A wood lathe with a cast iron bed is essential for stability and durability. It provides a solid foundation for precise woodworking, reduces vibration for cleaner cuts, and ensures your lathe will last for years. Investing in a cast iron bed means a reliable, smooth, and safe woodworking experience, making it a cornerstone for any serious hobbyist.

Ever reached for a woodworking tool and felt that familiar wobble? It’s a common frustration for beginners, and it often comes down to the foundation of your workshop. When we talk about woodturning, the lathe is the star of the show. But not all lathes are built the same. A key feature that separates the flimsy from the fantastic is the bed. If you’re aiming for smooth finishes and confident cuts, you’ve likely heard the term “cast iron bed” thrown around. It’s not just fancy lingo; it’s a design choice that makes a world of difference. This article will show you why a wood lathe with a cast iron bed is a true essential for anyone serious about bringing their creative visions to life. We’ll walk through its benefits, what to look for, and how it can elevate your entire woodworking experience.

Why a Cast Iron Bed is a Wood Lathe Essential

When you’re starting out in woodturning, you want tools that make the learning process smoother and safer. A wood lathe with a cast iron bed is one of those foundational pieces that pays off immediately and for years to come. It’s not just about looking impressive; it’s about performance you can feel. Let’s break down why it’s such a big deal.

Unmatched Stability and Reduced Vibration

Think about what a lathe does: it spins a piece of wood at high speeds while you carefully shape it with sharp tools. This process naturally creates vibrations. A lighter lathe, often with a steel or aluminum bed, will shake and rattle. This isn’t just annoying; it directly impacts your work. Vibrations lead to:

- Chatter marks on your wood, requiring more sanding.

- Difficulty in making precise cuts.

- Increased wear and tear on the tool rests and the lathe itself.

- A less enjoyable and potentially unsafe user experience.

Cast iron, due to its mass and density, is incredibly effective at absorbing and dampening these vibrations. A heavy cast iron bed acts like an anchor, keeping the entire machine steady. This means your tools glide more smoothly over the wood, leading to cleaner cuts right off the tool. Less vibration equals less sanding and more satisfaction with your finished projects.

Durability and Longevity

Woodworking tools are an investment. You want them to last. Cast iron is known for its incredible strength and resistance to wear. A lathe bed made from this material is built to withstand the rigors of regular use. Unlike lighter materials that can warp or dent over time, cast iron maintains its shape and integrity. This means the critical alignment of your lathe – the headstock, tailstock, and tool rest – remains consistent over years of operation. For a beginner, this means you’re not constantly fighting a machine that’s lost its precision. For a seasoned woodworker, it means a reliable workhorse that won’t let you down.

Precision and Accuracy

The stability provided by a cast iron bed directly translates into better precision. When the lathe is solid, your tool rests are steady, and your tools can be accurately positioned. This is crucial for tasks like:

- Turning consistent tapers.

- Planing perfectly round surfaces.

- Cutting precise joinery.

- Achieving very fine detail work.

A wobbly lathe makes these tasks significantly harder, if not impossible, to achieve with consistent results. The inherent rigidity of cast iron ensures that the geometry of the lathe remains true, allowing you to achieve the accuracy demanded by detailed projects.

Heat Dissipation

While not as critical as in metalworking, wood lathes can generate some heat, especially during prolonged use or when turning denser hardwoods. Cast iron has good thermal conductivity, helping to dissipate this heat more evenly. This can contribute to more stable performance over longer working sessions and prevent localized expansion that could affect precision.

Quick Comparison: Cast Iron vs. Lighter Materials

| Feature | Wood Lathe with Cast Iron Bed | Wood Lathe with Steel/Aluminum Bed |

|---|---|---|

| Stability | Excellent, very low vibration | Fair to good, noticeable vibration |

| Durability | Very high, long-lasting | Good, but can be prone to bending/scratching |

| Precision | High, consistent alignment | Moderate, can be affected by vibration |

| Weight | Heavy, requires stable mounting | Lighter, easier to move |

| Cost | Generally higher initial investment | Often more affordable |

As you can see, while lighter lathes might be tempting for their portability or lower cost, the advantages of a cast iron bed for performance and longevity are substantial. It’s an investment in better woodworking.

What to Look For in a Wood Lathe with a Cast Iron Bed

So, you’re convinced that a cast iron bed is the way to go. Great! But not all cast iron lathes are created equal. Here’s what to keep an eye out for when you’re shopping:

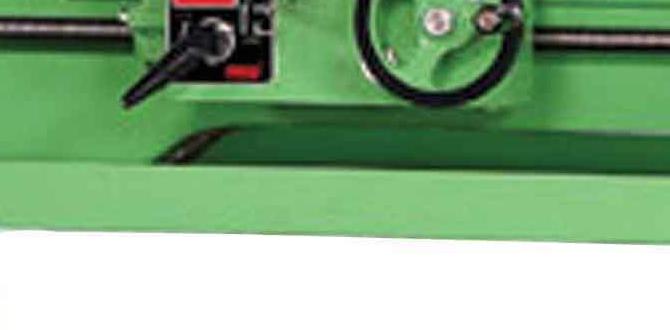

Bed Material and Construction

Obviously, you want the bed to be cast iron. But how thick and robust is it? A substantial “way” (the flat or V-shaped surfaces the tailstock and tool rest slide on) made of thick, heavy cast iron is ideal. Look at the overall construction; does it feel solid when you push on it? Higher-end lathes often have precisely machined ways for smooth movement of the tailstock and tool rest. Some entry-level lathes might use cast iron for the main structural components but have less emphasis on the precision of the ways themselves.

