Have you ever seen a machine cut metal with ease? The magic happens with the right tools. One of these tools is a milling tool arbor. But have you ever wondered how it stays in place? Attaching this tool correctly is key.

Let’s think about building blocks. If you don’t stack them right, they fall. The same idea applies to milling machines. Proper installation prevents accidents and ensures a smooth operation. Who knew that such a small piece could make a big difference?

Here’s a fun fact: The word “arbor” comes from Latin, meaning “tree.” Just like a tree stands strong, a well-installed milling tool arbor keeps the machine sturdy. Why is this important? A strong setup can save time and keep you safe. Isn’t it amazing how the right setup can change everything?

Understanding Milling Tool Arbor Installation Process

Milling Tool Arbor Installation

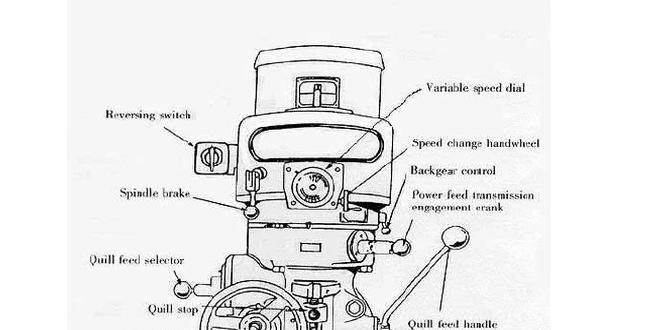

Ever wonder how a milling machine works its magic? The secret lies in the milling tool arbor installation. Imagine building blocks. Aligning them correctly is crucial. The arbor holds the milling tools, ensuring they fit snugly. This way, you get precise cuts every time. Make sure it’s clean and secure—imagine trying to draw with a wobbly pencil! It’s all about the right fit, like a puzzle where each piece sits perfectly.Understanding Milling Tool Arbors

Definition and purpose of milling tool arbors. Types of milling tool arbors and their specific uses.A milling tool arbor isn’t a tree that holds tools, but it’s quite useful in machining. It’s a clever part that connects your milling machine to the cutting tool. This connection is crucial, ensuring precision while crafting intricate designs.

Dive into the world of milling tool arbors and you’ll find various types. Some are for heavy-duty work, while others excel in delicate tasks. Here’s a simple guide:

| Type of Arbor | Specific Use |

|---|---|

| Shell End Mill Arbor | Perfect for machining flat surfaces. |

| Slitting Saw Arbor | Great for cutting precise slots. |

| Stub Arbor | Best for short reach work. |

Each arbor type has its superhero powers—some are strong, while others are stealthy. It’s essential to pick the right one for the job, much like a knight picking the perfect sword.

Essential Tools and Equipment

List of necessary tools for installation. Safety gear and precautions to take.Installing a milling tool arbor requires a few important tools and safety gear. You will need a wrenches set, screwdrivers, and a torque wrench. Don’t forget your safety goggles and gloves! These help keep you safe from metal shavings and other hazards during the work.

- Wrenches set

- Screwdrivers

- Torque wrench

- Safety goggles

- Gloves

Always double-check your equipment and follow these safety tips:

- Wear closed-toe shoes.

- Keep the workspace clean.

- Never rush the process.

What tools do I need for installation?

For the installation, you need a wrench set, screwdrivers, and torque wrench. Safety gear like safety goggles and gloves is also essential.

Preparing for Installation

Evaluating the milling machine for compatibility. Ensuring proper cleanliness and maintenance before installation.Before installing a milling tool arbor, check if your milling machine is suitable. Compatibility is key for smooth operation. Also, keep your work area clean. A clean machine works better and can last longer. Here’s how to prepare:

- Inspect the milling machine for correct fit.

- Clean all parts and remove debris.

- Ensure the machine is well lubricated.

Why is cleanliness important for installation?

Cleanliness helps to avoid damage and keeps your tool working well. It also prevents dust from affecting the machine’s parts.

Step-by-Step Guide to Installing a Milling Tool Arbor

Detailed procedures for mounting the arbor. Key considerations during the alignment process.To install a milling tool arbor, follow these easy steps. First, gather the needed tools: an arbor wrench, a level, and measuring tape. Next, secure the arbor to the machine. Make sure it’s tight but not overly so. Proper alignment is key for good performance. Check the following:

- Is the arbor centered?

- Is it level?

- Are all fasteners tight?

After aligning, do a quick test run. This ensures everything works smoothly. A properly installed arbor makes your work easier and safer!

Why is alignment important in arbor installation?

Alignment ensures that the tool cuts evenly and efficiently. Misalignment can cause tools to wear out quickly and lead to accidents.

Common Installation Challenges and Solutions

Identifying and troubleshooting common issues. Tips for ensuring stability and precision.Many people face issues during the milling tool arbor installation. It’s essential to spot these problems early. Typical challenges include misalignment and loose parts. Stability and precision are key for smooth operation. Here are some easy tips:

- Tighten all screws firmly.

- Make sure the arbor is aligned correctly.

- Check for any wear or damage.

By addressing these small issues, you can achieve a successful installation and avoid bigger problems later on. Remember, a little attention goes a long way!

What are common issues when installing a milling tool arbor?

Common issues include misalignment, loose components, and worn parts, which can lead to poor performance.

