Have you ever watched a metal lathe at work? It’s like magic! A simple piece of metal transforms into something amazing. The secret often lies in the spindle speed and the quill. These two parts play a big role in how well the lathe performs.

Imagine your favorite toy being made on one of these machines. The spindle speed helps control how fast the lathe spins the metal. If it spins too fast or too slow, the final piece might not be just right. It’s all about balance.

The quill, on the other hand, helps the cutting tool move correctly. It adjusts the depth of the cut. This movement is crucial for creating smooth and accurate shapes. What if I told you that even a small change in the spindle speed can lead to a completely different outcome?

Let’s dive deeper into how spindle speed and the metal lathe quill keep everything running smoothly. You’ll discover why knowing these parts can make you a better maker!

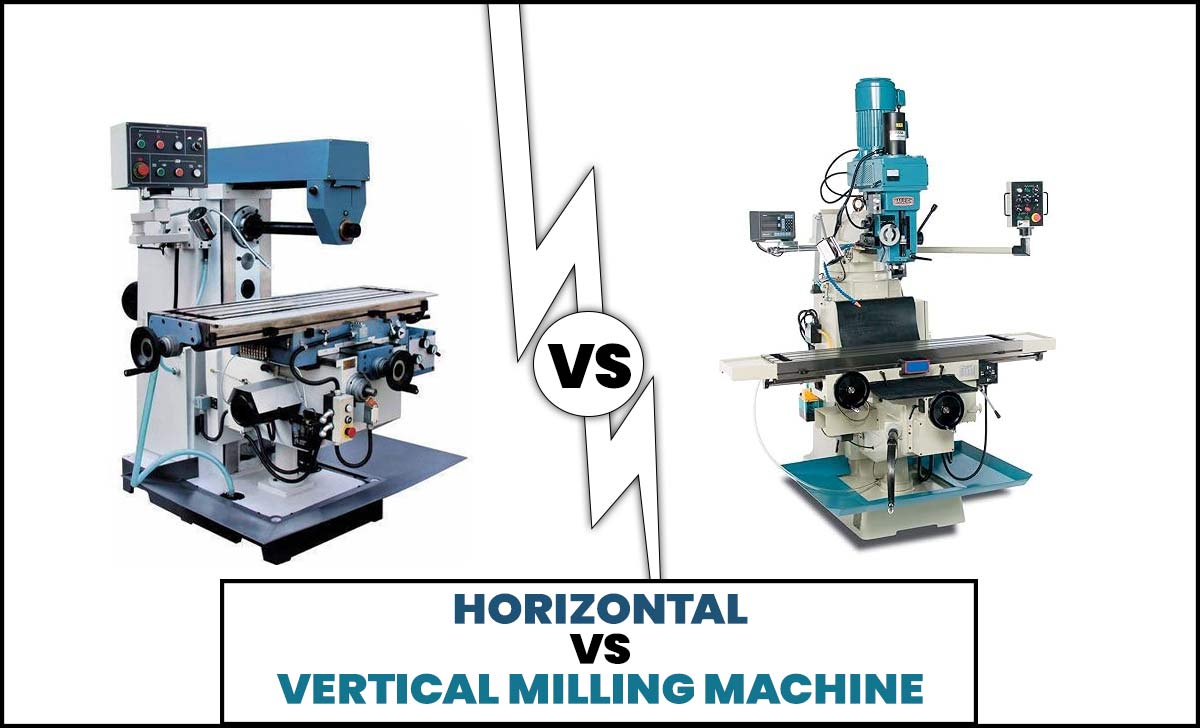

Understanding Spindle Speed On Metal Lathe Quill Mechanics Introduction When It Comes To Precision Machining, Especially In Metalworking, The Spindle Speed Of A Lathe Quill Plays A Crucial Role In Determining The Quality Of The Finished Product. Understanding How Spindle Speed Impacts Operations On A Metal Lathe Is Essential For Achieving Optimal Performance. What Is Spindle Speed? Spindle Speed Refers To The Rotational Speed Of The Lathe Spindle, Typically Measured In Revolutions Per Minute (Rpm). This Speed Is Integral To Various Machining Processes, As It Affects Cutting Efficiency, Tool Wear, And The Surface Finish Of The Workpiece. The Role Of The Quill In A Metal Lathe The Quill Is A Component That Houses The Tool Holder And Allows For Depth Adjustments During Machining. It Assists In The Precision Of Cutting Operations And Is Directly Influenced By The Spindle Speed. The Right Spindle Speed Can Enhance The Quill’S Performance, Thereby Improving The Overall Machining Process. Factors Influencing Spindle Speed Several Factors Determine The Optimal Spindle Speed For A Metal Lathe Quill: 1. **Material Type**: Different Metals Have Varying Properties That Require Specific Spindle Speeds For Efficient Cutting. 2. **Tool Geometry**: The Design And Condition Of Cutting Tools Affect How Fast They Can Effectively Cut Without Causing Damage. 3. **Cutting Depth And Feed Rate**: The Depth Of Cut And The Rate At Which The Tool Feeds Into The Material Are Pivotal In Deciding Spindle Speed. 4. **Type Of Operation**: Whether You Are Turning, Facing, Or Boring Affects The Required Spindle Speed. Calculating The Right Spindle Speed To Achieve The Best Results, Spindle Speed Should Be Calculated Based On The Material And Tooling Specifications. A General Formula Used Is: \[ \Text{Spindle Speed (Rpm)} = \Frac{\Text{Cutting Speed (Sfm)} \Times 12}{\Pi \Times \Text{Diameter (Inches)}} \] Here, Sfm (Surface Feet Per Minute) Depends On The Material Being Worked On, While The Diameter Refers To The Size Of The Workpiece. Conclusion Mastering Spindle Speed For A Metal Lathe Quill Is Vital For Optimal Machining Performance. The Right Speed Can Significantly Affect Cutting Efficiency, Tool Longevity, And Finish Quality. By Considering The Various Factors And Calculations Necessary For Determining Spindle Speed, Machinists Can Ensure That They Maximize Their Productivity And Achieve Excellent Results.

