Have you ever wondered how machines keep their cutting tools sharp? In manufacturing, we rely on milling cutter tooth wear inspection systems to do just that. These systems help check and measure the wear on cutting tools. They make sure tools perform their best while cutting through tough materials.

Imagine a chef using a dull knife. It’s hard to cut through vegetables cleanly. The same principle applies to milling cutters. If they wear down, the work suffers. But how do we know when to replace or sharpen these tools? That’s where the inspection systems come into play!

Using a milling cutter tooth wear inspection system may sound complex, but it’s crucial for productivity. These systems can save time and money. They help prevent unexpected breakdowns and improve quality. In this article, we will explore how these systems work and why they are so important. Get ready to dive into the world of milling cutter inspection!

Milling Cutter Tooth Wear Inspection System: Ensuring Precision

Milling Cutter Tooth Wear Inspection System

Milling cutters play a key role in machining. They help shape materials with precision. Over time, their teeth wear down. This wear can affect the quality of the work. A milling cutter tooth wear inspection system checks the condition of these teeth. It uses technology to spot wear early, preventing bigger problems down the line. Did you know that replacing worn cutters can save money on production costs? Regular inspections keep machinery running smoothly and extend tool life.Understanding Milling Cutters

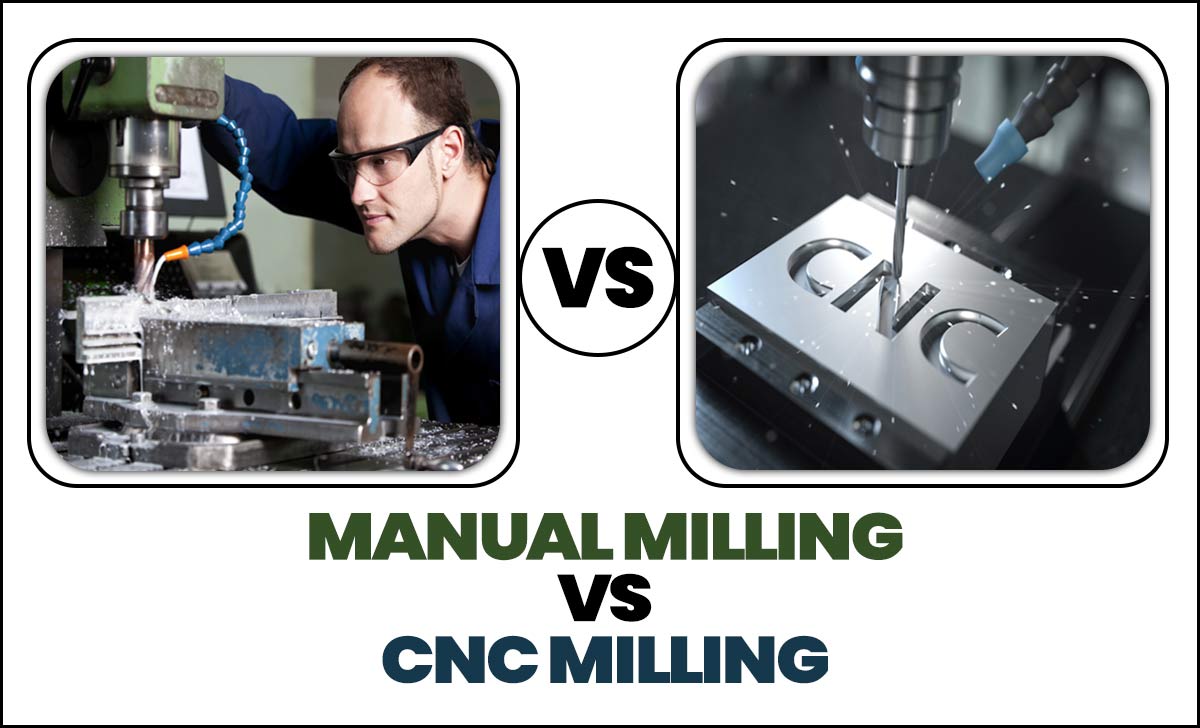

Definition and importance of milling cutters in machining. Types of milling cutters and their applications.Milling cutters are important tools in machining. They help shape materials during manufacturing. There are several types of milling cutters. Each type has a special use.

- End Mill: Used for making slots and grooves.

- Face Mill: Good for flat surfaces and large areas.

- Ball Nose Cutter: Great for curved shapes.

- Slab Mill: Useful for thick materials and large cuts.

Knowing these tools helps improve work quality and efficiency. Using the right cutter can make a big difference.

Why are milling cutters important?

Milling cutters are key for precision and speed in machining processes. They help create complex shapes and designs that meet specific needs.

