Have you ever watched a metal lathe in action? It’s fascinating! A precision metal lathe controller board plays a crucial role in this process. It’s like the brain of the machine, guiding it to carve out shapes with amazing accuracy.

Imagine you’re trying to build a perfect toy car with the exact dimensions. Without proper guidance, the car might come out all wrong. That’s where the controller board steps in. It helps the lathe cut metal just right, making sure your toy car looks just how you want it.

Did you know that the first lathes date back to ancient Egypt? Back then, craftsmen were limited in what they could create. Today, with a precision metal lathe controller board, we can achieve incredible results. This modern technology not only saves time but also opens up new possibilities for makers everywhere.

Precision Metal Lathe Controller Board: Key Features And Benefits

Understanding Precision Metal Lathe Controller Boards

Precision metal lathe controller boards are vital for modern machining. They allow users to control the lathe’s movements accurately. Ever wondered how these boards enhance performance? They integrate with software to make complex cuts easier. Plus, they improve efficiency and reduce waste. Imagine creating intricate designs with just a few clicks! These boards make machining more accessible, even for beginners. Discover how these tools can transform your projects and elevate your skills in metalworking.What is a Precision Metal Lathe Controller Board?

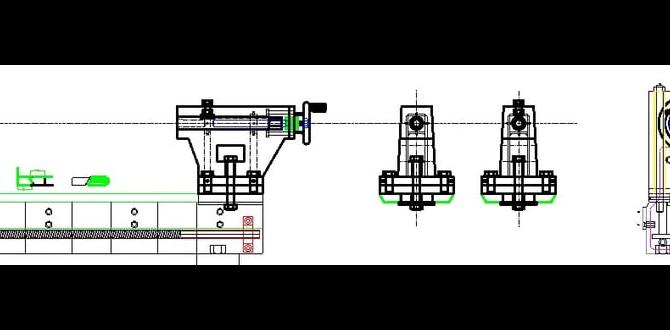

Definition and primary functions. Importance in modern machining processes.A precision metal lathe controller board is a small device. It controls the lathe, a machine that shapes metal. The board directs how fast and how much the metal spins. This technology is vital in modern machining. It helps create parts quickly and accurately.

- Precision: Ensures high accuracy in shaping metal.

- Speed: Increases production rates.

- Efficiency: Reduces waste of materials.

Without such boards, machining would be slower and less precise. They help industries meet high demands for quality parts.

What are the benefits of using a precision metal lathe controller board?

Using a precision metal lathe controller board enhances speed, accuracy, and efficiency. This leads to better quality products in less time.

Features of Precision Metal Lathe Controller Boards

Key components and specifications. Types of controller boards available in the market.Precision metal lathe controller boards are like the brains of your lathe machine. They help you control speed and direction. Key components include microcontrollers, driver chips, and user interfaces. You can find different types in the market. Some are basic while others have fancy features like touch screens. Here’s a quick look:

| Type | Features |

|---|---|

| Entry-Level | Simple controls, budget-friendly |

| Advanced | Touch screens, programmable settings |

| Pro | High precision, multitasking abilities |

These boards help turn those wild ideas into solid metal shapes! So, whether you’re a hobbyist or a pro, there’s a controller board for you!

Benefits of Upgrading to a Precision Controller Board

Improved accuracy and efficiency in machining. Enhanced control over the lathe’s operations.Upgrading your lathe with a precision controller board can feel like giving it a shot of espresso. Suddenly, the machine works faster and more accurately! With improved precision, you’ll notice that your cuts are cleaner, making your projects look great. Plus, you gain better control over every rotation and speed, which is pretty cool. Who wouldn’t want to whip up perfectly shaped metal parts without a hint of wobble? It’s machining magic!

| Benefits | Impact |

|---|---|

| Improved Accuracy | Finer details in workpieces |

| Increased Efficiency | Less time on each project |

| Enhanced Control | Smoother operations |

How to Choose the Right Controller Board for Your Metal Lathe

Key factors to consider (compatibility, functionality, price). Recommendations based on user requirements.Choosing the right controller board for your metal lathe can be a bit like picking the perfect pizza topping; there are key factors to consider! First, check compatibility with your lathe model. A board that doesn’t fit is like pineapple on pizza—debated and often unwelcome. Next, think about functionality; features that match your needs can save you from a machining meltdown. Finally, consider price; the best board isn’t always the most expensive one. Here’s a little table to help you out:

| Factor | Details |

|---|---|

| Compatibility | Ensure it fits your lathe model |

| Functionality | Look for features you need |

| Price | Find a balance between cost and quality |

Ready to become a lathe wizard? Evaluate these factors based on your specific requirements, and you’ll find the perfect match!

Installation and Setup Procedures

Stepbystep guide for installing a controller board. Tips for troubleshooting common installation issues.Installing a controller board can be fun and simple if you follow these steps. First, gather your tools and read the manual that comes with your board. Next, connect the wires correctly. Make sure to double-check the connections to avoid mistakes. If something goes wrong, don’t panic! Here are some tips:

- Check all wire connections.

