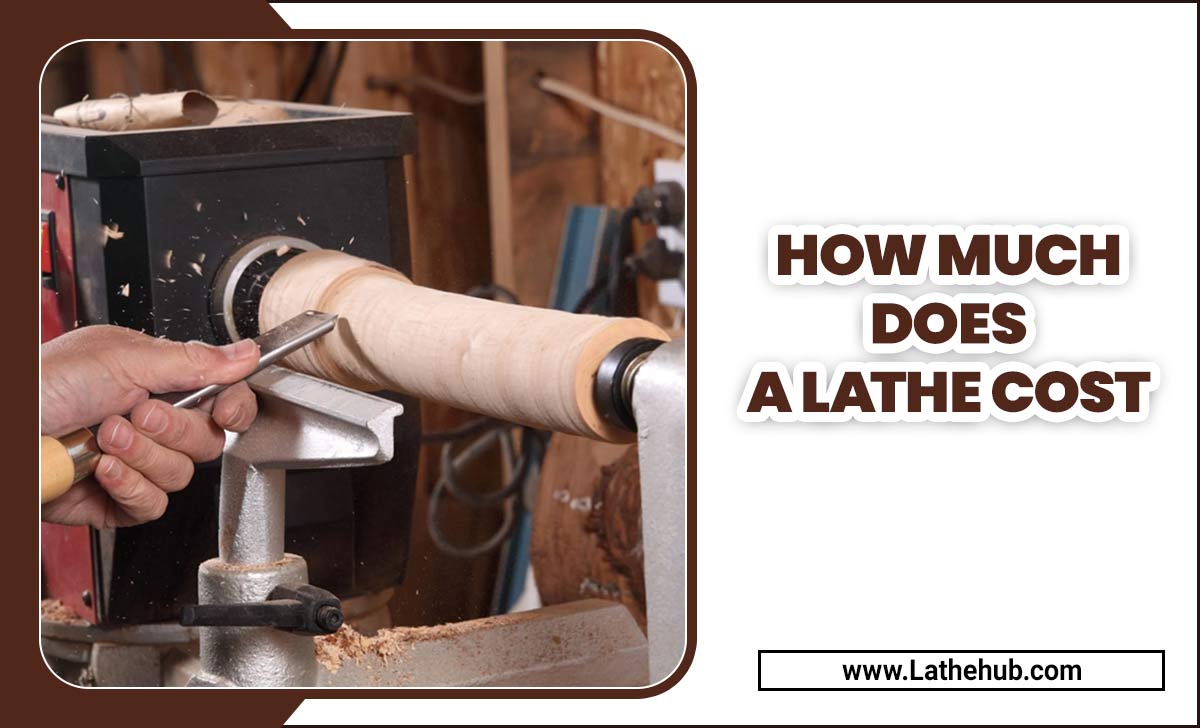

Wood lathes have been a staple tool in woodworking for centuries, allowing craftsmen to shape and turn wood into beautiful and intricate art pieces.

However, with the rise of modern technology and the increasing demand for metalworking, many have questioned whether a wood lathe can also be handy for metal. This may seem simple, but the answer is not as straightforward.

Here, we will explore the possibilities of a wood lathe being handy for metal, the factors to consider when turning metal on a wood lathe, and the pros and cons of using a wood lathe for metal work. So, let’s dive in and find out if you can use your trusty old wood lathe for your next metal project.

