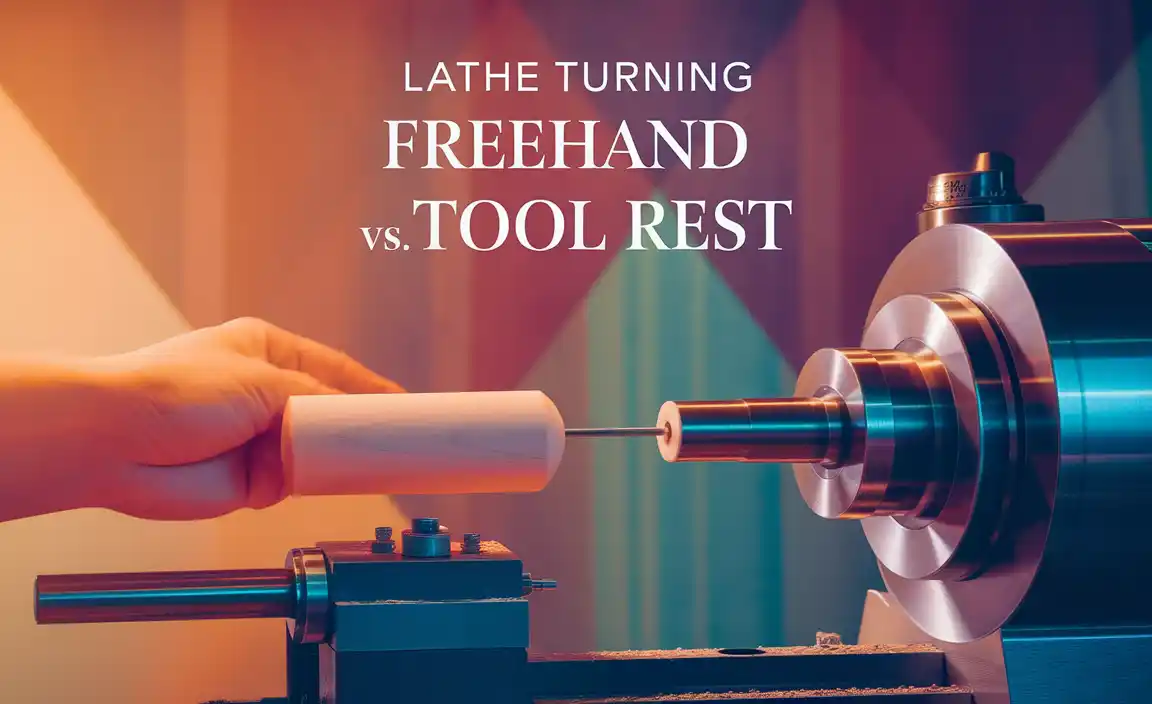

Have you ever seen a wood lathe in action? It’s amazing how a piece of wood spins fast, and then, with a skilled hand, gets shaped into beautiful objects. But do you know what’s even more fascinating? The clever tools that make this magic happen, like the wood lathe centering jig. If you enjoy making things with your hands, you might find these wood lathe centering jig ideas truly exciting. Let’s take a closer look at how these jigs work and why they’re so helpful.

Key Takeaways

- Centering jigs help create perfectly shaped wooden objects.

- Many wood lathe centering jig ideas can spark creativity.

- These jigs make woodturning safer and easier.

- DIY jigs can be made from household materials.

- Correct jig use leads to smoother woodturning results.

Simple DIY Wood Lathe Centering Jig Ideas

Creating your own wood lathe centering jig can be fun and rewarding. You don’t need to spend a lot of money on fancy tools. With a few simple materials, you can make a jig at home. Many woodworkers use wood scraps, screws, and a bit of creativity. You can design a jig that fits your needs perfectly. A homemade jig not only saves money but also improves your skills. Let’s explore some simple wood lathe centering jig ideas that you can try.

- Use an old piece of plywood.

- Gather some nails and screws.

- Try using a ruler for precise measurements.

- Consider using a pencil to mark spots.

- Look for online tutorials for guidance.

Once you’ve gathered your materials, sketch a plan for your jig. A basic design can be a square piece of wood with holes drilled for nails or screws. You can adjust the jig as you work, making small changes to suit each project. Experimenting with different designs can lead to discovering what works best for you.

Fun Fact or Stats : Many woodworkers say DIY jigs improve creativity and problem-solving skills!

