Milling equipment is a crucial component in manufacturing for various industries, including agriculture, construction, and food production. The accuracy of this equipment is essential in ensuring the quality and consistency of the final product.

From small-scale to large-scale operations, the precision of milling equipment plays a critical role in achieving desired outcomes and meeting industry standards. In recent years, there has been a growing demand for higher accuracy in milling equipment, spurred by technological advancements and increasing customer expectations.

As a result, manufacturers have been continuously improving and innovating their equipment to meet the ever-evolving needs of the market. We will delve into the concept of milling equipment accuracy, its importance, and the various factors contributing to achieving and maintaining high levels of precision.

Factors Affecting Milling Equipment Accuracy

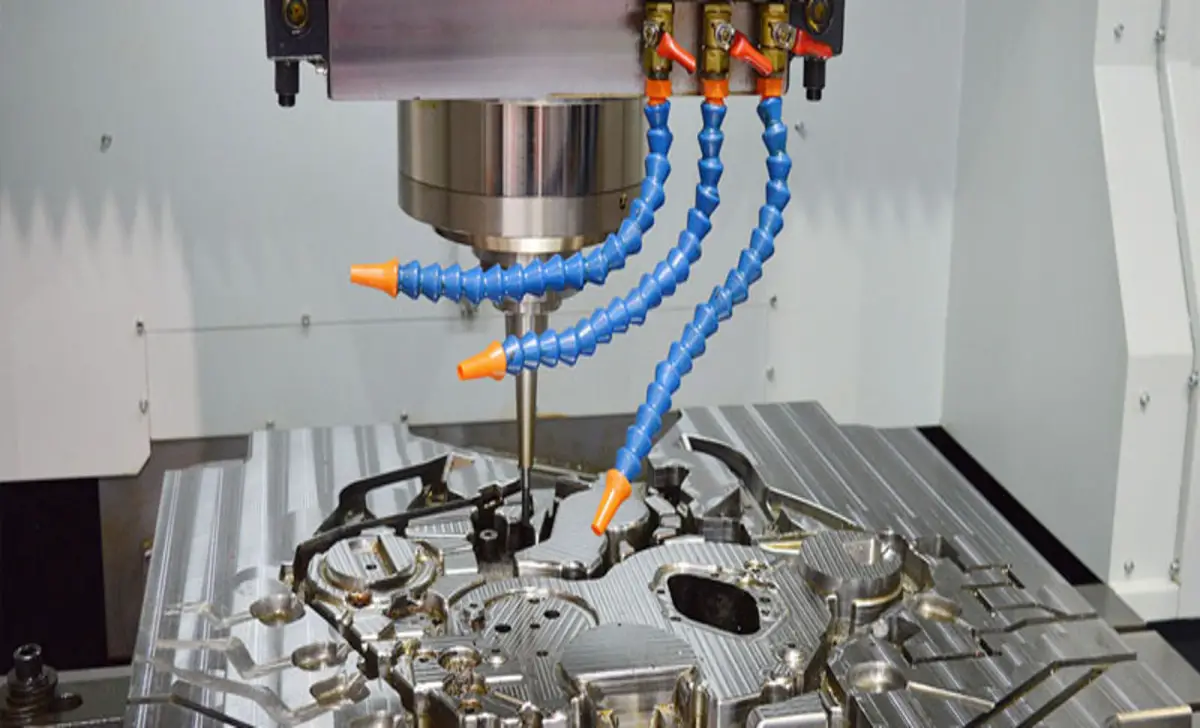

Machine tool accuracy plays a crucial role in machining operations in machine shops. The design and construction of the machine itself greatly influence its rigidity and stability, ensuring precise milling results. Additionally, spindle accuracy and the accuracy of axis movement are key factors affecting machining accuracy. These factors are especially important when using tools like boring machines, as they require high precision and reliability.

Types Of Milling Equipment

Vertical milling machines offer a wide range of accuracy features and capabilities. They are commonly used in various industries for precision machining processes. These machines can perform intricate tasks and achieve high accuracy levels. They are often used for drilling, cutting, and shaping materials.

