Turret lathes have been a staple in the manufacturing industry for over a century, revolutionizing how metal parts are produced. These machines have stood the test of time, with their design and functionality remaining relatively unchanged since their invention.

However, many people outside the manufacturing world may not be familiar with a turret lathe and its operation. Here, we will delve into conventional turret lathes, exploring their history, components, and how they work to create precise and intricate metal parts, whether you are a seasoned engineer or simply curious about the inner workings of these machines.

About Turret Lathe

A turret lathe is a type of machine tool overhang handy for metalworking. It has specific designs

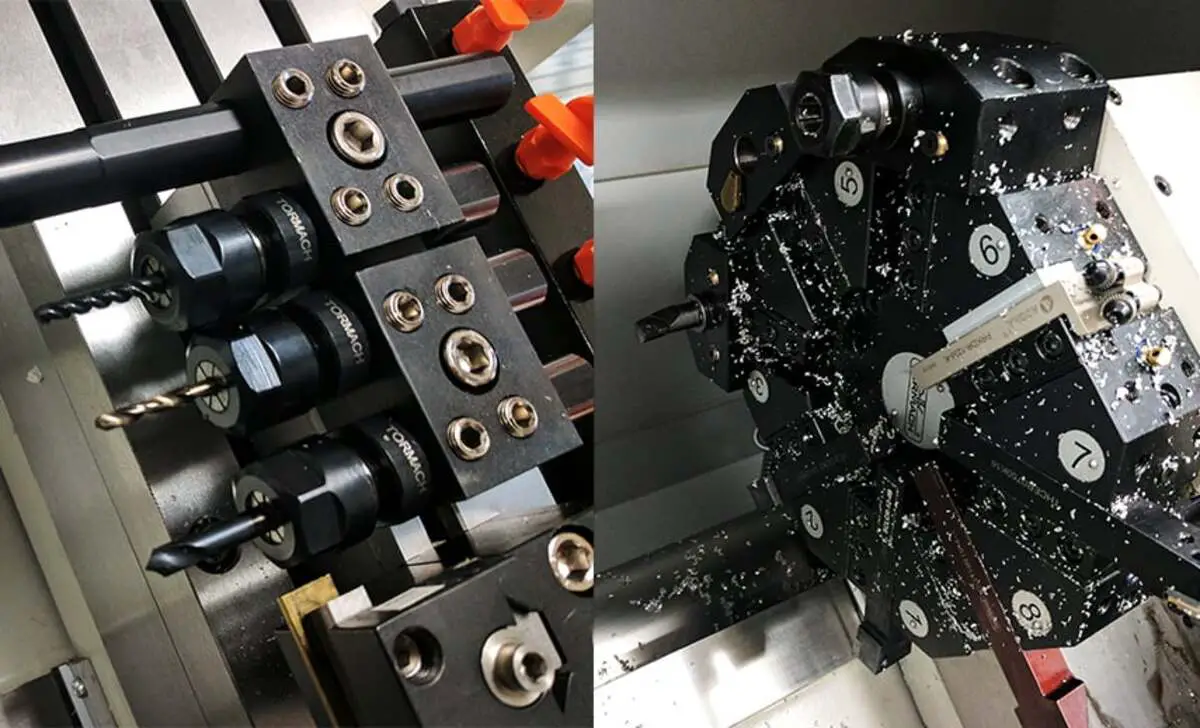

to perform a range of operations on a workpiece, such as turning, drilling, boring, and threading. The turret lathe gets its name from the turret, which holds multiple cutting process tools that can be rapidly indexed and positioned for various operations.

This allows for efficient and precise machining. Turret lathes are commonly handy in manufacturing processes requiring high production rates and accuracy. They are versatile machines that can handle various workpiece sizes and shapes. With their advanced features and capabilities, turret lathes are crucial in modern metalworking industries.

