Have you ever wondered how metal lathes make precise parts? They do it with tools and a foot brake. A tool post metal lathe foot brake is an essential part of this machine. It helps the operator stop the lathe quickly and safely.

Think about it. You’re working on a complex project. Suddenly, you need to stop! If you have a good foot brake, you can halt the machine in an instant. This feature makes your work safer and more efficient.

Did you know that using the right foot brake can extend your lathe’s life? It reduces wear and tear on the machine. That means fewer repairs and more time creating. It’s a win-win for everyone!

Join us as we explore everything about the tool post metal lathe foot brake. You’ll discover why it’s so important and how to use it effectively. Get ready to dive into the fascinating world of metalworking!

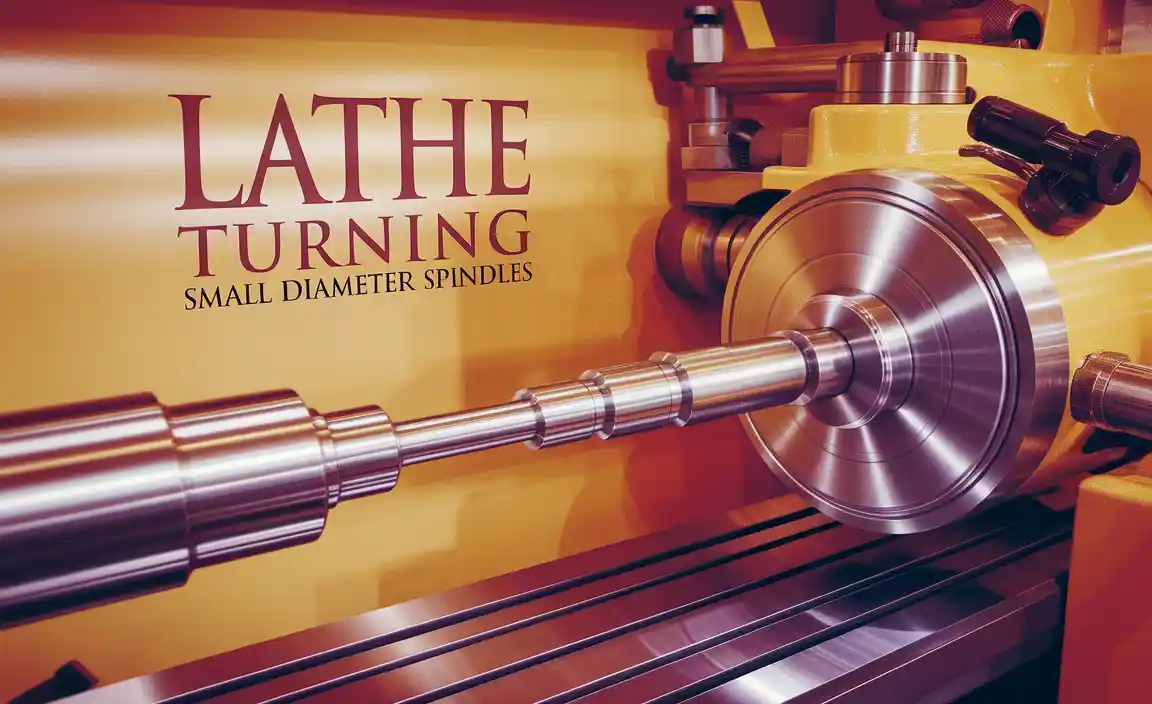

Tool Post Metal Lathe Foot Brake: Essential Safety Mechanism

Tool Post Metal Lathe Foot Brake

A tool post metal lathe foot brake is essential for safety and control. This device allows operators to quickly stop the lathe, preventing accidents. Imagine you’re working on a project when suddenly things go wrong. With a foot brake, you can easily halt everything, staying safe. Furthermore, it enhances your workflow by letting you keep both hands free for other tasks. Knowing how to use this simple yet effective tool can greatly improve your experience with metal lathes. Isn’t it fascinating how such a small tool can make a big difference?What is a Tool Post Metal Lathe Foot Brake?

Definition and purpose of a foot brake in metal lathes.. Differences between foot brakes and handoperated brakes..A foot brake for metal lathes is like a magic button for your feet. It helps stop the lathe quickly when you’re working. This is super useful because it lets you focus on your project without running around like a headless chicken. Unlike hand-operated brakes, which need your hands, a foot brake lets you keep both hands free for, you know, turning metal instead of tugging on levers.

| Feature | Foot Brake | Hand-Operated Brake |

|---|---|---|

| Operation | Feet | Hands |

| Hands-Free | Yes | No |

| Speed | Fast | Slower |

So remember, foot brakes offer safety and convenience while keeping your hands on the job. And hey, who doesn’t want to be a multitasking genius in the shop?

