Have you ever wondered how milling cutters get their names? It might seem like a small detail, but understanding the naming guide for ISO inserts can make a big difference. Imagine trying to choose the right tool for your project, but the names confuse you. That can be frustrating!

In the world of machining, specific names help identify milling cutters easily. Each name tells you something important about the tool. For example, it reveals its shape, size, and the material it works best with. Isn’t that neat?

Here’s a fun fact: the ISO insert naming system is used worldwide. It helps everyone speak the same language when discussing tools. This is crucial for both beginners and experienced machinists alike.

So, whether you are a hobbyist or a pro, our milling cutter ISO insert naming guide will help you understand these names better. Ready to dive in? Let’s explore the fascinating world of milling cutters together!

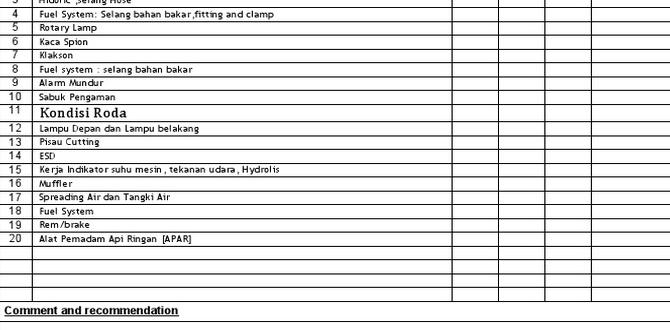

Milling Cutter Iso Insert Naming Guide: Understanding The Basics Introduction To Milling Cutter Iso Insert Naming The World Of Machining Can Often Feel Overwhelming, Particularly When It Comes To Understanding The Various Components Used In The Manufacturing Process. One Such Component Is The Milling Cutter Iso Insert. These Inserts Play A Crucial Role In Machining Operations, And Understanding Their Naming Conventions Can Significantly Aid In Selecting The Right Tools For Your Projects. This Article Serves As A Comprehensive Guide To The Naming System For Milling Cutter Iso Inserts, Providing You With The Knowledge You Need To Make Informed Decisions. What Is A Milling Cutter Iso Insert? A Milling Cutter Iso Insert Is A Cutting Tool Made From Hard Materials, Designed For Removing Material From A Workpiece. These Inserts Are Typically Shaped As Small, Replaceable Tips That Are Mounted On The Milling Cutter Body. The Iso (International Organization For Standardization) Has Established A Standardized Naming Convention That Helps Categorize These Inserts, Allowing Machinists To Easily Identify And Select The Appropriate Tool For Their Specific Milling Applications. Understanding The Naming Convention The Iso Insert Naming Convention Consists Of Several Key Elements That Provide Important Information About The Insert’S Geometry, Dimensions, And Material Composition. The Typical Structure Of An Iso Insert Name Can Be Broken Down Into Specific Components: 1. **Insert Shape**: The First Letter Often Indicates The Shape Of The Insert, Such As ‘T’ For Triangle Or ‘R’ For Round. 2. **Insert Size**: Following The Shape, A Numerical Code Usually Represents The Size Of The Insert. This Can Include Dimensions Like Length And Width. 3. **Corner Radius**: The Next Part Of The Nomenclature Often Refers To The Corner Radius, Which Is Important For Determining The Type Of Finish It Can Achieve. 4. **Material And Coating Type**: Inserts Are Also Identified By The Material They Are Made Of (E.G., Carbide, Ceramic) And Any Special Coatings Designed To Enhance Durability And Performance. Benefits Of Understanding Iso Insert Naming By Familiarizing Yourself With The Milling Cutter Iso Insert Naming Guide, You Can Enjoy Several Advantages: – **Enhanced Tool Selection**: With A Clearer Understanding Of The Naming Conventions, You Can Make Better Choices When Selecting Inserts, Ensuring You Get The Right Tool For Your Machining Needs. – **Improved Efficiency**: Knowledge About Different Types Of Inserts Can Lead To More Efficient Machining Processes, As You Can Match The Right Insert To Specific Materials And Machining Requirements. – **Cost-Effectiveness**: Using The Right Insert Can Reduce Wear On Tools And The Workpiece, Ultimately Saving Time And Money. Conclusion Understanding The Milling Cutter Iso Insert Naming Guide Is Essential For Anyone Involved In Machining. With A Solid Grasp Of The Naming Conventions, You Can Optimize Your Tool Selection, Enhance The Quality Of Your Work, And Reduce Operational Costs. As Machining Technologies Continue To Evolve, Keeping Abreast Of These Guidelines Will Ensure You Remain Competitive In The Industry.

Milling Cutter ISO Insert Naming Guide Summary

Understanding milling cutter ISO insert names can be tricky but fun! This guide simplifies key components of insert naming. Readers learn about different codes, like shape and size, which tell you how the insert works. Did you know that each letter and number reveals important info? This naming system helps manufacturers choose the right tools more easily. So, next time you see an insert, you’ll know exactly what the letters mean!The ISO Insert Naming System

Breakdown of the ISO nomenclature. Importance of understanding the naming structure for selection.The ISO naming system breaks down the features of milling cutters through a clear code. Each part of the name carries important information. For example, letters indicate the shape, while numbers show size. Understanding this system helps you choose the right tool for your job. A good fit means better results!

