Imagine you’re about to bake your favorite cake. You wouldn’t skip checking if you have all the ingredients, right? The same idea applies to milling in machining. Before running a tool, you need to ensure everything is perfect. That’s where a milling cutter toolpath verification checklist comes in.

Did you know that mistakes in machining can lead to waste and costly delays? Every industry wants to avoid that. A simple checklist can save time and materials. This ensures the right toolpath is followed, preventing issues before they happen.

In this article, we will explore why a milling cutter toolpath verification checklist is essential. We’ll dive into how it works and the key items to include. By the end, you’ll see how this handy tool can make your milling processes smoother and more efficient. So, let’s get started!

Milling Cutter Toolpath Verification Checklist: Essential Steps

Milling Cutter Toolpath Verification Checklist

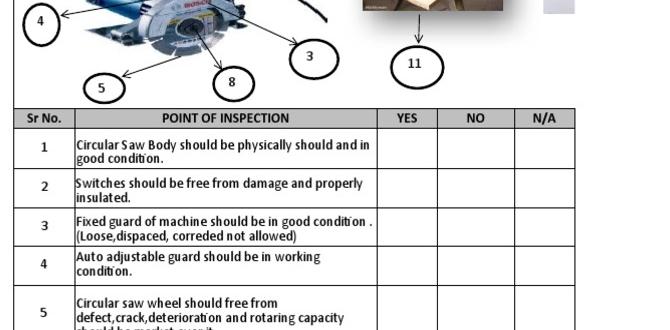

The milling cutter toolpath verification checklist helps ensure safe and accurate machining. It includes steps like checking tool alignment and verifying correct feed rates. Missing a single step can lead to costly mistakes. Imagine a misplaced tool creating defects in a new product; that’s why this checklist is vital! Effective use of this checklist can improve efficiency and reduce errors. Proper preparation leads to smoother operations and better results.Understanding Toolpath Verification

Definition and importance of toolpath verification. Key benefits of effective verification in milling processes.Toolpath verification checks the way a milling cutter moves. This is very important. It helps prevent mistakes that can ruin workpieces. An effective verification process offers many benefits:

- Improves accuracy

- Reduces waste

- Saves time

- Ensures safety

With proper verification, machinists avoid costly do-overs. This means better quality and happier customers. Understanding this process is key for anyone in machining.

Why is toolpath verification important?

Toolpath verification is important because it ensures accuracy, reduces errors, and enhances the overall quality of the milling process.

Essential Components of a Verification Checklist

List of critical points to verify before milling. Tools and software recommended for verification.Before you start milling, checking a few key points is essential. Think of it like packing for a trip—you don’t want to forget socks! Here are some critical items to verify:

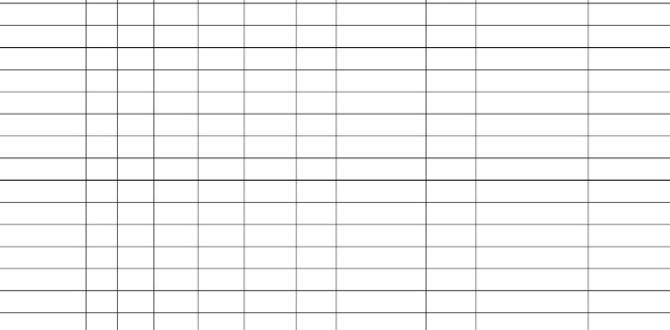

| Checklist Item | Description |

|---|---|

| Tool Selection | Choose the right milling cutter for the job. |

| Workpiece Setup | Ensure the workpiece is secure and positioned properly. |

| Speed and Feed Rates | Set optimal rates for effective cutting. |

Using the right tools and software adds superhero power to your milling checklist. Programs like CAM software can help ensure everything runs smoothly. Remember, a little verification goes a long way—like a good pair of shoes on an adventure!

Steps for Effective Toolpath Verification

Detailed procedures to follow in verification. Best practices for ensuring accuracy and efficiency.Verifying a toolpath is crucial for success in machining. Here are some steps to follow:

- Check the toolpath against the design. Make sure everything is correct.

- Review the set speeds and feeds. They should match the material type.

- Run a simulation. This helps catch any errors before actual machining.

- Use software tools for accuracy. Modern programs can spot issues faster.

Following these steps ensures your milling cutter toolpath is accurate. Proper verification saves time, resources, and prevents mistakes.

What are some best practices for toolpath verification?

