Have you ever wondered how we make tools like milling cutters? These tools help shape and cut materials in factories. But how do we know if they are working correctly? The answer lies in surface topography inspection.

Imagine turning on a favorite game. You expect it to work without any glitches. A milling cutter is much like that game. It must be perfect for the job. If its surface is damaged, it won’t cut well. This is where inspection comes in.

Fun fact: a smooth cutting edge can make all the difference! It helps machines run faster and smarter. In this article, we will explore how to inspect the surface topography of milling cutters.

Let’s uncover why inspection matters and how it keeps our tools sharp and efficient. Are you ready to dive into the world of milling cutters?

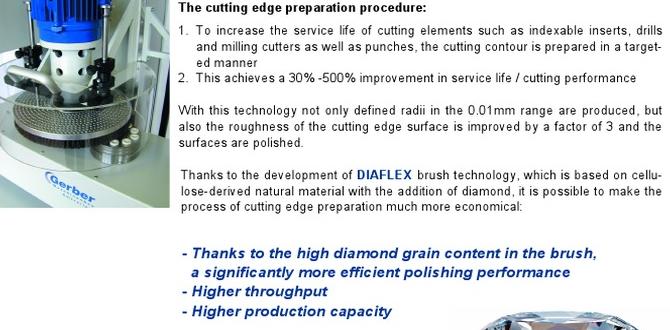

Milling Cutter Surface Topography Inspection: A Comprehensive Guide Milling Cutter Surface Topography Inspection Is A Critical Process In Manufacturing, Particularly In The Machining And Fabrication Industries. This Inspection Ensures That Milling Cutters Are Functioning Optimally And Producing The Desired Surface Quality. By Assessing The Surface Topography Of Milling Cutters, Manufacturers Can Achieve Higher Precision, Improve Product Quality, And Reduce Machining Costs. Understanding Milling Cutters And Their Importance Milling Cutters Are Rotary Cutting Tools Used In Milling Machines To Remove Material From A Workpiece. They Come In Various Shapes And Sizes, Each Designed For Specific Applications. The Precision Of These Tools Directly Affects The Quality Of The Finished Product. Therefore, Regular Inspection Of Their Surface Topography Is Essential To Ensure They Meet The Required Standards. What Is Surface Topography Inspection? Surface Topography Inspection Involves Analyzing The Surface Characteristics Of Milling Cutters. This Includes Assessing Features Such As Roughness, Wear Patterns, And The Geometry Of The Cutting Edges. Techniques Used In This Inspection Can Include Visual Examinations, Contact And Non-Contact Profilometry, And Advanced Imaging Technologies. Key Benefits Of Surface Topography Inspection 1. **Improved Tool Life**: Regular Inspections Help Identify Wear And Tear, Allowing For Maintenance Before Significant Damage Occurs. 2. **Enhanced Machining Efficiency**: A Well-Maintained Milling Cutter Operates More Efficiently, Leading To Better Machining Performance. 3. **Quality Assurance**: Ensures That The Finished Products Maintain The Desired Specifications And Tolerances. 4. **Cost Reduction**: Preventing Tool Failure Can Significantly Reduce Downtime And Associated Costs, Resulting In Improved Productivity. Techniques For Milling Cutter Surface Topography Inspection 1. **Contact Profilometry**: Involves Using A Probe That Physically Contacts The Surface To Measure Its Height Variations. 2. **Non-Contact Profilometry**: Employs Laser Or Optical Measuring Techniques To Capture Surface Measurements Without Any Physical Contact, Avoiding Potential Damage. 3. **Scanning Electron Microscopy (Sem)**: Provides Detailed Images Of The Surface Topography At A Microscopic Level, Allowing For In-Depth Analysis. 4. **3D Surface Imaging**: Offers A Comprehensive View Of The Cutter’S Surface, Revealing Complexities That May Not Be Apparent In 2D Views. Challenges In Surface Topography Inspection While The Need For Milling Cutter Surface Topography Inspection Is Clear, Several Challenges Can Arise: – **Access To Tools**: Some Milling Cutters May Have Complex Geometries, Making Them Difficult To Inspect Thoroughly. – **Operator Expertise**: Ensuring That Operators Are Well-Trained In Inspection Techniques Is Crucial For Accurate Assessments. – **Technological Limitations**: Not All Facilities May Have Access To Advanced Inspection Technologies, Impacting The Ability To Perform Precise Measurements. Conclusion Milling Cutter Surface Topography Inspection Is An Indispensable Aspect Of Modern Manufacturing. By Prioritizing This Process, Businesses Can Enhance The Performance Of Their Cutting Tools, Ensure High-Quality Production Outcomes, And Ultimately Achieve Increased Profitability. Investing In Proper Inspection Techniques Is Not Just About Compliance; It’S About Fostering A Culture Of Quality And Excellence Within The Manufacturing Process.

