Have you ever wondered how important it is to secure a milling tool properly? Many people overlook this step. But did you know that using the right torque guidelines for collets can make a big difference?

In the world of machining, even small mistakes can lead to major problems. If a milling tool is too loose, it can slip and ruin your project. If it’s too tight, it can damage both the tool and the machine. This is where collet torque guidelines come into play.

Imagine you are working on a project and your milling tool slips. Frustrating, right? By following proper collet torque guidelines, you can avoid this issue. It’s simple, yet many forget to pay attention.

Join us as we explore these essential guidelines. We will help you understand how to secure your milling tools effectively. Your projects will turn out better, and you’ll work with more confidence!

Milling Tool Collet Torque Guidelines: Essential Tips And Techniques

Milling Tool Collet Torque Guidelines

Choosing the right torque for milling tool collets is crucial for safe and efficient machining. If the torque is too low, tools may slip. If it’s too high, you risk damaging the collet or tooling. Understanding proper torque settings prevents breakage and enhances precision. For added safety, always use a torque wrench. Did you know that using the right torque can improve tool life by up to 20%? Following torque guidelines helps you get the best results.Understanding Collet Systems

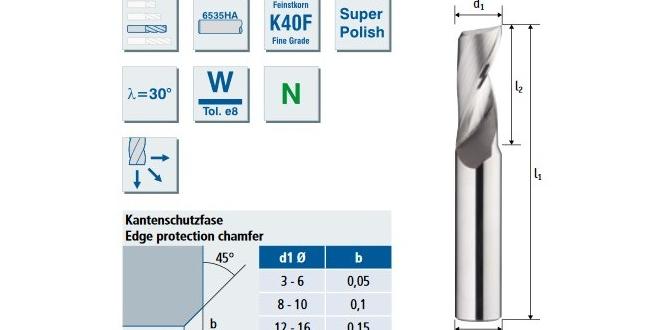

Definition and purpose of collets in milling. Different types of collets and their applications.A collet is a special tool used in milling machines. Its main job is to hold onto cutting tools securely. This helps to make precise shapes and cuts in materials like metal and wood. There are different types of collets, each suited for specific tasks.

- Spring collets: Flexible and great for various sizes.

- R8 collets: A common choice for milling machines.

- ER collets: Provide strong grip and stability.

Understanding collets helps you choose the right one for your project. This selection can lead to better results in your milling work.

What are the benefits of using collets in milling?

Collets ensure better precision and stability while cutting. They also help in preventing tool wear and damage.

Importance of Proper Torque Settings

Effects of incorrect torque on tool performance. Safety considerations in milling operations.Setting the right torque for your milling tools is very important. Incorrect settings can harm the tool and lead to problems. It can cause the tool to break or not work well. This may lead to rough finishes and wasted time. Safety is another big concern. If the torque is too high, parts can break and cause injuries. Always use proper torque to keep everything safe. Remember, correct torque helps your tools last longer and work better!

Why is correct torque so important?

Correct torque keeps tools safe and effective. Wrong settings can lead to serious issues, such as tool damage or accidents. It is key for everyone to follow torque guidelines closely.

Effects of Incorrect Torque:

- Poor tool performance

- Risk of accidents

- Increased tool wear

- Wasted material

Safety Considerations:

- Always check the torque before starting.

- Wear safety gear while working.

- Keep tools in good condition for safe use.

Factors Affecting Torque Values

Material types and their influence on torque requirements. Tool diameter and length considerations.Many factors change how much torque you need. First, the material type matters. Stronger materials often need more torque to hold tight. Next, think about tool diameter and length. A larger tool may require different torque than a smaller one. Finally, the length affects how the torque works too. Shorter tools usually need less force.

What are the main influences on torque requirements?

The main factors include material type, tool diameter, and length. Each factor can change how much torque is needed for the job.

- Material Type: Different materials, like steel or aluminum, behave differently.

- Tool Diameter: Bigger tools often require more torque.

- Tool Length: Shorter tools need less torque than longer ones.

Recommended Torque Specifications for Various Collets

Standard torque values for different collet types. Comparison of manufacturers’ specifications.Understanding the right amount of torque for your collet can keep everything running smoothly. Standard torque values vary between collet types, so knowing this is key. For example, a typical ER collet requires about 20-25 Nm of torque, while a CAT collet might need around 35 Nm. Manufacturers often highlight their own specs, which can differ slightly. So, resembling a chef with a recipe, check your tools carefully. Here’s a handy table to guide you:

| Collet Type | Torque Range (Nm) |

|---|---|

| ER | 20-25 |

| CAT | 30-35 |

| SK | 25-30 |

Always refer to your manufacturer’s guidelines, or you might end up tightening things like a kid on a swing—too much and you’ll break it!

