Have you ever wondered how machines cut through metal with such precision? It all comes down to the right tools and techniques. One essential tool in this process is the milling cutter insert. But did you know that the screw torque values for these inserts are crucial for their performance?

Getting the torque values just right can change everything about the cutting process. Imagine your favorite toy falling apart because the screws aren’t tight enough. The same idea applies to metalworking. Too much or too little torque can lead to problems. It can affect the insert’s fit and the quality of your work.

In this article, we will explore the importance of milling cutter insert screw torque values. We’ll uncover tips and tricks to help you understand how they impact your projects. Get ready to dive into an exciting world of machining!

Milling Cutter Insert Screw Torque Values Explained

Milling Cutter Insert Screw Torque Values

Understanding milling cutter insert screw torque values is key for any machining project. Proper torque ensures that your inserts stay secure and function effectively. Too little torque can cause inserts to loosen, while too much can damage them. Did you know that using the correct torque can improve tool life significantly? By following manufacturer recommendations, you enhance performance and reduce downtime. Always check torque specifications before starting your work to achieve the best results!Understanding Milling Cutter Inserts

Definition and purpose of milling cutter inserts. Types of milling cutter inserts available in the market.Milling cutter inserts are small, replaceable cutting tools used in milling machines. They fit into the milling cutter, helping to shape or finish materials like wood or metal. These inserts save time and money since you can replace them instead of the whole cutter. There are various types of milling cutter inserts, including indexable, solid, and coated versions. Each has its special job and comes with benefits!

| Type | Description |

|---|---|

| Indexable | Can be rotated and reused, offering cost savings. |

| Solid | Made from a single piece; great for tough jobs. |

| Coated | Have a special coating for longer life and better performance. |

In short, these nifty tools make milling easier and more efficient—just like a superhero saving the day!

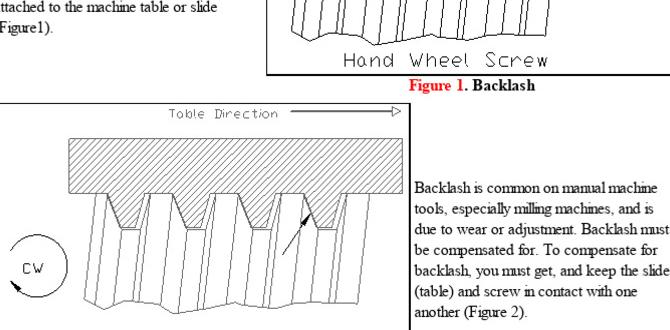

The Importance of Torque Values

Explanation of torque and its significance in machining. Impact of incorrect torque values on milling performance.Torque is like the magic number in machining. It’s the twist we give to screws, helping them hold things tight. Without the right torque, a milling cutter might feel wobbly and uncooperative. Imagine trying to ride a bike with a flat tire—不妙! Too much torque can break the screw, while too little can cause bad cuts and even accidents! Remember: enough torque means happy tools!

| Torque Value | Impact |

|---|---|

| Too High | Breaks screws |

| Too Low | Poor milling performance |

Factors Influencing Torque Values

Material properties of inserts and screws. Machine settings and environmental conditions.Several factors can change torque values. First, the materials used in inserts and screws matter. Stronger materials can stand up to better pressure. Next, machine settings are crucial. Adjusting speed and feed rates can make a big difference. Even the surrounding environment can influence performance. Humidity, temperature, and dirt can throw your torque off course like a squirrel chasing a nut! Understanding these aspects helps in getting the best results.

| Factor | Description |

|---|---|

| Material Properties | Stronger materials lead to better torque handling. |

| Machine Settings | Correct speed and feed rates optimize torque. |

| Environmental Conditions | Humidity and temperature can affect torque performance. |