Always document each verification step. This helps track changes and decisions. Regularly update your software for the latest tools and features. Involve your team in the process. Team reviews can spot mistakes others might miss.

Common Issues in Toolpath Verification

Frequently encountered problems and their causes. How to troubleshoot toolpath issues during verification.Toolpath verification can have its fair share of hiccups. Common issues might include misaligned paths, which can happen due to incorrect settings. Then there are unexpected tool collisions that feel like a game of bumper cars for milling machines. Don’t forget the dreaded simulation errors that pop up out of nowhere! The best way to tackle these problems is to check your settings and adjust accordingly. If a tool goes “whoops,” consult your verification checklist and keep calm. If needed, refer to the table below for quick troubleshooting tips!

| Issue | Cause | Troubleshooting Steps |

|---|---|---|

| Misaligned Paths | Incorrect settings | Check toolpath parameters |

| Tool Collisions | Paths overlapping | Review path routes |

| Simulation Errors | Software glitches | Restart software or update |

Case Studies: Successful Toolpath Verification

Examples of effective verification in realworld applications. Lessons learned from common pitfalls.Many companies have seen great success by using effective toolpath verification methods. For instance, a manufacturing firm improved its product quality by double-checking its milling cutter toolpaths. They discovered mistakes early, saving time and money. Some important lessons learned include:

- Always review toolpath settings.

- Check for potential collisions early.

- Regularly update verification software.

These practices help avoid errors that could impact production and safety. When companies verify wisely, they thrive!

How does toolpath verification help avoid mistakes?

Toolpath verification finds errors before cutting begins, saving time and costs associated with rework.

Future Trends in Toolpath Verification Technology

Innovations in software and tools for verification. Predictions for the future of milling cutter technology.New tools and software are changing how we check toolpaths. These innovations help make sure everything runs smoothly. Soon, we may see tools that use AI to catch mistakes faster. Virtual reality could let us visualize toolpaths in 3D, helping us see problems before they happen. Experts predict that improved data analysis will lead to safer and quicker milling cutter technologies. The future looks bright!

What are the latest innovations in verification software?

Innovations like AI and 3D simulations are leading the way in verification software. These tools make it easier to find mistakes before they affect production.

Key Innovations:

- Artificial Intelligence: Detects errors quickly.

- 3D Simulation: Allows for better visualization of toolpaths.

- Data Analysis: Improves safety and efficiency.

Conclusion

In conclusion, a milling cutter toolpath verification checklist is essential for successful machining. It helps you spot errors and ensures accuracy. Always check your setup, tools, and paths. This will prevent mistakes and save time. Ready to improve your skills? Review your checklist today, and consider reading more about machining best practices to enhance your knowledge and confidence!FAQs

What Are The Key Parameters To Verify In A Milling Cutter Toolpath To Ensure Accuracy And Efficiency?To make sure a milling cutter works well, check a few important things. First, look at the tool speed. It should be just right to cut smoothly. Next, check the feed rate, which is how fast the cutter moves. If it’s too fast or too slow, it won’t cut well. Also, make sure the cutter’s path is correct; it should follow the shape you want to make. Lastly, watch how deep the cutter goes into the material to avoid breaking.

How Can Software Simulations Assist In The Toolpath Verification Process For Milling Operations?Software simulations help us see how machines will move before we start milling. They show us the tool’s path on the computer. This way, we can spot and fix problems before cutting anything. It saves time and materials, making our work safer and more accurate. By using these simulations, we can be sure everything will work as planned.

What Specific Checks Should Be Performed To Prevent Tool Collision And Ensure Proper Clearance During Milling?To prevent tool collisions during milling, you should check a few things first. Make sure the tool is secure and won’t fall. Measure the distance between the tool and the piece you’re working on. Always adjust the machine settings to give enough room for the tool to move freely. Finally, double-check everything before you start.

How Does The Choice Of Cutting Speed And Feed Rate Impact The Verification Of The Milling Cutter Toolpath?The cutting speed is how fast the tool spins, and the feed rate is how quickly it moves forward. If we choose the wrong speed or feed rate, the tool might not cut properly. This can make our design look different than we planned. So, we need to pick the right speed and feed rate to ensure everything matches and works well.

What Protocols Should Be Followed To Document And Review The Results Of The Toolpath Verification Process?To document the toolpath verification process, we should start by writing down each step we take. Next, we can clearly note any mistakes we find in the toolpath. After that, we review those mistakes to understand how to fix them. Finally, we should keep all this information in a safe place so we can check it later. This way, we learn and improve our process each time.