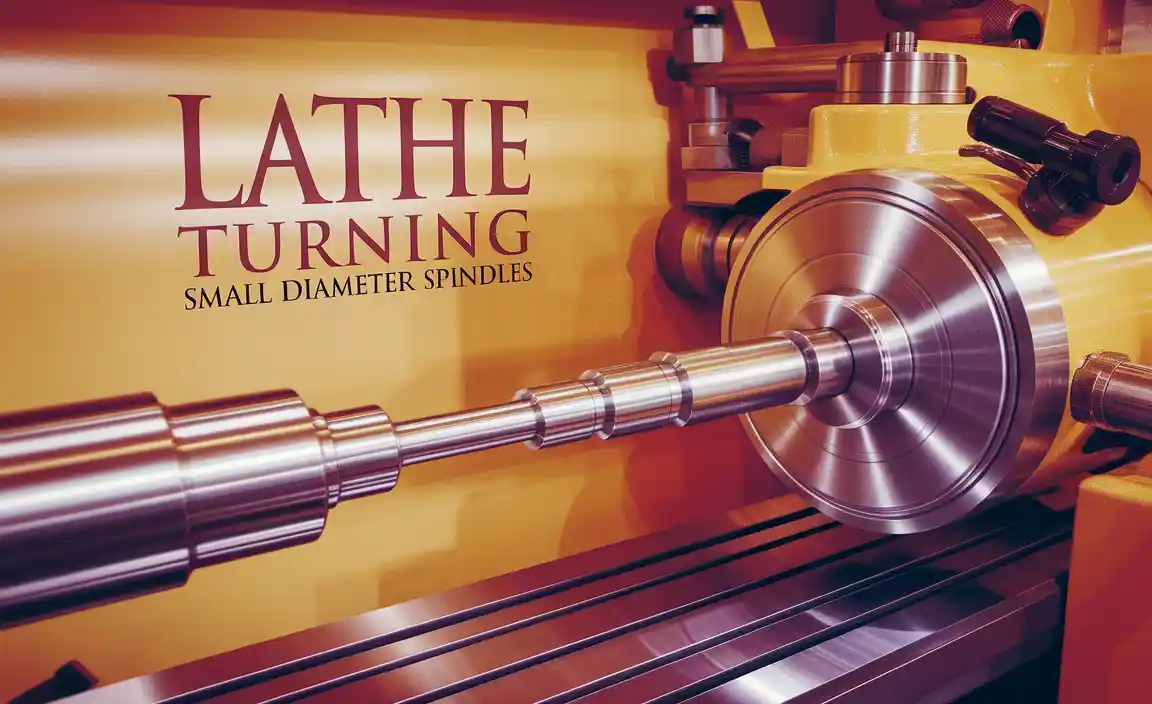

How A Wood Lathe Works

A wood lathe designed for working with wood may not be suitable for use with metal. The primary function of a wood lathe is to shape and turn wooden objects, such as bowls, spindle legs, or decorative pieces. It works by securing the wood between two centres and spinning it at various speeds while a cutting tool shapes it.

The design and construction of a wood lathe may not withstand the forces and vibrations generated when working with metal, which can lead to damage or injury. Therefore, using a lathe with specific designs for metalworking is generally recommended when working with metal materials.

Difference Between Wood And Metal Lathes

Wood lathes and metal lathes may look similar but have specific designs for different purposes. While it is possible to use a wood lathe for light metalworking tasks, use a lathe specifically designed for metal if you plan on working with this material extensively. Here are some key differences between the two:

- Construction: Wood lathes have cast iron or steel, while metal lathes use heavier-duty materials such as cast iron or hardened steel.

- Speed: Wood lathes rotate at higher speeds than metal lathes due to the softer nature of wood.

- Cutting Tools: Woodturning tools have a different design, with shorter lengths and shallower cutting angles, while metal lathe tools are longer and have a steeper cutting angle.

- Lubrication: Metal lathes require lubrication to reduce friction and heat buildup, whereas wood lathes do not need lubrication as wood generates less heat and friction.

Can A Wood Lathe Be Used For Metal? – Exploring The Possibilities

Exploring the potential of wood lathes for metal turning continues to captivate both woodworking and metal-turning enthusiasts. Manufacturers constantly enhance wood lathe capabilities for metal work, while metal turners experiment with various cutting tools, workpiece materials, and lathe modifications to expand the boundaries.

The potential cost savings and adaptability of wood lathes for metalwork are major driving forces behind ongoing research and experimentation. Additionally, collaborations between woodworking and metalworking experts play a pivotal role in exploring using wood lathes for metal turning. This synergistic approach contributes significantly to the continuous evolution of wood lathes for metal turning, opening up new possibilities for enthusiasts across both domains. Scroll down to detail: can a wood lathe be handy for metal?