Swing and Distance Between Centers

These are fundamental specifications for any lathe, regardless of bed material.

- Swing: This refers to the maximum diameter of a workpiece the lathe can accommodate. It’s measured from the center of the spindle line to the lowest point of the lathe bed. A larger swing means you can turn bigger bowls and platters.

- Distance Between Centers: This is the maximum length of a workpiece you can turn. It’s measured from the spindle face (with the headstock fully extended) to the tailstock center.

For a lathe with a cast iron bed, you’ll often find robust machines with good swing and distance capacities, as these heavier-duty builds are suited for larger projects. A common entry-level to intermediate cast iron lathe might offer a 12-inch or 14-inch swing and a 30-inch or 40-inch distance between centers.

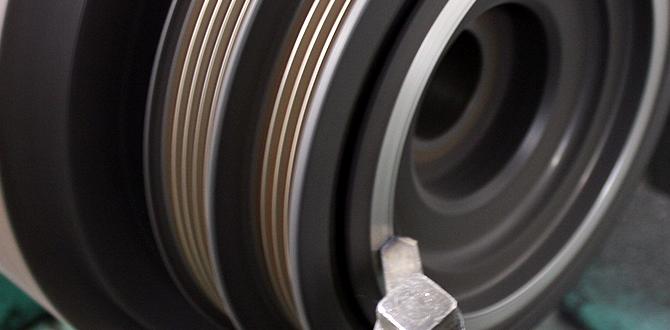

Motor Power and Speed Control

A powerful motor is essential for smooth turning, especially with denser woods or when performing aggressive cuts. For a cast iron lathe, which is designed for heavier work, you’ll look for motors typically ranging from 1 HP (for smaller benchtop models) up to 2 HP or more for larger floor-standing units. Variable speed control is a must. It allows you to:

- Start at a slow speed for material removal and shaping.

- Increase speed for finishing passes.

- Slow down significantly for any out-of-balance turning (like roughing out a large, wet bowl).

Look for lathes with electronic variable speed (EVS) for smoother adjustments and a wider speed range. A common speed range for a good all-around wood lathe is 250-4000 RPM.

Headstock and Tailstock Design

The headstock houses the motor and spindle, while the tailstock supports the other end of your workpiece. For a quality cast iron lathe:

- Headstock: Should be sturdy and mount securely to the bed. Look for a universal type spindle (e.g., 1″ x 8 TPI) which is standard for most attachments. A swivel headstock can be a bonus for turning larger-diameter bowls.

- Tailstock: Should move smoothly along the bed and lock down firmly. A quill that extends and retracts smoothly, with measurements marked, is very useful for drilling or reaming tenons.

Tool Rest and Banjo

The tool rest is where you support your turning tools. The banjo is the part that clamps the tool rest to the lathe bed. On a cast iron lathe, these components are usually substantial. The tool rest post should be thick and sturdy, and the banjo should have a positive locking mechanism that holds it in place securely. You want to be able to easily adjust the height and position of the tool rest without it shifting during use.

Outboard Turning Capabilities

Some wood lathes with cast iron beds are designed to allow you to swing the headstock around and mount a faceplate for turning very large diameter, but relatively thin items like platter bowls or candle stands. This is often referred to as “outboard turning” and requires a lathe with a robust enough structure and sometimes a dedicated outboard banjo.

Choosing the Right Type

Lathes with cast iron beds fall into a few categories:

- Benchtop Lathes: Compact, designed to sit on a workbench. Still benefit greatly from a cast iron bed for stability, but will be smaller overall. Good for smaller items and limited space.

- Toolroom Lathes: Often larger, more powerful, and with highly precise ways. These are exceptional but usually come with a higher price tag.

- Floor-Standing Lathes: These are the most common type for serious hobbyists and professionals. Typically feature robust cast iron beds, powerful motors, and greater swing/distance between centers.

For a beginner looking for an essential, long-lasting machine, a good quality benchtop or a smaller floor-standing model with a cast iron bed provides an excellent balance of features, performance, and value. Many woodworkers start with a quality benchtop cast iron lathe and upgrade later, but starting with cast iron is rarely a regret.

