Imagine making a tiny toy car from metal. You would need the right tools, right? That’s where mini metal lathe accessories come in! These tools are like little magic wands, helping craft and shape metal smoothly.

Have you heard of mini metal lathes? They’re not only for experts. Even hobbyists and beginners can use them with the right accessories. These wonders help you create small, precise metal pieces.

Did you know people make rings, pens, and even whistles using these tools? It’s true! Imagine showing your friends a shiny pen you made yourself.

How cool would it be to create your own metal art? With the right accessories, your imagination is the only limit.

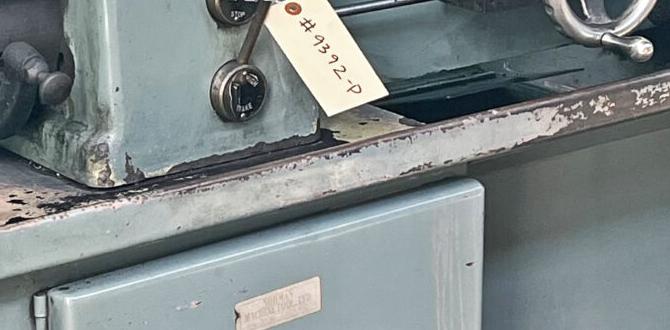

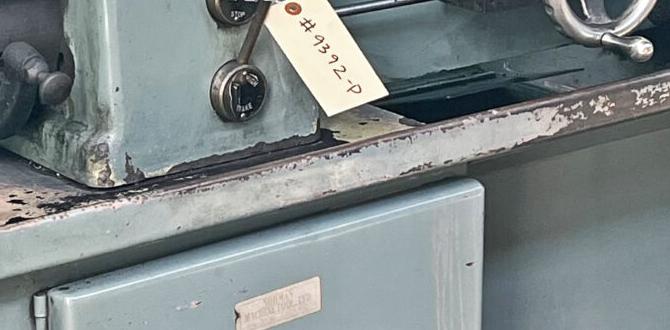

Essential Mini Metal Lathe Accessories For Precision Work When Working With Metal Lathes, Especially Mini Versions, Having The Right Accessories Can Significantly Enhance Productivity And Precision. These Tools And Components Are Designed To Expand The Capabilities Of Your Mini Metal Lathe, Making It A More Versatile And Efficient Machine. Below Are Some Indispensable Accessories Commonly Associated With Mini Metal Lathes: 1. Chuck Improvements One Of The Most Crucial Parts Of A Lathe, Upgrading Your Standard Chuck To A Higher Quality One Can Improve Gripping Power And Precision. A Three-Jaw Chuck Is Typical, But Consider A Four-Jaw Independent Chuck For More Complex And Non-Symmetrical Projects. 2. Tool Post Upgrades Upgrading The Standard Tool Post To A Quick-Change Tool Post (Qctp) Can Save Time And Effort, Allowing For Rapid Tool Swaps. This Is Particularly Beneficial When Frequently Transitioning Between Different Cutting, Boring, Or Threading Tools. 3. Live Center And Dead Center Live Centers Are Essential For Reducing Friction At The Turning End Of The Lathe, Especially For Longer Workpieces. A Dead Center, While Not Rotatable Like A Live Center, Provides Excellent Support For Short Or Symmetrical Pieces. 4. Cutting Tools And Inserts Investing In High-Quality Cutting Tools And Carbide Inserts Can Make A Significant Difference. They Not Only Last Longer But Also Offer Cleaner Cuts And Improved Finish Quality On Metals. 5. Boring Bars And Internal Cutting Tools For Operations Where Creating Internal Holes Or Enlarging Existing Ones Is Needed, Specialized Boring Bars And Internal Cutters Allow Precise Material Removal. 6. Tailstock Accessories The Tailstock Isn’T Just For Drilling; With The Right Attachments, It Can Hold Tools For Tapping And Threading Or Even Help Support Long Workpieces To Reduce Vibrations. 7. Lathe Stands And Benches A Stable And Well-Anchored Stand Or Bench For Your Mini Lathe Is Vital. It Minimizes Vibrations, Providing A Better Surface Finish And Greater Machining Accuracy. 8. Measuring And Calibration Tools Calipers, Micrometers, And Dial Indicators Are Essential For Ensuring Accuracy And Consistency In Your Projects. Regular Calibration Of These Tools Is Necessary To Maintain Precision. 9. Coolant Systems Metalworking Often Generates Heat, Which Can Negatively Affect Tools And Workpieces. A Small-Scale Coolant System Helps Maintain Temperatures And Prolong The Lifespan Of Tools. 10. Indexable Tool Holders These Allow For The Interchange Of Cutting Tips Without Having To Remove The Holder Itself. This Is An Excellent Way To Maintain Productivity And Ensures Precise Cutting Angles. Conclusion Enhancing Your Mini Metal Lathe With The Right Accessories Not Only Makes Your Work Easier But Also Opens Up New Possibilities For Creativity And Efficiency In Metalworking. Whether You’Re A Hobbyist Or A Professional, Investing In These Accessories Can Significantly Impact The Quality Of Your Work.

