Have you ever wondered how machines can shape metal or wood? Two popular techniques are milling cutter pocketing and contouring. Both are essential in manufacturing, but they do different things.

Imagine you’re carving a piece of wood. Pocketing is like digging a hole, creating a space inside the material. In contrast, contouring is about following the surface curves smoothly, like shaping the edge of a vase.

Here’s a fun fact: the right technique can save time and money. Choosing between pocketing and contouring can affect the final product. So, why does this matter for you? Understanding these methods helps you make smarter choices in projects, whether big or small.

Join us as we explore milling cutter pocketing and contouring. Learn which method is best for your next project!

Milling Cutter Pocketing Vs Contouring: Key Differences Explained

Milling Cutter Pocketing vs Contouring

Milling cutter pocketing and contouring are important in machining. Pocketing removes material to create a space or pocket. Imagine carving out a cookie shape from dough. This method is efficient for deep cuts. On the other hand, contouring shapes the outer edges. Think of tracing a picture’s outline. It’s great for creating smooth surfaces. Understanding these techniques helps improve your machining outcomes and adds creativity to your projects. Which method will you choose for your next creation?What is Pocketing in Milling?

Definition and explanation of pocketing.. Typical applications and industries using pocketing..Pocketing in milling is a method used to create a hollow space in a material. This process removes material to form pockets, making shapes like grooves and slots. It is popular in many industries, such as:

- Manufacturing

- Aerospace

- Automotive

- Woodworking

Pocketing helps improve the strength of parts while reducing weight. Machines like CNC mills use this technique for precise operations.

What are common uses for pocketing?

Pocketing is used for creating precise shapes, reducing weight, and improving strength in various materials.

What is Contouring in Milling?

Definition and explanation of contouring.. Differences between contouring and other milling techniques..Contouring is a method used in milling to create smooth and curved surfaces. It’s like drawing a round shape but with a machine! Unlike other milling techniques, which might focus on straight lines or pockets, contouring pays special attention to shapes and edges. Imagine making a cookie of various fun shapes instead of just round ones. The key difference is that contouring is all about those gentle curves and precise details. Here’s a quick comparison:

| Technique | Description |

|---|---|

| Contouring | Creates smooth, curved surfaces. |

| Pocketing | Removes material to create cavities or pockets. |

So, if you’re looking for smooth designs, contouring is the way to go!

Key Differences Between Pocketing and Contouring

Comparison of techniques used in pocketing and contouring.. Discussion on toolpath strategies and their implications..Pocketing and contouring are like two best friends in milling. Pocketing removes lots of material quickly, while contouring shapes the edges. Think of pocketing as getting rid of extra frosting on a cupcake—fun and fast! On the other hand, contouring is like carefully decorating the edges to make it look pretty.

Toolpath strategies differ too. Pocketing often uses zigzag paths for speed, while contouring favors smooth curves for fine details. These choices impact finish quality and processing time—like rushing to finish a test versus taking your time to get it right.

| Technique | Strategy | Implication |

|---|---|---|

| Pocketing | Zigzag paths | Faster material removal |

| Contouring | Smooth curves | Better detail and finish |

In the end, choosing between them depends on your project needs. Fast and fun, or neat and precise? You decide!

Advantages of Pocketing

Benefits of using pocketing for material removal.. Situations where pocketing is preferable..Pocketing has some cool perks for removing material. First off, it’s super efficient! It clears out big areas quickly, saving both time and energy. If you have a thick block of material, pocketing is your best buddy. It’s also great for creating deep pockets and cavities without much fuss. Need perfection? Pocketing can help avoid tools getting stuck. Plus, it’s like a ninja for shapes, giving you those smooth, finished edges.

| Benefit | Description |

|---|---|

| Efficient | Removes material quickly. |

| Deep Cavities | Perfect for making holes or pockets. |

| Smooth Edges | Creates nice finished shapes. |

| Tool Safety | Reduces risk of tool getting stuck! |

In short, pocketing is the superhero of machining! Need to remove a lot of material? Pick pocketing. It’s efficient and produces excellent results every time. Who knew cutting could be so effective—and fun!

Advantages of Contouring

Benefits of contouring for precision and finish.. Examples of projects where contouring shines..Contour cutting is like giving a fancy haircut to your projects. It brings precision and a smooth finish that makes everything look sharp and professional. Whether you’re creating custom parts for machines or designing eye-catching art pieces, contouring truly shines. Imagine a jigsaw puzzle where every piece fits just right! Here’s a quick look at some cool projects where contouring works wonders:

| Project Type | Benefit of Contouring |

|---|---|

| Custom Gears | Perfect fit and function |

| Artistic Designs | Enhanced detail and finesse |

| Furniture Making | Stylish edges and curves |

With contouring, your work can go from “meh” to “wow” in no time!

Choosing the Right Technique for Your Project

Factors to consider when selecting pocketing vs contouring.. How material type and design influences the decision..Choosing the right technique can change your project results. Consider the following factors before deciding between pocketing and contouring:

- Material Type: Some materials cut better with one technique than the other.

- Design Complexity: Simple designs may work well with pocketing, while detailed shapes can benefit from contouring.

- Tooling Time: Look at how long each method takes; faster isn’t always better.

Think about your project needs. A good choice helps you save time and money.

What should I consider for pocketing vs contouring?

Consider the material type, design complexity, and tooling time when choosing.

