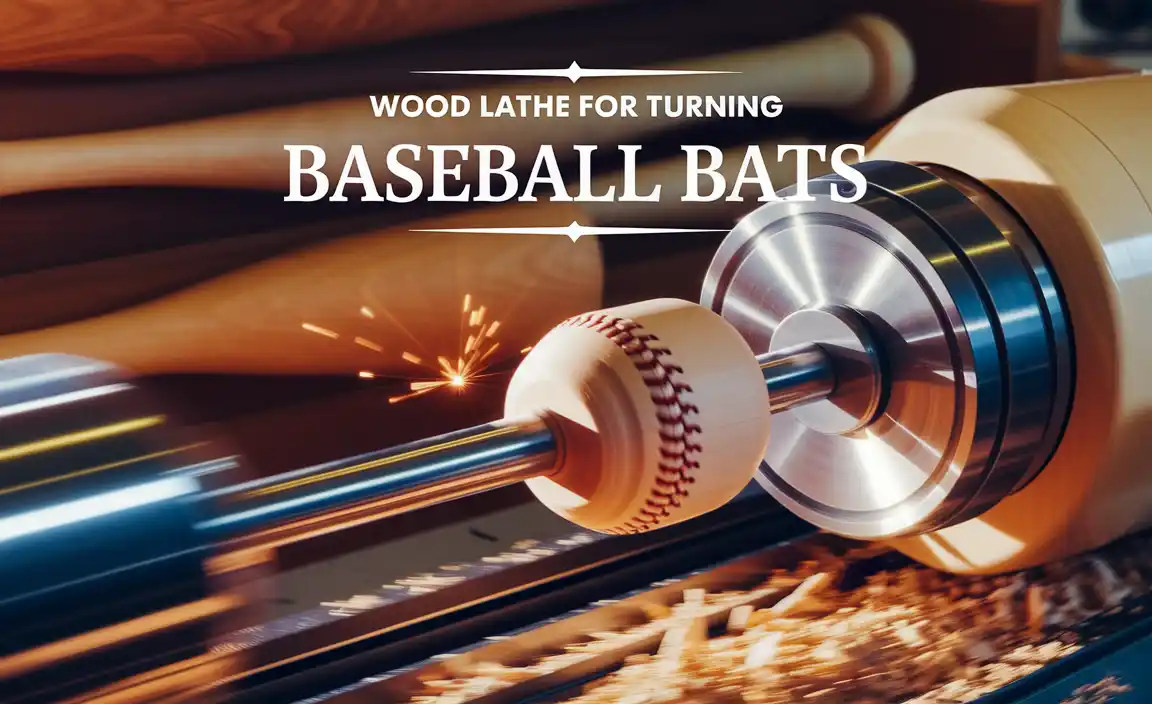

Have you ever watched a carpenter carve wood? Imagine making everything smoother and more useful. That’s what a milling machine does with the help of a fluting tool. Such machines are like sculptors for metal and other materials. They cut tiny grooves into hard surfaces, making them just right for different uses.

Think about a giant robot drawing tiny lines on a big canvas. That’s what happens when a milling machine uses a fluting tool. These tools shape and refine, making unimaginable wonders. But how do they work exactly? And why are they so crucial across industries?

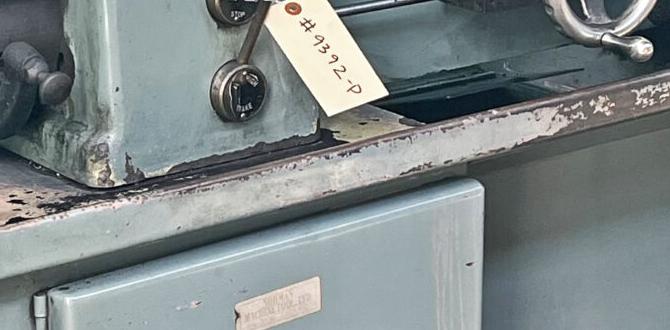

Fun fact: milling machines have been sharpening tools since the early 1800s! They’ve come a long way from their first designs. Today, you find them in many workshops, quietly shaping our world, one slice at a time. Let’s dive deeper into their fascinating world!

Understanding Milling Machine Fluting Tools Efficiently

Milling Machine Fluting Tool: A Curious Craft

Imagine a giant pencil sharpener. That’s what a fluting tool in a milling machine does, but it carves grooves and notches into metal. It helps make things like screws and gears. The tool spins quickly, carving perfectly even lines. This amazing machine can change speed to handle tough metals or smooth out delicate materials. Ever wondered how bridges stand strong or cars run smoothly? It’s these fantastic tools at work, sculpting metal into shapes that fit together just right.Understanding Milling Machine Fluting Tools

Definition and purpose of fluting tools. Importance in milling operations.Fluting tools are helpers for milling machines. They have special grooves and make it easier to shape materials. Ever wondered why they look so wavy? That’s the magic of flutes! Flutes help in removing material from the workpiece smoothly. In milling operations, these tools are important because they make everything run like a game of chess with every piece in its place. Think of them as the chefs in a kitchen, chopping what needs to go and making sure the dish looks just right.

Here’s a quick look at their role:

| Fluting Feature | Importance |

|---|---|

| Grooves | Aid in smooth cutting |

| Precision | Ensures accurate shaping |

| Efficiency | Speeds up operations |

Fluting tools make milling easier and effective. They ensure materials are shaped with precision and efficiency. Make sure your fluting tools are friends, not foes! Have you wondered what would happen if they went on strike? It’s best not to find out!

