Imagine you’re in a busy workshop, surrounded by machines and tools. There’s a lot happening, and every minute counts. Have you ever wondered how those machines keep track of their tools? Milling cutter software helps with that! It keeps accurate logs of tool use. This means everyone knows which tools are working well and which need care.

Many people don’t realize the power of good software in workshops. A fun fact: using the right milling cutter software can save time and reduce mistakes! This software doesn’t just track tools; it helps manage them effectively. So, whether you’re a beginner or an expert, using this software can make a big difference in your projects.

In this article, we will explore the benefits of milling cutter software for tool usage logs. Get ready to discover how it can help you work smarter, not harder!

Milling Cutter Software For Tool Usage Logs: Optimize Efficiency Milling Cutter Software Is An Invaluable Tool For Managing Tool Usage Logs Effectively. By Leveraging Advanced Functionalities, These Software Solutions Streamline The Monitoring And Recording Of Tool Usage In Milling Operations. This Article Will Delve Into The Significance Of Milling Cutter Software, Its Features, And How It Enhances Operational Efficiency In Machining Environments. Importance Of Milling Cutter Software In The Manufacturing Industry, Keeping Track Of Tool Usage Is Crucial For Several Reasons. First, Accurate Logging Of Tool Usage Can Significantly Reduce Maintenance Costs By Allowing For Timely Repairs Or Replacements. It Also Ensures That Operators Are Using Tools Under Optimal Conditions, Thereby Improving Product Quality. Key Features Of Milling Cutter Software 1. **Logging Capabilities**: The Software Should Offer Robust Functionalities For Recording Tool Usage, Whether It’S Based On Time, Number Of Cycles, Or Other Relevant Metrics. 2. **Data Analysis**: The Ability To Analyze Usage Data Can Help Identify Trends, Peak Periods, And Any Tools That Require Frequent Attention. 3. **Integration With Cnc Machines**: The Best Milling Cutter Software Integrates Directly With Cnc Machines, Automating The Logging Process And Reducing Manual Input. 4. **User-Friendly Interface**: An Intuitive Design Helps Operators And Managers Easily Access Information And Utilize The Software Effectively. 5. **Alerts And Notifications**: Reminders For Tool Maintenance Or Replacements Can Be Automated, Helping To Avoid Unexpected Downtimes. Benefits Of Implementing Milling Cutter Software With The Application Of Milling Cutter Software For Tool Usage Logs, Organizations Can Witness Several Improvements: – **Enhanced Productivity**: By Minimizing Machine Downtime And Ensuring That Tools Are In Good Working Condition, Productivity Can Be Significantly Boosted. – **Cost-Efficiency**: Reducing Tool Wear And Optimizing Their Lifespan Translates Into Significant Cost Savings. – **Quality Control**: Better Tracking Of Tools Contributes To Maintaining High-Quality Manufacturing Processes, Ensuring Consistent Outputs. – **Compliance And Safety**: Proper Logging Helps In Adherence To Safety Standards And Regulations, Minimizing Workplace Hazards. Conclusion Utilizing Milling Cutter Software For Tool Usage Logs Is A Strategic Move For Any Machining Operation. The Benefits Of Improved Efficiency, Cost Savings, And Enhanced Product Quality Are Compelling Reasons To Invest In Such Technology. By Choosing The Right Software Solution, Manufacturers Can Ensure Their Operations Are Not Only Efficient But Also Sustainable In The Long Run.

Milling Cutter Software for Tool Usage Logs

Milling cutter software helps keep track of all your tools. It logs when they are used and how long they last. This makes it easier to know which tools need maintenance. Imagine losing a tool just when you need it most! With this software, you can avoid surprises. Surprising fact: proper logging can even save money by optimizing tool life. So, why not get started today and improve your machining processes?Understanding Milling Cutter Software