Finding Materials at Home

Do you think you have no materials for a wood lathe jig? Think again! Many items around your house can become part of your new tool. That old cutting board in the kitchen? It could be the perfect base! Broken rulers can provide the straight lines you need. Even those leftover screws from other projects can be useful. Look around your home and collect the materials for your jig.

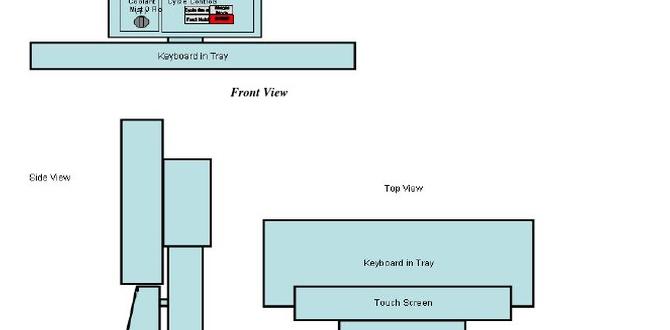

Designing Your Custom Jig

Have you ever designed something from scratch? Drawing your jig plan is like creating a blueprint for your new tool. Use a piece of paper and pencil to sketch your ideas. Think about the size and shape that will work best on your lathe. Remember, you can always make changes as you go. Designing your jig means it will fit your needs perfectly.

Using Your Homemade Jig

Now that you have your jig, it’s time to use it! Place it on your lathe and secure it properly. Make sure it’s stable before you start spinning your wood. A well-made jig will hold your wood steady and true. It’s exciting to see how your homemade tool helps create smooth, beautiful wood pieces. Always remember: safety first!

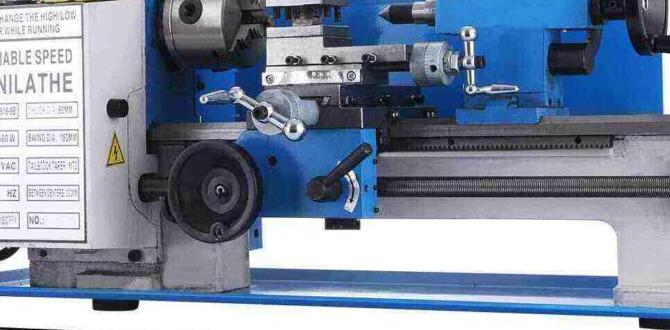

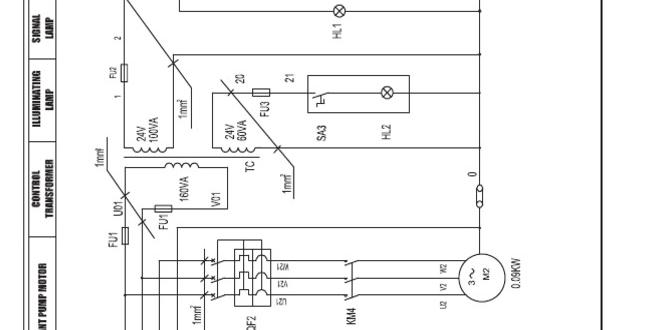

Buying a Wood Lathe Centering Jig

Sometimes, buying a ready-made wood lathe centering jig is the best option. Many stores sell high-quality jigs. These jigs can save time and effort. They are often made from durable materials, ensuring long-lasting use. When choosing a jig, think about your needs. Some jigs are adjustable, while others are designed for specific tasks. Buying the right jig can improve your woodturning experience.

- Check online reviews for reliability.

- Consider the material quality.

- Look for adjustable options.

- Compare prices across different stores.

- Ensure compatibility with your lathe model.

When you buy a jig, follow the instructions for setup and use. A good jig makes woodturning more accurate and safe. It helps center your wood pieces perfectly, preventing mistakes. Enjoy the satisfaction of crafting with precise tools.

| Jig Feature | DIY Jig | Store-Bought Jig |

|---|---|---|

| Cost | Low | Varies (Moderate to High) |

| Customizability | High | Low to Medium |

| Durability | Varies by materials | High |

| Ease of Use | Medium | High |

Fun Fact or Stats : In 2020, over 70% of woodworkers used store-bought jigs!

Choosing the Right Jig for You

Are you wondering which jig is best for you? Consider how often you use your lathe. If you turn wood often, investing in a quality jig could be wise. For occasional use, a DIY jig will do the trick. Think about the types of projects you like. Some jigs are better for bowls, while others work for chair spindles.