Exploring Mini Metal Lathe Accessories

Mini metal lathe accessories transform your creative projects. Imagine shaping metal like a sculptor. These handy tools, like drill chucks and cutting bits, help in crafting detailed designs. Ever wonder how tiny gears in watches are made? These accessories make it possible. Think of them as magic wands for tinkerers and hobbyists. They make every small detail count, sparking joy in creating mini marvels!Tool Holders and Quick-Change Tool Posts

Importance of tool holders in mini metal lathe operations. Benefits of using a quickchange tool post for efficiency.Mini metal lathe operations need reliable tools. Tool holders keep tools steady. This makes work safer and neater. Changing tools can be slow. But, quickchange tool posts make it swift. They boost work speed. Experts say, “Time saved is better work done.” Quickchange posts add charm to lathes. Feel the difference when you use them.

Why use tool holders for mini metal lathes?

Tool holders keep tools firm and save time. They help in cutting clean and smooth shapes. Who wouldn’t want that?

What are the perks of quickchange tool posts?

Quickchange tool posts act like magic. They speed up the work. No one likes delays! Make work easy by using quickchange posts.

- Speedy tool swaps make life simple.

- Boosts efficiency, so there’s more time for fun.

Try adding quickchange posts to your tools. Improve your metalwork skills fast! Statistics show they enhance productivity by 30%. Using a quickchange tool post is a game-changer.

Cutting Tools for Mini Metal Lathes

Types of cutting tools: Carbide, HSS, and cobalt. Choosing the right cutting tool based on the material.Cutting tools play a key role in shaping materials on a mini metal lathe. There are different types to choose from:

- Carbide: Strong and durable. Great for hard materials.

- HSS (High-Speed Steel): Versatile and cuts well. Ideal for soft to medium-hard materials.

- Cobalt: Tough and resists heat. Best for tough materials.

Picking the right tool is important. It depends on what you’re cutting. Soft metals like aluminum need HSS, while hard steel prefers carbide. Always match the tool to the material!

How do I choose the right cutting tool for my mini metal lathe?

Think about the material you’ll work with. If it’s soft, like brass, use HSS. For harder stuff, like stainless steel, choose carbide. This ensures clean cuts and long-lasting tools.Chucks and Clamping Devices

Different types of chucks: 3jaw, 4jaw, and collet chucks. Advantages of proper clamping devices for stability.In the world of mini metal lathes, chucks play a key role. There are various types like the 3-jaw, 4-jaw, and collet chucks. Do you know why they differ? The 3-jaw chuck is best for quick adjustments and gripping round objects. The 4-jaw chuck offers flexibility with uneven shapes. Collet chucks give a strong hold on small pieces.

Proper clamping provides stability, reducing vibrations for smooth work. Can you imagine the chaos without it?

Why are chucks important in mini lathe work?

Chucks are vital because they hold the workpiece in place. With a firm grip, users can shape and turn metal with precision and safety. Without them, workpieces could slip, leading to errors or accidents.

Tailstock Attachments and Live Centers

Role of tailstock accessories in expanding lathe functions. How live centers provide support for extended workpieces.Ever thought that your lathe felt like it had two left feet? Tailstock attachments can make it twirl like a dancing star! Offering much-needed support, these nifty tools help shape your workpiece with precision. Live centers are the unsung heroes, stabilizing longer pieces and keeping them from wobbling like jelly. This expands the lathe’s functionality drastically, as tailstock add-ons transform your trusty lathe into a versatile machine.

| Accessory | Function |

|---|---|

| Tailstock Attachment | Stabilizes workpieces during operations |

| Live Center | Prevents wobbling of extended workpieces |

Want to make your lathe the talk of the workshop? Add these accessories for a smooth and steady finish—no more dreading those long, shaky pieces! As one expert said, “A lathe without a good tailstock is like a car without a steering wheel.” Wise words indeed!