History And Evolution Of Turret Lathes

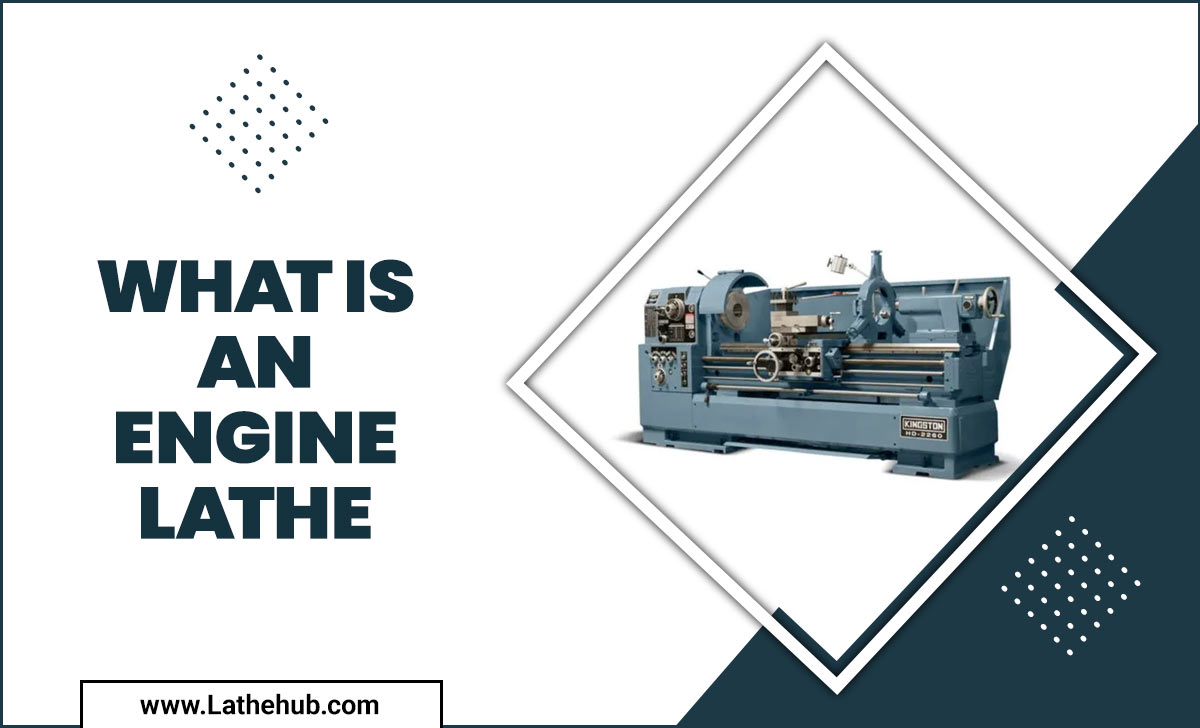

The turret lathe, also known as a capstan lathe or engine lathe, has a rich history of evolution and innovation. Initially, manual turret lathes were handy for the repetitive production of duplicate parts, where tool changes were time-consuming and labour-intensive. However, with advancements in technology, turret lathes have undergone significant transformations.

The adoption of turret head tooling allowed for faster tool changes, improving efficiency and reducing machining time. Additionally, we introduced high-precision spindle speed control, which enhances machining accuracy and improves workpiece quality.

3 Types Of Turret Lathes

One of the key advantages of the turret lathe is its ability to perform roughing and finishing operations in a single setup. This eliminates the need for multiple machines or tool changes, streamlining the production process and improving overall efficiency. Additionally, the precision and repeatability of the turret lathe ensure consistent and accurate results, which is crucial for industries like aerospace and automotive, where tight tolerances are critical.

