Have you ever wondered why a milling cutter is so important in machining? Imagine trying to cut wood with a dull knife. It just doesn’t work well, right? The same goes for milling cutters. Their stiffness affects how well they cut materials.

In the world of machining, milling cutters play a vital role. They shape and create parts for many tools we use every day. But did you know that the stiffness of these cutters can make or break a project? Stronger cutters provide better results. They help produce accurate shapes and smooth finishes.

Let’s explore why milling cutter stiffness is crucial. Understanding this can transform your approach to machining. Ready to dive in and discover the surprising impact of cutter stiffness?

The Importance Of Milling Cutter Stiffness In Machining

Milling Cutter Stiffness Importance

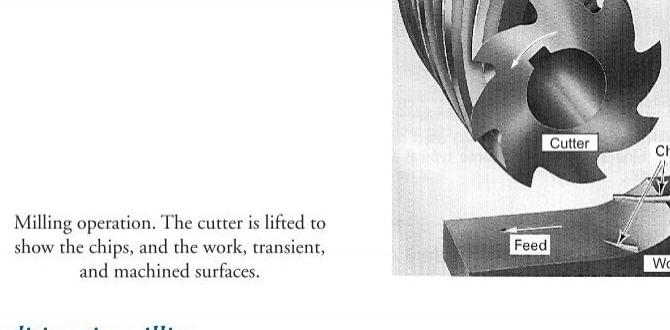

Milling cutter stiffness plays a vital role in machining. It determines how well the cutter withstands forces during operation. A stiffer cutter reduces vibrations, leading to better precision. Imagine trying to cut through thick wood with a wobbly blade. The results wouldn’t be neat, right? High stiffness not only improves the quality of the cut but also extends tool life. Understanding this can help improve any machining process. A small change can make a big difference!Understanding Milling Cutter Stiffness

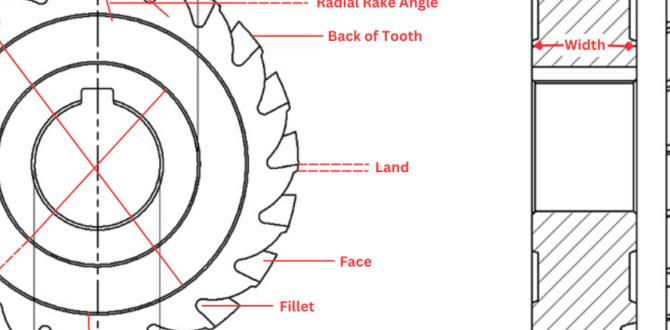

Definition of milling cutter stiffness. Factors influencing stiffness in milling cutters.Milling cutter stiffness is the ability of a cutter to resist bending under pressure. A stiffer cutter can make cleaner cuts and last longer. Several factors affect stiffness, such as:

- Material: Harder materials create stiffer cutters.

- Diameter: Thicker cutters are usually stiffer.

- Length: Shorter cutters bend less.

- Design: Certain shapes can add more strength.

Understanding these factors helps ensure better performance in milling tasks.

Why is milling cutter stiffness important?

A stiff milling cutter improves cutting accuracy and tool life. It reduces vibrations, which can cause damage to both the cutter and the workpiece.

Role of Stiffness in Machining Processes

How stiffness affects cutting efficiency. Relation between stiffness and machining accuracy.Stiffness plays a huge role in machining. Imagine trying to cut a cake while it wobbles. That’s how machines feel without stiffness! It impacts cutting efficiency. If your milling cutter is sturdy, it cuts smoothly, like butter. On the flip side, a weak cutter wobbles and struggles, leading to messy cuts and wasted time. Furthermore, toughness relates to precision. A stiff cutter ensures that every cut is accurate. With the right stiffness, you can achieve impressive results, like a master chef slicing a perfect pie.

| Stiffness Level | Cutting Efficiency | Machining Accuracy |

|---|---|---|

| High | Very Efficient | Precise Cuts |

| Medium | Moderately Efficient | Acceptable Cuts |

| Low | Poor Efficiency | Messy Cuts |

Factors Affecting Milling Cutter Stiffness

Material properties of the cutter. Geometric considerations of the milling tool.Many things affect how stiff a milling cutter is. First, the material properties play a big role. Strong materials make the cutter last longer and resist changes. For example, high-speed steel (HSS) is tougher than regular steel.

