Have you ever wondered how machines can carve and shape materials with such precision? Milling machines are key players in this world. They turn raw materials into finished products. Each machine tool serves a special purpose. From cutting to drilling, these tools help create amazing things.

Imagine a world without these tools. Cars, airplanes, and even your favorite toys would look different. That’s why a milling machine tools list is so important. It helps people understand what tools they need for specific jobs. Knowing the right tools can make all the difference.

Did you know that there are many types of milling tools? Some are big and heavy, while others are small and precise. Each type has unique features that make it great for certain tasks. Learning about these tools can be fun and useful.

So, let’s dive into the world of milling machine tools. You might discover tools that spark your interest or ideas for your next project!

Comprehensive Milling Machine Tools List For Beginners

Milling Machine Tools List

Milling machines are essential for making precise parts in various industries. A milling machine tools list includes items like end mills, face mills, and drilling tools. Each tool serves a unique purpose, helping to shape and refine materials. Did you know some milling machines can create complex shapes from metal? Knowing your tools boosts your skills and efficiency in projects. With the right tools, you can turn your creative ideas into real designs!Key Milling Machine Components

Explanation of the main components of a milling machine. Importance of each component in the milling process.A milling machine has several important parts. The spindle holds cutting tools. It’s vital for shaping materials. The table is where materials sit. It moves to help shape them. The motor powers the machine. It makes everything run smoothly.

- Spindle: Holds tools for cutting.

- Table: Holds materials and moves.

- Motor: Powers the milling machine.

What does the spindle do?

The spindle rotates and holds the cutting tool. It’s key in shaping materials and affects precision.

Why is the table important?

The table holds the material. It moves in different directions, helping create various shapes.

How does the motor help?

The motor powers everything. It ensures the machine works efficiently and accurately. It’s like the beating heart!

Amazing Fact!

Did you know milling machines can create airplane parts? They’re precise and strong!

These components work together. They make sure shapes are accurate and precise. Each part is important in making materials into the right size and shape.

Essential Milling Machine Tools

Cutting tools: End mills, face mills, and drills. Tool holders and their role in securing cutting tools.No magic happens without the right tools. A milling machine feels the same way! It needs a bit of help from some friends: the cutting tools. With end mills, face mills, and drills, each cutting tool is like a knight on its quest, shaping and sculpting metal. Just imagine if a magician needed a magic wand to cast spells. Well, our wizards here need tool holders to ensure these cutting tools stay secure and sharp! Without them, it would be like trying to juggle without actually holding the balls—chaos!

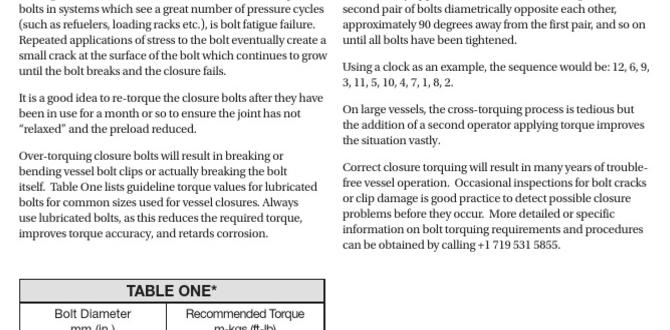

| Tool Type | Function |

|---|---|

| End Mills | Cut through metal sideways and make grooves. |

| Face Mills | Offers the big chop for flat surfaces. |

| Drills | Pierce into the material like a pro. |

Remember, a king is nothing without his knights! Similarly, these tools and holders must work together like a knight with his trusty steed to get the job done right.

Specialized Milling Tools and Their Uses

Slotting tools and their applications. Gear cutting tools for specific machining tasks.Picture a bustling workshop. What’s that sound? It’s the whirr of specialized milling tools! Slotting tools are the chart-toppers here. They skillfully carve grooves and slots, making each piece fit like a puzzle. Then, we have the rockstars: gear cutting tools. These are the maestros behind gears that spin smoothly in machines. Together, they turn raw metal into intricate parts. Precision is their game, and they play it well!

| Tool Type | Primary Application |

|---|---|

| Slotting Tools | Creating precise grooves |

| Gear Cutting Tools | Molding gears for smooth function |

Tool Materials: Choosing the Right Ones

Common materials used for milling tools. Factors influencing material selection: durability, cost, and application.Milling tools are made from many materials. Each choice affects how well the tool works. Common materials include high-speed steel and carbide. Carbide is popular because it’s tough. It can cut hard metals easily. High-speed steel is less expensive. It’s best for softer materials. Stainless steel and ceramic are other options.

