Have you ever wondered how precise shapes are made in metal? It’s all thanks to milling tools for slotting operations. These special tools create grooves and slots in materials like wood, metal, and plastic. Imagine building an amazing model that needs perfect slots for fitting parts together. That’s where milling tools come into play!

Many people might not realize how crucial these tools are in factories and workshops. Did you know that a simple groove can make a huge difference in things we use every day? From machinery to toys, the work of milling tools shapes our world!

In this article, we will explore the types of milling tools for slotting operations. We will also uncover their secrets and show you how they help craftsmen create incredible designs. So, are you ready to dive into the fascinating world of milling tools?

Milling Tools For Slotting Operations: Essential Guide

Milling Tools for Slotting Operations

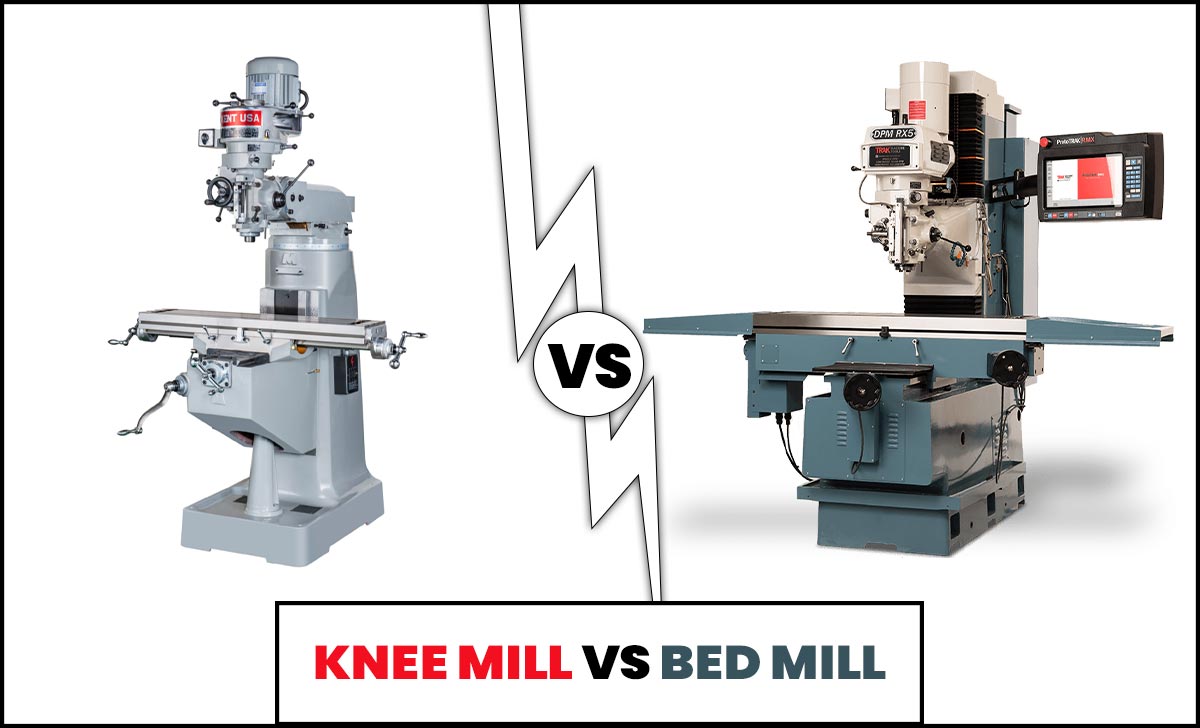

Milling tools for slotting operations are essential for creating precise grooves. These tools can cut narrow spaces and ensure accurate dimensions. Imagine needing to fit two parts together. Using the right milling tool means a perfect match! Did you know there are different types, like end mills and slot drills? Each serves a unique purpose. Knowing which to choose can make your projects easier and more efficient. Discovering the right milling tool opens up endless possibilities in machining!Types of Milling Tools Used in Slotting