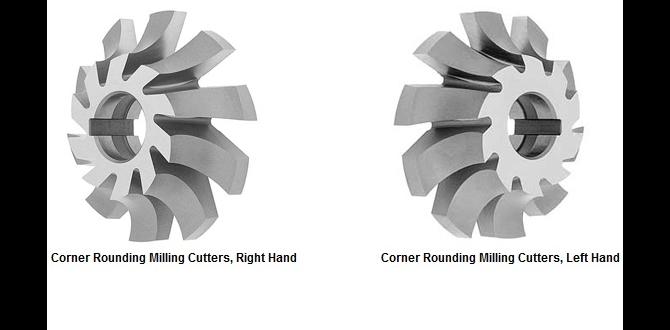

Next, geometric considerations matter too. The shape and size of the cutter can change how it cuts. A wider cutter might be stiffer but less flexible. A thinner cutter, however, may bend easily. Both properties are important when making the right choice.

What affects milling cutter stiffness?

Cutter material and design are key factors that influence stiffness.Key Factors:

- Material type (e.g., HSS, carbide)

- Cutter width and diameter

- Cutting edge angle

- Tool length

Measuring and Calculating Milling Cutter Stiffness

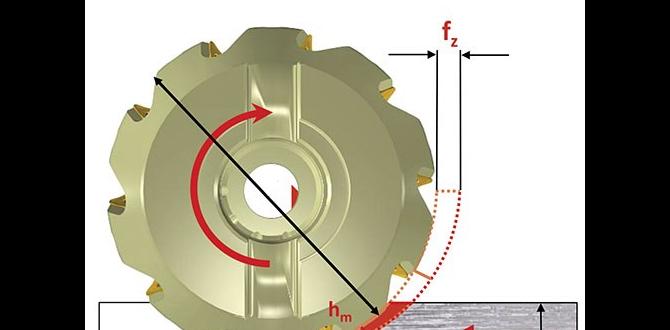

Common methods for stiffness measurement. Mathematical models for stiffness calculation.Measuring the stiffness of milling cutters helps ensure they work well. Several methods help in finding this stiffness:

- Use a force gauge to measure resistance when cutting.

- Check how much the cutter bends under a load.

- Utilize vibration analysis to observe the cutter’s response.

Mathematical models can also calculate stiffness. These formulas consider factors like the material, shape, and size of the cutter. Understanding stiffness helps in choosing the right cutter for any job.

What are common methods for measuring stiffness?

Common methods include force gauges, bending tests, and vibration analysis.How do you calculate stiffness mathematically?

Stiffness can be calculated using formulas that consider the cutter’s material and dimensions.Effects of Low Stiffness on Machining Outcomes

Consequences for tool wear and tear. Impact on surface finish and dimensional tolerances.Low stiffness in milling cutters can cause big problems. It leads to faster tool wear. A worn tool doesn’t cut well. This affects the surface finish. Your parts may look rough, not smooth. They might not fit together correctly, causing bad dimensional tolerances. This can make projects cost more and take longer. Check out these effects:

- Increased tool wear

- Poor surface finish

- Incorrect part sizes

What happens if stiffness is low during machining?

Low stiffness can lead to quick tool damage. This not only wastes materials but also increases costs significantly.

When a milling cutter lacks stiffness, firms often face delays. Tools may need to be replaced or repaired frequently. Hence, investing in sturdy milling tools is wise.