Spindle Speed Metal Lathe Quill

The spindle speed of a metal lathe quill is essential for precision in machining. Understanding how to adjust this speed allows for better control over the cutting process. It can prevent mistakes that cause defects in the final product. Did you know that the right spindle speed can enhance tool life? Choosing the wrong speed can lead to damage and wasted materials. Getting this aspect right is crucial for anyone aiming to become a skilled machinist.Understanding Spindle Speed

Definition of spindle speed in metal lathe operations. Importance of spindle speed in machining processes.Spindle speed is how fast the spindle on a metal lathe rotates. Think of it as the engine’s revs, but for cutting metal instead of racing! It’s crucial because the right speed helps create smooth cuts and shapes. If it’s too slow, your lathe might produce jagged edges. If it’s too fast, you can burn through your material like it’s butter. Finding just the right speed keeps your work neat and your tool from waving a white flag!

| Spindle Speed (RPM) | Application |

|---|---|

| 100-300 | Large, rough cuts |

| 400-800 | Medium finishing |

| 900-1200 | Fine, detailed work |

So, always remember: spindle speed matters! It makes a big difference in getting perfect results without extra drama.

Factors Affecting Spindle Speed

Material properties and their influence on spindle speed. Tool geometry and cutting conditions impacting spindle performance.Many factors can change spindle speed. First, material properties play a big role. Harder materials might need lower speeds to avoid blunt tools. Imagine trying to jog on a treadmill while it’s set to sprint—no fun! Next, tool geometry affects cutting. Sharp edges slice smoothly, while dull edges struggle, slowing things down. Lastly, cutting conditions, like speed and feed, directly impact performance. Think of it as baking: too fast, and you get a mess instead of a cake!

| Factor | Influence on Spindle Speed |

|---|---|

| Material Properties | Harder materials require slower speeds to prevent damage. |

| Tool Geometry | Sharp tools work better and faster than dull ones. |

| Cutting Conditions | Speed and feed adjustments affect overall performance. |

Determining the Optimal Spindle Speed

Methods for calculating the ideal spindle speed for various materials. Use of surface footage for spindle speed adjustments.Finding the right spindle speed can feel like hunting for buried treasure. Using the surface footage method helps a lot! It means you measure how fast the tool moves across the material’s surface. First, check your material type; different ones like to spin at different speeds. If you think of metal as a dance partner, keep the rhythm smooth! Use this quick formula:

| Material Type | Surface Feet per Minute (SFM) |

|---|---|

| Aluminum | 600-900 SFM |

| Steel | 100-300 SFM |

| Brass | 500-1200 SFM |

This table helps you choose the right speed. Remember, slow and steady sometimes wins the race, but don’t be afraid to add a little spin to keep it fun!