Essential Accessories for Your Cast Iron Lathe

Once you have your robust wood lathe with a cast iron bed, you’ll need a few key accessories to get started. These aren’t just nice-to-haves; they are crucial for safety, versatility, and achieving good results.

Turning Tools

You can’t turn wood without tools! For beginners, a basic set of woodturning chisels is essential. Look for a set that includes:

- Gouge: For roughing out shapes and general turning. A “flute” or “spindle” gouge is a good starting point.

- Scraper: Used for smoothing, especially on end grain. A round nose scraper is very useful.

- Skew Chisel: A versatile tool for fine shaving, cutting beads, and parting off. Mastering the skew is a rite of passage in woodturning!

A good set of quality HSS (High-Speed Steel) chisels will hold their edge longer and are easier to resharpen. For safety, it’s recommended to purchase tools from reputable manufacturers. Resources like NIST (National Institute of Standards and Technology) provides guidance on tool quality and standards that might indirectly benefit your understanding of tool performance.

Face Shields and Safety Gear

This is non-negotiable. Woodturning can send chips flying with surprising force.

- Full Face Shield: A must-have. Unlike safety glasses, a face shield protects your entire face from flying debris, dust, and accidental tool slips.

- Dust Mask or Respirator: Wood dust can be harmful to your lungs over time. Invest in a quality respirator that fits well.

- Hearing Protection: Lathes can be noisy. Earplugs or muffs will protect your hearing.

- Appropriate Clothing: Avoid loose sleeves or jewelry that could get caught in the spinning wood.

Safety is paramount, and proper gear is the first line of defense. Organizations like the Occupational Safety and Health Administration (OSHA) have extensive resources on woodworking safety that are highly relevant.

Chucks

While you can initially mount wood directly between centers, a lathe chuck opens up a world of possibilities, especially for bowls and off-center work. A chuck securely grips the wood using jaws, offering much better control and safety than friction alone.

- Scroll Chucks: These have expanding or contracting jaws that grip either a tenon (an expanded section of wood) or a recess (a hollowed-out section).

- Jaw Types: Chucks come with various jaw sets for different tasks – gripping tenons, holding small spindles, flat faceplates, and specialized jaws for bowl holding.

For a beginner with a cast iron lathe, a good quality 3-jaw or 4-jaw scroll chuck with a standard jaw set (e.g., for gripping 3-4 inch tenons) is an excellent investment. Look for reputable brands known for accuracy and reliable jaw action.

Drive Centers and Live Centers

These are used to support wood mounted between the headstock and tailstock.

- Drive Center: Mounts in the headstock spindle (often via an adapter or directly into the chuck). It has a point or prongs that dig into the end of the wood to transfer the rotational force from the motor. A spur drive is common.

- Live Center: Mounts in the tailstock. It has a bearing so it spins with the wood, reducing friction and preventing scorching. It simply supports the end of the workpiece.

Most lathes come with a basic spur drive and a live center. As you progress, you might look at more specialized drive centers or upgraded live centers for specific tasks.

Dust Collection System

Even with a cast iron bed’s stability, wood turning creates a lot of fine dust. A dedicated dust collection system (shop vac with a good filter, or a dedicated dust collector) is essential for a healthier workshop environment and cleaner work. Connect it to a lathe specifically designed for dust collection ports, or use a dust collection hood that drapes over the tool rest.

Sharpening System

Dull tools are dangerous and frustrating to use. You’ll need a way to keep your chisels sharp. This can include sharpening stones (water stones, oil stones), diamond plates, or a powered grinder with jigs designed for turning tools. Learning proper sharpening techniques is as important as learning turning techniques.

Accessory Table: Getting Started

| Accessory Type | Beginner Recommendation | Why it’s Important |

|---|---|---|

| Turning Tools | Basic set of 3-5 HSS chisels (gouge, scraper, skew) | Essential for shaping wood; quality tools are safer and easier to use. |

| Safety Gear | Full face shield, respirator, earplugs | Protects against flying debris, dust inhalation, and noise. Non-negotiable. |

| Chuck | Quality 3 or 4-jaw scroll chuck with standard jaws | Securely holds wood for turning bowls and other projects; much safer than friction alone. |

| Centers | Spur drive center & live center | Support wood when mounted between headstock and tailstock; essential for spindle turning. |

| Sharpening System | Water stones or diamond plates | Keeps tools sharp for safe and efficient cutting. |

| Dust Collection | Shop vac with fine dust filter / dust extractor | Improves air quality and workshop cleanliness. |

Having these essential accessories ready will make your experience with your new cast iron wood lathe much more productive and safe from day one.

Step-by-Step: First Project on Your Cast Iron Lathe

Let’s get you turning! A simple spindle project is a great way to start. Imagine turning a basic table leg, a candlestick, or even just practice dowels. For this, we’ll focus on a simple practice spindle.

Step 1: Safety First!

Double-check your safety gear. Put on your face shield, respirator, and hearing protection. Make sure your lathe’s power cord is not a trip hazard and that the area around the lathe