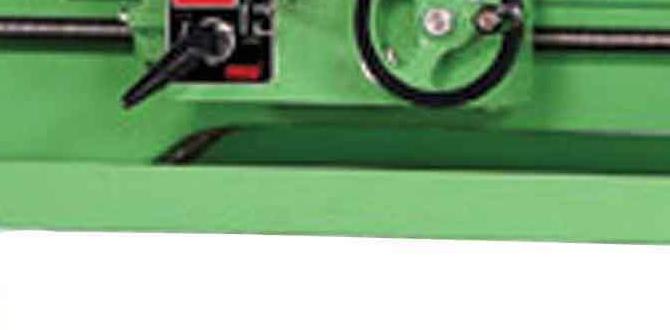

Have you ever wondered how a metal lathe works? These machines shape metal into amazing parts. But here’s a secret: spindle speed plays a big role in how well they perform.

Imagine you are making a metal part. You want it to be smooth and perfect, right? The spindle speed helps you achieve that. But what happens if you need to stop quickly? That’s where the foot brake comes in.

There’s a story about a young machinist who learned this the hard way. One day, he was so focused on the spindle speed that he forgot to check the foot brake. He ended up with a messy part! From that day on, he knew the importance of both speed and safety.

In this article, we will explore how spindle speed and a metal lathe’s foot brake work together. You’ll find tips on how to use them safely and effectively. Get ready to dive into the world of metalworking!

Spindle Speed Metal Lathe Foot Brake: Enhancing Safety And Precision

Spindle Speed Metal Lathe Foot Brake

Understanding spindle speed on a metal lathe is crucial for effective machining. The foot brake plays a vital role in safety and control. It helps operators stop the spindle quickly when needed. Imagine you’re working on a project, and you need to halt suddenly—this brake is your lifeline. Properly adjusting spindle speed boosts performance and prevents tool damage. Exploring these features makes you a better lathe operator, ensuring quality results every time. Wouldn’t that feel great?What is Spindle Speed?

Definition of spindle speed in metal lathes. Importance of spindle speed in machining processes.Spindle speed in metal lathes is how fast the spindle rotates while working. It’s vital for getting the job done right. Think of it like the engine of a car revving up; the higher the speed, the faster you can go! Proper spindle speed can improve the finish on your workpiece and make cutting easier. Too fast? You’ll overheat your tools and ruin the fun!

| Spindle Speed (RPM) | Effect on Machining |

|---|---|

| Low Speed | Better control, good for hard materials |

| Medium Speed | Balance of speed and control |

| High Speed | Fast cuts, but risk of tool damage |

Choosing the right spindle speed is like picking the right dance moves. Too slow, and you step on toes; too fast, and you become a whirlwind! Always know your materials and adjust accordingly.

Factors Affecting Spindle Speed

Material type and its impact on spindle speed. Tooling considerations and their role in optimal speed selection.Several things can change how fast a spindle spins. First, the type of material you use matters. Softer materials need a slower spindle speed, while harder ones require a faster speed. Second, what tool you choose also plays a big role. Sharp and proper tools work best at optimal speeds. Using the wrong tool makes you feel like trying to run a marathon in flip-flops—very tricky!

| Material Type | Recommended Spindle Speed |

|---|---|

| Wood | 1500-3000 RPM |

| Aluminum | 500-1000 RPM |

| Steel | 300-500 RPM |

Getting spindle speed right helps in making a great finish, and we all like shiny, smooth things, right?

Calculating the Optimal Spindle Speed

Formula for calculating spindle speed (RPM). Example calculations for different materials.To find the best spindle speed for a metal lathe, you can use this simple formula: RPM = (Cutting Speed x 12) / Diameter. Cutting speed is measured in feet per minute (FPM). For example:

- If cutting aluminum with a diameter of 3 inches and a cutting speed of 600 FPM, RPM is 2400.

- For steel, with a diameter of 2 inches and a cutting speed of 100 FPM, RPM becomes 600.

Choosing the right spindle speed helps improve your work quality and tool life.

What is the importance of spindle speed?

The correct spindle speed can lead to smoother cuts and a better finish. It can also reduce tool wear. Using the wrong speed may damage both the material and the machine.

Understanding the Foot Brake Mechanism

Explanation of foot brake functionality in metal lathes. Importance of the foot brake for safety and precision.The foot brake on metal lathes is crucial for safety and control. It helps stop the machine quickly, preventing accidents. Imagine needing to pause work to avoid a mistake; the foot brake makes this easy. Here’s how it works:

- Prevents Injury: It stops the lathe faster.

- Precise Operation: It allows for careful adjustments.

- Easy Access: Foot-operated for quick use.

This combination of safety and precision makes the foot brake an important part of using a metal lathe.

Why is the foot brake important?

The foot brake is important because it keeps users safe and helps them work more accurately.

Benefits of Using a Foot Brake

Enhanced control during machining operations. Reduced risk of accidents and improved workflow.A foot brake offers many benefits during machining tasks. It helps users keep better control of their machines. With this smooth control, operators can work faster and safer. Using a foot brake also decreases the chance of accidents, making the workspace safer for everyone. This leads to a stronger workflow, allowing for more efficient work. A simple press of the foot can be a big time-saver!

What is the impact of using a foot brake?

Using a foot brake enhances control, lowers accident risk, and improves workflow. This can help both beginner and expert machinists achieve the best results.