End Mills: Characteristics and applications in slotting.. Slot Drills: Differences between slot drills and regular drills..When it comes to slotting, choosing the right milling tools is key. End mills are great for creating slots and grooves. They have sharp edges and can cut through materials easily. They work in various projects, whether you’re making furniture or building models. On the other hand, slot drills are not your average drill bits! They have a special design that lets them create precise slots. Unlike regular drills, they can plunge straight down and cut sideways, too. Think of them as the multitaskers of the drilling world!

| Type of Tool | Characteristics | Applications |

|---|---|---|

| End Mills | Sharp edges, versatile | Creating slots, grooves |

| Slot Drills | Special design, multi-directional | Precision slotting |

Material Considerations for Milling Tools

HighSpeed Steel vs. Carbide: Pros and cons for slotting tasks.. Coatings and Heat Resistance: Enhancing tool life and performance..Choosing the right material for milling tools is like picking between chocolate or vanilla ice cream—both are great! High-Speed Steel (HSS) tools are strong and easy to sharpen, but they might not last as long in tough jobs. On the other hand, carbide tools are tougher and can handle more heat, making them stars for slotting tasks.

Coatings can help these tools live longer, like putting on sunscreen to avoid sunburn. They boost heat resistance and performance. Check out this handy table:

| Tool Type | Pros | Cons |

|---|---|---|

| High-Speed Steel | Easy to sharpen, cost-effective | Not as durable, struggles under heat |

| Carbide | Very tough, longer life | More expensive, brittle if dropped |

In the end, picking the right tool means balancing cost and performance. Remember, even the toughest superhero needs the right gadgets!

Choosing the Right Tool for Slotting Applications

Factors Influencing Tool Selection: Depth, width, and material of the slot.. Tool Geometry and Design: How it affects slotting efficiency and finish..Picking the right milling tool for slotting can feel like a treasure hunt with lots of shiny options! First, think about the depth, width, and material of the slot. These factors matter a lot. A deeper or wider slot needs bigger tools. Next, tool geometry and design can make or break your slotting game. A well-designed tool can slice through material like butter, leaving a smooth finish. Have fun choosing!

| Factor | Importance |

|---|---|

| Depth | Choose a tool that matches the slot depth. |

| Width | Wider slots need bigger tools, simple as that! |

| Material | Pick a tool that works well with your material type. |

| Tool Design | A smart design improves efficiency and finish. |

Techniques for Effective Slotting Operations

Speed and Feed Rates: Optimal settings for different materials.. Coolant Usage: Importance in maintaining tool integrity and surface finish..Finding the right speed and feed rates is key for smooth slotting. Different materials need different settings. For softer materials, try higher speeds but lower feeds. For hard materials, go slower with higher feeds to avoid breakage. Add the right coolant, too! Coolants keep tools from overheating and help finish surfaces cleanly. Think of it as sunscreen for your machines—no one likes a burnt tool!

| Material Type | Speed (RPM) | Feed Rate (IPM) |

|---|---|---|

| Aluminum | 8,000 | 20 |

| Steel | 3,000 | 15 |

| Stainless Steel | 1,500 | 10 |

Common Challenges in Slotting Operations

Tool Wear and Breakage: Causes and preventative measures.. Chip Removal: Strategies for effective chip management during slotting..Slotting operations can be tricky, and tool wear is a common headache. Sometimes, tools wear out faster than a kid loses a tooth! This can happen due to high speeds or improper alignment. To prevent breakage, use the right cutting speed and keep an eye on your tools.