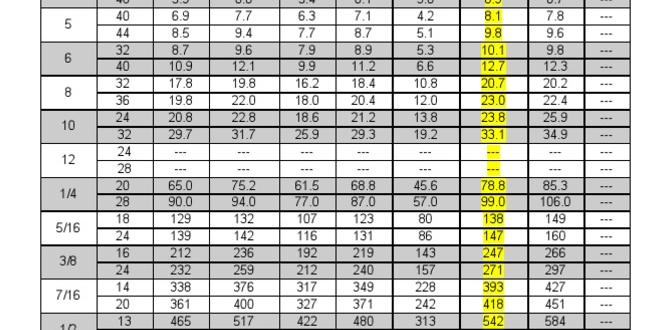

Recommended Torque Values for Common Milling Cutter Inserts

Standard torque values for various types of milling cutter inserts. Comparison of torque values for different materials.Correct torque values keep your milling cutter inserts happy and efficient. Generally, the standard torque for most inserts ranges from 20 to 30 Nm (Newton meters). However, this can change based on the insert material. For example, carbide inserts need more love and usually require a torque around 25-35 Nm. Here’s a quick comparison:

| Insert Material | Recommended Torque (Nm) |

|---|---|

| High-Speed Steel | 20-25 |

| Carbide | 25-35 |

| Ceramic | 30-40 |

Using the right torque ensures your tools work like a charm. Remember, too much torque is like over-cooking spaghetti—it doesn’t end well! Stick to the recommended values to keep everything in check.

Adjusting Torque Values for Specific Applications

Guidelines for modifying torque values based on machining needs. Case studies showcasing torque adjustments in realworld applications.Modifying torque values can help with different machining tasks. It’s important to adjust according to the tool and material. Here are some guidelines:

- Match the torque with the tool’s specifications.

- Consider the type of material being used, like soft or hard metals.

- Test different torque levels to find the best fit.

In real-world cases, companies saw better results by changing their torque settings. This one simple change made their machines run smoother and faster.

What should you consider when adjusting torque values?

When adjusting torque values, focus on the material type, tool specifications, and specific needs of the machining process. Each task may require a unique setting for optimal performance.

Common Mistakes and Troubleshooting

Typical errors in setting torque values. Solutions for undertorquing and overtorquing issues.Setting the right torque values can be a bit tricky. Many folks make the classic blunders of undercutting or over-torquing. Undercutting leaves screws loose and can ruin your day, while over-torquing just might snap them like a twig! To avoid these, always double-check torque specifications. If you find yourself in a pinch, here’s a handy table to help you spot common errors:

| Error | Solution |

|---|---|

| Undertorquing | Re-tighten to recommended values. |

| Overtorquing | Gently loosen and reset the torque. |

Following these simple fixes can save you from a world of trouble! Remember, it’s about finding that happy middle ground—just like balancing cookies and milk!

The Future of Milling Cutter Insert Technologies

Innovations in insert design and material science. How torque values may evolve with new technologies.The world of milling cutter inserts is changing fast! New designs and materials are popping up like popcorn at a movie. These innovations promise better performance, meaning they can cut faster and last longer. As we explore these new technologies, torque values will likely adjust too. Picture this: with smarter designs, we might even set records for torque values. It’s like upgrading from a bicycle to a rocket ship, zooming into the future!

| Innovation | Description |

|---|---|

| Advanced Materials | Stronger and lighter materials for longer-lasting inserts. |

| Smart Design | Shapes that boost efficiency and reduce torque needs. |

Conclusion

In summary, understanding milling cutter insert screw torque values helps ensure better performance and tool lifespan. Proper torque prevents damage and improves efficiency. Always refer to your tool’s manual for specific values. You can enhance your skills by practicing with different settings. For more information, consider reading articles or guides on tool maintenance and usage. Happy milling!FAQs

Here Are Five Questions Related To Milling Cutter Insert Screw Torque Values:Sure! Please provide the five questions related to milling cutter insert screw torque values, and I’ll be happy to help with the answers.

