Have you ever watched a metal lathe spin and wondered how it works? Imagine turning a block of metal into a smooth cylinder. It’s fascinating, right? Now, let’s make that process even cooler with automation. A setup guide for metal lathe automation can help you do just that.

Setting up a metal lathe can feel tricky, but it doesn’t have to be. With the right steps, you can easily automate your lathe. This guide will show you how to increase your efficiency and make your work easier.

Did you know that automating your metal lathe can save you hours of time? Picture finishing a project faster than ever. You can spend more time creating and less time running the machine. That sounds great, doesn’t it?

Get ready to dive into a world where metal lathes and automation go hand in hand. With simple instructions, you’ll be on your way to mastering this powerful tool. Let’s explore how you can transform your metalworking experience!

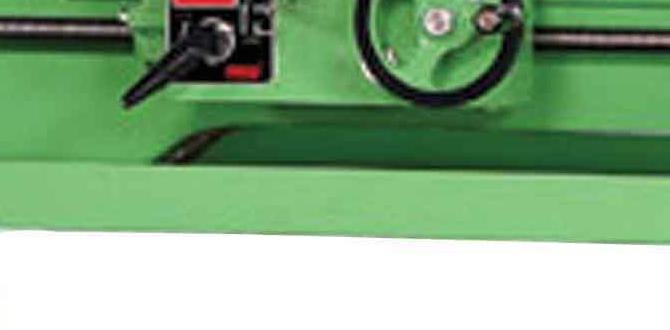

Comprehensive Setup Guide For Metal Lathe Automation Techniques — Introduction Metal Lathe Automation Has Transformed The Manufacturing Process, Making It More Efficient And Precise. This Setup Guide Aims To Provide You With Essential Steps And Tips For Automating Your Metal Lathe Operations, Enhancing Productivity And Consistency In Your Projects. Understanding Metal Lathe Automation Metal Lathe Automation Involves Incorporating Automated Systems Into The Traditional Lathe Processes To Increase Efficiency. Automation Can Include Features Like Cnc (Computer Numerical Control), Automated Tool Changing, And Real-Time Monitoring Systems. Understanding These Elements Is Crucial For Any Setup. Step 1: Selecting The Right Metal Lathe Your Journey Begins With Selecting A Metal Lathe That’S Suitable For Automation. Considerations Include: – **Type**: Cnc Lathes Are Typically Preferred For Automation Due To Their Programmability. – **Size And Capacity**: Ensure The Lathe Meets Your Specific Project Requirements. – **Compatibility**: Check That Available Automation Systems Can Integrate With Your Chosen Lathe Model. Step 2: Planning Your Automation Setup Before Delving Into Actual Setup, Plan Your Automation Carefully: – **Workflow Design**: Map Out The Entire Workflow From Raw Material Entry To Finished Product Output. – **Software Selection**: Choose Cad/Cam Software Compatible With Your Lathe For Programming. – **Safety Measures**: Incorporate Safety Protocols To Protect Operators And Equipment. Step 3: Installing Hardware Components Once Your Planning Phase Is Complete, You Can Begin Installation: – **Cnc Controller**: Install A Cnc Controller That Is Compatible With Your Lathe. – **Sensors And Cameras**: Include Sensors For Position Feedback And Cameras For Quality Inspection. – **Tool Changer**: If Applicable, Set Up An Automated Tool Changer To Increase Efficiency In Changing Tools During Operation. Step 4: Software Configuration After Your Hardware Is In Place, Configure The Necessary Software: – **Machine Setup**: Input Machine Parameters Into The Cnc Software. – **Programming**: Develop Cnc Programs Using The Previously Selected Cad/Cam Software. – **Testing**: Run Simulations To Ensure Everything Operates As Expected Before Actual Machining. Step 5: Training And Maintenance It’S Essential To Train Operators And Establish Maintenance Routines: – **Operator Training**: Provide Thorough Training On The New Automated Systems And Software. – **Maintenance Schedule**: Set Up A Regular Maintenance Schedule To Ensure The Longevity And Reliability Of Your Automated Lathe. Conclusion Automating Your Metal Lathe Can Yield Significant Benefits In Terms Of Efficiency And Productivity. By Following This Setup Guide, You Can Ensure A Smooth Transition Into Automation, Equipping Your Workshop With The Tools Needed For Modern Manufacturing Demands. Embrace The Future Of Machining With A Well-Planned And Efficiently Implemented Metal Lathe Automation System.

Summary of Metal Lathe Automation Setup Guide

Discover how to make your metal lathe smarter with automation! This setup guide shows you step-by-step ways to enhance your lathe operations. Learn about essential tools and software needed for automation. Have you ever imagined a lathe that works on its own? With the right setup, it can! You’ll explore helpful tips to optimize your workflow and improve precision. Unlock the potential of your metal lathe and turn your shop into a powerhouse of innovation!Understanding Metal Lathe Automation

Definition and significance of metal lathe automation. Benefits of automating metal lathes in manufacturing processes.Metal lathe automation helps machines work faster and more accurately. This means they can make parts without much help from people. Automating metal lathes is important because it saves time and makes things better. Here are some benefits:

- Increased efficiency: Machines can run all day without getting tired.

- Better precision: Automation makes fewer mistakes.

- Lower costs: Less labor means more savings.

- Faster production: Businesses can meet more orders quickly.

Overall, metal lathe automation changes how products are made. It helps factories keep up with demand and improve quality.

What are the advantages of metal lathe automation?

The advantages include faster production times, improved accuracy, and reduced labor costs. Automating processes helps businesses stay competitive in a busy market.