Milling Cutter Surface Topography Inspection

Milling cutter surface topography inspection reveals important details hidden in the cutting tools we use. This process checks for imperfections that can affect performance. Did you know that even tiny flaws can lead to big problems in machining? By examining the surface, technicians can find issues like wear or chips. This helps ensure high-quality cuts and extends tool life. Understanding this inspection is key to better manufacturing outcomes. What would your next project look like with top-notch tools?Importance of Surface Topography in Milling Cutters

Explanation of how surface topography impacts milling cutter performance and lifespan.. Discussion on the relationship between surface imperfections and machining accuracy..The surface topography of milling cutters plays a key role in how well they work. Rough surfaces can lead to poor cutting performance. This means cutters may wear out faster. Smooth surfaces help in achieving precise cuts. They also enhance the cutter’s life. Any flaws on the surface can cause mistakes in machining. Imperfections lead to inaccurate shapes and sizes in finished products.

How does surface topography affect milling cutter performance?

Surface topography impacts the efficiency and lifespan of milling cutters. A smoother surface results in better cutting. Roughness causes wear, reducing their effectiveness.

- Smooth surfaces improve cutting speed.

- Surface flaws can result in inaccurate machining.

- Proper inspection ensures longer cutter life.

Inspection Methods for Milling Cutter Surface Topography

Detailed description of tactile vs. nontactile inspection methods.. Advantages and disadvantages of each inspection method..There are two main ways to check the surfaces of milling cutters: tactile and nontactile methods. Tactile inspection uses touch to feel the surface. It is good because it is simple and inexpensive. However, it can miss tiny details. Nontactile inspection uses sensors or cameras. This method is fast and can spot very small features. But, it can be costly and needs special tools.

- Tactile Inspection Advantages: Simple and low cost.

- Tactile Inspection Disadvantages: Misses small details.

- Nontactile Inspection Advantages: Quick and detects tiny features.

- Nontactile Inspection Disadvantages: Expensive and requires special equipment.

What is tactile vs. nontactile inspection?

Tactile inspectionnontactile inspection uses advanced technology like cameras or lasers. This difference makes them suitable for various tasks and budgets.

Parameters Affecting Surface Topography Quality

Exploration of factors such as cutting speed, feed rate, and tool material.. Analysis of how these parameters contribute to surface finish quality..The quality of surface topography depends on several important factors. Each one plays a key role in how the surface of the material will look and feel after cutting. Here are some critical parameters:

- Cutting speed: This is how fast the cutter moves through the material. Higher speeds can improve surface quality but may increase wear on the tool.

- Feed rate: This is how fast the material moves against the cutter. A slower feed can lead to a smoother surface, while a faster feed may cause bumps.

- Tool material: The type of material used for the cutter matters. Harder materials can cut more cleanly and last longer.

These elements work together to create the best surface finish. Understanding their effects can ensure better quality in milling cutter surface topography inspections.

What is the best cutting speed for milling?

The best cutting speed varies based on the material and tool used. However, typically a speed of 150-200 feet per minute is ideal for many metals. Always adjust based on your specific project needs.

Key takeaway:

Remember, the right combination of cutting speed, feed rate, and tool material leads to a better finish!

Common Defects in Milling Cutters and Their Implications

Identification of typical surface defects (e.g., chipping, wear).. Discussion of the impact of these defects on machining operations..Milling cutters can develop common defects that affect their performance. Chipping happens when small pieces break off the cutting edge. This can lead to uneven cuts. Wear occurs from repeated use and makes the cutter less effective. These issues can cause:

- Lower quality cuts

- Increased machine vibrations

- Longer production times

- Higher tool replacement costs

Regular inspection helps catch these problems early. This way, we can keep operations running smoothly.

What are the common surface defects in milling cutters?

Typical defects includechipping andwear. Chipping leads to poor cutting quality, while wear can reduce cutter efficiency.

