Have you ever wondered how to choose the right milling cutter for t-slots? It can be tricky with so many options available. Selecting the perfect t-slot milling cutter can make a big difference in your projects.

Imagine you’re working on a cool project. You need a t-slot for your design, but you don’t know where to start. Choosing the wrong cutter might ruin your hard work. But don’t worry! This guide will help you find the best t-slot milling cutter for your needs.

Did you know that using the right cutter can save you time and money? It’s true! You can achieve smoother cuts and better results when you pick wisely. This selection guide will walk you through everything you need to know about t-slot milling cutters.

So, are you ready to dive in? Let’s explore the best ways to choose the right t-slot milling cutter!

T-Slot Milling Cutter Selection Guide: Choosing The Best Tools

Choosing the right T-slot milling cutter can make a big difference in your project. Different materials and cutter shapes can improve your work’s efficiency and quality. Did you know that the right cutter can save you time and money? Consider factors like cutter diameter, material hardness, and coating type for the best results. With the right tools, you can tackle tough tasks easily and achieve smooth, precise finishes.

Understanding T-Slot Milling Cutters

Definition and purpose of Tslot milling cutters. Common applications in machining and manufacturing.

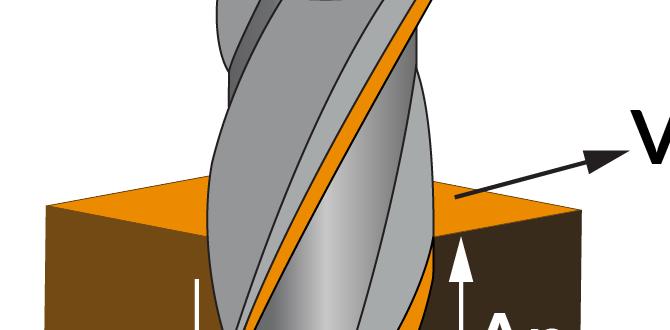

T-slot milling cutters are special tools designed to create T-shaped slots in materials. They work wonders in machining and manufacturing, making it easier to fit or attach other parts. Imagine them as the friendly chefs that cut into metals, preparing them for a perfect meal! Commonly used in industries like automotive and construction, these cutters help in making precise grooves and slots. Talk about multitasking! Here’s a quick look at their applications:

| Application | Description |

|---|---|

| Automotive Industry | Used for creating slots for assembling parts. |

| Furniture Manufacturing | Help make joints in wooden furniture. |

| Construction | Used to create slots for connectors and supports. |

In short, T-slot milling cutters are key players that help build things smoothly and quickly!

Types of T-Slot Milling Cutters

Description of different types (e.g., standard, long, and special). Advantages and disadvantages of each type.

There are three main types of t-slot milling cutters: standard, long, and special. Standard cutters are great for regular tasks and fit most machines. They are like your dependable umbrella—always there when it rains! However, they may not handle deep grooves well. Long cutters, on the other hand, reach further into those pesky grooves but can be quite tricky to manage, like a cat stuck in a tree! Finally, special cutters are tailor-made for unique jobs, offering super precise cuts, but they might cost a bit more, and not everyone has them in their toolbox. Here’s a handy comparison:

| Type | Advantages | Disadvantages |

|---|---|---|

| Standard | Versatile and widely available | May struggle with deep cuts |

| Long | Great for deep grooves | More challenging to handle |

| Special | Highly precise for unique tasks | Can be expensive and rare |

Key Specifications to Consider

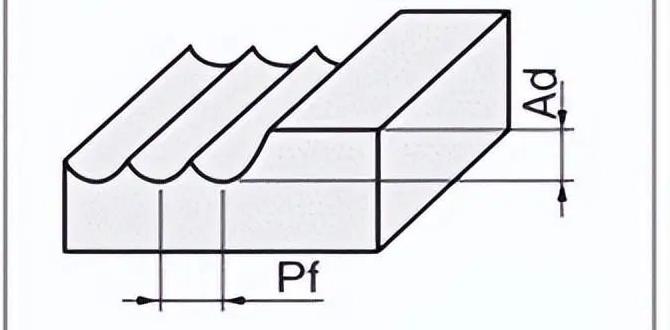

Important measurements (diameter, width, number of teeth). Impact of specifications on machining efficiency and quality.

Choosing the right t-slot milling cutter is like picking the best pizza topping—everyone has their favorites! Important measurements to consider include diameter, width, and number of teeth. A larger diameter can cut through tougher materials faster. Width can determine how much material you remove at once. More teeth usually mean a smoother finish but can slow down the process. Be smart and match your cutter’s specs to your project—it’s the secret sauce to machining success!

| Specification | Impact |

|---|---|

| Diameter | Faster cutting for tough materials |

| Width | Controls material removal rate |

| Number of Teeth | Affects finish and speed |

Choosing the Right Size and Shape

Guidelines for selecting the appropriate size for specific jobs. Influence of shape on cutting performance and application suitability.

Picking the right size and shape can feel like choosing what to wear on picture day. It’s important! The right size ensures the cutter fits your work. Too big? It’s like wearing clown shoes; you might trip over your tasks. Too small? You could miss the mark entirely!

Shape matters too. A flat shape can glide through materials, while a round one might get stuck, just like a cat in a cardboard box. For best results, look at the job specifics—to find that perfect match!

| Job Type | Recommended Size | Best Shape |

|---|---|---|

| Wood Cutting | Medium | Flat |

| Metal Finishing | Small | Round |

| Plastic Milling | Large | Flat |

Remember, choosing the right cutter is serious business. A wise choice not only saves time but also gives you a job well done. So get out there and make the right pick!