Common Mistakes in Pocketing and Contouring

Frequently encountered errors in each technique.. Tips for avoiding mistakes and ensuring quality results..Errors can happen during pocketing and contouring. Common mistakes include wrong tool selection and improper speeds. These can lead to poor results. To avoid these issues, follow these tips:

- Choose the right milling cutter.

- Confirm speeds and feeds carefully.

- Check workpiece setups often.

- Run test cuts before full projects.

Quality work needs attention. Mistakes can cost time and money. Use these tips to improve your results!

What are common problems in pocketing and contouring?

Common problems include tool wear and material damage. This can make the final product uneven. It’s important to check your work carefully. These steps help keep projects smooth and precise.

Case Studies: Pocketing vs Contouring in Real Applications

Analysis of successful projects utilizing pocketing.. Review of scenarios where contouring was the better choice..Many successful projects showcase the power of pocketing. It excels in creating deep slots and removing large amounts of material quickly. For instance, in automotive manufacturing, pocketing helped produce lightweight car parts, reducing costs and improving fuel efficiency. However, contouring shines in detailed work, like artistic engravings on jewelry. It maps curves flawlessly for intricate designs. Sometimes, the choice is clear: pocketing for speed, contouring for finesse!

| Technique | Use Cases | Benefits |

|---|---|---|

| Pocketing | Car parts, heavy machinery | Fast material removal, cost-effective |

| Contouring | Jewelry, art pieces | Precision, intricate designs |

The Future of Milling Techniques

Emerging trends in milling cutter technology.. Predictions on the evolution of pocketing and contouring methods..The world of milling is changing fast! New trends in milling cutter technology are popping up everywhere. Machines are getting smarter, and tools are becoming sharper. Imagine a robot helping with every cut! What a time to be alive!

Experts believe pocketing and contouring will evolve into even faster and precise techniques. In the future, we might see tools that adjust themselves while cutting. Talk about a tool with a mind of its own! This will lead to savings in time and materials. Less waste means more green, and we love that!

| Emerging Trend | Description |

|---|---|

| Smart Technology | Machines that learn and improve from each cut. |

| Eco-Friendly Materials | Using materials that reduce waste in the milling process. |

So, gear up for a future where milling is not just about cutting but also about creativity and efficiency. Who knows? One day, your milling cutter might just ask you for coffee while it works!

Conclusion

In summary, pocketing removes large areas of material, creating a pocket shape, while contouring follows curved paths. Both methods use milling cutters but serve different purposes. Understanding these differences can help you choose the right technique for your projects. To dive deeper, explore tutorials on milling machines and practice using both techniques. You’ll gain valuable skills for your future creations!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Pocketing Vs Contouring:Sure! Pocketing is like carving out a hole in a block of wood. You take out material to make space. Contouring is more like tracing the shape of the edge. You follow the design without cutting deep into the material. Both use a milling cutter, which is like a special tool that spins to cut.

Sure! Please provide the question you would like me to answer.

What Are The Primary Differences Between Pocketing And Contouring In Milling Operations?Pocketing and contouring are two different ways to cut shapes in materials. Pocketing creates a deep hole or a cavity; it removes a lot of material from inside. Contouring follows the edge of a shape; it is more about cutting along the outside. We can think of pocketing as digging a box and contouring as drawing a line around it. Both make cool shapes, but they do different things!

In What Scenarios Would Pocketing Be Preferred Over Contouring For A Milling Project?We would choose pocketing when we need to remove a lot of material from inside a shape. It’s best for making holes or spaces that are flat on the bottom. If you want to create a deep area quickly, pocketing is also a good choice. Contouring works better for edges, but pocketing handles bigger jobs well.

How Do The Cutting Paths Differ Between Pocketing And Contouring, And What Impact Does This Have On Machining Efficiency?In pocketing, the cutting tool moves in a pattern that digs out a shape from inside a material. In contouring, the tool follows the edge of a shape, cutting all around it. Pocketing can take longer because it removes more material at once. Contouring is usually faster since it just trims the edges. This difference affects how quickly we can make things.

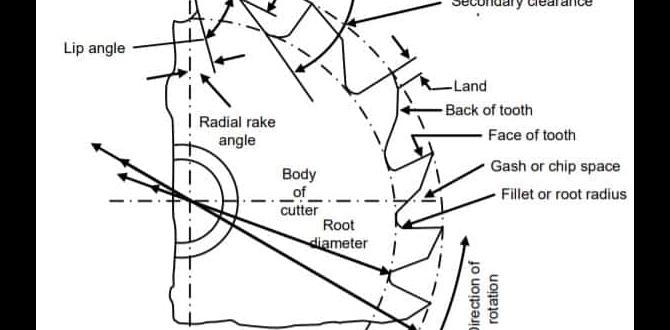

What Types Of Milling Cutters Are Most Suitable For Pocketing Versus Contouring, And Why?For pocketing, we use end mills because they can reach deep into the material. They help create pockets or holes easily. For contouring, we often choose ball nose mills. They have a rounded tip, which makes smooth edges and curves. Each type helps us shape materials in different ways!

How Can The Choice Between Pocketing And Contouring Affect The Finish Quality And Tolerances Of The Machined Part?When you machine a part, choosing pocketing or contouring can change how smooth it is. Pocketing makes holes or shapes deeper and can leave rough edges. Contouring follows the part’s shape closely, which usually gives a nicer finish. If you want a perfect fit, contouring helps the part match better. So, each choice can change the look and measurements of your part!