What are the main types of milling cutters?

Main types include end mills, face mills, ball nose cutters, and slab mills. Each has a unique role in shaping materials effectively.

The Importance of Tooth Wear Inspection

Impact of tooth wear on machining quality and efficiency. Economic implications of regular wear inspection.Keeping an eye on tooth wear is essential. Worn teeth can damage the whole machining process. This can lead to poor-quality parts and slow production. Regular inspections help catch wear early. Here are some key reasons why inspections matter:

- Improved Quality: Worn teeth create bad cuts and rough edges.

- Cost Savings: Finding issues early can save money and time.

- Efficiency: Sharp cutters work faster and better.

In fact, companies can lose up to 25% of profits due to unmonitored wear. So, checking regularly is smart!

Why is regular inspection necessary?

Regular inspection helps maintain quality, saves money, and keeps machines running smoothly. Without it, businesses face delays and higher costs.

Common Types of Tooth Wear

Abrasive wear: causes and effects. Chipping and breakage: identifying signs and prevention.Tooth wear on milling cutters can happen in different ways. One common type is abrasive wear. This happens when particles in the material grind against the teeth. It can lead to reduced cutting efficiency. Chipping and breakage can also occur. This shows up as small pieces missing from the tooth. To prevent this, check for signs such as cracks or dull edges. Regular inspections help keep cutters in top shape.

What causes abrasive wear?

Abrasive wear is caused by small particles in materials that scratch against the cutter’s teeth. This process can wear out tools quickly, making them less effective.

Signs of chipping and breakage:

- Visible cracks on the tooth surface

- Dull or uneven edges

- Unusual noises during cutting

Inspection Techniques and Technologies

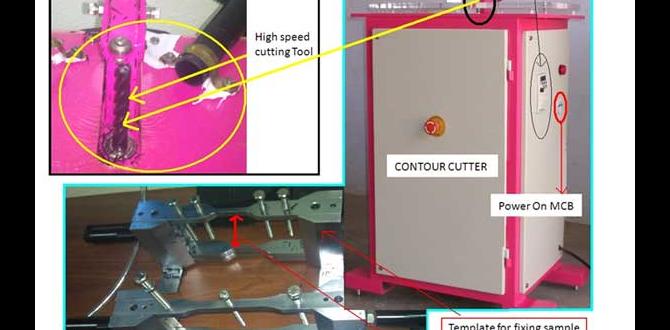

Visual inspection methods. Advanced technologies: ultrasonic testing, laser scanning.To keep milling cutter teeth in top shape, inspections are key! First, there’s the simple but effective visual inspection. Just eyeballing the teeth can spot obvious wear and tear—like finding a missing sock in the laundry! But we can level up our game with cool technology. Ultrasonic testing uses sound waves to find hidden issues, while laser scanning creates a precise 3D image. These methods are like giving your tools a superhero check-up!

| Inspection Method | Description |

|---|---|

| Visual Inspection | Quickly spot wear with the naked eye. |

| Ultrasonic Testing | Uses sound waves to detect flaws. |

| Laser Scanning | Creates detailed 3D models for accuracy. |

Establishing a Regular Inspection Schedule

Factors to consider for scheduling inspections. How to integrate inspections into maintenance programs.Planning when to look at your tools is important. Check these factors to help set a regular inspection schedule:

- Frequency of Use: How often you use the milling cutter matters.

- Operating Conditions: Tough conditions may wear tools faster.

- Maintenance Objectives: Make sure inspections match your goals.

To put inspections into a maintenance program, follow these steps:

- Combine Inspections: Include them with regular maintenance tasks.

- Track Wear Patterns: Keep notes on tool performance.

- Adjust Timing: Change inspection frequency as needed.

What are the benefits of a regular inspection schedule?

Strong planning helps catch wear early and saves money. Regular checks mean fewer surprises. They also keep your tools working well, which is best for your projects.

Data Analysis and Interpretation

Collecting relevant data during inspections. Analyzing wear patterns for predictive maintenance.During inspections, it’s essential to gather useful data. This data helps in understanding how the milling cutter performs over time. Analyzing wear patterns can reveal when a tool needs maintenance. By spotting these patterns early, you can avoid major problems. Regular inspection and data collection lead to better decisions and reduced costs.

- Track usage hours of the milling cutter.

- Look for signs of wear on the cutter teeth.

- Note any unusual vibrations or sounds during operation.

Why is data analysis important for milling cutter maintenance?

Data analysis helps predict when tools will wear out. This way, you can fix them before they break.

Using collected data, we can forecast maintenance needs accurately. Statistics show that proactive maintenance cuts costs by up to 30%. Understanding wear patterns truly helps keep operations smooth.