Common Issues with Spindle Speed and Foot Brake

Trouble symptoms related to incorrect spindle speed. Faults associated with foot brake mechanisms and solutions.Having trouble with spindle speed? You might see symptoms like a choppy finish or loud noises, which are signs it’s not in sync. If your project feels like a rollercoaster ride, it’s time to check that speed! On the foot brake side, if it feels sticky or doesn’t stop smoothly, your safety is on the line. A quick oiling can do wonders. Remember, a happy lathe means happy projects!

| Trouble Symptoms | Possible Solutions |

|---|---|

| Choppy finish | Check spindle speed settings |

| Loud noises | Inspect for wear and tear |

| Sticky foot brake | Apply lubricating oil |

Best Practices for Spindle Speed Management

Recommended rpm settings for various materials. Regular maintenance tips to ensure longevity and accuracy.Managing spindle speed is like a dance. Different materials have their own rhythm. For example, aluminum enjoys a smooth pirouette at about 1,000-3,000 RPM, while steel prefers a slower waltz around 500-1,500 RPM. To keep your lathe spinning sweetly, regular maintenance is key. Check the foot brake often, and don’t skip oil changes. A well-maintained machine performs better! Here’s a quick look:

| Material | Recommended RPM |

|---|---|

| Aluminum | 1,000-3,000 |

| Brass | 500-2,000 |

| Steel | 500-1,500 |

| Cast Iron | 300-1,200 |

Happy spinning!

Case Studies and Practical Applications

Realworld scenarios demonstrating effective spindle speed usage. Case studies highlighting the impact of foot brakes on production efficiency.Using a spindle speed effectively can change the game in metalworking. One bakery in the city improved their lathe operations by adjusting speeds and saw production rise by 30%! Oh, the sweet smell of progress! Foot brakes play a big role, too. A factory found their release time reduced by 50% with a better foot brake system, making everyone happier and saving money. Efficiency is a recipe for success, after all!

| Case Study | Impact |

|---|---|

| Bakery Lathe Upgrade | 30% production increase |

| Factory Foot Brake Overhaul | 50% faster release time |

Conclusion

In summary, spindle speed on a metal lathe affects how quickly you can work. The foot brake is vital for safe and quick stops. Understanding these tools helps you use your lathe wisely. Remember to practice using the brake and adjusting the spindle speed as needed. For more tips, check out guides on metalworking to improve your skills!FAQs

What Is The Purpose Of A Foot Brake In A Metal Lathe, And How Does It Interact With Spindle Speed?A foot brake in a metal lathe helps you stop the spinning parts quickly. When you press the brake with your foot, it slows down the spindle. The spindle is the part that spins the metal. This makes it safer for you to work and change tools without waiting long for it to stop.

How Can Adjusting The Spindle Speed Affect The Effectiveness Of The Foot Brake During Machining Operations?Adjusting the spindle speed changes how fast the machine spins. When the spindle spins faster, it can be harder to stop quickly. This means the foot brake might not work as well. If you slow down the spindle, the brake can stop the machine more easily. So, finding the right speed helps you use the brake better.

What Safety Precautions Should Be Taken When Using The Foot Brake On A Metal Lathe To Stop The Spindle Quickly?When you use the foot brake on a metal lathe, always wear safety glasses to protect your eyes. Make sure your clothes are tight and not too loose. Keep your hands and other body parts away from the moving parts. Ensure there are no tools or foreign objects near the brake area. Finally, always check that your foot is ready to hit the brake when you need to stop quickly.

Can The Design Of A Foot Brake Influence User Comfort And Control When Operating A Metal Lathe At High Spindle Speeds?Yes, the design of a foot brake can make a big difference. If the brake is easy to use, you feel more comfortable. This helps you control the lathe better, especially at high speeds. A good design means you can stop quickly and safely. So, a well-made foot brake helps you work smoothly and confidently.

What Maintenance Practices Are Recommended For Ensuring The Foot Brake Functions Effectively In Conjunction With The Spindle Speed On A Metal Lathe?To keep the foot brake working well on a metal lathe, check it often. You should clean the brake parts regularly to remove dirt. Make sure the brake pads are not worn out and replace them if needed. Keep the area around the brake clear so it can work properly. Always test the brake before starting work to ensure it’s safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of A Foot Brake In A Metal Lathe, And How Does It Interact With Spindle Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot brake in a metal lathe helps you stop the spinning parts quickly. When you press the brake with your foot, it slows down the spindle. The spindle is the part that spins the metal. This makes it safer for you to work and change tools without waiting long for it to stop.”}},{“@type”: “Question”,”name”: “How Can Adjusting The Spindle Speed Affect The Effectiveness Of The Foot Brake During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the spindle speed changes how fast the machine spins. When the spindle spins faster, it can be harder to stop quickly. This means the foot brake might not work as well. If you slow down the spindle, the brake can stop the machine more easily. So, finding the right speed helps you use the brake better.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using The Foot Brake On A Metal Lathe To Stop The Spindle Quickly? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use the foot brake on a metal lathe, always wear safety glasses to protect your eyes. Make sure your clothes are tight and not too loose. Keep your hands and other body parts away from the moving parts. Ensure there are no tools or foreign objects near the brake area. Finally, always check that your foot is ready to hit the brake when you need to stop quickly.”}},{“@type”: “Question”,”name”: “Can The Design Of A Foot Brake Influence User Comfort And Control When Operating A Metal Lathe At High Spindle Speeds? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, the design of a foot brake can make a big difference. If the brake is easy to use, you feel more comfortable. This helps you control the lathe better, especially at high speeds. A good design means you can stop quickly and safely. So, a well-made foot brake helps you work smoothly and confidently.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Ensuring The Foot Brake Functions Effectively In Conjunction With The Spindle Speed On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake working well on a metal lathe, check it often. You should clean the brake parts regularly to remove dirt. Make sure the brake pads are not worn out and replace them if needed. Keep the area around the brake clear so it can work properly. Always test the brake before starting work to ensure it’s safe.”}}]}