Chip management is another fun challenge. If chips pile up, it’s like a snowstorm in your workshop! Keeping the area clean helps you work better. Using flood coolant or high-pressure air can help keep chips under control. Don’t let those pesky chips ruin your day!

| Challenge | Solution |

|---|---|

| Tool Wear | Use proper speeds and regular checks. |

| Chip Removal | Utilize coolant and air blasts. |

Maintenance and Care for Milling Tools

Cleaning and Sharpening Techniques: Best practices for tool longevity.. Storage Solutions: Ensuring milling tools remain in optimal condition..Keeping milling tools in tip-top shape is vital for smooth slotting operations. Regular cleaning is key; wiping away metal shavings and coolant can prevent rust. Try using a soft brush or cloth to make it fun. Sharpening tools regularly is like giving them a spa day—it helps them cut better! For storage, use a clean, dry area. Magnets and racks keep tools organized and safe from damage. Treat your tools right, and they will thank you with perfect slots!

| Maintenance Tips | Benefits |

|---|---|

| Regular Cleaning | Prevents rust and wear |

| Frequent Sharpening | Enhances cutting efficiency |

| Proper Storage | Protects from damage |

Future Trends in Milling Tools for Slotting

Advancements in Material Technology: Impact on performance and durability.. Automation and Smart Milling: How technology is transforming slotting operations..New materials are changing milling tools. Stronger and lighter materials help tools last longer and work better. This leads to less wear and tear. Automation is also changing slotting operations. Smart machines use technology to improve speed and accuracy. With these tools, mistakes happen less often. Workers can focus on other important tasks. Together, these advances make slotting more efficient and reliable.

How are materials improving milling tools?

Advancements in material technology lead to better performance and durability.

Benefits of Smart Milling

- Faster operations

- Increased precision

- Fewer errors

Conclusion

In summary, milling tools for slotting operations are essential for precise cuts in materials. They help create grooves and slots easily. Using the right tools makes your work better and faster. Explore different types of milling tools and their uses to enhance your skills. You can find more information online or in books. Start practicing, and you’ll become an expert in no time!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Tools For Slotting Operations:Milling tools help us cut shapes into materials like metal or wood. For slotting, we use special tools called slotting cutters. These tools make grooves or slots in the material. They are important for making parts that fit together. Using the right tool makes our work easier and more accurate!

Sure! Please provide the question you want me to answer, and I’ll be happy to help you.

What Types Of Milling Cutters Are Commonly Used For Slotting Operations, And How Do They Differ In Terms Of Design And Application?For slotting operations, we commonly use end mills and slot drills. End mills have flat ends and can cut both sideways and down. Slot drills have a pointed shape that helps make straight slots. You pick an end mill for deeper cuts and a slot drill for shallower ones. Each cutter has a special design for different kinds of slots.

How Do Chip Load And Feed Rates Impact The Performance Of Milling Tools During Slotting Operations?Chip load is how much material each tooth of a tool cuts at once. A good chip load helps the tool do its job better. If the feed rate, or how fast we move the tool, is too high or too low, it can cause problems. We can break tools or make bad cuts if things aren’t balanced. So, it’s important to find the right chip load and feed rate for the best results.

What Are The Advantages And Disadvantages Of Using Solid Carbide End Mills Versus High-Speed Steel (Hss) Tools For Slotting?Solid carbide end mills are very strong. They cut faster and stay sharp longer than high-speed steel (HSS) tools. This means you can finish your work quicker. However, they can break easily if you drop them. HSS tools are tougher but may wear out faster and need more time to cut. You can choose based on what you need!

What Factors Should Be Considered When Selecting The Appropriate Milling Tool For Deep Slotting Versus Shallow Slotting Applications?When choosing a milling tool, think about the depth of the slot you need. For deep slots, you want a tool that cuts strong materials well. It should have longer flutes to reach deep down. For shallow slots, a shorter tool works fine. Also, consider the speed of cutting and the material you are using!

How Do Coolant And Lubrication Affect The Tool Life And Surface Finish In Slotting Operations Using Milling Tools?Coolant and lubrication help keep the tool cool and clean. When cutting metal, tools can get very hot and dull quickly. By using coolant, you stop the heat and make the tool last longer. Lubrication also helps make the surface smooth, so the finished product looks nice. Together, they improve both how long tools last and how good the work looks!