Sure, I can help with that! Please share the question you want me to answer.

What Are The Recommended Torque Values For Securing Different Types Of Milling Cutter Inserts?The torque value is how tight we need to screw in the milling cutter inserts. For ceramic inserts, we use about 10 to 15 Newton-meters. For carbide inserts, we should use 5 to 8 Newton-meters. Always check the instructions to be sure!

How Does The Material Composition Of A Milling Cutter Insert Affect The Required Screw Torque Values?The material of a milling cutter insert changes how much you need to tighten the screws. If the insert is hard, it may need more torque, which means you have to turn the screw tighter. Softer materials might need less torque because they grip better. This helps keep everything in place while you cut. So, the material choice really matters!

What Tools Or Equipment Are Best Suited For Accurately Measuring Torque When Installing Milling Cutter Inserts?To measure torque when installing milling cutter inserts, we can use a torque wrench. A torque wrench helps you tighten things to the right amount. You can find digital or click-type torque wrenches, and both work well. It’s important to follow the recommended torque settings for your milling cutter inserts. Using the right tool will help keep everything secure.

What Are The Consequences Of Under-Torquing Or Over-Torquing The Screws On Milling Cutter Inserts?If we don’t twist the screws on milling cutter inserts enough, they can fall out while we work. This can ruin our project and make messes. If we twist them too much, we can break the screws or the tool itself. Both problems can waste time and money, so we need to be careful. It’s best to follow the right amount of twist for the screws.

Are There Specific Industry Standards Or Guidelines For Torque Values When Working With Milling Cutter Inserts In Various Applications?Yes, there are industry standards for torque values when using milling cutter inserts. These guidelines help us know how tight to fasten them. Different materials and machines might need different amounts of tightness. You should always check the manufacturer’s instructions for the best torque. This helps keep the tools safe and working well!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Milling Cutter Insert Screw Torque Values:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the five questions related to milling cutter insert screw torque values, and I’ll be happy to help with the answers.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I can help with that! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Recommended Torque Values For Securing Different Types Of Milling Cutter Inserts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque value is how tight we need to screw in the milling cutter inserts. For ceramic inserts, we use about 10 to 15 Newton-meters. For carbide inserts, we should use 5 to 8 Newton-meters. Always check the instructions to be sure!”}},{“@type”: “Question”,”name”: “How Does The Material Composition Of A Milling Cutter Insert Affect The Required Screw Torque Values?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of a milling cutter insert changes how much you need to tighten the screws. If the insert is hard, it may need more torque, which means you have to turn the screw tighter. Softer materials might need less torque because they grip better. This helps keep everything in place while you cut. So, the material choice really matters!”}},{“@type”: “Question”,”name”: “What Tools Or Equipment Are Best Suited For Accurately Measuring Torque When Installing Milling Cutter Inserts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque when installing milling cutter inserts, we can use a torque wrench. A torque wrench helps you tighten things to the right amount. You can find digital or click-type torque wrenches, and both work well. It’s important to follow the recommended torque settings for your milling cutter inserts. Using the right tool will help keep everything secure.”}},{“@type”: “Question”,”name”: “What Are The Consequences Of Under-Torquing Or Over-Torquing The Screws On Milling Cutter Inserts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If we don’t twist the screws on milling cutter inserts enough, they can fall out while we work. This can ruin our project and make messes. If we twist them too much, we can break the screws or the tool itself. Both problems can waste time and money, so we need to be careful. It’s best to follow the right amount of twist for the screws.”}},{“@type”: “Question”,”name”: “Are There Specific Industry Standards Or Guidelines For Torque Values When Working With Milling Cutter Inserts In Various Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are industry standards for torque values when using milling cutter inserts. These guidelines help us know how tight to fasten them. Different materials and machines might need different amounts of tightness. You should always check the manufacturer’s instructions for the best torque. This helps keep the tools safe and working well!”}}]}