Have you ever wondered what makes a milling cutter so effective? The answer lies in two important factors: rake angle and feed per tooth. These might sound technical, but they are key to understanding how milling cutters work. Imagine cutting through wood or metal smoothly and quickly. That’s what a good rake angle can do for you.

Let’s think about a pizza cutter. If the blade is sharp and the angle is right, it slices through cheese and toppings easily. The same idea applies to milling cutters. If the rake angle is set correctly, it helps the cutter move through the material with less effort. But there’s more! The feed per tooth plays a huge role too. This means how much material the cutter bites off with each turn.

Curious about how these factors work together? Knowing the right rake angle and feed per tooth can make your cutting tasks easier and faster. So, let’s dive deeper into how these concepts can improve your milling efficiency!

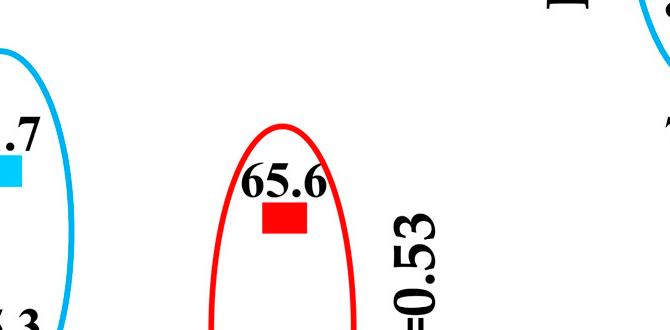

Milling Cutter Rake Angle Vs Feed Per Tooth: Understanding The Differences — Milling Is A Fundamental Process In Manufacturing That Involves Removing Material From A Workpiece To Achieve The Desired Shape And Size. Among The Myriad Of Factors That Influence The Efficiency And Quality Of Milling Operations, Two Critical Parameters Are The Rake Angle Of The Milling Cutter And The Feed Per Tooth. Understanding The Interplay Between These Two Elements Can Greatly Enhance Machining Performance And Tool Longevity. What Is Rake Angle? The Rake Angle Is Defined As The Angle Formed Between The Cutting Edge Of The Tool And A Plane Parallel To The Workpiece. It Plays A Significant Role In Determining The Cutting Efficiency And Chip Formation During The Milling Process. A Positive Rake Angle Can Help Facilitate Easier Chip Removal, Reducing Cutting Forces And Enhancing Tool Life, While A Negative Rake Angle May Increase Friction And Heat, Leading To A Decrease In Tool Performance. What Is Feed Per Tooth? Feed Per Tooth Is The Amount Of Material Fed Into The Cutter For Each Tooth That Makes Contact With The Workpiece. This Parameter Directly Impacts Both The Surface Finish Of The Machined Part And The Overall Machining Time. It Is Typically Measured In Millimeters Or Inches Per Tooth And Can Impact The Cutting Forces And Temperature Generated During The Milling Process. Careful Selection Of Feed Per Tooth Is Essential For Optimizing The Milling Operation, Balancing Productivity With Workpiece Quality. The Relationship Between Rake Angle And Feed Per Tooth Understanding The Relationship Between Rake Angle And Feed Per Tooth Is Crucial For Achieving Optimal Results In Milling Operations. 1. **Efficiency**: A Well-Chosen Rake Angle Paired With An Appropriate Feed Per Tooth Ensures Optimal Cutting Efficiency. For Example, A Suitable Rake Angle Can Reduce Cutting Forces, Allowing For Higher Feed Rates Without Compromising The Tool’S Integrity. 2. **Chip Formation**: The Rake Angle Affects Chip Thickness And Shape. When Combined With The Correct Feed Per Tooth, It Can Help Minimize Cutting Resistance, Thereby Improving Chip Evacuation And Reducing The Chances Of Tool Wear. 3. **Surface Finish**: Both Parameters Play A Role In The Surface Finish Of The Workpiece. An Unfavorable Rake Angle Or Excessive Feed Per Tooth Can Lead To A Rough Finish, While Optimal Levels Of Both Can Enhance The Quality Of The Final Product. Conclusion In Conclusion, The Milling Cutter Rake Angle And Feed Per Tooth Are Key Factors That Interact Closely To Influence Machining Performance. A Thorough Understanding Of How They Affect Each Other Can Empower Machinists And Engineers To Make Informed Choices That Maximize Productivity While Maintaining High-Quality Output. By Carefully Adjusting These Parameters According To The Specific Material And Desired Outcomes, Effective Milling Operations Can Be Achieved.