Why Metal Lathes Are Preferred For Metal Work

People favour metal lathes for their rigidity and precision, ensuring accurate cutting, threading, and turning of metal workpieces. The tooling on metal lathes, such as carbide inserts and indexable tooling, delivers superior performance for metal work.

Additionally, metal lathes can handle a broader range of metals, including stainless steel, aluminium, and titanium, compared to wood lathes. The spindle speed, chuck, and tailstock of metal lathes are tailored to the demands of metal turning operations, emphasizing efficiency and durability. Manufacturers prioritize the construction of metal lathes to meet the challenging requirements of metalwork, making them the preferred choice for metal-turning operations.

The Possibility Of Using A Wood Lathe For Metal

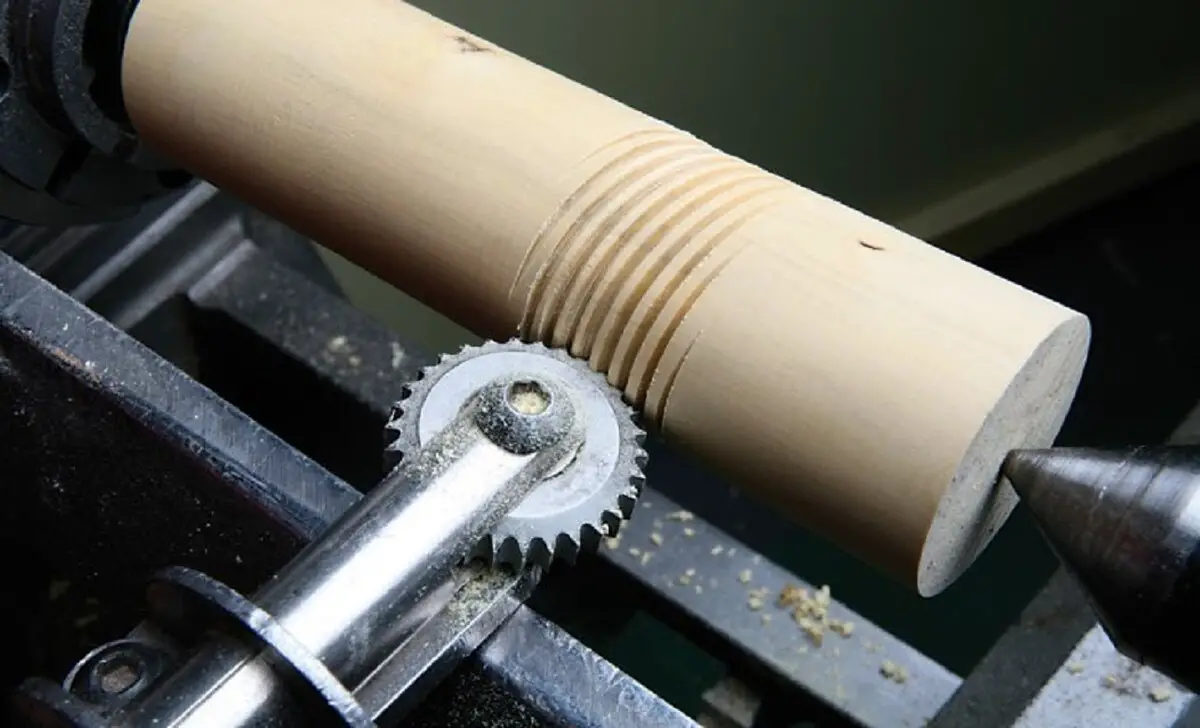

Wood lathes can be handy for soft metals like copper and brass at lower speeds. Woodturners often modify their lathes for metal turning, adding a metal chuck or tool post. The process requires careful consideration of tooling, vibration, and cutter selection. Precision bearings and tool holders ensure successful metal turning on a wood lathe. Expert metal turners emphasize the importance of safety precautions when using a wood lathe for metal work.