When choosing materials, consider these factors:

- Durability: Will the tool last long?

- Cost: Is it within budget?

- Application: Does it fit the task?

Picking the right material saves time and money. It makes the cutting process smoother and more efficient.

What materials are best for drilling?

High-speed steel and carbide are top choices for drilling. These materials are durable and cut well. For tough jobs, carbide is the go-to. Buying the right quality ensures efficiency and better results.

How do I know what tool material to choose?

Think about the task. Consider the metal type you are cutting. Look at the cost and durability. Comparing these factors helps make a smart choice. Reading reviews or asking experts can also help.

Tool Maintenance and Performance Optimization

Recommended practices for tool maintenance. Tips for optimizing tool performance and longevity.Keeping tools in top shape is important. Here are some tips.

- **Clean tools** after each use to remove dust and debris.

- **Lubricate moving parts** regularly to prevent rust.

- **Check for signs** of wear or damage.

- **Store tools** in a dry place to avoid corrosion.

- **Sharpen blades** often for better performance.

Following these steps helps tools last longer. They also work better when taken care of. Tools that perform well can save time and effort. Isn’t it nice when things work smoothly?

### **What is the best way to clean a tool?**Using a soft cloth with mild soap is best. This removes dirt without scratching the tool.

Innovations and Trends in Milling Tools

Recent technological advancements in milling tools. Future trends and their potential impact on the industry.Innovations in milling tools bring exciting changes. Machines now use lasers for precise shaping. One future trend is **smart milling machines**. They can adjust speed on their own. This saves time and energy. New tools use stronger materials. This makes them last longer. Such advancements make factories work better.

- Laser technology enhances precision.

- Smart tools adapt autonomously.

- Durable materials extend machine life.

What is the impact of smart tools on the industry?

Smart tools make big changes. They help factories save costs and finish jobs faster. These tools reduce errors, making work safer. The industry becomes more efficient. Workers gain new skills to use these advanced machines. Overall, it leads to more productivity.

Conclusion

In summary, a milling machine tools list helps you understand essential tools for machining projects. Knowing common tools like end mills and cutters is vital. You can use this list to choose the right equipment for your needs. Explore more about these tools to improve your skills. Start working on projects and practicing today!FAQs

What Are The Essential Milling Machine Tools Needed For A Beginner Machinist To Get Started?To start using a milling machine, you need a few basic tools. First, you’ll need cutting tools like end mills, which are like special drill bits that cut metal. You’ll also need a vise to hold whatever you’re working on tightly. Safety goggles are important to protect your eyes. Lastly, have a brush for cleaning metal bits, so your workspace stays tidy.

How Do Different Milling Tools, Such As End Mills, Face Mills, And Chamfer Mills, Differ In Their Applications And Functions?Milling tools help us shape and cut materials like metal or wood. End mills are like pencils that cut through the sides and bottom of a material. Face mills are like erasers that make a material’s surface flat. Chamfer mills work like scissors that cut the edges to make slanted corners. Each tool helps create different shapes and designs.

What Are The Advantages Of Using Carbide-Tipped Milling Tools Compared To High-Speed Steel Tools In Milling Operations?Carbide-tipped tools are stronger and last longer than high-speed steel (HSS) tools. This means you don’t have to change them as often while using them for cutting. They also cut faster, which saves time. Plus, they can handle hard materials better than HSS tools.

How Does The Selection Of Milling Machine Tools Affect The Surface Finish And Precision Of A Machined Part?When we pick the right milling tools, we make parts smooth and the right size. A sharp tool cuts better, so the surface looks shiny. If the tool is dull, it can make the part rough. The tool’s shape also matters; some shapes help us cut very precisely. Picking the right tool is like picking the right crayon for drawing neat lines.

What Are The Latest Advancements In Milling Machine Tool Technology, And How Do They Improve Machining Efficiency And Accuracy?Milling machines have gotten better with cool new features. Some now have computers to help make better cuts, and these are called Computer Numerical Control (CNC) machines. They can work faster and more precisely, like a robot taking its time to do it just right. These updates mean we can make parts more accurately and waste less material. So, everything gets done quicker and looks just like we want it!