Milling Cutter Rake Angle vs Feed Per Tooth

Understanding milling cutter rake angle and feed per tooth is crucial for machining. The rake angle affects how cutting tools slice through materials. A positive rake angle reduces cutting force but may wear out faster. Meanwhile, the feed per tooth is how far the cutter moves for each tooth in one rotation. Balancing these two factors is key to achieving a smooth finish. It’s like finding the right speed when pedaling a bike—too fast or too slow can lead to problems.Milling Cutter Basics

Definition and purpose of milling cutters. Types of milling cutters and their applications.Milling cutters are tools used to shape materials like metal and wood. Their main job is to cut shapes or grooves, making them essential in manufacturing. There are different types of milling cutters for various tasks. For instance, flat end mills create smooth surfaces, while ball end mills are great for rounded shapes. Each cutter has its own special skills, kind of like superheroes for machining!

| Type of Milling Cutter | Application |

|---|---|

| Flat End Mill | Creating flat, smooth surfaces |

| Ball End Mill | Making curved or contoured shapes |

| Face Mill | Machining large flat areas |

In short, milling cutters are like the Swiss Army knives of metalworking. With the right cutter, you won’t just be cutting; you’ll be creating masterpieces! Who knew cutting could be this fun?

Understanding Rake Angle

Definition of rake angle in milling. Importance of rake angle on cutting performance.The rake angle is the angle formed between the cutting edge and the workpiece. It plays a key role in how a milling cutter performs. Knowing this angle helps in making better cuts. A correct rake angle can make cutting easier and faster. Too much or too little rake angle can lead to problems like tool wear or poor finishes. So, adjusting the rake angle is crucial for smooth operations and good results.

Why is Rake Angle Important?

The rake angle directly affects cutting efficiency. Often good rake angles lead to:

- Better chip removal: Less clogging during cutting.

- Improved surface finish: Cleaner and smoother edges.

- Extended tool life: Less wear on the cutter.

Feed Per Tooth Explained

Definition of feed per tooth. Factors influencing feed per tooth settings.Feed per tooth is a way to measure how much material a cutting tool removes with each tooth during milling. Think of it like taking bites of your favorite pizza—the bigger the bite, the faster you finish! Several things affect this setting. For instance, the type of material, the cutting speed, and how sharp the tool is can change the feed per tooth. Finding the perfect bite can lead to a smoother finish and happier tools, much like finding the right slice of pizza makes you happy!

| Factor | Influence on Feed per Tooth |

|---|---|

| Material Type | Harder materials need slower feeds. |

| Cutting Speed | Higher speeds can allow greater feeds. |

| Tool Sharpness | Sharper tools work better with higher feeds. |

Relationship Between Rake Angle and Feed Per Tooth

How rake angle affects material removal rate. Impact of feed per tooth on surface finish and tool wear.The rake angle plays a big role in how materials are removed. A bigger rake angle makes cutting easier. This means faster material removal. For the feed per tooth, it affects the surface finish. A larger feed can lead to a rougher finish. It also increases tool wear. This means tools might need replacing more often. Here’s how they relate:

- Rake Angle: Higher angles help in easier cutting.

- Material Removal Rate: Bigger angles lead to faster material removal.

- Feed per Tooth: Higher feed can create a rougher finish.

- Tool Wear: More feed increases wear on tools.

How does rake angle impact cutting performance?

A higher rake angle improves cutting performance by reducing cutting forces and making material removal easier.

Key Points:

- Improved tool life with optimal rake angles.

- Good balance of feed improves surface quality.

Optimizing Milling Parameters

Strategies for selecting correct rake angles. Guidelines for adjusting feed per tooth for different materials.Choosing the right rake angle for your milling cutter is key to effective machining. A sharp rake angle helps cut smoothly, while a flatter angle adds strength. For different materials, adjusting the feed per tooth is essential. Softer materials like aluminum can use higher feeds, while harder materials need slower feeds. Here are some quick tips:

- For soft materials, use a high rake angle and a fast feed rate.

- For hard materials, use a low rake angle and a slow feed rate.

By understanding these choices, you can improve your machining results and save time.

What is an optimal rake angle for milling?

The optimal rake angle depends on the material type. Generally, a rake angle between 10° to 20° works well for soft materials, while 0° to 10° suits harder materials.