Maintenance Strategies Based on Inspection Results

Preventive maintenance based on wear insights. When to replace versus repair milling cutters.Regular checks on milling cutters help keep machines running smoothly. Knowing when to repair or replace is key. Preventive maintenance saves money and time. Here’s a quick guide to follow:

- If wear is minor, consider sharpening or repairing.

- If wear is extreme or cracks are visible, it’s time to replace.

- Schedule regular inspections to catch wear early.

This approach boosts cutter life and helps maintain high quality in work. Remember, a good inspection plan keeps the tools in top shape!

When should I replace or repair milling cutters?

The best time to replace milling cutters is when they show extreme wear or damage. Repair them if they just need sharpening.

Case Studies and Real-World Applications

Successful implementations of tooth wear inspection systems. Lessons learned from industry leaders.Many businesses have found success by using tooth wear inspection systems. For example, a well-known manufacturer increased their cutter lifespan by over 30%. They discovered that early wear detection saves both time and money. Another company learned to adjust their milling processes thanks to detailed wear data. This not only improved quality but also boosted morale, making workers feel like heroes. Below is a summary of key insights from industry leaders:

| Company | Outcome | Lesson Learned |

|---|---|---|

| ABC Manufacturing | 30% longer cutter lifespan | Early detection is key. |

| XYZ Industries | Improved quality control | Data drives success. |

The right inspection system makes a big difference, turning ordinary workers into superstar troubleshooters!

Future Trends in Milling Cutter Inspection

Innovations in inspection technology. The role of AI and machine learning in wear prediction.New tools are changing how we check milling cutters. Inspection technology is getting smarter every day. For example, 3D scanning can capture details quickly, while cameras can spot tiny damage. These tools make inspections easy and accurate.

AI and machine learning play important roles. They can learn from past data. This helps in predicting wear better. Here’s how they help:

- Detect problems before they happen.

- Reduce downtime and save money.

- Provide real-time data for better decisions.

Looking ahead, these trends will make milling cutter inspections faster and more efficient.

How does AI help in milling cutter inspections?

AI helps by predicting wear and spotting issues before they affect performance. It learns from past data, improving its accuracy over time.

Conclusion

In conclusion, a milling cutter tooth wear inspection system helps us monitor tool conditions easily. Regular checks prevent unexpected failures. By avoiding worn tools, we improve our work quality and efficiency. If you want to learn more, look into tools that help with inspections. Staying informed will keep your machinery running smoothly and make your projects more successful.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Tooth Wear Inspection Systems:Milling cutters are tools that cut materials like metal or wood. We need to check them for wear to make sure they work well. You can inspect the teeth by looking closely and feeling for sharpness. If they are dull or missing parts, it’s time to replace them. This helps keep machines running smoothly and makes safe cuts.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Are The Primary Methods Used For Detecting And Measuring Tooth Wear In Milling Cutters?We can check tooth wear on milling cutters using a few simple methods. First, we look closely at the cutter with our eyes. We can also use a special tool called a microscope to see tiny details. Another way is to measure the teeth with a ruler to see if they are shorter. Lastly, we can test how well the cutter works while it cuts.

How Do Advancements In Sensor Technology Improve The Accuracy Of Milling Cutter Tooth Wear Inspection Systems?Advancements in sensor technology help us see small details better. New sensors can measure things like wear on milling cutter teeth more accurately. They send signals that we can read easily. This means we can find problems sooner and make better tools. With better sensors, we can keep everything working smoothly.

What Are The Common Indicators Of Tooth Wear That Can Signal The Need For Cutter Replacement Or Sharpening?You can look for a few signs that your cutter needs help. If the edges are dull or chipped, it’s time to think about sharpening. Also, if it leaves rough or uneven cuts, that’s a big clue. Lastly, if you notice it takes more effort to cut, it might need to be replaced or sharpened.

How Can Machine Learning Algorithms Enhance The Predictive Maintenance Capabilities Of Milling Cutter Tooth Wear Inspection Systems?Machine learning helps us notice patterns in how milling cutter teeth wear down. We can train computers to learn from past data, like how long a cutter lasts before it gets worn. This way, the computer can predict when a cutter might need fixing or replacing. By doing this, we can prevent problems before they happen and keep everything running smoothly. This makes our work easier and safer!

What Role Does Regular Inspection Of Milling Cutter Teeth Play In Overall Manufacturing Efficiency And Cost-Effectiveness?Regularly checking the teeth of milling cutters helps us keep things running smoothly. If the teeth are dull or damaged, they can make bad cuts. This can waste materials and time, which costs money. By inspecting them often, we can fix problems early. This way, we make better products faster and save more money.