- Letter codes describe cutter shapes.

- Numbers reveal size and specifications.

Knowing the ISO format helps avoid mistakes. It makes picking the right cutter easy. You gain confidence and improve your work’s quality!

Why is Learning the ISO Naming Important?

Understanding the naming structure helps you select the best tools for your projects. You can save time and finish work efficiently by using the right milling cutter!

Key Components of ISO Insert Names

Explanation of letters and numbers used in naming. Role of geometry, tolerance, and material type in naming.ISO insert names have letters and numbers that mean different things. These can tell us about the shape, size, and purpose of the cutting tool. Here is what the components can mean:

- Letters: Show the type of insert and its shape, like T for triangular.

- Numbers: Indicate measurement and size. Higher numbers may mean larger tools.

- Geometry: The tool’s angles affect how it cuts materials.

- Tolerance: Refers to how closely parts must fit together.

- Material type: Different materials are suited for different tasks.

These details are important for choosing the right milling cutter.

What do letters and numbers mean in ISO insert names?

The letters and numbers give clues about the insert’s type and size. For example, T means triangular, while numbers indicate measurements.

What role do geometry and tolerance play?

Geometry helps in shaping cuts effectively. Tolerance ensures parts fit together well for better performance.

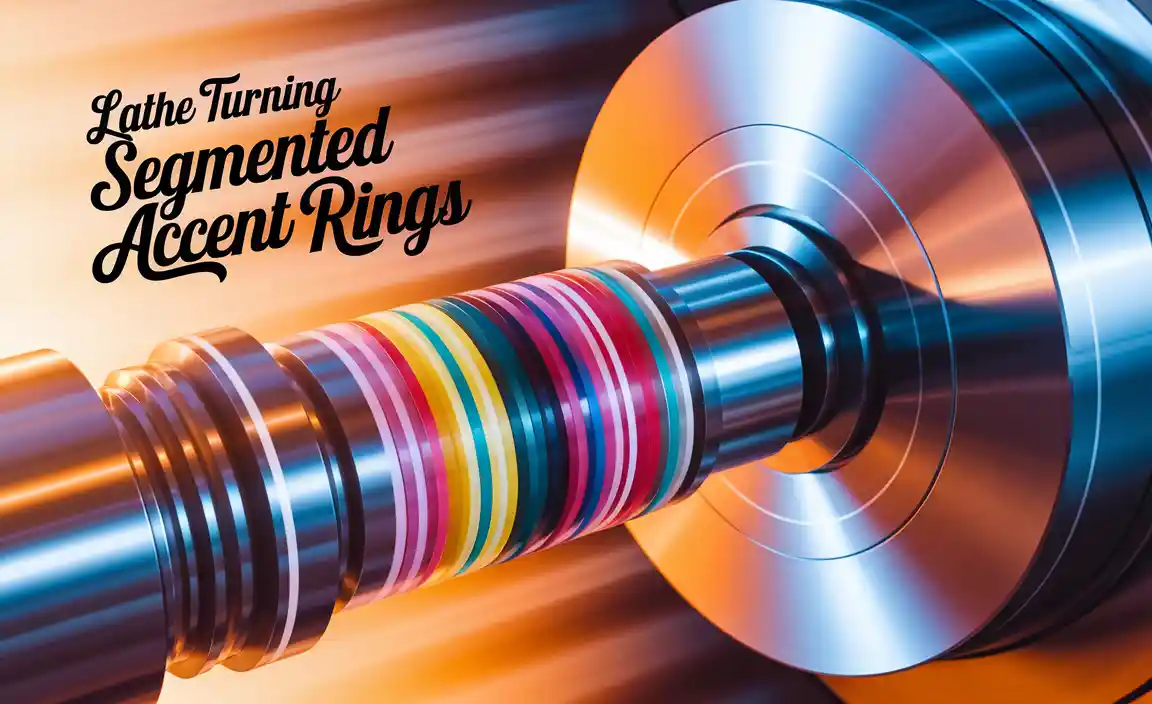

Categories of ISO Inserts

Types of inserts based on geometry (e.g., flat, round, square). Classification based on application (finishing, roughing, etc.).Inserts come in many fun shapes! There are three main types based on geometry: flat, round, and square. Flat inserts are great for smooth surfaces, while round ones can handle tricky corners. Square inserts? They’re the multitaskers of the bunch! Based on use, inserts can be divided into finishing and roughing types. Finishing inserts give things a polished look, like a shiny new toy. Roughing inserts are like bulldozers, removing lots of material quickly!

| Insert Type | Shape | Application |

|---|---|---|

| Flat | Flat | Finishing |

| Round | Round | Versatile |

| Square | Square | Roughing |

In short, knowing your insert categories can help you choose the right one for your task. So, next time you pick an insert, think of it like choosing a snack! Maps can help, but the best option depends on your adventure!