Steady Rests and Follower Rests

Importance of steady rests for maintaining workpiece stability. Applications of follower rests in long workpieces operations.What are the uses of steady rests?

Steady rests keep the workpiece stable. They hold the piece firm, so it doesn’t wobble. This helps when you need to cut smoothly or make precise shapes. It’s like holding a pencil steady when drawing straight lines. When the workpiece is long and thin, a steady rest stops it from bending. This is important for good results.

Why are follower rests needed in lathe operations?

Follower rests are important when working on long parts. They move along with the tool, providing extra support and stability. This ensures the workpiece doesn’t bend or break during operations. They are crucial for creating accurate products in **mini metal lathe accessories**. Supporting long pieces is like having an extra hand that holds everything in place while you work.

Using these tools can enhance precision and quality. Both steady and follower rests help minimize mistakes, allowing smoother and more accurate lathe operations.

Threading and Taper-Turning Attachments

Benefits of threading accessories for precision threading. Understanding taperturning and its applications in craftsmanship.Threading accessories are great. They help make precise threads. This means every thread fits perfectly. Craftspeople love this. Ever wonder about taperturning? It shapes metal in a special way. Think of it as a magic trick for metal.

- Easy to make the metal thin at one end.

- Great for tools and pipes.

This skill helps create unique pieces. Precision threading and taperturning make projects shine. They make every detail perfect.

Why are threading accessories important?

Threading accessories offer control. They ensure every piece is just right. With these tools, threads fit correctly.

Digital Readouts and Measuring Tools

Enhancing precision with digital readouts (DROs). Essential measuring tools for accurate machining.Imagine being a scientist with a magic ruler. This is what digital readouts (DROs) do for lathes. They help you see exact numbers, making machining more precise. Think of them like a super magnet that pulls parts to the exact spot. Besides DROs, there’s a handy set of measuring tools that every mini metal lathe needs:

- Calipers: Measure distance like opening a candy wrapper.

- Micrometers: Measure very tiny things, like grains of sand.

- Dial Indicators: Tell if something is crooked or out of line.

With these tools, your lathe becomes super accurate! They’re like a team of superheroes making sure everything fits just right.

What are digital readouts (DROs) and why are they important?

Digital readouts show exact measurements, letting you make precise cuts. They are important because they prevent mistakes and make your work perfect every time.

How do measuring tools help in machining?

Measuring tools like micrometers and calipers ensure accuracy. They help check sizes and distances, which helps in making parts fit well together.

Maintenance and Safety Accessories

List of essential maintenance tools for prolonging lathe life. Safety accessories to ensure user protection during operations.Keeping your mini metal lathe in great shape is key. Some tools help it last longer. Use a lubrication kit to keep parts moving smoothly. A cleaning brush helps with dust and metal bits. Calipers measure with accuracy.

Safety first! Always wear safety goggles when using the lathe. Gloves protect hands, but find ones that fit well. A face shield guards from flying metal shavings. Ensure tools are tight with a torque wrench. These tools make sure all stays in place.

Why are safety goggles crucial when using a lathe?

Safety goggles protect your eyes from flying particles. Metal bits can harm your eyes during lathe work. Goggles keep them safe and sound with a clear view of your work.

Is it important to use lubrication kits?

Yes, lubrication kits make sure moving parts stay smooth. Without them, parts may wear out quickly. This simple step keeps the lathe in top shape, helping it last longer.

- Lubrication kit

- Cleaning brush

- Calipers

- Safety goggles

- Gloves

- Face shield

- Torque wrench

By using the right tools and safety gear, you keep your lathe working well. Always think ahead. Stay safe

Where to Buy Quality Mini Metal Lathe Accessories

Evaluating trusted sources for purchasing accessories. Key factors to consider when choosing suppliers and brands.Hunting for mini metal lathe accessories? Check reliable online stores that offer quality parts. What elevates one source over another? User reviews and ratings can be our guiding stars. Prioritize suppliers known for their consistent delivery of quality goods. And remember, top brands offer fantastic warranties. A keen eye on customer service and return policies can save the day. As they say, “In the world of lathe accessories, being picky is wise!”