Preparing Your Workspace for Automation

Key considerations for layout and ergonomics. Safety protocols and environmental factors.Setting up your space for automation is important. Keep your tools and equipment within reach. This makes your work easier and safer. Good layout helps prevent accidents and saves time. Remember these key points:

- Design your workstation for comfort.

- Ensure good lighting for visibility.

- Follow safety rules for handling machines.

Also, consider keeping your workspace clean and organized. A neat area reduces risks and improves focus. Your safety and productivity depend on it!

What should I consider for workspace safety?

Think about safety signs and protective gear. Always keep emergency tools handy. Plan for proper ventilation to avoid harmful fumes.

Step-by-Step Setup Process for Automation

Initial setup and calibration of metal lathe. Integrating CNC controls and programming basics.Setting up your metal lathe for automation may sound tricky, but it’s as easy as pie—especially if that pie is already baked! Start with the initial setup and calibration. Make sure everything is leveled and secure. Next, integrate your CNC controls. This helps the machine know exactly what dance moves to perform. A little programming will get you to the finish line faster than a squirrel after a nut!

| Step | Action |

|---|---|

| 1 | Check Setup |

| 2 | Calibrate Tools |

| 3 | Integrate CNC |

| 4 | Write Basic Program |

With these steps in mind, you’ll have your metal lathe singing a sweet tune of automation. Remember, practice makes perfect—just like riding a bike or mastering the art of snack time!

Common Challenges in Metal Lathe Automation

Identifying potential issues during setup. Troubleshooting tips and preventive measures.Setting up metal lathe automation can be tricky. You might face issues during the setup. Common problems include clogs, misalignments, and software errors. These hiccups can slow you down.

Here are some troubleshooting tips:

- Check all connections and cables regularly.

- Ensure tools are clean and correctly aligned.

- Update software to the latest version.

Preventive measures can help avoid future setbacks. Regular maintenance is key. Always follow the manufacturer’s guide for best results. Identifying issues early makes the setup smoother and more efficient.

What are some common problems during metal lathe automation setup?

Common problems include misalignments, software glitches, and wear on parts. Regular checks and maintenance can help fix and prevent these issues.What preventive measures can I take?

- Perform regular maintenance checks.

- Keep the workspace tidy and organized.

- Use high-quality tools and materials.

Maintenance Practices for Automated Metal Lathes

Recommended routine checks and servicing schedules. Best practices for prolonging equipment lifespan.Regular checks keep automated metal lathes in top shape. Make a list of key tasks to complete monthly. Check the oil levels, clean the filters, and inspect the belts. This takes only a little time but prevents big problems later. Follow these best practices:

- Inspect tools for wear.

- Calibrate settings regularly.

- Clean machines to avoid dust build-up.

With these routines, your equipment can last longer and work better!

What are essential maintenance checks for metal lathes?

Key maintenance checks include checking oil levels, examining belts for damage, and ensuring all parts are clean and well-lubricated.

Evaluating Automation Performance

Metrics to assess efficiency and productivity improvements. How to make datadriven adjustments for optimization.To improve automation performance, track metrics that show how well your metal lathe is working. Pay attention to speed and quality of the products made. With clear numbers, it’s easier to spot what needs fixing. Sleepy machines waste time, and we don’t want that! Here’s how to measure:

- Track production speed

- Measure error rates

- Monitor machine downtime

With these metrics, you can make smart choices. Use data to adjust processes for better results. This means tweaking settings to keep the machines in tip-top shape. Automation can save time and boost productivity!

What metrics help evaluate automation performance?

Key metrics include production speed, error rates, and machine downtime. They show how well the automation is working, helping you make improvements.

Conclusion

In summary, a setup guide for metal lathe automation helps you streamline your projects. By following clear steps, you can improve efficiency and precision. Make sure to learn about safety features, tool settings, and programming basics. We encourage you to explore more resources or tutorials for hands-on practice. Start automating your lathe today and enjoy the benefits!FAQs

What Are The Essential Components Needed For Automating A Metal Lathe Setup?To automate a metal lathe, you need a few important parts. First, you need a computer to control the machine. Next, you’ll want sensors to check where the tools are. You also need motors to move the lathe and tools. Finally, you should have a program that tells everything what to do.

How Do You Integrate A Cnc Controller With A Traditional Metal Lathe For Automation?To connect a CNC controller to a metal lathe, you first need to attach motors to the lathe. Then, you connect these motors to the CNC controller, which acts like the brain. You also need to connect sensors that help the CNC know where the lathe is. Finally, you program the CNC to tell the lathe what to do automatically. This way, the machine can work on its own!

What Safety Precautions Should Be Considered When Automating A Metal Lathe?When automating a metal lathe, we need to be very careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Make sure the machine has emergency stops to shut it down quickly. Lastly, never work alone; have someone nearby to help if needed.

How Can I Program The Cnc Controller To Optimize The Machining Process On A Metal Lathe?To program the CNC (Computer Numerical Control) controller for a metal lathe, start by choosing the right tools. You can set the speed and feed rate, which affect how fast the metal is cut. Next, write the instructions for each step of the process. Finally, test your program to make sure it works well and make changes if needed. This will help us get better results and save time!

What Are The Common Challenges Faced During The Automation Of A Metal Lathe And How Can They Be Overcome?When we automate a metal lathe, we might face a few challenges. One challenge is programming the machine to do what we want. We can overcome this by practicing and learning the software. Another challenge is making sure everything fits together, like the tools and parts. We can check the sizes carefully and do tests before starting. Lastly, we need to keep the machine safe and clean to work well.