- Ensure power is off before starting.

- Look for loose parts.

With patience, you can do it! Soon, you’ll be ready to start creating great projects.

What should I do if the controller board doesn’t turn on?

If the board doesn’t turn on, check the power supply and confirm all connections are secure. Also, verify the fuse is intact.

Quick Checklist:

- Power supply is plugged in

- Wires connected tightly

- Fuse checked

Maintenance Tips for Longevity of Controller Boards

Regular maintenance routines. Common pitfalls to avoid for optimal performance.To keep your controller board running well, regular care is essential. Checking connections and cleaning dust can help. Always use the right tools during repairs. Avoid overloading the machine; it can damage the board. Here are a few tips:

- Check wires monthly.

- Clean with compressed air.

- Update software regularly.

A little maintenance goes a long way to ensure a long life for your precision metal lathe controller board.

What are some common pitfalls to avoid?

Rushing repairs or ignoring signs of wear can lead to big problems. Always examine your board for any unusual sounds or smells. This helps prevent costly mistakes.

Best Practices for Operators Using Precision Metal Lathe Controllers

Safety measures to follow. Techniques to maximize productivity and precision.Using a precision metal lathe controller requires special care. Safety is key. Always wear protective gear like goggles and gloves. Keep hands clear of moving parts. Being focused helps. Stay alert to avoid accidents. Here are some tips to boost productivity and precision:

- Set the right speed for your material.

- Check tools regularly for sharpness.

- Plan your project steps before starting.

When operators follow these best practices, they work safely and get better results.

What is the best safety gear for lathe operators?

It is essential to wear goggles, gloves, and ear protection to keep safe while using a lathe.

Future Trends in Metal Lathe Controller Technology

Emerging technologies and innovations. Predictions for the future of precision machining automation.New tech makes metal lathes smarter and faster. Automation is a big part of this change. Soon, we will see more machines working without help from people. They will use sensors to keep track of their work. This means fewer mistakes and better products.

- More use of artificial intelligence.

- Better sensors for precision.

- Faster data sharing.

- More user-friendly software.

In the coming years, we can expect a big change in precision machining. Machines will work together, making everything smoother than before. This is an exciting time for makers and builders!

What technologies will be important for the future?

Artificial intelligence and smart sensors will play a huge role in making metal lathes better. These tools will help machines to operate more accurately and efficiently.

Conclusion

In summary, a precision metal lathe controller board is essential for accurate machining. It helps you control speed and movement effectively. Understanding its parts can improve your projects. We recommend exploring more resources or tutorials to gain hands-on experience. With practice, you’ll be able to create impressive metalwork. Let’s dive deeper into this fascinating topic together!FAQs

Certainly! Here Are Five Related Questions About Precision Metal Lathe Controller Boards:Sure! A precision metal lathe controller board helps control how a machine works when making metal parts. It tells the machine where to move and how fast to go. This makes it easier to make exact shapes from metal. You can think of it like the brain of the machine, helping it function better. Would you like to learn more about how it works?

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For In A Precision Metal Lathe Controller Board?When choosing a controller board for a precision metal lathe, look for a few important features. First, it should have easy controls. This helps you move pieces smoothly. Second, check if it has good speed settings. You want to adjust how fast the lathe spins. Finally, make sure it has safety options to keep you safe while you work.

How Does A Precision Metal Lathe Controller Board Improve Machining Accuracy And Efficiency?A precision metal lathe controller board helps us by giving precise commands to the machine. This means it can cut metal exactly where we want it to. With less guessing, we make fewer mistakes. It also speeds up our work because the machine runs better and faster. Overall, we create better parts more quickly.

What Types Of Software Can Be Used To Program And Control A Precision Metal Lathe Controller Board?You can use different types of software to control a precision metal lathe. Some popular ones are Mach3, LinuxCNC, and Universal Gcode Sender. These programs help you tell the lathe what to do. They make it easier to create and move designs. You just need to install one on your computer and connect it to the lathe.

How Do Different Communication Protocols (E.G., Usb, Ethernet) Affect The Performance Of A Precision Metal Lathe Controller Board?Communication protocols, like USB and Ethernet, help different parts of a metal lathe talk to each other. USB is usually faster for short distances. But Ethernet can work over longer distances and is good for connecting many machines. If we use the right protocol, the lathe can work better and smoother. This makes sure our projects turn out just right!

What Are Some Common Troubleshooting Steps For Issues Encountered With Precision Metal Lathe Controller Boards?If your metal lathe isn’t working right, there are a few things you can try. First, check the power supply to make sure it’s plugged in and turned on. Next, look at the wires for any damage or loose connections. You can also restart the machine to see if that helps. Finally, consult the manual to find specific problems and solutions.