Key Features of High-Quality Fluting Tools

Material composition and durability. Design aspects enhancing performance.Imagine your favorite cookie baked with the finest ingredients—fluting tools are no different! They must be made from strong materials like carbide or high-speed steel to slice like a hot knife through butter. These tools are designed with magic in their grooves and angles, making them cut fast and smooth. Curious what makes a tool durable and efficient? Let’s check it out:

| Feature | Why It Matters |

|---|---|

| Material Composition | Tough materials ensure long-lasting performance. |

| Enhanced Design | Special designs give superb precision and speed. |

If you ever wondered how these tools get the job done without breaking a sweat, it’s all about their materials and design. Remember, even the tiniest tool can pack a powerful punch!

Factors to Consider When Choosing a Fluting Tool

Compatibility with milling machines. Specific requirements of the milling process.Choosing the right fluting tool isn’t like picking candies; it needs a bit more thought! First, check if the tool can dine with your milling machine—compatibility is key! Machines are fussy eaters and don’t like just anyone. Second, consider what the milling process demands. Some tasks need specific tools that are superheroes at cutting. The wrong pick might turn your work into a comedy routine with no audience! To keep things straight:

| Consideration | Why It’s Important |

|---|---|

| Machine Compatibility | Avoid awkward tool-machine misfits and possible damage |

| Milling Requirements | Ensure tool meets the specific needs of the process |

Remember, a well-matched tool makes a milling machine do the happy dance!

Best Practices for Using Fluting Tools

Techniques for optimizing performance. Maintenance and care tips.Ensure tools are sharp for clean cuts.

Adjust speed settings to match material.

Keep the surface clean and free of debris.

Regularly check and replace worn parts.

How can you increase the lifespan of a fluting tool?

Maintaining your tool keeps it running smoothly. Clean the tool after each use. Lubricate moving parts to prevent rust. Store tools in a dry place.What are some best practices for safety?

Always wear safety gear like gloves and goggles. Ensure the machine is off before adjusting any parts. Do not leave the machine unattended while in operation.Following these best practices helps you get the most out of your milling machine. Remember, regular care leads to better performance. And it keeps you safe, too!

Latest Innovations in Fluting Tool Technology

Recent advancements in design and materials. Impact on efficiency and product quality.New fluting tool technology is improving fast. Recent designs are lighter and stronger. This helps the tools last longer and perform better. The new materials allow for smoother cutting. These changes lead to better efficiency and quality in products. Manufacturers can now produce items faster and with fewer mistakes. It’s exciting to see how innovation drives success in this field!

How does new fluting tool technology affect manufacturing?

New fluting tool technology increases speed and accuracy. This means companies can make better items quickly. It also helps save money by reducing waste.

Key Benefits:

- Stronger designs

- Improved materials

- Faster production

- Higher product quality

Comparing Fluting Tools: What Sets the Best Apart?

Criteria for evaluation. Case studies of topperforming tools.Choosing the right fluting tool can feel like a quest for the holy grail of milling machines. First, you want to evaluate key factors. Look for material quality, cutting efficiency, and durability. Some tools can flute like a pro while others barely make a noise!

We found top tools performing wonderfully in various tests. For example, Tool A slices through materials like butter, while Tool B is tougher than a hard candy. The differences can be big, so let’s narrow it down:

| Tool | Cutting Efficiency | Durability |

|---|---|---|

| Tool A | 9/10 | 8/10 |

| Tool B | 7/10 | 9/10 |

In the end, the best tool fits your needs. Remember, not every hero wears a cape; some just have really sharp edges!

Conclusion

A milling machine fluting tool helps create grooves on materials. It’s essential for making patterns or better grip surfaces. Such tools increase work precision and productivity. If you’re curious, explore how milling machines work or try using one in a workshop. Practice makes perfect, and there’s always more to learn about these fascinating tools!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Machine Fluting Tools:Milling machine fluting tools help make grooves or patterns on materials like metal or wood. These tools spin really fast and cut shapes. They are important for making things like tools and parts for machines. You need a special machine to use them safely. With the right fluting tool, you can create smooth and nice designs!

Sure! Please provide the question you’d like answered.

What Is The Primary Function Of A Fluting Tool In Milling Operations?A fluting tool helps shape and cut materials like metal or wood. It has special grooves, or flutes, that make it easier to remove bits of material. When you use this tool, it creates nice edges or designs on your workpiece. So, we use it to make things look better and fit together well.

How Do Different Flute Geometries Affect The Performance And Efficiency Of Milling Operations?Different flute shapes on a milling tool can change how well it cuts. Flutes are the grooves on the tool that help remove material. Some shapes let chips escape easily, making cutting faster. Others can make a smoother finish but may cut slower. So, choosing the right flute shape helps you get better results in milling.

What Materials Are Commonly Used To Manufacture Fluting Tools For Milling Machines?Fluting tools for milling machines are often made from high-speed steel (HSS) and carbide. High-speed steel is strong and resists heat well. Carbide is even harder and lasts longer. We use these materials to make sure the tools can cut accurately and stay sharp.

Can Fluting Tools Be Customized For Specific Applications, And If So, How?Yes, we can customize fluting tools for special jobs. You can change the size and shape of the tool’s cutting edges. This helps it work better with different materials. You can even change the material of the tool itself, making it stronger or more flexible. By customizing, we make sure the tool does exactly what you need it to do!

What Maintenance Practices Are Essential To Prolong The Life And Effectiveness Of Fluting Tools In Milling Machines?To keep fluting tools in milling machines working well, you should clean them after use. You need to check for any damage or wear regularly. It’s important to keep them sharp so they cut better. Finally, store the tools in a dry place to avoid rust. These steps help the tools last longer and work correctly.