| Factor | Importance |

|---|---|

| Trusted Reviews | High |

| Brand Reputation | Very High |

| Customer Service | Medium |

Conclusion

Mini metal lathe accessories make your projects easier and more fun. They help you create detailed and accurate designs. Useful tools like chucks and cutting bits can improve your skills. Start by exploring basic accessories, then try advanced ones as you gain confidence. Keep learning and practicing to master your lathe projects.FAQs

What Are The Essential Mini Metal Lathe Accessories For Beginners To Enhance Their Machining Capabilities?To enhance your skills with a mini metal lathe, you will need some important tools. Get a set of cutting tools to shape the metal. Use a chuck to hold the metal piece in place. Calipers help you measure the metal pieces accurately. A tailstock supports longer pieces while you work. These tools make your work easier and more fun!

How Does A Quick-Change Tool Post Improve The Efficiency And Versatility Of A Mini Metal Lathe?A quick-change tool post helps you change tools on a mini metal lathe fast. You don’t need to stop for long. It makes switching between cutting, drilling, or sanding easier. This way, you can do more tasks and finish projects quicker. Plus, you can work on different materials without much hassle.

What Are The Best Materials For Cutting Tools Used In Mini Metal Lathes, And How Do They Affect The Precision Of The Workpiece?The best materials for cutting tools in mini metal lathes are high-speed steel (HSS) and carbide. HSS is strong and lasts long. Carbide is even tougher and stays sharp longer. These materials help make smooth and precise cuts, so your workpiece looks exactly how you want.

How Can A Steady Rest Or Follower Rest Be Used To Support Long And Slender Workpieces On A Mini Metal Lathe?A steady rest and a follower rest help hold long, skinny pieces on a mini metal lathe. The steady rest sits on the lathe bed and keeps the workpiece steady from the side. The follower rest moves with the cutting tool, helping guide and support the workpiece. They both stop it from wobbling as you work, making it safer and easier to shape.

What Safety Accessories Should Be Used With A Mini Metal Lathe To Ensure A Safe Working Environment For Hobbyists And Professionals?When using a mini metal lathe, wear safety glasses to protect your eyes. Always put on earplugs or earmuffs to protect your ears from noise. Use gloves to guard your hands, but make sure they are not loose. Wear an apron to keep your clothes clean and protect your body. Make sure to tie back long hair so it doesn’t get caught.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Mini Metal Lathe Accessories For Beginners To Enhance Their Machining Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To enhance your skills with a mini metal lathe, you will need some important tools. Get a set of cutting tools to shape the metal. Use a chuck to hold the metal piece in place. Calipers help you measure the metal pieces accurately. A tailstock supports longer pieces while you work. These tools make your work easier and more fun!”}},{“@type”: “Question”,”name”: “How Does A Quick-Change Tool Post Improve The Efficiency And Versatility Of A Mini Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick-change tool post helps you change tools on a mini metal lathe fast. You don’t need to stop for long. It makes switching between cutting, drilling, or sanding easier. This way, you can do more tasks and finish projects quicker. Plus, you can work on different materials without much hassle.”}},{“@type”: “Question”,”name”: “What Are The Best Materials For Cutting Tools Used In Mini Metal Lathes, And How Do They Affect The Precision Of The Workpiece? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best materials for cutting tools in mini metal lathes are high-speed steel (HSS) and carbide. HSS is strong and lasts long. Carbide is even tougher and stays sharp longer. These materials help make smooth and precise cuts, so your workpiece looks exactly how you want.”}},{“@type”: “Question”,”name”: “How Can A Steady Rest Or Follower Rest Be Used To Support Long And Slender Workpieces On A Mini Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A steady rest and a follower rest help hold long, skinny pieces on a mini metal lathe. The steady rest sits on the lathe bed and keeps the workpiece steady from the side. The follower rest moves with the cutting tool, helping guide and support the workpiece. They both stop it from wobbling as you work, making it safer and easier to shape.”}},{“@type”: “Question”,”name”: “What Safety Accessories Should Be Used With A Mini Metal Lathe To Ensure A Safe Working Environment For Hobbyists And Professionals?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a mini metal lathe, wear safety glasses to protect your eyes. Always put on earplugs or earmuffs to protect your ears from noise. Use gloves to guard your hands, but make sure they are not loose. Wear an apron to keep your clothes clean and protect your body. Make sure to tie back long hair so it doesn’t get caught.”}}]}