Importance of Foot Brakes in Metal Lathes

Enhancing operator safety during operation.. Improving precision and control in machining processes..Foot brakes play a crucial role in metal lathes. They help keep operators safe while working, making accidents less likely. Imagine trying to stop a puppy running wild—it’s better when you have an easy way to hit the brakes! These brakes also improve precision in machining, allowing for better control. With a solid foot brake, you can avoid that famous “oops” moment that happens when things go wrong. After all, no one wants to be the star of a blooper reel in the workshop!

| Benefits of Foot Brakes | Why It Matters |

|---|---|

| Enhances Safety | Reduces the risk of accidents. |

| Improves Control | Allows for precise machining adjustments. |

How to Install a Foot Brake on Your Metal Lathe

Stepbystep installation guide.. Common tools and materials needed for installation..Installing a foot brake on your metal lathe can feel like trying to teach a cat to fetch, but it’s easier than it sounds! Follow these simple steps to get rolling. First, gather your tools: a wrench, screwdriver, and some bolts. You’ll also need a foot brake kit. Next, read the instructions that come with it. Now, let’s get started! Follow the steps below:

| Step | Action |

|---|---|

| 1 | Turn off your lathe and unplug it. |

| 2 | Locate the spot for the foot brake. |

| 3 | Secure the brake in place with bolts. |

| 4 | Connect the brake wires properly. |

| 5 | Test the brake to make sure it works! |

And voilà! Your foot brake is ready for action. Remember, safety first! Always check your equipment before use. A well-installed foot brake will make your metal lathe experience smoother than butter on a hot pancake!

Maintenance Tips for Foot Brakes

Routine checks and maintenance schedules.. Troubleshooting common issues..Keeping foot brakes in tip-top shape is vital for safety and smooth operation. Start by checking the brake pads for wear and tear. It’s like a game of “Is this shoe ready for a marathon?” If you hear squeaking, it’s time for some TLC! Create a maintenance schedule—maybe once a month—just like you’d visit the dentist. And if things go wrong, troubles can often be traced back to dirt or rust. Cleanliness is next to brake-ness!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect brake pads | Monthly | Look for wear or damage |

| Clean components | Every 2 months | Remove dust and rust |

| Check for unusual noises | Regularly | Address issues early |

Remember, even the best foot brake can take a break! Handle problems early, and you’ll ensure a smooth ride every time.

Upgrading Your Metal Lathe with a Foot Brake

Benefits of upgrading from manual brake systems.. Considerations for selecting the right foot brake for your lathe..Upgrading to a foot brake for your lathe can make your work easier and safer. Manual brakes can be a hassle. Imagine trying to stop your lathe with your hand while juggling tools—yikes! A foot brake allows you to stop the machine quickly, giving you more control. Plus, it frees up your hands for other tasks. When choosing a foot brake, think about the size, type, and compatibility with your machine. A well-chosen brake can make all the difference!

| Considerations | Description |

|---|---|

| Size | Make sure it fits your lathe. |

| Type | Choose between mechanical and hydraulic options. |

| Compatibility | Check if it works with your current setup. |

Safety Practices When Using Foot Brakes

Best practices for safe operation.. Tips for training operators on effective foot brake use..Using a foot brake properly is key to staying safe while working with a metal lathe. First, always wear safety gear like goggles and sturdy shoes. This protects you from flying debris, which can feel like getting hit by a tiny superhero! Training workers on effective use is crucial. Show them how to apply the brake gently and consistently. Practice makes perfect—just like learning to ride a bike! Always keep the area clear to avoid tripping over tools. Here are some quick tips:

| Tip | Description |

|---|---|

| Wear Safety Gear | Always use goggles and protective footwear. |

| Train Users | Give hands-on training for the best brake control. |

| Keep Area Clean | A tidy space equals fewer accidents. |

These practices help keep everyone safe. Remember, better safe than sorry—it’s much harder to fix a mistake than to avoid it in the first place!

Common Mistakes to Avoid with Foot Brakes

Identifying and correcting improper usage.. Preventative measures to avoid wear and tear..Using foot brakes incorrectly can lead to accidents. Always check your foot position before using them. One common mistake is pressing too hard; this can cause wear on the brake. To avoid this, practice soft, controlled presses. Preventative measures are key! Regular maintenance helps too. Make sure to clean any dust or debris that might gather. Here’s a handy tip: keep your foot brake area tidy—no one likes tripping over tools!

| Common Mistakes | Prevention Tips |

|---|---|

| Pressing too hard | Practice soft presses |

| Ignoring maintenance | Regularly clean brake area |

| Foot placement issues | Check before using |

Conclusion

In conclusion, a tool post metal lathe foot brake is essential for safe and efficient operation. It allows you to stop your lathe quickly. Understanding how it works can improve your skills. We encourage you to explore more about lathe safety and maintenance. You can find helpful guides online to enhance your knowledge and skills. Stay safe and keep learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Foot Brakes:Sure! Tool post metal lathe foot brakes help you stop the lathe easily. They are like a pedal you push with your foot. This keeps your hands free to work on your project. You can slow down or stop the machine safely. It’s important to use the brake to stay safe while making things!

