Have you ever wondered how machines create such precise parts? The answer often lies in the milling cutter. This tool spins rapidly to shape materials in amazing ways. But what forces act on it while it works? One major factor is the tangential force.

Tangential force plays a crucial role in how well a milling cutter performs. It can affect the quality of cut and even the life of the tool. Understanding this force can help engineers and hobbyists alike.

Did you know that the exact angle of the cutter can change this force? A small adjustment can lead to more power or smoother cuts. Imagine adjusting your bike’s wheels to ride faster or smoother. Each tweak matters!

By diving into milling cutter tangential force analysis, we can unlock better techniques. Whether you’re a curious learner or a pro, grasping these concepts is vital. Let’s explore how this knowledge can make all the difference in cutting!

Milling Cutter Tangential Force Analysis: Understanding Forces

Milling Cutter Tangential Force Analysis

Milling cutter tangential force analysis helps explain how cutting tools work during machining. Understanding this force is crucial for improving tool performance. It influences the quality of the final product and helps in minimizing tool wear. Have you ever wondered why some cuts are smoother than others? The tangential force plays a big role! By analyzing these forces, machinists can adjust their methods for better results and longer tool life. It’s a game changer in manufacturing!What is Tangential Force in Milling?

Definition of tangential force in milling operations. Importance of tangential force in machining efficiency and component life.Tangential force in milling refers to the force that works parallel to the cutting surface. It plays a key role in how a milling cutter removes material. Understanding this force is important for several reasons:

- Machining Efficiency: Higher tangential force can boost productivity.

- Component Life: Proper management of this force can extend tool life.

By monitoring tangential force, operators can make better choices. This leads to less waste and longer-lasting tools. Think of it like a car engine; smooth operation makes it last longer!

What is tangential force’s impact on milling?

Tangential force affects how fast and efficiently a milling cutter works. The right amount can increase speed and reduce wear on tools, making work easier and cheaper.

Factors Affecting Tangential Force

Material properties and their influence on cutting forces. Geometry of cutting tools and its impact on force generation.Many things affect tangential force during cutting. First, the material properties of both the tool and workpiece play a big role. Harder materials create more resistance. Think of it like a stubborn piece of bread; a sharp knife is needed to slice it easily!

Next, the geometry of cutting tools matters. If the tool is dull or not shaped well, it struggles. Imagine trying to scoop ice cream with a fork. Not the best choice!

| Factor | Impact |

|---|---|

| Material Hardness | Higher forces needed for harder materials |

| Tool Shape | Affects how smoothly the tool cuts |

| Cutting Speed | Higher speeds can reduce force |

In essence, better materials and sharper, well-designed tools lead to less tangential force. Cutting can be easier than spreading peanut butter if you have the right tools!

Mathematical Modeling of Tangential Force

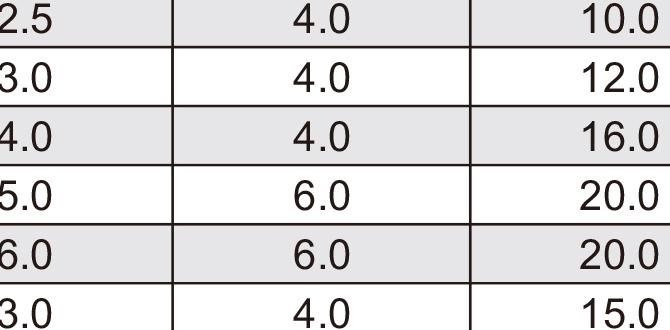

Key equations and formulas in calculating tangential force. Role of cutting parameters (speed, feed rate, depth of cut).Calculating tangential force involves important equations. The main equation is F_t = k * D * N, where F_t is the tangential force, k is a constant, D is the diameter of the cutter, and N is the number of cutting edges. Key cutting parameters affect this force:

- Speed: Faster speeds can increase force.

- Feed Rate: Higher feed rates add to the force needed.

- Depth of Cut: Deeper cuts raise the tangential force.

Understanding these factors helps in better milling cutter performance.

What are the key equations for tangential force?

Key equations for tangential force focus on the cutter’s size and speed. One main equation is F_t = k * D * N. This shows how diameter and cutting edges affect the force needed during milling.

Analyzing Tangential Force in Different Milling Operations

Comparison between conventional and highspeed milling. Influence of milling strategies (upcut vs downcut).Understanding tangential force is key in milling operations. Comparing conventional and high-speed milling shows big differences. Conventional milling uses larger forces, which can cause tools to wear out quickly, while high-speed milling reduces these forces and increases efficiency. Additionally, the milling strategy matters. An upcut pulls the tool away from the material, causing a lighter force. In contrast, a downcut pushes the tool down, creating more force. Here’s a fun little comparison:

| Milling Strategy | Tangential Force Impact |

|---|---|

| Conventional Milling | Higher force, faster wear |

| High-Speed Milling | Lower force, longer tool life |

| Upcut | Lighter impact, less chatter |

| Downcut | Stronger force, smooth finish |

Remember, the right choice can make your tool feel like it’s on vacation rather than working overtime!

