the cutter to see if it breaks. Another method is the impact test, where we hit the cutter with a force to check its strength. These tests help us know if the cutter can handle tough jobs.

How Does The Design Of A Milling Cutter Contribute To Its Resistance Against Impact Forces?The design of a milling cutter helps it handle impact forces. It has strong materials that can take hits without breaking. The shape of the cutter also spreads out the force, so no single part gets too much pressure. This makes the cutter last longer and work better. When we use well-designed cutters, they can cut through tough stuff without getting damaged.

Are There Specific Applications Or Industries Where Higher Impact Resistance In Milling Cutters Is Particularly Critical?Yes, there are places where tough milling cutters are very important. In car manufacturing, for example, they cut hard metal parts. In construction, they shape materials like concrete. These jobs need strong tools that won’t break easily. So, using cutters with high impact resistance helps keep everything running smoothly.