Selecting the Right ISO Insert

Factors to consider when choosing an ISO insert. Guidelines for matching inserts with specific milling operations.Choosing the right ISO insert is important for successful milling. Some key factors to think about include:

- Material type: What you are cutting matters.

- Cutting speed: Faster speeds may need stronger inserts.

- Insert shape: Different shapes work better for specific tasks.

Match inserts to milling tasks for best results. For example, use:

- Flat inserts for smooth finishes.

- Curved inserts for intricate designs.

Always check the manufacturer’s guidelines for the best fit.

What factors should you consider when selecting ISO inserts?

Factors include material type, cutting speed, and insert shape. These will help you pick the best insert for your milling needs.

Maintenance and Care for ISO Inserts

Best practices for maintaining ISO inserts. Signs that an insert needs replacement.Keeping ISO inserts in good shape is vital for smooth machining. Here are some best practices:

- Clean inserts regularly to remove chips and dust.

- Store them safely to prevent damage.

- Check for wear signs often.

You’ll know it’s time for a replacement if:

- You see visible chipping or cracks.

- The insert struggles to cut through materials.

- There is a rough finish on your workpiece.

By following these steps, you can extend the life of your ISO inserts and maintain quality work.

When should I replace my ISO inserts?

Look for specific signs. If you notice a rough finish on the workpiece, it’s time to swap them out. Chipping or visible cracks mean they need immediate replacement.

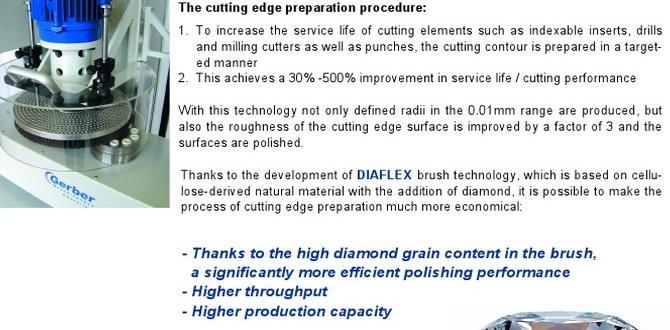

Future Trends in Milling Cutter Technology

Innovations in ISO insert design and materials. Predictions for the future of milling insert technologies.Milling cutter technology is always changing, and exciting innovations are on the way! New ISO insert designs are lighter and tougher, making cutting easier and more fun. Materials like ceramic and carbide are becoming superstars. They last longer and help save time. Predictions say we’ll see smart inserts that can talk to machines. How cool is that? Get ready for a future where milling cutters might even have their own little personalities!

| Innovation | Description |

|---|---|

| Advanced Materials | Durable, heat-resistant, and lightweight materials will boost performance. |

| Smart Inserts | Technology that allows inserts to communicate with machines for better precision. |

| Design Improvements | Shapes that reduce drag and increase efficiency. |

Conclusion

In conclusion, understanding the milling cutter ISO insert naming guide helps you identify tools easily. You learn about different codes and specifications. This knowledge boosts your machining skills. Remember to check the details for better tool choices. We encourage you to explore more about these tools to enhance your projects. Keep practicing, and you’ll become an expert in no time!FAQs

What Are The Key Components Of Iso Insert Naming Conventions For Milling Cutters?ISO insert naming conventions for milling cutters have important parts. First, they describe the shape of the insert. Next, they show the size of the insert, like how wide or thick it is. Then, they tell you what material the insert is made from, like metal or ceramic. Lastly, they often include a code for how the insert is used. By knowing these parts, you can pick the right insert for your job.

How Do Different Iso Insert Shapes And Sizes Influence Milling Cutter Performance?Different shapes and sizes of ISO inserts change how well the milling cutter works. Some shapes cut better in certain materials, like metal or wood. Bigger inserts can remove more bits of material quickly. But smaller inserts might be better for detailed work. So, the right shape and size help us get the best results!

What Is The Significance Of The Iso Insert Designation System In Selecting The Appropriate Milling Cutter For Specific Applications?The ISO insert designation system helps you choose the right milling cutter for your job. It gives information about the cutter’s shape and size. This way, you pick the best tool for cutting different materials. Using the right cutter makes your work easier and better.

How Can One Interpret The Various Numerical And Alphabetical Codes Associated With Iso Inserts?To understand the codes on ISO inserts, start with the letters. They tell you the type of insert and what it can do. The numbers usually show the size and shape. For example, a letter “P” means it’s for cutting metals. You can look up these codes in a chart or online to learn more.

What Considerations Should Be Made When Choosing Iso Inserts For High-Speed Milling Operations?When choosing ISO inserts for high-speed milling, think about the material you’re cutting. Make sure the insert can handle that type, like steel or aluminum. Check the shape and design of the insert, as some work better for certain tasks. Also, consider the cost and how long the insert lasts. Finally, always follow your machine’s guidelines for the best results.