However, it is important to note that even with advanced technology, machining errors can occur. To mitigate this risk, many companies rely on professional machining services that ensure precise results throughout the machining process.

- Vertical milling machine

- Horizontal milling machine

- Universal milling machine

- Bedtype milling machine

- Turret milling machine

Overview Milling Equipment

Milling equipment is crucial in various manufacturing processes, particularly in shaping and refining materials. One essential type of milling machine used in these processes is the vertical milling machine. This machine utilizes a vertical spindle to remove material from a workpiece. With its ability to perform precise cuts and produce complex shapes, the vertical milling machine is an indispensable tool in the manufacturing industry. Its versatility and efficiency make it a preferred choice for many production applications.

Feature

- Advanced milling equipment for efficient processing

- Precision and consistency in grinding and particle sizes

- Versatile models for various materials and applications

- Automated controls and monitoring systems for efficiency and quality control

Techniques For Improving Milling Equipment Accuracy

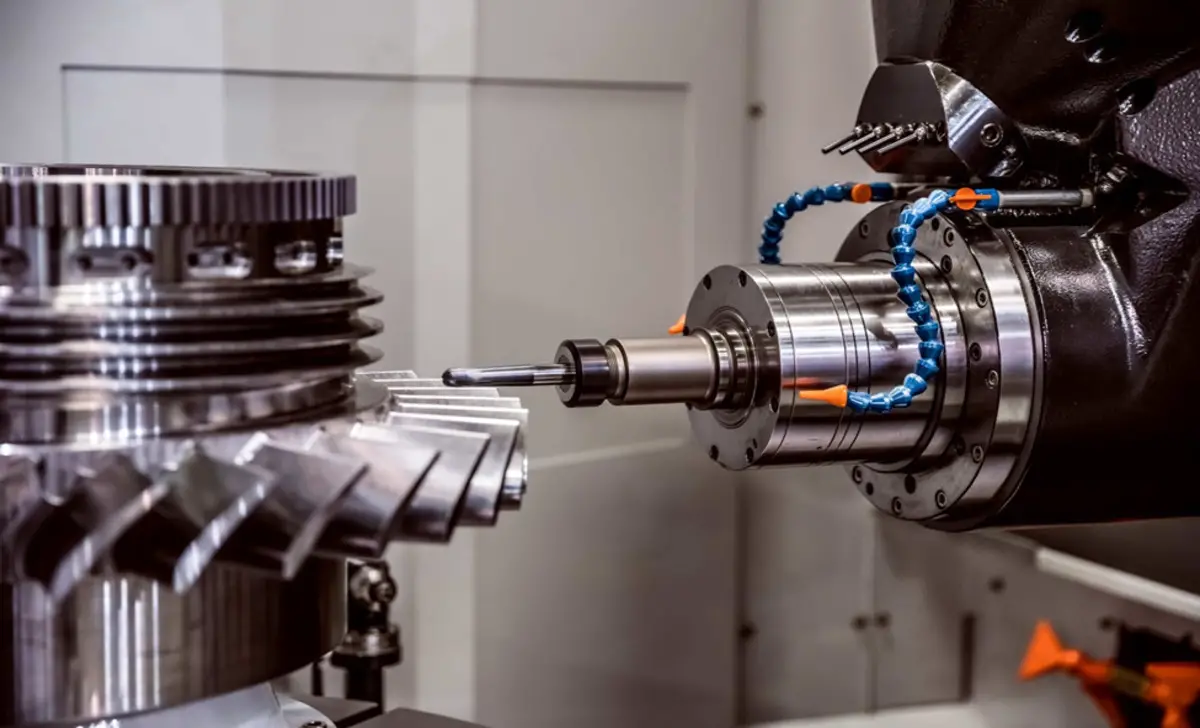

There are various techniques available for enhancing the accuracy of milling equipment. One approach involves using advanced calibration methods to ensure precise measurements and alignments. Implementing high-quality cutting tools and computer numerical control (CNC) systems can improve accuracy.

