Have you ever wondered how machines make perfect shapes from metal? The secret often lies in a variable speed metal lathe. This tool can spin metal at different speeds to create everything from car parts to art. But what happens when we automate that process? Imagine a lathe that does all the work for you!

Automation in metalworking is not just a trend; it’s a game-changer. With each advance in technology, we discover better ways to work. Variable speed metal lathe automation allows for smoother operations and more precise creations. It means less human error and more time for creativity.

Did you know that factories using automation can increase their production by over 30%? That’s a surprising fact! Imagine your next project completed faster and with better results. Could this be the future of metalworking? Let’s take a closer look at how this exciting technology is shaping the industry.

Variable Speed Metal Lathe Automation: Enhancing Precision And Efficiency

Understanding Variable Speed Metal Lathe Automation

Variable speed metal lathe automation is changing how we work with metal. Imagine a machine that adjusts its speed on the fly, allowing for smoother cuts and better precision. This technology helps in making parts faster and with less human error. Did you know that some lathes can even learn from previous tasks? They can adapt to different metals, making them very versatile. With automation, the future of metalworking looks bright and efficient. Why not explore how this innovation could enhance your projects?Understanding Variable Speed Metal Lathes

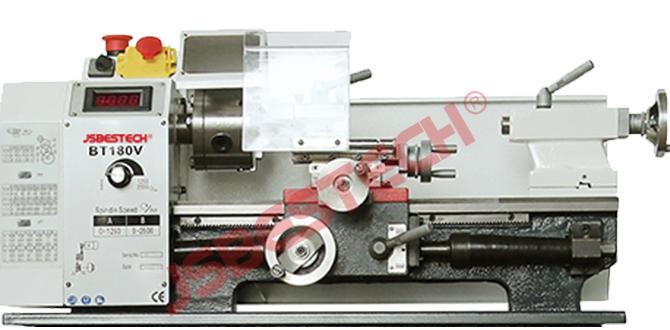

Definition and key features. Advantages of variable speed control.A variable speed metal lathe is a machine that shapes metal by rotating it. It offers key features like adjustable speeds and precise controls. With variable speed control, users can change the rotation speed quickly and easily. This adaptability brings several benefits:

- Better precision: Adjust speeds for different materials.

- Improved efficiency: Complete jobs faster.

- Reduced wear: Less stress on tools means longer life.

Using a variable speed lathe can make metalworking not only easier but also more fun!

What are the advantages of variable speed metal lathes?

The advantages include better precision, increased efficiency, and reduced tool wear. These benefits make them great for both hobbyists and professionals.

Importance of Automation in Metalworking

Enhancing precision and efficiency. Reducing human error and labor costs.Automation in metalworking is like having a superhero sidekick. It boosts precision and efficiency, making sure parts come out just right every time. You know, like when you bake cookies and always get the perfect shape—no more wonky edges! Plus, it cuts down on human mistakes and lowers labor costs. Who needs extra stress? With machines doing the heavy lifting, workers can relax a bit and focus on the fun stuff.

| Benefits of Automation | Details |

|---|---|

| Precision | Consistent quality in every part |

| Efficiency | Faster production times |

| Reduced Human Error | Fewer mistakes, more smiles! |

| Lower Labor Costs | Save money, buy more snacks! |

In the world of metalworking, automation is no laughing matter—unless you’re the one saving time and money!

Key Components of Automated Variable Speed Lathes

Motor and control systems. Sensors and feedback mechanisms.Automated variable speed lathes rely on key components to function well. This includes motor and control systems that adjust the speed based on material type. They also use sensors and feedback mechanisms to monitor performance. These tools help keep everything running smoothly. Here are the main parts:

- Powerful motors control speed.

- Control systems provide precise adjustments.

- Sensors track position and speed.

- Feedback systems ensure accuracy.

What are the benefits of automated variable speed lathes?

Automated variable speed lathes improve efficiency and accuracy. They reduce waste and save time, leading to better results in less time. This makes them great for professionals and hobbyists alike.

Choosing the Right Variable Speed Metal Lathe

Factors to consider (size, capacity, features). Top brands and models.Picking the right variable speed metal lathe can feel like choosing a pet—you want to make sure it fits your space and lifestyle. First, look at size and capacity; make sure your new tool can handle your projects without hogging all the room. Next, consider important features, like digital speed control or automatic feed, which make life a whole lot easier. Some top brands to check out include Jet, Grizzly, and Shop Fox. Their models are like the superheroes of lathes—powerful and dependable! Here’s a quick table to help you weigh your options:

| Brand | Model | Best Feature |

|---|---|---|

| Jet | JWL-1442 | Variable speed control |

| Grizzly | G0766 | High torque motor |

| Shop Fox | W1837 | Easy-to-read display |

Integrating Automation into Existing Metalworking Processes

Steps for retrofitting a manual lathe. Software and tools for automation.Automation can make metalworking much easier. Retrofitting a manual lathe is like giving it a cool makeover! First, swap out old parts with newer ones to make it more efficient. You’ll need sensors and motors to help your lathe do its thing without you. Next, use software that tells the lathe what to do. This makes it faster and more accurate. Here’s a fun table to show some steps and tools you might need:

| Steps | Tools Required |

|---|---|

| 1. Remove Old Parts | Wrench, Screwdriver |

| 2. Install New Motors | Electric Motor, Mounting Kit |

| 3. Add Sensors | Proximity Sensors |

| 4. Set Up Software | Automation Software |

Once everything is set up, your lathe can work faster than a cheetah on roller skates! With automation, you save time and boost productivity, giving you more time for coffee breaks and snacks!