Best Practices for Surface Topography Inspection

Recommendations for routine inspection and maintenance protocols.. Tips for documenting and analyzing inspection results for continuous improvement..Keeping an eye on your milling cutter’s surface is like checking your ice cream for hidden sprinkles—essential for a sweet experience! Regular inspecting is key. It helps ensure the cutter stays sharp and effective. Make a schedule and stick to it! Use a checklist for each inspection. This way, nothing gets missed.

| Inspection Task | Frequency |

|---|---|

| Visual inspection | Weekly |

| Performance testing | Monthly |

| Thorough cleaning | After each use |

Keep a log of your findings. This will show patterns over time. Spotting a problem early can save you from a future meltdown—like when your ice cream cone flips upside down! Remember, continuous improvement is the name of the game. Make changes based on what your inspections tell you!

Future Trends in Milling Cutter Inspection Technologies

Insights into emerging technologies and methods for enhancing inspection accuracy.. Predictions on how these developments will shape the milling industry..New technologies are changing how we inspect milling cutters. Automation and machine learning are helping to spot tiny flaws faster and more accurately. These tools can check the surfaces in ways that people cannot. As a result, we expect to see stronger and more precise milling in the future. The milling industry will be safer, with fewer mistakes and better tools for everyone.

What are the key improvements in milling cutter inspection?

This question is important because new methods will save time and money. One big change is using 3D scanning technology. It allows for better detail and accuracy. Companies are also exploring Artificial Intelligence to monitor inspection processes.

Future Trends: Key Areas of Development

- Automation: More robots will perform inspections.

- Machine Learning: AI will analyze data to improve accuracy.

- 3D Scanning: This provides detailed topography of surfaces.

Conclusion

In conclusion, inspecting milling cutter surface topography is essential for quality machining. It helps prevent mistakes and improves product durability. You can enhance your skills by exploring tools and techniques for this inspection. Understanding the surface can lead to better results in your projects. We encourage you to read more or practice inspecting for yourself to see the difference it makes!FAQs

Sure! Here Are Five Questions Related To The Topic Of Milling Cutter Surface Topography Inspection:Sure! Here are answers to five questions about checking the surfaces of milling cutters. 1. **What is a milling cutter?** A milling cutter is a tool that helps shape metal or wood. It spins very fast to cut through materials. 2. **Why do we inspect milling cutters?** We inspect milling cutters to make sure they are sharp and not worn out. A good cutter works better and lasts longer. 3. **How do we check the surface of a milling cutter?** We can look at the cutter closely or use special tools to measure its surface. This helps us see if it needs fixing. 4. **What happens if a milling cutter is damaged?** If a milling cutter is damaged, it can make bad cuts. This can waste materials and time in work. 5. **How can we take care of milling cutters?** We can clean them after use, store them safely, and check them often. This helps them stay in good shape.

Sure! Please provide the question you would like me to answer, and I will help you with that.

What Are The Key Parameters To Consider When Assessing The Surface Topography Of A Milling Cutter?When we look at a milling cutter, we need to check a few key things. First, we see the shape of the cutting edges. Are they sharp or worn down? Next, we check how smooth the surface is. A smoother surface makes better cuts. Finally, we look at the angle of the edges, which helps us understand how well it will cut. These things help us know if the cutter works well or needs replacing.

How Do Different Inspection Methods, Such As Optical Microscopy And Scanning Electron Microscopy, Compare In Their Effectiveness For Analyzing Milling Cutter Surfaces?Optical microscopy uses light to look at small details on milling cutter surfaces. It can show us shapes and colors really well. Scanning electron microscopy, or SEM, uses a special beam to see even smaller details. SEM can show us textures and tiny cracks that optical microscopy might miss. So, SEM is usually better for finding very small problems on the cutter surfaces.

What Role Does Surface Roughness Play In The Performance And Longevity Of Milling Cutters?Surface roughness is how smooth or bumpy a milling cutter’s edge is. If the surface is rough, it can get dull quickly. This makes the cutter work harder and may break sooner. A smoother cutter stays sharper for longer, helping us make better cuts. Keeping cutters smooth helps them last more and work better!

How Can Wear Patterns Detected Through Topography Inspection Influence The Maintenance Schedule Of Milling Cutters?When we check the tops of milling cutters closely, we can see where they are worn down. These wear patterns help us understand how much they have been used. By knowing this, we can plan when to maintain or replace them. This means we can keep them working well and avoid breaking them. So, looking at wear patterns helps us take good care of our tools!

What Technological Advancements Have Improved The Accuracy And Efficiency Of Milling Cutter Surface Topography Inspection In Recent Years?Recent technology has made it easier to check the surfaces of milling cutters. We now use 3D scanners to create detailed pictures. These scanners are fast and show small details clearly. There are also special computer programs that help us analyze the pictures quickly. These improvements help us make better tools in less time!