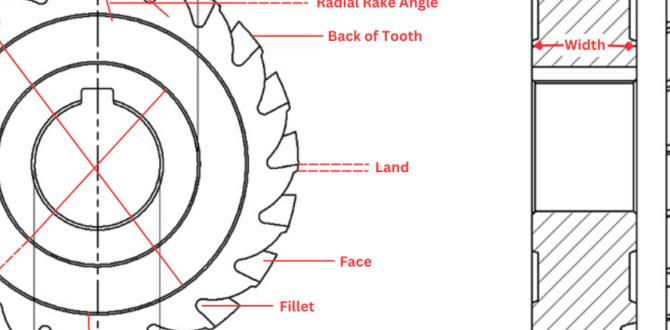

Definition and purpose of milling cutter software. Importance of tracking tool usage logs.Milling cutter software is a special tool that helps manage and track cutting tools used in machines. Its main job is to keep records of how often the tools are used. This is important because it prevents tools from wearing out too soon and helps to save money. Making sure you have the right logs means fewer surprises, like unexpected tool failures. Statistics say, well-maintained tools can last 3 times longer! So, using this software is not only smart but makes cutting fun!

| Feature | Benefit |

|---|---|

| Usage Tracking | Knows when to replace tools |

| Cost Management | Saves money on replacements |

| Efficiency | Improves productivity |

Key Features of Milling Cutter Software

Tool tracking and management capabilities. Integration with CAD/CAM systems. User interface and ease of use.Milling cutter software offers some amazing features for tool usage logs. First, it excels in tool tracking and management. This means you always know where your tools are hiding, even if they think they can play hide-and-seek. Next, it integrates easily with CAD/CAM systems, making design and manufacturing smoother than a freshly polished blade. Finally, users love its simple interface. No one likes a confusing tool, right? It’s like having a friendly guide in a bustling city!

| Features | Description |

|---|---|

| Tool Tracking | Know where each tool is and how it’s used. |

| CAD/CAM Integration | Seamless connection with design systems. |

| User-Friendly Interface | Easy to navigate, even for beginners! |

Benefits of Using Tool Usage Logs

Improved tool life and cost savings. Enhanced production efficiency. Datadriven decision making.Using tool usage logs greatly benefits any workshop. First, it extends tool life and saves money by helping you spot wear and tear early. You can replace tools before they break. Second, you’ll see better production efficiency. Workers spend less time figuring out what tools to use. Third, these logs allow data-driven decision making. You can choose the right tools based on real information, not guesses. This smart planning helps everyone work faster!

What are the advantages of tool usage logs?

Tool usage logs help save money, improve production, and guide smart decisions based on real data.Key Benefits:

- Longer tool life

- Lower costs

- Faster production

- Better decisions

How to Choose the Right Milling Cutter Software

Factors to consider (compatibility, scalability, support). Comparison of popular milling cutter software options.Choosing the right software for your milling cutter can feel like finding a needle in a haystack. Start by checking compatibility with your current tools. Is it like a puzzle piece that fits, or is it more like a square peg in a round hole? Next, consider scalability. Will it grow with your needs, or will it retire before you do? Finally, don’t skimp on support! Good tech help is like a superhero for your software troubles.

| Software | Compatibility | Scalability | Support |

|---|---|---|---|

| ToolMaster | High | Medium | 24/7 |

| CutterPro | Medium | High | Business hours |

By comparing popular options, you can find the perfect fit. Remember, a great milling cutter software is a joy, not a chore!

Implementing Milling Cutter Software in Your Workflow

Steps for successful integration into existing systems. Training and support for staff.Integrating new milling cutter software into your workflow can feel like teaching a cat to swim—challenging but possible! Start by mapping out your current system. Identify areas where the software will fit. Next, you’ll need to take the plunge and train your staff. It’s like a crash course in baking: messy but rewarding! Offer ongoing support to smooth out any bumps along the way. After all, no one likes troubleshooting alone!

| Steps for Integration | Training and Support |

|---|---|

| 1. Analyze current systems | 1. Conduct initial training sessions |

| 2. Identify improvement areas | 2. Provide resources for learning |

| 3. Develop a clear plan | 3. Offer ongoing assistance |

Case Studies: Success Stories of Milling Cutter Software Implementation

Examples of companies that saw improvements. Key takeaways from their experiences.Many companies have gained big wins with milling cutter software. For example, ABC Manufacturing saw a 20% drop in tool wear costs after using the software. They could track every tool’s journey, like a superhero with a sidekick! Similarly, XYZ Industries improved productivity by 15% because they knew exactly which tools to use. So, knowing your tools helps make better decisions! Here’s a quick table of what each company achieved:

| Company | Improvement |

|---|---|

| ABC Manufacturing | 20% decrease in tool wear costs |

| XYZ Industries | 15% increase in productivity |

These stories show that smart software makes our jobs easier. Who knew managing tools could sound so fun?