Impact of Cutting Tool Material on Tangential Force

Exploration of various cutting tool materials (carbide, HSS, coated tools). How material selection affects force performance and wear.Choosing the right cutting tool material is like picking the best ice cream flavor—it makes all the difference! Materials like carbide, HSS (high-speed steel), and coated tools each have unique properties. Carbide tools are tough and last a long time, while HSS tools are great for softer materials. Coated tools combine the best of both worlds, helping to reduce wear and keep tangential forces in check. Here’s a quick comparison:

| Material | Durability | Performance | Cost |

|---|---|---|---|

| Carbide | High | Excellent | Higher |

| HSS | Medium | Good | Lower |

| Coated Tools | Very High | Superior | Higher |

So, if you want your tools to cut like a hot knife through butter, choose wisely!

Case Studies: Real-world Applications of Tangential Force Analysis

Examples from industries utilizing force analysis for optimization. Lessons learned and improvements made from tangential force data.Many industries use tangential force analysis to improve their processes. For example, the automotive industry studies cutting forces to enhance vehicle part manufacturing. Lessons learned include:

- Higher precision in cutting tools reduces waste.

- Optimal speeds cut down manufacturing time.

- Improved designs of milling cutters increase durability.

These changes lead to better products and more efficient production. Companies find that analyzing tangential forces can make processes smoother and save money.

What are real-world applications of tangential force analysis?

Real-world applications include improving tool designs, saving costs, and enhancing product quality in various manufacturing sectors.

Optimizing Milling Processes Based on Tangential Force Analysis

Strategies for reducing tangential force to enhance performance. Balancing productivity and tool life through optimized settings.Improving milling processes can boost efficiency. One way to do this is by reducing tangential force. A few strategies include:

- Choose the right tool material.

- Adjust cutting speed and feed rate.

- Maintain sharp cutter edges.

Balancing productivity and tool life is key. Proper settings can enhance performance while keeping tools longer lasting. Remember, less force can lead to smoother cuts.

How can tangential force be minimized in milling?

Use the correct tool geometry and optimal speeds to lower tangential force and improve the milling process.

Future Trends in Milling Cutter Force Analysis

Emerging technologies and their potential impact. Predictions for advancements in milling cutter design and analysis.New tech is shaking things up in milling cutter force analysis! We can expect smarter machines that understand cutting forces like a comedian knows their punchlines. AI and sensors will help us predict how tools act. Imagine a future where your milling cutter can tell you when it’s tired! Design advancements will focus on lighter materials and better aerodynamics, making cutting quicker and easier. The future looks bright, or should we say, blade-tastic!

| Emerging Technologies | Impact on Milling Cutter Analysis |

|---|---|

| AI & Machine Learning | Faster prediction of cutting forces |

| Smart Sensors | Real-time data for better decisions |

| Innovative Materials | Lighter tools for less energy use |

Conclusion

In conclusion, milling cutter tangential force analysis helps us understand the forces at play during cutting. This knowledge can improve efficiency and reduce wear on tools. By studying these forces, you can enhance your machining techniques. We encourage you to explore more about milling processes and practice analyzing forces in your projects for better results. Happy learning!FAQs

Sure, Here Are Five Questions Related To The Analysis Of Tangential Force In Milling Cutters:Sure! Here are five questions about tangential force in milling cutters: 1. What is a milling cutter? 2. How does tangential force help the cutter work? 3. Why do we need to measure this force? 4. What happens if the force is too high? 5. How can we make the force stronger or weaker? These questions help us understand how milling cutters cut materials!

Sure! Please provide the question you would like me to answer.

What Factors Influence The Tangential Cutting Force Experienced By A Milling Cutter During Operation?The tangential cutting force is the push that happens when a milling cutter spins and cuts through material. Several things affect this force. First, the type of material we are cutting matters; some are harder and need more force. Second, the shape and sharpness of the cutter can change how easily it cuts. Finally, how fast we move the cutter and how deep we cut also plays a big role. So, when we use a milling cutter, these factors can change how much force we feel.

How Does The Geometry Of The Milling Cutter, Such As Cutter Diameter And Flute Design, Affect The Tangential Force Generated During The Machining Process?The shape of the milling cutter affects how much force it uses. A bigger cutter diameter can push harder against the material. The flute design, which is the cutouts on the cutter, helps remove shavings. This keeps everything cool and reduces extra force. So, the cutter’s size and shape really matter when we use it to cut materials.

What Role Does Cutting Speed Play In The Tangential Force Analysis Of Milling Operations, And How Can It Be Optimized For Improved Performance?Cutting speed is how fast the tool moves while cutting. It affects the tangential force, which is the push that helps slice the material. If the cutting speed is too slow, more force is needed, which can make the tool wear out faster. We can improve performance by finding the right speed that cuts well without using too much force. This way, we save energy and make better cuts!

How Can The Tangential Force Be Measured And Calculated During A Milling Operation, And What Tools Or Methods Are Commonly Used For This Analysis?To measure the tangential force during milling, we can use special tools like force sensors or dynamometers. These tools are attached to the machine, and they feel the pressure made by the cutter. We can calculate the force by checking the readings from these sensors. Sometimes, we can even use simple calculations, like force equals mass times acceleration, if we know how fast everything is moving. This helps us understand how hard the tool is working!

In What Ways Can The Understanding Of Tangential Forces In Milling Contribute To Tool Wear Prediction And Overall Machining Efficiency?Understanding tangential forces in milling helps us know how much pressure is on the tool. This pressure can cause the tool to wear out faster. If we predict tool wear well, we can change the tool before it breaks. This keeps our machines running smoothly and saves time and money. Overall, we can make machining more efficient and less wasteful.