1.Horizontal Turret Lathe

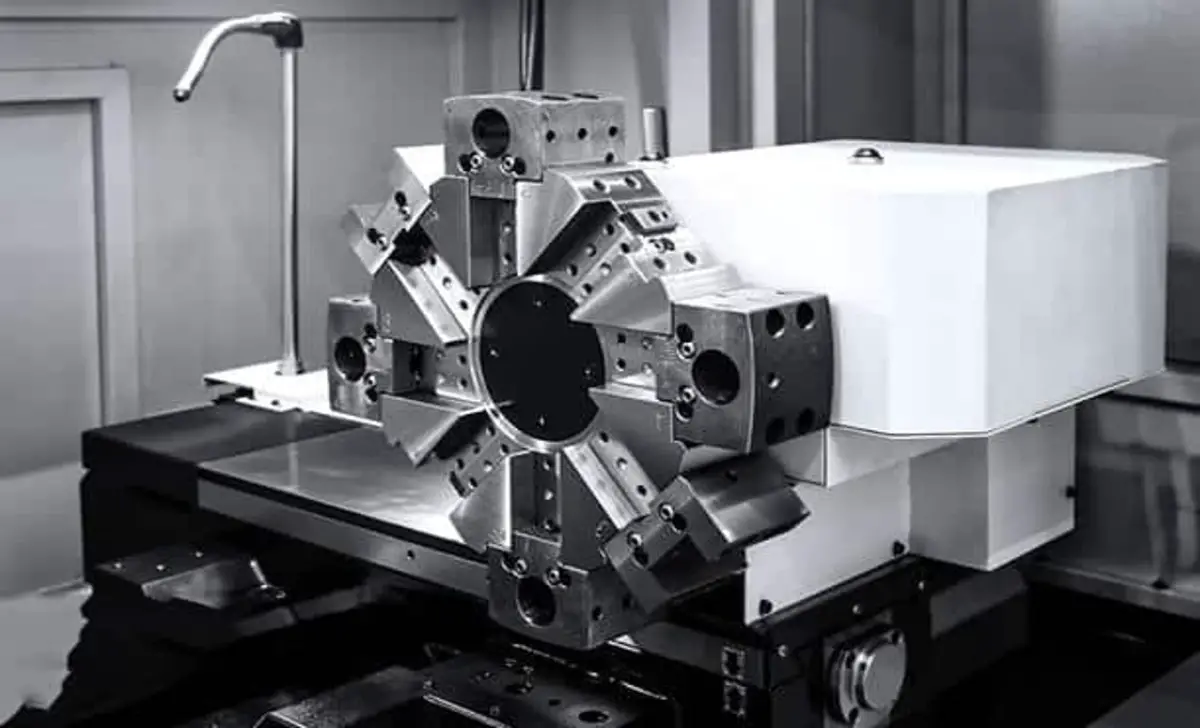

Horizontal turret lathes are popular for their versatility and heavy-duty capabilities. They feature a turret head mounted on a ram, allowing cutting operations on large workpieces. The turret head holds multiple cutting tools, enabling the machine to perform different operations without requiring manual tool changes.

One of the key features of horizontal turret lathes is the indexable tool holder, which offers flexibility in tooling options. The spindle speed control of horizontal turret lathes allows for high-precision machining, making them ideal for applications that require tight tolerances.

2.Vertical Turret Lathe

Vertical turret lathes, also known as vertical lathes, are designed for machining smaller workpieces with precision. Unlike horizontal turret lathes, the turret head of vertical lathes is mounted on a vertical axis. This design allows for better accessibility to the workpiece during cutting operations.

Vertical turret lathes have servo-electric motor-driven clamps for tool post-clamping, ensuring efficient machining with minimal tool movement. The hexagonal turret head of vertical lathes provides multiple tooling options, allowing for diverse machining requirements. The feed rate control of vertical turret lathes ensures smooth machining of workpieces with varying diameters.

3.Twin Turret Lathe

Twin turret lathes have specific designs for simultaneous turning operations, increasing productivity in mass production. These lathes feature two turret tool heads, allowing two different cutting operations to be performed simultaneously.

The electric headstock clutches of twin turret lathes enable quick tool changes, reducing setup time and increasing efficiency. With a type of drive system, they offer high precision in machining multiple workpieces at different initial positions. Twin turret lathes, or turning centres, are widely handy in industries requiring high-volume production and precise machining.

Exploring CNC Turret Lathes

In recent years, the introduction of computer numerical control (CNC) technology has revolutionized turret lathe operations. CNC turret lathes use numerical control to control cutting operations precisely, reducing the need for manual intervention. These lathes feature a single cutting tool controlled by a turret, which can perform versatile turning, facing, and drilling operations.

CNC turret lathes‘ lightweight, indexable automatic tool holder allows different cutting tools, optimizing machining processes. CNC turret lathes are popular for their high-speed spindle, allowing for efficient machining of workpieces of varying diameters. These lathes have become integral to mass production industries, offering accurate and repeatable machining operations in less time.