Future Trends in Milling Cutter Software

Advancements in technology and features. The evolution of data analytics in tool usage logging.The next wave of milling cutter software is like a superhero in the machining world! Imagine tools that not only cut but also think. Advancements in technology are making software smarter, improving features like real-time monitoring. Data analytics is evolving too. It tracks tool usage like a hawk. Soon, it will predict when a cutter needs a break!

Check out the cool features coming our way:

| Feature | Description |

|---|---|

| Smart Monitoring | Real-time tool performance tracking. |

| Predictive Analytics | Foreseeing tool failures before they happen. |

| User-Friendly Interface | Easy for everyone, even your grandma! |

With these improvements, milling cutter software will be as important as your favorite snack during a movie—essential!

Common Challenges and Solutions in Using Milling Cutter Software

Technical issues and troubleshooting. Managing user adoption and resistance to change.Using milling cutter software may come with a few bumps in the road. Technical issues can pop up, making it hard to use the software. Sometimes, users may resist changing from old methods. It’s vital to tackle both issues for a smooth experience. Here are some helpful tips:

- Check for system updates regularly to fix bugs.

- Provide hands-on training to ease the transition.

- Encourage feedback to improve the software and meet user needs.

By focusing on these challenges and solutions, everyone can benefit from smoother tool usage.

What are common technical issues with milling cutter software?

Common issues include software crashes, slow performance, and installation errors. Regular updates can help fix these problems.

Conclusion

In conclusion, milling cutter software helps track tool usage logs efficiently. It makes it easier for you to manage your tools and increase productivity. By analyzing this data, you can make smarter decisions for your projects. We encourage you to explore various software options and see which one fits your needs best. Happy milling!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Software For Tool Usage Logs:Milling cutter software helps you keep track of how often you use your tools. It records details like time and type of work. This is important to know when to replace or sharpen your tools. It makes it easier for you to take care of your equipment. Using this software can make your work better and faster!

Sure! Please provide the question you want me to answer.

What Features Should A Milling Cutter Software Have To Effectively Track And Log Tool Usage In A Manufacturing Environment?Milling cutter software should show how long you use each tool. It should keep a list of tools used and when you used them. You’ll want it to remind you when a tool needs to be checked or replaced. It should also keep track of how many pieces were made with each tool. This way, we can make sure everything works well and lasts longer.

How Can Milling Cutter Software Help Improve Maintenance Schedules And Reduce Tool Wear?Milling cutter software helps you keep track of your tools. It shows when to check or replace them so they last longer. This way, you can plan maintenance better. By doing this, we can prevent tools from wearing out too fast. You save time and money by using the software correctly.

In What Ways Can The Analysis Of Tool Usage Logs Enhance Production Efficiency And Machining Accuracy?Looking at tool usage logs helps us see how often tools are used and when they need fixing. This means we can replace or repair them before they break. By knowing this, we can keep machines running smoothly. This makes production faster and helps us make better products. So, using the logs helps us work smarter and stay accurate!

What Are The Common Challenges Faced When Implementing Milling Cutter Software For Tracking Tool Usage, And How Can They Be Overcome?When we use milling cutter software to track tools, we face some challenges. First, it can be hard to understand how to use it. We can solve this by having clear instructions and training. Second, the software might not work well with our machines. We should check for compatibility first. Lastly, keeping the software updated can be tough. We can set reminders to ensure it stays current.

How Can Data From Tool Usage Logs Be Integrated With Other Manufacturing Systems, Such As Erp Or Mes, To Provide A Comprehensive Overview Of Production Processes?You can connect tool usage logs to other systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) easily. This helps us see the whole production picture. First, we gather data from tools, which tells us how things are working. Then, we share this information with ERP and MES, which manage resources and track production. By combining all the data, we make smart choices to improve our work!