Adjusting the Quill for Proper Spindle Speed

Stepbystep guide to adjusting the quill on a lathe. Importance of quill alignment for accuracy and performance.Want to get your lathe spinning like a pro? First, check the quill alignment. If it’s off, your projects can turn out wobbly. To adjust the quill, follow these easy steps:

| Step | Action |

|---|---|

| 1 | Loosen the quill locking screw. |

| 2 | Align the quill with the spindle. |

| 3 | Tighten the screw again. |

| 4 | Check your work by spinning the spindle! |

Proper alignment ensures better accuracy and performance. This means no more wonky pieces flying off! Remember, a well-aligned quill is like a cake – if the layers are crooked, it’s just not as sweet. Happy lathe-ing!

Common Problems with Spindle Speed and Quill Alignment

Identification of frequent issues encountered during machining. Solutions to rectify spindle speed and quillrelated problems.Machining can be finicky, especially with spindle speed and quill alignment. Sometimes the spindle speed feels like a slow snail race. Other times, it spins faster than your dad trying to fix a lawnmower! Common issues include vibration, chatter, and misalignment. Luckily, solutions are at hand. Tighten loose parts, adjust bearings, and check for dirt or debris. Think of it as giving your metal lathe a spa day!

| Problem | Solution |

|---|---|

| Vibration | Tighten components |

| Chatter | Adjust feed rate |

| Misalignment | Realign quill |

Maintenance Tips for Spindle Speed Optimization

Regular checks and adjustments to maintain spindle performance. Best practices for lubricating and servicing the spindle and quill.To keep your spindle spinning smoothly, regular checks are essential. Look for signs of wear and tear. Adjust settings to ensure top performance. Lubrication is also key. Apply oil often to keep moving parts happy. Here are some easy tips:

- Check belts and pulleys for wear.

- Clean the spindle and quill regularly.

- Use the right lubricant for your machine.

- Inspect for any loose screws or bolts.

Following these steps will help your spindle speed run like new!

How do I lubricate a metal lathe quill?

Use a light machine oil and apply it to the quill’s moving parts. Wipe off any excess oil to prevent dust buildup.

Advanced Techniques for Achieving Precision

Techniques for finetuning spindle speed under various conditions. Use of digital readouts and monitoring systems for enhanced accuracy.To improve precision, experts fine-tune spindle speed for different tasks. This helps to create better finishes on metal. Digital readouts and monitoring systems can make precision even better. These tools provide real-time data. So, you can adjust as you work. Here are some techniques:

- Check the speed regularly.

- Use a digital readout for exact numbers.

- Adjust based on material type.

- Monitor temperature changes during the process.

How can I improve my spindle speed accuracy?

You can improve spindle speed accuracy by using digital tools for real-time monitoring. Regular checks and adjustments during your work will help achieve better results.

Conclusion

In summary, spindle speed affects how fast your metal lathe quill works. Choosing the right speed helps you create smooth and precise cuts. Remember, faster speeds can be risky with hard materials. You can improve your skills by experimenting with different speeds. Keep exploring more about lathes, and you’ll make better projects in no time!FAQs

What Factors Determine The Optimal Spindle Speed For Machining Different Materials On A Metal Lathe Quill?To find the best spindle speed for machining, you need to consider the type of material you’re using. Softer materials, like aluminum, work well at higher speeds. Harder materials, like steel, need slower speeds to avoid damage. You should also think about the tool shape and size. Finally, the machine’s power can limit how fast you can go.

How Do Variations In Spindle Speed Affect The Quality And Precision Of The Finished Workpiece On A Lathe?When you change the spindle speed on a lathe, it changes how fast the tool cuts the material. If the speed is too high, it can make the piece hot and rough. If it’s too low, the cut can be slow and not smooth. Finding the right speed helps make a nice, clean finish and keeps everything straight. This way, your finished piece looks good and fits well.

What Are The Common Methods For Adjusting Spindle Speed On A Metal Lathe, And How Do They Vary Between Different Lathe Models?To adjust the spindle speed on a metal lathe, you can use a lever, a dial, or buttons. Some lathes have a gearbox that lets you change speeds by turning a knob. Others have a digital display where you can set the speed. Different lathe models may use different methods, like a manual handle or an automatic system. Always choose the method that works best for your machine.

How Does The Spindle Speed Influence Tool Wear And Longevity During Metal Turning Operations?Spindle speed is how fast the tool spins while cutting metal. If you go too fast, the tool can wear out quickly. This happens because heat builds up and makes the tool hot. A slower speed can help the tool last longer. So, finding the right speed is important for keeping your tools in good shape.

What Are The Safety Considerations To Keep In Mind When Operating A Metal Lathe At High Spindle Speeds?When using a metal lathe at high speeds, keep safety in mind. Always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing. Check that tools and pieces are secure before starting. Finally, never stand directly in front of the machine while it runs.