Common Problems and Solutions

Issues related to incorrect rake angle selection. Challenges with inappropriate feed per tooth and troubleshooting tips.Choosing the wrong rake angle can lead to many issues. You might see poor surface quality or excessive tool wear. These problems can slow down work and cost more money. Similarly, if the feed per tooth is not set right, it can cause chattering or vibration during cutting. Both issues need quick fixes. Here are some tips:

- Always match the rake angle to your material.

- Adjust feed per tooth based on the cutter size.

- Check for vibrations; they often signal a problem.

Fixing these issues helps you achieve better cuts and saves time.

What happens if the rake angle is wrong?

Using the wrong rake angle can make cutting harder. You’ll face more friction and faster tool wear.

What if the feed per tooth is too high?

High feed rates can lead to poor finish quality and increased noise levels.

Case Studies and Practical Applications

Realworld examples of rake angle and feed adjustments. Comparative analysis of different setups and their outcomes.In real-world situations, choosing the right rake angle and feed per tooth can change everything. For example, Company A tried a steep rake angle with a high feed rate. They found that it produced rough surfaces. Oops! Meanwhile, Company B selected a flatter rake angle and a lower feed. Their results were smooth and shiny, like a well-polished apple! Adjustments matter!

| Company | Rake Angle | Feed Rate | Outcome |

|---|---|---|---|

| Company A | Steep | High | Rough Surface |

| Company B | Flatter | Low | Smooth Finish |

When comparing these two setups, the results speak volumes. Company A learned that a little change can go a long way. Company B? Well, they are more popular than a cat video on the internet! So, remember, the right rake angle and feed can mean the difference between a good day and a not-so-good day in the shop.

Conclusion

In summary, the milling cutter rake angle and feed per tooth work together to improve cutting efficiency. A positive rake angle helps reduce cutting force, while the right feed per tooth ensures smooth machining. By adjusting these factors, you can optimize your milling process. Keep experimenting and learning to achieve better results. For more tips, check out additional resources!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Rake Angle Versus Feed Per Tooth:Sure! The rake angle is the tilt of the cutter’s edge that helps it cut better. A higher rake angle can make cutting easier but may wear out faster. Feed per tooth is how much material the cutter removes in one turn. If you feed too much, the cutter can break. It’s all about finding the right balance!

Sure! Please give me the question you want me to answer.

How Does The Rake Angle Of A Milling Cutter Influence The Cutting Forces Experienced During The Milling Process?The rake angle of a milling cutter is the slant of the cutting edge. If the rake angle is steep, the cutter cuts through materials easier. This means less force is needed, so the machine works better. If the angle is flat, the cutter pushes harder, using more force. So, the rake angle helps decide how tough the cutting will be.

In What Ways Does Increasing The Feed Per Tooth Affect The Surface Finish Of A Machined Component When Using A Specific Rake Angle?When we increase the feed per tooth, it means we are making the tool move faster. This can create a rougher surface finish on the part we are making. A rougher finish looks less smooth and can have tiny bumps. If we want a smooth finish, we need to use a lower feed. The rake angle can help, but too much feed makes it harder to get a nice surface.

What Are The Optimal Rake Angles For Various Materials Being Milled, And How Do They Interact With Different Feed Per Tooth Settings?When we mill different materials, the rake angle is important. A rake angle is how sharp the cutting edge is. For soft materials like aluminum, a positive rake angle works well. For hard materials like steel, a neutral or negative rake angle is better. Feed per tooth is how much material we remove with each cut. A higher feed per tooth works better with a good rake angle. If your rake angle is not right, it can make cutting harder.

How Can Adjusting The Rake Angle Impact The Chip Formation Process In Relation To Feed Per Tooth During Milling Operations?Adjusting the rake angle changes how the cutting tool meets the material. If you make the angle bigger, the tool cuts easier. This means it can form better chips with less effort. When the feed per tooth is higher, a good rake angle helps keep chips flowing smoothly. With the right adjustments, you can make the milling process faster and smoother!

What Considerations Should Be Taken Into Account When Selecting A Milling Cutter’S Rake Angle And Feed Per Tooth For Achieving Maximum Tool Life And Productivity?When choosing a milling cutter’s rake angle, think about the material you’re cutting. A steeper angle helps cut softer materials easier, while a flatter angle works better for tough materials. For the feed per tooth, use a slower feed for better tool life, but a faster feed can help get more done quickly. You need to balance tool life and speed to achieve the best results. Always check how the cutter performs and make adjustments as needed.