Regular maintenance and inspections are also crucial to identify any issues that may affect the precision of the milling equipment. By employing these techniques, manufacturers can achieve higher levels of accuracy in their milling processes, resulting in better-quality products.

1. Regular Calibration And Maintenance

Regular calibration and maintenance of milling equipment are paramount to ensure accurate results. By calibrating the machines regularly, potential errors and inaccuracies can be identified and corrected, leading to more precise outcomes.

Additionally, routine maintenance procedures such as cleaning, lubricating, and inspecting the equipment can prevent wear and tear, prolonging its lifespan and optimizing its performance. Therefore, it is highly recommended that a comprehensive calibration and maintenance schedule be implemented to guarantee the accuracy and efficiency of milling operations.

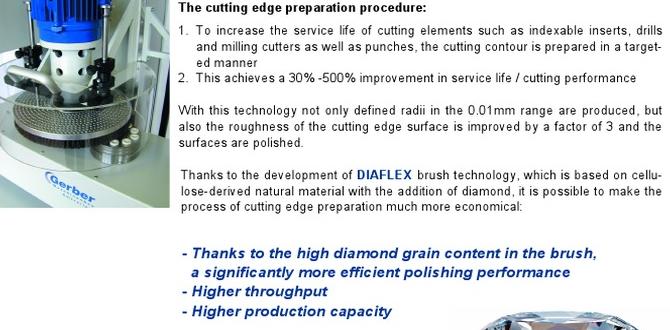

2. Tool Selection And Inspection

Tool selection and inspection are important factors in ensuring accuracy in milling equipment. Firstly, choosing the right tools for specific milling tasks is important, ensuring they are suitable for the materials and desired outcomes. Secondly, regular inspection of tools is necessary to check for wear and damage, as this can significantly affect the accuracy and quality of milling operations. By prioritizing proper tool selection and diligent inspection, milling processes can be optimized for optimal results.

3. Proper Workpiece Setup And Fixturing

Proper workpiece setup and fixturing are crucial for achieving milling equipment accuracy. Techniques for accurate alignment and positioning of workpieces are vital in ensuring precise milling. Workpieces can be securely held in place by utilizing fixtures, minimizing any potential movement or shifting during the milling process. This allows for consistent and accurate results, ultimately contributing to the overall quality of the finished product.

Advanced Methods For Achieving High Milling Equipment Accuracy

Advanced methods for achieving high milling equipment accuracy are essential in various industries, such as manufacturing and engineering. These methods utilize cutting-edge technologies and precision techniques to ensure precise measurements and smooth operation of milling machines.

Incorporating computer numerical control (CNC) systems, laser calibration, and advanced sensor technology, these methods enable operators to achieve tight tolerances, improve product quality, and enhance overall productivity. By implementing these advanced techniques, companies can optimize their milling processes and stay competitive in the ever-evolving market.

1. Adaptive Control Systems

Adaptive control systems are a revolutionary technology that brings numerous benefits to milling equipment accuracy. These systems utilize real-time data and advanced algorithms to monitor and adjust the milling process continuously. By doing so, they can compensate for variations in material properties, tool wear, and environmental conditions, ensuring consistent and precise results.

The integration of adaptive control systems enhances milling accuracy by minimizing errors, improving surface finish, reducing scrap rates, and optimizing machining parameters. This not only increases productivity but also enhances the overall quality of the milled products.

2. Metrology And Measurement Techniques

In the field of metrology and measurement techniques, various tools are available for accurately measuring the precision of milling equipment. These tools provide an overview of the machinery’s accuracy and allow adjustments accordingly. By analyzing these measurements, operators can identify areas that require improvement and make adjustments to enhance overall accuracy. This process enables manufacturers to achieve higher levels of precision in their milling operations, resulting in improved quality and efficiency in their products.

Common Challenges And Troubleshooting Tips

In the realm of milling equipment, typical challenges may occur. These challenges can affect the accuracy of milling processes. Identifying these common accuracy issues, such as inconsistent milling depths or uneven surface finishes, is important. Troubleshooting tips can be implemented to address these concerns.

