Have you ever wondered how tools wear out during work? Imagine cutting through metal, wood, or other materials every day. Over time, the tools can change. These changes are called wear patterns. In the world of machining, milling cutters are essential tools. Understanding their wear patterns can help us improve our work.

What if a small change could make a big difference? By looking at real examples of milling cutter wear, we can discover why some tools last longer. Each wear pattern tells a story about how the tool was used. These stories can reveal secrets that help us avoid problems.

For instance, did you know that some cutters wear down differently based on the material they cut? This surprising fact can shape how we choose our tools. By learning about these examples, we can make smarter choices in our projects. Join us as we explore milling cutter wear pattern examples!

Milling Cutter Wear Pattern Examples: Understanding Tool Wear

Milling cutter wear can reveal important clues about tool performance. Common wear patterns include flank wear, crater wear, and notch wear. Each pattern indicates different issues, like improper feed rates or cutting speeds. Did you know that observing these patterns can help extend tool life? Understanding them allows you to adjust techniques and prevent costly mistakes. Keep an eye on wear patterns to improve your milling outcomes!

Types of Milling Cutter Wear Patterns

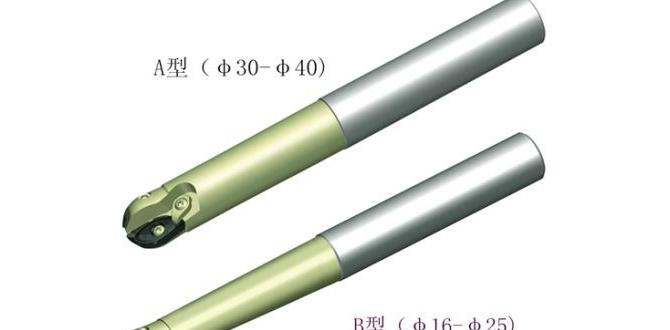

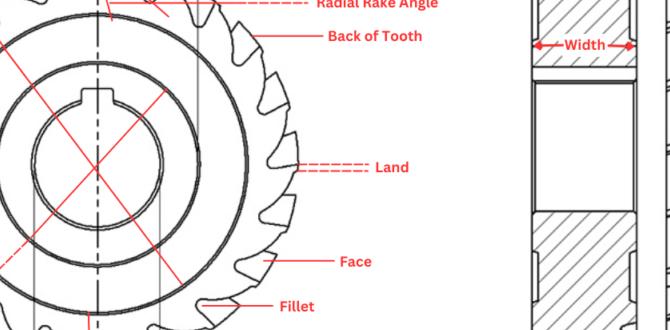

Explanation of common wear patterns: flank wear, crater wear, and notch wear.. Visual examples illustrating each type of wear pattern..

Milling cutters can wear out in different ways, each telling a story of hard work. Let’s look at three common types. First up is flank wear, which happens on the side of the cutter. It’s like the cutter is slowly losing its edge, kind of like how we lose a battle with a tough pizza! Then we have crater wear, which makes a pit on the face of the cutter. Think of it as the cutter’s dimple—it might be cute, but it’s not doing its job well. Finally, there’s notch wear, where chunks get chipped away, making the cutter look like it’s been in a fight with a rogue bolt. Here’s a quick table to sum it all up:

| Wear Type | Description | Visual Example |

|---|---|---|

| Flank Wear | Worn side of the cutter | 😬 |

| Crater Wear | Pit on the face of the cutter | 😅 |

| Notch Wear | Chipped sections of the cutter | 😲 |

Each pattern shows how the cutter handles tough jobs. Regular checks can help catch these issues before they become major problems!

Factors Influencing Wear Patterns

Discussion of material hardness and its impact on wear.. Effects of cutting speed, feed rate, and depth of cut on wear patterns..

Several factors can affect wear patterns on milling cutters. One major factor is material hardness. Harder materials often lead to faster wear because they create more friction. Imagine trying to slice through a rock with a butter knife—tough, right? Next, cutting speed plays a big role. If you go too fast, the cutter wears out quickly. Conversely, a slower speed can prolong its life. Finally, the feed rate and depth of cut are crucial. More aggressive cutting can mean more wear. Think of it as jogging versus sprinting—both will tire you out but one will wear you down faster!

| Factor | Impact on Wear |

|---|---|

| Material Hardness | Harder materials increase wear |

| Cutting Speed | Higher speeds lead to faster wear |

| Feed Rate | Increased rate can enhance wear |

| Depth of Cut | Deeper cuts can create more wear |

Measuring Wear Patterns in Milling Cutters

Techniques for assessing wear: optical microscopy and wear analysis software.. Importance of regular inspection and its role in maintenance..

To check wear patterns, use special tools. Optical microscopy helps view tiny details on the cutter. Wear analysis software makes data easier to understand. Regular inspection is key for keeping tools sharp. It helps find problems early and saves money. Strong maintenance routines improve tool life and enhance productivity.

How do I check for wear on milling cutters?

Look through a microscope or use software to analyze wear patterns.

- Inspect cutters regularly.

- Use optical tools for details.

- Analyze data with software.

Case Studies: Real-World Examples

Analysis of specific industries and their common wear patterns.. Detailed examination of wear patterns from actual milling processes..