Improving Milling Cutter Stiffness

Design modifications for enhanced stiffness. Selection of materials to boost performance.To make a milling cutter stronger, we can focus on two key things: design and materials. First, clever design modifications can increase stiffness. Think of it like adding braces to your teeth; they help keep things in line! Next, selecting the right materials plays a huge role. Using tougher materials adds to durability. It’s like picking the best superhero for a mission! Below is a table to highlight some effective design changes and materials:

| Design Modifications | Materials |

|---|---|

| Increasing wall thickness | High-speed steel |

| Ribbed structures | Cobalt alloys |

| Optimized geometry | Carbide |

Strong cutters mean better performance and longer life. So, let’s make our tools as tough as a badger in a boxing ring!

Case Studies and Real-World Applications

Examples of stiffness optimization in industrial settings. Comparative analysis of stiffness in various milling applications.Many industries have improved their processes by focusing on stiffness optimization. For example, a car manufacturing group adjusted their milling cutters. They found that stiffer cutters made smoother parts faster. Similarly, a tool company studied stiffness in woodwork. Their results showed that parts last longer with stiffer tools. Here’s a quick look at these findings:

- In automotive: Stiffness improved production speed by 20%.

- In woodworking: Stiffer cutters extended tool life by 15%.

These real-world examples highlight how stiffness can make a big difference in milling applications. Companies that pay attention to this can save time and money.

How does stiffness affect milling performance?

Stiffness increases precision and reduces tool wear. It leads to better finishes and longer tool life. Stiffer milling cutters create fewer vibrations and cut faster.

Future Trends in Milling Cutter Design and Stiffness

Innovations in materials and technologies. Predictions for the evolution of milling cutter performance.New materials and technologies are changing milling cutter designs. Innovations, like lightweight composites and hard coatings, increase stiffness and durability. This leads to better performance and longer life. In the future, we can expect:

- Advanced materials for stronger and lighter cutters.

- Smart technology integration for real-time adjustments.

- Improved designs for precision and efficiency.

These trends will help manufacturers make faster cuts with less waste. As tools evolve, milling cutters will become even more effective.

What are the key benefits of new milling cutter technologies?

The key benefits include increased precision, reduced production costs, and enhanced durability. This means tools last longer and work better.

Conclusion

In conclusion, milling cutter stiffness is vital for achieving clean cuts and good finishes. Stiffer cutters reduce vibrations and improve accuracy. If you want better results in your projects, consider the stiffness of your tools. Next time you choose a milling cutter, look for a sturdy option. For more tips, explore resources on tool selection and milling techniques!FAQs

How Does The Stiffness Of A Milling Cutter Influence The Quality Of The Machined Surface Finish?The stiffness of a milling cutter, which is the tool that carves and shapes materials, affects how smooth the surface will be. A strong, stiff cutter can cut better and gives a nicer finish. If the cutter is weak, it might bend or vibrate while cutting. This bending creates rough spots on the surface. So, stiffer cutters help us make smooth and clean surfaces.

In What Ways Does Cutter Stiffness Affect The Overall Machining Performance And Productivity In Milling Operations?Cutter stiffness is how strong the tool is when it cuts. If the cutter is stiff, it holds its shape better. This helps you make cleaner cuts and reduces mistakes. When the cuts are good, you can work faster and get more done. Strong cutters last longer too, which means less time fixing them.

What Are The Common Factors That Contribute To The Stiffness Of A Milling Cutter?The stiffness of a milling cutter comes from a few key things. First, the material it’s made from matters. Harder materials are usually stiffer. Second, the shape of the cutter helps too; thicker parts are more rigid. Lastly, how the cutter is held in place also affects its stiffness. If it’s secured well, it will work better.

How Can The Stiffness Of A Milling Cutter Be Tested Or Measured During The Manufacturing Process?You can test the stiffness of a milling cutter by bending it. We use a special machine that pushes on the cutter. This shows how much it bends when pressure is applied. If it bends too much, it means it’s not stiff enough. You can also measure how it cuts through materials to see if it’s strong.

What Design Modifications Can Be Made To Improve The Stiffness Of Milling Cutters Without Compromising Their Cutting Ability?To make milling cutters stiffer, we can change their shape. We can use thicker materials or add extra support where needed. Using special coatings can also help by making them stronger. We must ensure these changes don’t make cutting harder. By balancing strength and sharpness, we can create better tools.