Key Considerations When Operating Turret Lathes

The turret lathe derives its name from the turret, a rotating additional tools holder mounted on the machine’s bed. This configuration enables rapid tool changes and eliminates the need for manual repositioning, thereby increasing productivity and reducing downtime. The turret can hold multiple cutting tools simultaneously, allowing for a wide range of operations such as turning, drilling, boring, and threading.

Safety Measures For Using Turret Lathes

Safety is of utmost importance when using turret lathes. Proper chuck clamping is essential for securely holding workpieces during machining operations. Clamping tools and attachments securely onto the turret head is crucial for safe machining processes.

Turret lathe operators should also ensure correct saddle and ram positioning for stable cutting operations. Observing torque and speed control successive axial tool holder settings prevents BOT tool holders’ post clamps from releasing during machining. These safety measures protect the machine operator and contribute to the turret lathe’s longevity and efficiency.

How Has The Use Of Turret Lathes Evolved?

The use of turret lathes has evolved significantly, thanks to technological advancements and changing industry demands. Initially, turret lathes were primarily handy for the repetitive production of duplicate parts, where manual tool changes were time-consuming.

However, introducing numerical control and automated processes has revolutionized turret lathe operations. Today, turret lathes are used in various industries for high-volume production and smaller-scale projects. The repetitive production capabilities of turret lathes and their precision and efficiency make them an invaluable tool in the manufacturing sector.

Maintenance And Troubleshooting Of Turret Lathes

The turret lathe is known for its high spindle speeds, enabling it to efficiently machine materials such as metals, plastics, and composites. With advanced control systems and precision engineering, it can achieve tight tolerances and smooth surface finishes, meeting the stringent requirements of modern manufacturing processes. Here are Maintenance and Troubleshooting of Turret Lathes:

- Lubricate regularly to ensure smooth operation.

- Check and adjust tooling for proper alignment

- Inspect and clean the turret regularly to prevent debris buildup

- Monitor and adjust cutting parameters for optimal performance

- Troubleshoot common issues such as tool breakage or chatter

- Regularly inspect and replace worn or damaged parts

- Keep a log of maintenance activities and repairs for future reference

- Train operators on the safe and proper use of the turret lathe

Conclusion

Turret lathe is a versatile machine that has evolved to meet the changing needs of industries. With various types available, including horizontal, vertical, and twin turret dedicated turret lathe, these machines offer precision and efficiency in metalworking operations. CNC turret lathes became popular as technology advanced, providing automated control and increased productivity.

To ensure optimal performance, operating a turret lathe requires adherence to safety measures and regular maintenance. Over the years, the American turret lathe has proven to be a reliable and essential separate tool setup in manufacturing. So, whether you’re a beginner or an expert in machining, understanding turret larger convertible lathe and their working principles can greatly benefit your projects.

Frequently Asked Questions

1.What Is The Difference Between A Turret Lathe And A Regular Lathe?

Ans: Turret lathes differ from regular toolroom lathes in several ways. Turret bench lathes have a rotating tool holder that can hold multiple tools, enabling faster changes. Regular lathes usually have only one cutting tool and require manual changes.

2.What Are The Advantages Of A Turret Lathe?

Ans: Turret’s earlier lathes offer several advantages. They eliminate the need for machine resetting, allowing for multiple operations. These machines are highly efficient, reducing production time and costs.

3.What Is A Turret On A Lathe?

Ans: A turret on a lathe serves as a tool holder, allowing for the use of multiple cutting tools. It enables quick and efficient tool changes during machining, increasing productivity and accuracy.

4.What Tool Cannot Be Used On A Turret Lathe?

Ans: Boring bars longer than the machine’s capacity and large-diameter cutters should not be used on a turret lathe. It is important to select appropriate cutting tools and adhere to safety guidelines for optimal performance.

5.How Does A Turret Lathe Work?

Ans: A turret lathe operates by using a tooling turret instead of a tailstock. Multiple cutting tools in the turret enable faster and more efficient machining. When a tool is selected, the gun turret rotates to position it before the workpiece.