Benefits of Automating Your Metal Lathe

Increased production rates. Enhanced product consistency and quality.Automating your metal lathe can bring many benefits. First, it can increase production rates. This means you make more parts in less time. Second, automation helps enhance product consistency and quality. Each piece comes out the same, which is important for customers. This can lead to more sales and happy clients!

What are the main benefits of automating a metal lathe?

Automation boosts speed and makes products more reliable. You can produce items quickly and with fewer mistakes. This saves time and money!

Here are some key points:

- Faster production.

- Better quality control.

- Less manual labor needed.

Common Challenges in Variable Speed Lathe Automation

Technical issues and troubleshooting. Training and skill development for operators.Automation is exciting, but it comes with some tricky hurdles. One of the biggest challenges is dealing with technical issues. Sometimes, machines just don’t want to cooperate. It’s like a toddler refusing to eat vegetables! Operators need solid training too. If they can’t figure out the controls, the lathe becomes a very expensive paperweight. Thankfully, good training programs can help. Here’s a quick look at common challenges:

| Challenge | Solution |

|---|---|

| Technical Glitches | Regular maintenance and updates |

| Operator Skills | Hands-on training and workshops |

Future Trends in Metal Lathe Automation

Advancements in machine learning and IoT. Sustainability and green manufacturing practices.Exciting changes are coming in the world of metal lathe automation! With machine learning and the Internet of Things (IoT), machines will learn faster than ever. Imagine a lathe that talks to you about what it needs—like a metalworking buddy!

Also, let’s not forget about our planet. More companies are focusing on sustainability. By using eco-friendly practices, they save energy and materials. Who knew making things could help the Earth?

| Trends | Description |

|---|---|

| Machine Learning | Machines that get smarter and faster with each use! |

| IoT Integration | Connecting machines for better teamwork! |

| Sustainability | Green practices for a healthier planet! |

So, if you’re dreaming of a metal lathe that can both craft and care for our environment, the future looks bright and shiny!

Conclusion

In conclusion, variable speed metal lathe automation can greatly improve your machining projects. It offers precision and flexibility, making your work easier. You can adjust speeds for different tasks, leading to better results. If you’re interested, explore more about machine settings and automation tools. This knowledge will help you take your skills to the next level!FAQs

What Are The Key Benefits Of Automating A Variable Speed Metal Lathe In Industrial Applications?Automating a variable speed metal lathe makes it easier to work. It helps you create parts faster and more accurately. You don’t have to watch it all the time, so you can do other tasks. It also reduces mistakes, which saves time and materials. This means you can make more products and earn more money!

How Does Automation Improve Precision And Consistency In Machining Processes On A Variable Speed Metal Lathe?Automation helps make machining more precise and consistent. With machines doing the work, you get exact cuts every time. They follow set patterns, so mistakes are less likely. This means your pieces are all the same size and shape. Overall, you can trust the machine to do the job right!

What Types Of Sensors And Control Systems Are Commonly Used In The Automation Of Variable Speed Metal Lathes?In variable speed metal lathes, we often use sensors and control systems to help them work better. Sensors can detect speed and position, allowing the lathe to adjust how fast it spins. Control systems then use this information to change the speed or direction of the lathe. This makes it easier to shape metal accurately and safely. Together, these tools help make metalworking faster and more precise.

What Challenges Might Manufacturers Face When Integrating Automation Technologies Into Existing Variable Speed Metal Lathe Setups?Manufacturers can face many challenges when adding automation to metal lathes. First, the old machines might not work well with new technology. Next, training workers to use the new systems can take time and effort. We also need to make sure the new parts fit properly. Finally, spending money on new equipment can be tough for some companies.

How Can Software Advancements Enhance The Automation Capabilities Of Variable Speed Metal Lathes?Software advancements can make variable speed metal lathes work better and faster. With new programs, these machines can automatically change speeds for different tasks. This means you don’t have to do it manually, saving time and energy. We can also make the machines learn from their work, so they improve over time. This all helps us create better products with less effort!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Automating A Variable Speed Metal Lathe In Industrial Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating a variable speed metal lathe makes it easier to work. It helps you create parts faster and more accurately. You don’t have to watch it all the time, so you can do other tasks. It also reduces mistakes, which saves time and materials. This means you can make more products and earn more money!”}},{“@type”: “Question”,”name”: “How Does Automation Improve Precision And Consistency In Machining Processes On A Variable Speed Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation helps make machining more precise and consistent. With machines doing the work, you get exact cuts every time. They follow set patterns, so mistakes are less likely. This means your pieces are all the same size and shape. Overall, you can trust the machine to do the job right!”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Control Systems Are Commonly Used In The Automation Of Variable Speed Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In variable speed metal lathes, we often use sensors and control systems to help them work better. Sensors can detect speed and position, allowing the lathe to adjust how fast it spins. Control systems then use this information to change the speed or direction of the lathe. This makes it easier to shape metal accurately and safely. Together, these tools help make metalworking faster and more precise.”}},{“@type”: “Question”,”name”: “What Challenges Might Manufacturers Face When Integrating Automation Technologies Into Existing Variable Speed Metal Lathe Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manufacturers can face many challenges when adding automation to metal lathes. First, the old machines might not work well with new technology. Next, training workers to use the new systems can take time and effort. We also need to make sure the new parts fit properly. Finally, spending money on new equipment can be tough for some companies.”}},{“@type”: “Question”,”name”: “How Can Software Advancements Enhance The Automation Capabilities Of Variable Speed Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Software advancements can make variable speed metal lathes work better and faster. With new programs, these machines can automatically change speeds for different tasks. This means you don’t have to do it manually, saving time and energy. We can also make the machines learn from their work, so they improve over time. This all helps us create better products with less effort!”}}]}