Sure! Please provide the question you’d like me to answer.

What Are The Advantages Of Using A Foot Brake On A Tool Post Metal Lathe Compared To Traditional Hand-Operated Brakes?Using a foot brake on a tool post metal lathe lets you stop the machine quickly without using your hands. This means you can keep your hands free to work on your project. It’s also easier for you to control the lathe while standing, making your work safer. Plus, you can stay focused, as you don’t need to reach for a hand lever. Overall, it makes machining smoother and more comfortable!

How Does A Foot-Operated Brake Mechanism Enhance Safety And Efficiency During Metal Lathe Operations?A foot-operated brake lets you stop the lathe quickly using your foot. This keeps your hands free to work safely. It helps prevent accidents because you can stop fast if something goes wrong. It also makes it easier for you to control the machine while you’re busy. This means you can work quicker and stay safe at the same time!

What Are The Key Components Of A Foot Brake System In A Tool Post Metal Lathe, And How Do They Function Together?A foot brake system in a tool post metal lathe has a few important parts. First, there’s the foot pedal you push. When you press it, the brake line sends a signal to the brake mechanism. This mechanism then clamps down on the lathe’s spinning parts, slowing them down. Together, these parts help you stop the lathe safely and quickly using just your foot.

How Can A Metal Lathe Operator Effectively Maintain And Troubleshoot Foot Brake Systems To Ensure Optimal Performance?To keep the foot brake working well, you should check it often. Look for dirt or rust that could block it. You can clean any grime you see with a cloth. If the brake feels loose or does not work, ask for help or look for a broken part. Always wear safety gear while working!

Are There Specific Design Considerations To Keep In Mind When Installing A Foot Brake On A Custom Or Existing Tool Post Metal Lathe?When installing a foot brake on a metal lathe, think about safety first. Make sure the brake is easy to reach with your foot. You want it to stop the lathe quickly if needed. Check that the brake fits well with the lathe without getting in the way. Finally, test the brake to make sure it works properly before using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Foot Brakes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Tool post metal lathe foot brakes help you stop the lathe easily. They are like a pedal you push with your foot. This keeps your hands free to work on your project. You can slow down or stop the machine safely. It’s important to use the brake to stay safe while making things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Foot Brake On A Tool Post Metal Lathe Compared To Traditional Hand-Operated Brakes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a foot brake on a tool post metal lathe lets you stop the machine quickly without using your hands. This means you can keep your hands free to work on your project. It’s also easier for you to control the lathe while standing, making your work safer. Plus, you can stay focused, as you don’t need to reach for a hand lever. Overall, it makes machining smoother and more comfortable!”}},{“@type”: “Question”,”name”: “How Does A Foot-Operated Brake Mechanism Enhance Safety And Efficiency During Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot-operated brake lets you stop the lathe quickly using your foot. This keeps your hands free to work safely. It helps prevent accidents because you can stop fast if something goes wrong. It also makes it easier for you to control the machine while you’re busy. This means you can work quicker and stay safe at the same time!”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Foot Brake System In A Tool Post Metal Lathe, And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot brake system in a tool post metal lathe has a few important parts. First, there’s the foot pedal you push. When you press it, the brake line sends a signal to the brake mechanism. This mechanism then clamps down on the lathe’s spinning parts, slowing them down. Together, these parts help you stop the lathe safely and quickly using just your foot.”}},{“@type”: “Question”,”name”: “How Can A Metal Lathe Operator Effectively Maintain And Troubleshoot Foot Brake Systems To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake working well, you should check it often. Look for dirt or rust that could block it. You can clean any grime you see with a cloth. If the brake feels loose or does not work, ask for help or look for a broken part. Always wear safety gear while working!”}},{“@type”: “Question”,”name”: “Are There Specific Design Considerations To Keep In Mind When Installing A Foot Brake On A Custom Or Existing Tool Post Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When installing a foot brake on a metal lathe, think about safety first. Make sure the brake is easy to reach with your foot. You want it to stop the lathe quickly if needed. Check that the brake fits well with the lathe without getting in the way. Finally, test the brake to make sure it works properly before using the lathe.”}}]}