Factors To Consider When Turning Metal On A Wood Lathe

Woodturners carefully assess the workpiece’s material, diameter, and length before embarking on a metal turning with a wood lathe. Adjusting the tool post, holder, and rest is essential to accommodate metal turning. Understanding the cutting forces, chatter, and vibration associated with metal turning on a wood lathe is crucial for a successful outcome.

Consideration of the availability of metal lathe tooling, adaptors, and accessories is important when planning for metal turning. Safety precautions, such as wearing protective gear and securing the workpiece. These are crucial to ensure a safe metal-turning experience on a wood lathe.

Pros And Cons Of Using A Wood Lathe For Metal

Using a wood lathe for metal can be a creative and innovative way to explore new possibilities in your craftsmanship. While people traditionally find wood lathes handy for woodworking, they can also adapt them to work with certain types of metal. Here are some pros and cons of Using a Wood Lathe for Metal.

Pros

- Versatility: This can be handy for wood and metal turning.

- Cost-Effective: More affordable than dedicated metal lathes.

- Smaller Footprint: Takes up less space, suitable for smaller workshops or home use.

- Ease Of Use: Simple and easy to operate, beginner-friendly.

Cons

- Limited Capabilities: Not suitable for heavy-duty or precision metal work.

- Potential Damage: Using it for metal turning can cause wear and tear, leading to damage or reduced longevity.

Case Studies Of Successful Metal Turning On Wood Lathe

Experienced woodturners share their success stories of metal turning on a wood lathe. Highlighting the precision and craftsmanship achievable with the right tools and techniques. An appraiser evaluates the quality of metal-turned products from a wood lathe. Emphasizing the potential for high-quality output in skilled hands.

Wood lathe manufacturers exhibit successful metal turning case studies, showcasing the lathe’s capabilities in handling soft metals with detailed dimensions and intricate designs. Users of metal lathes provide valuable insights into the challenges of using a wood lathe for metalwork and how they effectively address them, underscoring the adaptability and possibilities of woodturning for metal applications.

Expert Opinions On Using Wood Lathe For Metal

Seasoned woodturners offer insights into the feasibility of utilizing wood lathes for metal turning, addressing the safety measures, tooling, and techniques necessary for metal work on a wood lathe. Manufacturers of wood lathes actively seek guidance from metal lathe experts to improve their product’s metal-turning capabilities.

At the same time, industry professionals debate the advantages and disadvantages of wood lathes for metal work. Additionally, expert turners share their experiences transitioning from woodturning to metal turning on a wood lathe, providing valuable perspectives on the practicalities and challenges.

Conclusion

While a wood lathe is primarily designed for working with wood, it can be handy for turning metal under certain circumstances. However, it is important to note that using a wood lathe for metal has limitations and challenges. Metal lathes are specifically engineered to handle the rigours of metalworking and provide greater precision and control.

They are equipped with adjustable speed, higher horsepower, and sturdier construction. When using a wood lathe for metal, it is crucial to consider factors like the type of metal, appropriate tools and accessories, and safety precautions. Ultimately, it is possible to experiment with metal on a wood lathe. Investing in a dedicated metal lathe for professional and efficient metalworking is recommended.

Frequently Asked Questions

1.Can You Spin Metal On A Wood Lathe?

You’ll need the right setup to spin metal on a wood lathe, including a metal spinning attachment or faceplate for safety and effectiveness. Remember that metal spinning requires different tools and techniques so additional training may be necessary. Prioritize safety by wearing appropriate gear and following proper procedures.

2.Can You Turn Copper On A Wood Lathe?

Yes, it is possible to turn copper on a wood lathe. However, using the right cutting tools for metalworking, such as carbide-tipped or high-speed steel, is important. You should also wear safety gear when working with metal on a wood lathe.

3.Why Do People Not Use Metal Lathes For Woodturning?

Metal lathes are unsuitable for woodturning due to their design and cutting tools. Woodturning requires a softer touch and generates more dust, which can clog up the motor of a metal lathe. Additionally, the speed and torque required for woodturning differ from those needed for metalworking.

4.What Is A Wood Lathe?

Wood lathes are versatile machines that shape wood by rotating it on a spindle. They come in different sizes and can be manual or computerized, making them suitable for various woodworking projects.