Best Practices for T-Slot Milling Cutter Usage

Tips for optimal cutting speeds and feeds. Maintenance and care to extend cutter life.

Proper use of a t-slot milling cutter helps achieve the best results. Start with the right cutting speeds and feeds. Use slower speeds for harder materials and faster for softer ones. Keep the feed rate steady to avoid damaging the cutter.

To extend cutter life, regular maintenance is key. Clean the cutter after each use. Inspect it for wear and replace as needed. Here are some important tips:

- Use proper cutting oil or coolant.

- Store in a dry, clean place.

- Avoid excessive heat buildup.

What is the best speed for t-slot milling cutters?

Finding the right speed is crucial. For mild steel, aim for 80-100 SFM. For aluminum, try 200-300 SFM. Always check your material for best results!

Common Mistakes to Avoid

Typical errors in cutter selection and application. Strategies for ensuring successful milling operations.

Choosing the wrong cutter can lead to big problems. Common mistakes include picking the wrong size or type of cutter. This can cause damage to both the cutter and the workpiece. Also, not adjusting settings can hurt the quality of the work. To avoid these mistakes, follow these tips:

- Know your materials well.

- Choose the right cutter for your task.

- Check your machine settings.

- Test on scrap material first.

Remember, careful planning leads to successful milling. Every detail counts in getting the job done right.

What are typical cutter selection errors?

Typical cutter selection errors include incorrect size or material type, overlooking the machine’s capabilities, and failing to consider the milling process. These mistakes can reduce efficiency and affect the quality of the final product.

Frequently Asked Questions

Addressing common queries related to Tslot milling cutters. Clarification of misconceptions in the selection process.

Many wonder how to choose the right T-slot milling cutter. Common questions often pop up, like, “Do I need special tools?” or “What size should I choose?” The answer is simple: select based on your project needs! A common misconception is that expensive cutters are always better. Not true! The best cutter fits your machine and material. Have fun with it! Finding the right cutter is like picking the best ice cream flavor—everyone has their favorite!

| Common Questions | Clarifications |

|---|---|

| Do I need special tools? | No, just the right cutter! |

| What size should I choose? | Match it to your project! |

| Are expensive cutters better? | Not necessarily, choose wisely! |

Resources for Further Learning

Recommended books, articles, and videos on Tslot milling cutters. Online forums and communities for ongoing support and advice.

Learning more about t-slot milling cutters is easy with great resources. Consider reading books that focus on machining techniques. Articles in trade magazines offer tips and techniques too. Videos on platforms like YouTube show the process in action. Join online forums to ask questions and get help from others who share your interests. Here are some useful resources:

- Books on milling techniques

- Articles in machining magazines

- YouTube tutorial videos

- Machining forums for expert advice

What are good resources for learning about T-slot milling cutters?

Look for books and articles that explain cutting tools and their uses. Watch videos to see cutters in action. Join forums to connect with other learners and experts.

Conclusion

In summary, choosing the right t-slot milling cutter is crucial for your projects. Consider the material, size, and type for best results. Remember, practice makes perfect! Check guidelines and charts for help. Don’t hesitate to explore more resources on this topic. You’ll become a pro in no time! Happy milling!

FAQs

Sure! Here Are Five Related Questions On The Topic Of T-Slot Milling Cutter Selection:

Sure! When choosing a t-slot milling cutter, you should think about the size you need. The size must fit the machine and the t-slot size. Next, look at the material. Different materials, like steel or aluminum, need different cutters. You should also consider how many teeth the cutter has. More teeth can help make a smoother cut. Finally, remember to check the cutter’s coating. A good coating helps it last longer.

Sure! Please share the question you need help with, and I’ll provide an answer.

What Are The Key Factors To Consider When Selecting A T-Slot Milling Cutter For Specific Machining Applications?

When choosing a t-slot milling cutter, think about the material you’re cutting. Different materials need different types of cutters. Check the size of the t-slot you need to create; it helps to pick the right cutter size. Also, consider the speed of your machine. A good cutter should work at the right speed for the best results. Finally, choose a cutter that feels comfortable for you to use.

How Do Different Materials Of T-Slot Milling Cutters, Such As High-Speed Steel And Carbide, Affect Performance And Durability?

T-slot milling cutters can be made from different materials, like high-speed steel and carbide. High-speed steel is strong and works well for simple jobs. But it may wear out faster than carbide. Carbide is tougher and lasts longer, making it better for hard materials. So, if you want your tools to last, carbide is often the best choice.

What Are The Typical Sizes And Geometries Of T-Slot Milling Cutters, And How Do They Influence Cutting Efficiency?

T-slot milling cutters come in different sizes and shapes. They can be small or large, and some are thick while others are thin. The size and shape help them cut better or faster. For example, a wider cutter can make a bigger groove in one pass, saving time. So, choosing the right cutter helps you work more efficiently.

How Can The Choice Of Cutting Speed And Feed Rate Impact The Effectiveness Of A T-Slot Milling Cutter?

The cutting speed is how fast the cutter moves while working. If it’s too fast, it can overheat and break. The feed rate is how quickly the cutter goes down into the metal. If you go too slow, it won’t cut well, but if you go too fast, it can ruin the part. Choosing the right speed and feed helps the cutter work better and last longer.

What Maintenance Practices Are Essential For Extending The Lifespan Of T-Slot Milling Cutters During Regular Use?

To help t-slot milling cutters last longer, you should keep them clean. After each use, wipe off any dirt or dust. Check the cutters for any damage, like chips or cracks, and fix them quickly. Always store the cutters in a safe place, like a toolbox, to prevent accidents. Finally, make sure to use them correctly to avoid unnecessary wear.