Common Challenges For Milling Equipment:

- Equipment breakdowns or malfunctions

- Insufficient or uneven feed material

- Excessive vibration or noise during operation

- Inconsistent or poor-quality output

- Material blockages or clogging in the milling process

Troubleshooting Tips For Milling Equipment:

- Regular maintenance and inspection

- Adjust feed rates and material flow

- Balance rotating parts and ensure alignment

- Check and calibrate milling settings

- Clear material blockages promptly

Operator Skill And Training

Operator skill and training play a crucial role in ensuring the accuracy of milling equipment. Proper machine setup and calibration are of utmost importance to achieve precise results. Operators must also continuously monitor and make necessary adjustments to maintain the desired level of accuracy. By prioritizing these factors, operators can maximize the efficiency and effectiveness of milling equipment.

Measuring And Evaluating Milling Equipment Accuracy

Measuring and evaluating milling equipment accuracy involves using various metrology tools and techniques. These include coordinate measuring machines (CMM), which can precisely measure the dimensions and geometrical features of the equipment.

Laser trackers and interferometers are also utilized to track the movements and vibrations of the milling equipment, ensuring precise and accurate results. Dial indicators and micrometers are employed to measure smaller components and ensure their accuracy within tight tolerances. These tools and techniques are crucial in maintaining milling equipment’s overall accuracy and quality, ensuring optimal performance and reliable results.

Pros And Cons Of Milling Equipment

Milling equipment is essential in various industries, offering numerous advantages and a few disadvantages. On the positive side, it allows for precise and efficient material removal, enabling the production of complex parts with tight tolerances. Additionally, milling machines can handle various materials, from metals to plastics.

Pros Of Milling Equipment:

- High precision and accuracy in machining

- Ability to produce complex and intricate parts

- Versatility in handling different materials and sizes

- Increased productivity and efficiency in manufacturing processes

- Option to automate operations for higher throughput

Cons Of Milling Equipment:

- Initial cost investment can be high

- Regular maintenance and upkeep are necessary

How To Choose The Right Milling Machine

Choosing the right milling machine is crucial for any machining operation. There are several factors to consider, such as the type of material you will be working with, the size and complexity of the parts you will be milling, and your budget. It is important to research and compare different models, considering their features, capabilities, and reputation in the industry.

- Determine milling needs and goals.

- Consider size and capacity.

- Evaluate power and speed options.

- Research types of milling machines

- Assess rigidity and stability

- Examine support and service availability

- Set a budget and compare prices

- Read reviews and seek recommendations

Conclusion:

The importance of accuracy in milling equipment cannot be overstated. Accuracy is essential for any company or professional using milling equipment, from ensuring precise cuts and measurements to increasing overall efficiency and productivity. One of the primary reasons accuracy is so important in milling equipment is to ensure precise cuts and measurements. Even the slightest deviation from the intended dimensions can result in faulty parts and costly errors.

By investing in high-quality, reliable machinery and regularly maintaining and calibrating it, businesses can achieve the utmost accuracy and success in their operations. This can lead to delays in production and a decrease in overall quality, ultimately affecting a company’s bottom line.

FAQ:

1.What Is The Accuracy Level Of CNC?

The accuracy level of CNC (Computer Numerical Control) machines can vary depending on various factors such as the type of machine, its design, build quality, and the operator’s skill.

2.What Is The Accuracy Of The Milling Process?

The accuracy of the milling process can vary depending on various factors, such as the type of milling machine, the quality of the tooling, the skill of the operator, and the complexity of the part being machined.

3.What Is The Quality Of Milling?

Milling quality refers to the precision and consistency of grinding or cutting materials, such as metal or wood, to create desired shapes or sizes.

4.What Are Milling Defects?

Milling defects refer to imperfections or flaws during the milling process, a machining operation that removes material from a workpiece using rotary cutters.

5.What Is The Golden Rule Of Milling?

The golden rule of milling is always to use the correct cutting tools and parameters for the machined material. This ensures optimal performance, accuracy, and surface finish while prolonging the tool’s lifespan.