Have you ever wondered how long a milling cutter can really last? It’s a common question in machining. A milling cutter is a special tool used to shape materials like metal and wood. But just like any tool, it wears down over time. This wear can change how well the cutter works. Wouldn’t it be handy if we could detect this wear early?

Imagine cutting a piece of metal. Everything seems fine at first. But as the cutter wears, you might end up with rough edges or even broken pieces. This can waste time and materials. Detecting milling cutter wear can help avoid these problems. It can save money and make sure the work is done right!

In this article, we’ll explore different methods and tools for milling cutter wear detection. You’ll learn why it matters and how it can improve your machining process. So, let’s dive in and discover the secrets of keeping those milling cutters sharp and effective!

Milling Cutter Wear Detection: Key Strategies And Techniques

Milling Cutter Wear Detection

Milling cutter wear detection is crucial for efficient machining. When cutters wear out, they can lead to poor quality parts and increase costs. Wouldn’t it be better to catch wear early? Techniques like visual inspections and advanced sensors help identify wear signs. Using this knowledge can save time and materials. Fun fact: Regular wear checks can improve tool life significantly. Understanding how to detect wear helps keep projects on track and budgets in check.Understanding Milling Cutters

Definition and types of milling cutters. Importance of milling cutters in machining processes.Milling cutters are tools used in machining to shape and cut materials. They come in different types, each designed for specific tasks. Common types include:

- Flat End Mill

- Ball End Mill

- Corner Radius Mill

Why Are Milling Cutters Important?

They help in producing high-quality parts quickly. This saves time and money for manufacturers. Milling cutters also improve the accuracy of designs. Good tools lead to better products!

Causes of Milling Cutter Wear

Common factors contributing to wear. Impact of material properties on cutter lifespan.Milling cutters face wear from several common factors. Heat is a big culprit; too much can cause the cutter to lose its sharpness. Continual friction also wears it down over time, like when you rub two sticks together. The material being cut matters too. Softer materials can lead to faster wear, while tougher ones may demand more strength from the cutter. Here’s a quick look:

| Factor | Impact |

|---|---|

| Heat | Can dull the cutter |

| Friction | Accelerates wear |

| Material Hardness | Affects lifespan |

So, keep an eye on the materials and temperatures. Remember, a happy cutter makes for happy machining!

Indicators of Wear in Milling Cutters

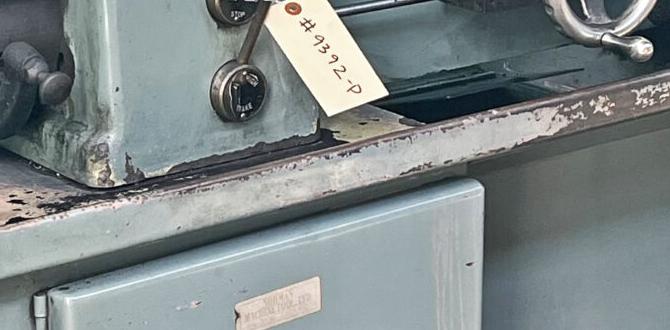

Visual signs of wear and degradation. Measurement techniques for assessing wear levels.Milling cutters can show signs of wear that are hard to miss. You might spot chipping or discoloration on the cutter’s edges. These little clues tell you it’s time for a check-up. There are also some clever tools that help measure wear. For example, a micrometer can give you precise readings to see just how worn out your cutter is.

| Wear Indicator | Description |

|---|---|

| Chipping | Small pieces missing from the cutting edges. |

| Discoloration | Changes in color due to heat or friction. |

| Measurement Tools | Micrometers and calipers help assess wear. |

So next time you’re working, give your milling cutters a good look. Remember, a worn cutter is like a tired dog—it just can’t fetch as well!

Impact of Wear on Machining Performance

Effects on surface finish and dimensional accuracy. Influence on tool life and cost efficiency.Milling cutter wear affects how well machining works. Wear can make the surface finish rough and change the size of parts. A smooth surface looks better and fits better. If tools wear out quickly, it costs more to replace them. This means less money for other things. Here are a few key effects:

- Surface Finish: Poor wear leads to rough surfaces.

- Dimensional Accuracy: Worn tools can create parts that are not the right size.

- Tool Life: More wear means needing new tools sooner.

- Cost Efficiency: Frequent replacements increase costs.

What are the effects of wear on machining?

The effects include poor surface quality and size changes in parts. Worn tools can lead to costly mistakes and less production value.