Different industries showcase unique wear patterns in milling processes. For example, in the automotive sector, cutters often suffer from abrasion and chipping. In contrast, the aerospace industry sees wear mainly due to heat and thermal fatigue. This difference is crucial for manufacturers to understand. Here’s a quick look at wear patterns across several industries:

| Industry | Common Wear Patterns |

|---|---|

| Automotive | abrasion, chipping |

| Aerospace | thermal fatigue |

| Woodworking | gumming, dullness |

Understanding these patterns helps in choosing the right tools, leading to smoother operations and fewer unexpected surprises—like a dog that suddenly learns to dance!

Strategies for Minimizing Wear

Recommendations for selecting the right cutter materials and coatings.. Best practices in machining to reduce wear patterns..

Choosing the right cutter materials is key to fighting wear. Think of it as picking your superhero outfit! Tough coatings, like titanium nitride, can add strength and help last longer. Always keep your tools sharp, because dull cutters wear out faster. Also, try reducing speed and feed rates; it’s like easing up on the gas pedal of a race car. You’ll save money and time while keeping your cutters happier!

| Cutter Material | Benefits |

|---|---|

| Titanium Nitride | Strong and durable, reduces friction. |

| Carbide | Resists wear, great for tough materials. |

| High-speed Steel | Cost-effective, can handle moderate wear. |

Impact of Wear on Machining Performance

Correlation between wear patterns and machining efficiency.. Effects on surface finish and dimensional accuracy..

Milling cutters wear over time, and this affects how well they work. As tools wear, machining efficiency can drop. When wear becomes noticeable, changes happen. The surface finish may look rough. Dimensional accuracy might decrease, leading to messy results. Good wear patterns lead to better machining, while bad ones can create issues. It’s important to monitor tool wear for top results.

What are common effects of wear on machining performance?

Common effects include poor surface finish, reduced dimensional accuracy, and lower machining efficiency. Regular checks can spot wear patterns early.

Key Effects:

- Poor surface finish

- Reduced accuracy

- Lower efficiency

Future Trends in Milling Cutter Technology

Innovations in materials and coatings to combat wear.. Advancements in machining technologies aimed at reducing wear patterns..

The future of milling cutter technology looks exciting! Innovations in materials and coatings are crucial to help prevent wear. Stronger materials will last longer, cutting costs and time. Better coatings can reduce friction and wear, increasing tool life significantly. Advancements also focus on machining technologies that minimize wear patterns. This helps cutters stay sharp longer, ensuring smooth operation. Overall, these developments promise to improve efficiency and lower costs in manufacturing.

- New materials for longer life.

- Advanced coatings to reduce friction.

- New machining technologies to limit wear.

What are the benefits of new milling cutter technologies?

New technologies offer many advantages. They improve durability and help manufacturers save money. Stronger cutters mean less frequent replacements. This leads to smoother operations and better products.

Conclusion

In summary, understanding milling cutter wear patterns can help you improve your machining. We’ve seen examples like flank wear, crater wear, and edge chipping. Recognizing these patterns allows you to adjust tools and conditions for better results. Keep exploring this topic, and you’ll gain skills to enhance your projects. Start by monitoring your tools closely for wear!

FAQs

Sure! Here Are Five Questions Related To Milling Cutter Wear Patterns:

Sure! When we use a milling cutter, which is a tool for cutting, it can get worn out. You might notice that some parts wear down faster than others. This can happen because of how hard or soft the material we cut is. We should check the cutter often to see how it’s wearing. This helps us know when to replace it.

Sure! Just go ahead and ask your question, and I’ll be happy to help!

What Are The Common Types Of Wear Patterns Observed On Milling Cutters, And How Do They Affect Machining Performance?

Milling cutters can wear out in different ways. Common wear patterns include flaking, where pieces chip away, and dullness, where the edges become blunted. These problems make it harder to cut materials smoothly. If cutters wear out, we need to replace them to keep making good parts. Regularly checking and caring for them helps us work better.

How Can The Analysis Of Wear Patterns On Milling Cutters Help Predict Tool Lifespan And Optimize Maintenance Schedules?

We can look at how milling cutters wear down to figure out how long they will last. By checking the wear patterns, we learn what makes the tools break faster. This helps us plan when to change or fix them. So, we can keep everything running smoothly and make sure we’re not wasting time or money.

What Factors Contribute To The Formation Of Specific Wear Patterns On Milling Cutters During Machining Operations?

Milling cutters can wear out in different ways. This happens because of how hard the metal is, the speed we use, and the kind of material we cut. If we push too hard or go too fast, the cutters can wear out faster. The heat from cutting also makes them wear differently. Keeping an eye on these things helps the cutters last longer.

How Do Different Materials Being Machined Influence The Wear Patterns Observed On Milling Cutters?

When you cut different materials, they can wear out the milling cutters in different ways. Hard materials, like metal, can make the cutters dull quickly. Softer materials, like wood, might not wear the cutters down as much. Each material causes unique patterns of wear based on how tough it is to cut. So, we need to choose the right cutter for the job.

What Techniques Or Technologies Are Available For Monitoring And Analyzing Milling Cutter Wear Patterns In Real-Time?

To watch how milling cutters wear out, we can use special sensors. These sensors feel vibrations and changes in sound while the cutter works. We can also use cameras to see any damage up close. Some machines have smart computers that look at this data and tell us when a cutter needs to be changed. These tools help us keep our machines running smoothly and safely.