Post-Installation Checks

Steps for verifying proper installation. How to test tool performance and make adjustments.After installing the milling tool arbor, you should check its setup. Start by ensuring everything is tight and secure. Look for any hidden faults. Then, test the tool. Run it at a slow speed first to make sure it works well. Here are quick checks to do:

- Check for vibrations: Unusual shaking means something is wrong.

- Listen for sounds: A strange noise can signal a problem.

- Measure the cuts: Make sure the cuts are smooth and even.

If adjustments are needed, loosen the arbor and reposition it. Test again to ensure proper performance. Trust your instincts; if something feels off, it probably is!

How do I know if the milling tool is working correctly?

You can look for signs like smooth cuts, no vibrations, and normal sounds while it runs.Maintenance and Care for Your Arbor

Regular maintenance practices to extend arbor life. Signs of wear and when to replace components.Taking care of your arbor is simple but important. Regular checks can keep it working great and help it last longer. Look for these signs of wear:

- Rust or discoloration

- Unusual noises while in use

- Looseness in the parts

Replace any worn-out parts quickly. This can prevent bigger problems later. Regular maintenance includes cleaning and oiling the arbor. It’s like giving your tools a spa day! A well-cared-for arbor can last for years.

What are the signs that my arbor needs replacement?

Common signs include rust, unusual noises, or loose parts. If you notice any of these, it’s time for action!

Enhancing Milling Performance with Proper Arbor Use

Techniques to optimize milling operations. How arbor selection impacts machining results.Using the right arbor can make a big difference in milling. The right choice ensures smoother cuts and better surface finishes. Here are some helpful tips:

- Choose the right diameter for your tool.

- Keep the arbor clean and free from damage.

- Use the right speed for your milling machine.

These techniques help improve milling operations. Remember, the right arbor shapes the quality of your work. A good choice can lead to great results.

What is the impact of arbor selection on machining results?

The right arbor affects precision and efficiency. A suitable arbor leads to better tool control and reduced vibration, enhancing overall performance.

Conclusion

Installing a milling tool arbor is crucial for smooth machining. First, ensure all parts are clean. Then, tighten everything securely to prevent wobbling. Check alignment often to ensure precision. By following these steps, you improve safety and accuracy. Practice regularly to get better, and consider reading more guides or watching videos to master the process.FAQs

What Are The Necessary Steps To Properly Install A Milling Tool Arbor On A Milling Machine?To install a milling tool arbor, first, make sure the machine is off. Next, clean the arbor and its hole with a cloth. Then, slide the arbor into the hole until it fits snugly. Use the tightening tool to secure the arbor in place. Finally, check that everything is tight before turning on the machine.

How Do You Ensure The Arbor Is Correctly Aligned After Installation?To make sure the arbor is aligned correctly, we first check it with a level. We place the level against the arbor and see if it’s straight. If it’s not, we can adjust it by loosening the screws. Then, we tighten the screws back up once it looks right. Finally, we double-check with the level to be sure it’s perfectly aligned.

What Safety Precautions Should Be Taken During The Milling Tool Arbor Installation Process?When we install the milling tool arbor, we must stay safe. First, always wear safety glasses to protect your eyes. Next, make sure the machine is turned off and unplugged before you start. We should also keep our hands away from moving parts. Finally, ask for help if you’re unsure about anything!

How Can You Identify If An Arbor Is Compatible With Your Specific Milling Machine Model?To check if an arbor fits your milling machine, first look at the machine’s manual. The manual tells you the right size and type of arbor to use. You can also measure the spindle, which is the part where the arbor connects. Make sure the numbers match. If you’re unsure, ask an adult or a tool expert for help.

What Tools Or Equipment Are Essential For A Successful Milling Tool Arbor Installation?To install a milling tool arbor, you need a few important tools. First, you need a wrench to tighten parts. Next, use a torque wrench to check if everything is tight enough. A hammer can help fit pieces together. Finally, protect your eyes with safety goggles while you work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Necessary Steps To Properly Install A Milling Tool Arbor On A Milling Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a milling tool arbor, first, make sure the machine is off. Next, clean the arbor and its hole with a cloth. Then, slide the arbor into the hole until it fits snugly. Use the tightening tool to secure the arbor in place. Finally, check that everything is tight before turning on the machine.”}},{“@type”: “Question”,”name”: “How Do You Ensure The Arbor Is Correctly Aligned After Installation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the arbor is aligned correctly, we first check it with a level. We place the level against the arbor and see if it’s straight. If it’s not, we can adjust it by loosening the screws. Then, we tighten the screws back up once it looks right. Finally, we double-check with the level to be sure it’s perfectly aligned.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Milling Tool Arbor Installation Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we install the milling tool arbor, we must stay safe. First, always wear safety glasses to protect your eyes. Next, make sure the machine is turned off and unplugged before you start. We should also keep our hands away from moving parts. Finally, ask for help if you’re unsure about anything!”}},{“@type”: “Question”,”name”: “How Can You Identify If An Arbor Is Compatible With Your Specific Milling Machine Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if an arbor fits your milling machine, first look at the machine’s manual. The manual tells you the right size and type of arbor to use. You can also measure the spindle, which is the part where the arbor connects. Make sure the numbers match. If you’re unsure, ask an adult or a tool expert for help.”}},{“@type”: “Question”,”name”: “What Tools Or Equipment Are Essential For A Successful Milling Tool Arbor Installation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a milling tool arbor, you need a few important tools. First, you need a wrench to tighten parts. Next, use a torque wrench to check if everything is tight enough. A hammer can help fit pieces together. Finally, protect your eyes with safety goggles while you work!”}}]}