Best Practices for Monitoring Wear

Recommendations for regular inspection and maintenance. Tools and software for effective wear monitoring.Keeping an eye on your milling cutters is like checking your pet’s food bowl—better safe than sorry! Regular inspections can help catch wear before it becomes a big problem. Use tools like calipers for size checks and shiny cameras to spot sneaky cracks. Monthly checks work wonders, but don’t forget about software programs that can monitor wear in real time! Here’s a handy table:

| Inspection Method | Frequency | Recommended Tools |

|---|---|---|

| Visual Inspection | Weekly | Flashlight, Magnifying Glass |

| Dimensional Check | Monthly | Calipers, Micrometers |

| Software Monitoring | Continuous | Wear Monitoring Software |

Adopting these practices can keep your equipment sharp and running smoothly. Happy milling!

Case Studies and Real-World Applications

Examples of successful wear detection strategies. Lessons learned from different industries.Many industries have found effective strategies for detecting milling cutter wear. For example, a car manufacturing plant used sensors to monitor wear in real-time. They saved time and reduced costs. A food processing company implemented regular checks. This helped them avoid unexpected breakdowns. These examples show that using milling cutter wear detection helps prevent problems and boosts productivity.

- Real-time monitoring saves time and money.

- Regular checks lead to fewer breakdowns.

- Data analysis improves decision-making.

What are some successful wear detection strategies?

Successful strategies include using sensors for constant monitoring and conducting regular wear inspections. These methods help catch issues early.

Future Trends in Milling Cutter Wear Detection

Advancements in AI and machine learning applications. Potential for automation in wear detection processes.Exciting times lie ahead in the world of milling cutter wear detection! Advanced AI and machine learning can spot wear patterns faster than you can say “sharp edge.” These technologies analyze data from sensors to predict when cutters need replacing. Imagine a robot waving goodbye to dull tools!

Moreover, automation could soon play a huge role. Picture machines that check their own wear like superheroes checking their capes. This could save time and ensure that tools stay sharp.

| Technology | Benefit |

|---|---|

| AI | Faster wear detection |

| Automation | Self-checking tools |

In short, the future of milling cutter wear detection looks bright and sharp, just like we want our tools to be!

Conclusion

In conclusion, milling cutter wear detection is crucial for keeping machines efficient and accurate. You can spot wear through visual checks or advanced sensors. This helps prevent tool failure and saves costs. We encourage you to explore more about wear detection methods. Understanding these techniques can significantly improve your machining projects and ensure better results. Happy learning!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Wear Detection:Sure! Here are five questions related to milling cutter wear detection: 1. **What is a milling cutter?** A milling cutter is a tool we use to cut and shape materials like metal or wood. 2. **How do we know when a cutter is worn out?** We can see signs like poor cuts or rough edges. If the cuts aren’t clean, the cutter might be worn out. 3. **Why is it important to check for wear?** Checking for wear helps us make sure our cuts are smooth. It also helps our tools last longer. 4. **Can wear affect how we work?** Yes, when a cutter wears out, it can slow us down and make our work harder. 5. **What should we do if we find wear?** If we find wear, we should either sharpen the cutter or replace it with a new one.

Sure! Just let me know what question you want me to answer, and I’ll help you!

What Are The Primary Indicators Of Wear In Milling Cutters, And How Can They Be Effectively Measured?The main signs of wear in milling cutters are roundness, sharpness, and rough edges. You can look at the cutter carefully to see these signs. Using a tool microscope, you can measure the cutter’s edge closely. If the edge is dull or damaged, it means the cutter needs to be replaced. Keeping an eye on these signs helps us know when to change the tools.

What Technological Advancements Have Been Made In The Field Of Milling Cutter Wear Detection, Such As The Use Of Sensors And Machine Learning Algorithms?Recently, we have seen exciting improvements in noticing when milling cutters wear down. Sensors can now measure how cutters are working while they spin. These sensors send signals to computers, telling us what’s happening. We also use machine learning, which means computers learn and get better at spotting wear over time. This helps prevent problems before they happen!

How Can Real-Time Monitoring Of Milling Cutter Wear Improve The Overall Efficiency And Quality Of Machining Processes?Real-time monitoring helps us see when a milling cutter is getting worn out. When we know this, we can change the cutter before it breaks. This means we spend less time fixing things and can keep making parts. It also helps us make better parts because the cutter stays sharp longer. In the end, we work faster and make high-quality products.

What Are The Common Methods For Visually Inspecting Milling Cutters For Wear, And How Do They Compare To More Advanced Detection Techniques?We can check milling cutters for wear by looking at them closely. We check for chips, dull edges, or discoloration. This is simple and quick. Advanced methods, like using special cameras or sensors, can give more detailed information. However, they are usually more complicated and expensive than just looking with our eyes.

How Does The Material Composition Of A Milling Cutter Influence Its Wear Rate And The Detection Of Wear Over Time?The material of a milling cutter affects how fast it gets worn out. Harder materials last longer but can be harder to check for wear. Softer materials wear down quicker, making it easier to see damage. By using strong materials, we can cut more before needing a replacement. Understanding this helps us choose the right cutter for the job.