Common Mistakes in Torque Application

Misunderstandings about torque values. Physical errors in the application process.Many people mix up torque values, thinking that a higher number always means better results. Wrong! Applying too much torque can actually break things. Then there are the physical errors, like not lining up the tool properly. It’s like trying to put a square peg in a round hole—confusing and messy! Keep these points in mind to avoid common pitfalls:

| Common Mistake | Consequences |

|---|---|

| Ignoring torque specs | Tool failure or breakage |

| Poor alignment | Inaccurate cuts |

Remember, applying the right torque is like seasoning food. Too much can ruin the dish!

Best Practices for Maintaining Collet Performance

Regular cleaning and inspection techniques. Guidelines for proper storage and handling.Keeping your collet in top shape is no small task. Regular cleaning is key; dirt and grime can ruin its performance faster than you can say, “Uh-oh!” A gentle brush or compressed air works wonders. Always inspect for cracks and wear. No one wants a surprise malfunction!

For storage, keep those collets in a dry, clean place, away from the sun. Think of it as their cozy home. Handle them carefully too; dropping them is a big no-no. Trust me, collets don’t bounce well!

| Best Practices | Tips |

|---|---|

| Cleaning | Use a brush or compressed air regularly. |

| Inspection | Check for cracks and wear before use. |

| Storage | Keep in a dry, clean area out of sunlight. |

| Handling | Touch with care; dropping is not cool! |

Real-World Case Studies and Examples

Success stories from industries using optimal torque settings. Lessons learned from torque failures in milling operations.Many industries have enjoyed success by using the right torque settings for milling tools. For example, a car manufacturer reported a 25% increase in production speed when they used the correct torque on their collets. This simple change made a big difference! On the flip side, some companies faced failures. They discovered that too much torque caused tools to break, leading to costly downtime.

- Correct torque improves efficiency.

- Too much torque can damage tools.

- Proper settings save money and time.

Learning from these examples helps many industries. They show how important it is to follow milling tool collet torque guidelines. These practices lead to smoother operations and better results.

What are common lessons learned from torque failures?

Common lessons include the importance of using precise torque settings to avoid tool breakage and downtime. Another lesson is to regularly check torque for consistent performance. This can keep machinery running smoothly and save money.

Conclusion

In summary, understanding milling tool collet torque guidelines is vital for safe and effective machining. Proper torque ensures tools stay secure and perform well. Always check the manufacturer’s specifications for the right settings. We encourage you to practice these guidelines during your projects. For more detailed insights, explore resources on machining safety and tool management. Happy milling!FAQs

What Are The Recommended Torque Specifications For Securing Different Sizes Of Milling Tool Collets?When you tighten milling tool collets, you need to use the right amount of force. For small collets, like 1/8 inch, you should use about 10 to 15 foot-pounds of force. For bigger collets, like 1/2 inch, you can use about 20 to 25 foot-pounds. Always check the tool’s instructions to be sure you’re doing it right!

How Does Collet Material Affect The Required Torque For Proper Clamping?The material of the collet changes how much tightness you need. For example, a soft material might need less force to hold things. Harder materials usually need more force to keep items in place. So, we have to adjust our tool’s strength based on the material. This helps ensure our work stays safe and secure.

What Are The Potential Consequences Of Over-Torquing Or Under-Torquing A Collet During Milling Operations?If you over-torque a collet, it can get damaged or break. This may cause a tool to slip or fall out during use. If you under-torque it, the tool might not hold tightly, leading to poor cuts. Both problems can create safety risks and waste materials. Always make sure to use the right amount of force!

Are There Specific Torque Wrenches Or Tools That Are Best Suited For Applying The Correct Torque To Milling Tool Collets?Yes, there are special torque wrenches for milling tool collets. These tools help you tighten the collet safely. You want a wrench that shows you how much force you’re using. A good option is a click-type wrench; it makes a sound when you reach the right tightness. This way, you know your collet is secure!

How Often Should Torque Settings Be Checked Or Calibrated To Ensure Optimal Performance And Safety In Milling Applications?You should check torque settings regularly, at least once a week. This helps make sure everything works well and stays safe. If you notice any problems, check them right away. Keeping everything in good shape helps you do a better job. Always follow the machine’s instruction manual for the best advice.