Where to Buy Quality Jigs

Finding the perfect jig might seem daunting. Start by checking online woodworking stores. Many offer detailed reviews from other woodworkers. You can also visit local hardware stores. Staff can offer advice on the best jigs for your needs. Take your time and choose carefully.

Understanding Jig Features

Do you know what to look for in a jig? Pay attention to the materials used. Metal jigs are durable but can be heavier. Wood or plastic jigs are lighter but may wear faster. Adjustable jigs provide flexibility for different projects. Understanding these features will help you make the best choice.

Maintaining Your Wood Lathe Centering Jig

Once you have your jig, it’s important to take care of it. Regular maintenance will keep it in top condition. Clean your jig after every use. Remove any dust or small wood particles. Check screws and joints for tightness. A well-maintained jig ensures better performance and safety.

- Wipe down after each use.

- Inspect for loose parts regularly.

- Store in a dry place.

- Avoid exposure to extreme temperatures.

- Lubricate movable parts if needed.

Storing your jig properly will also extend its life. Keep it in a safe, dry place away from moisture. If it has any metal parts, consider using a rust-preventing spray. Regular checks and care ensure your jig serves you well for many projects.

Fun Fact or Stats : Jigs can last over 10 years with proper care!

Cleaning Your Jig

Do you clean your tools regularly? Keeping your jig clean is crucial for its longevity. Use a soft cloth to wipe away dust after each use. For deeper cleaning, use a brush to reach tight spaces. Avoid harsh chemicals, as they might damage the surface. Clean tools work better and safer.

Storing Your Jig Safely

Where do you store your jig? Choose a dry, cool place away from direct sunlight. Moisture can cause rust and degrade materials. A dedicated spot in your workshop keeps it safe and makes it easy to find. Safe storage extends the life of your jig.

Regular Inspections

How often do you check your tools for wear? Regular inspections can catch problems early. Look for loose screws or parts, and tighten them. Check for cracks or worn-out areas. Spotting issues early prevents bigger problems and keeps your jig working smoothly.

Innovative Wood Lathe Centering Jig Ideas

Have you ever thought about inventing a new tool? Many woodworkers enjoy creating innovative jigs. These new designs offer fresh solutions to common problems. Some inventors use 3D printing to create unique jig parts. Others experiment with different materials for strength and flexibility. Innovation leads to exciting wood lathe centering jig ideas.

- Explore 3D printing for custom parts.

- Test different materials like metal and plastic.

- Incorporate adjustable features for versatility.

- Share ideas with others for feedback.

- Stay open to new design inspirations.

If you enjoy experimenting, try designing a new jig. Start with a problem you face during woodturning. Think about how a jig could solve it. Work through different designs and test them. Sharing your ideas with the woodworking community can provide valuable insights.

Fun Fact or Stats : 3D printing can create a jig in just hours!

Exploring 3D Printing

Have you heard of 3D printing? It’s a powerful tool for jig makers. You can design a jig on a computer and print it out. This method allows for precise, custom parts. 3D printing opens a world of possibilities for unique jig designs. Try it and see what you can create!

Experimenting with Materials

Do you like trying new things? Experimenting with different materials can enhance your jigs. Metal provides strength, while plastic offers flexibility. Wood remains a classic choice for its ease of use. Mixing materials can result in innovative designs.

Collaborating with Others

Do you enjoy working with friends? Collaborating with other woodworkers can lead to breakthroughs. Share your ideas and get feedback. Others might have insights you hadn’t considered. Working together makes the process more fun and often results in better jigs.

Conclusion

Wood lathe centering jig ideas can transform your woodworking experience. Whether you make your own jig or buy one, these tools are essential. They help you achieve precise, safe, and beautiful woodturning projects. With care and creativity, your jig will be a trusty companion in your workshop. Enjoy exploring and creating!

FAQs

Question: What is a wood lathe centering jig?

Answer: A wood lathe centering jig is a tool that helps hold wood securely on a lathe. It ensures the wood is centered, making the turning process accurate and safe. Using a jig can improve the quality of your woodturning projects significantly.

Question: How can I make a simple wood lathe centering jig?

Answer: You can make a simple jig using plywood, screws, and nails. First, cut the plywood into a square. Drill holes for the screws to secure it to the lathe. This DIY approach is cost-effective and allows customization to suit your needs.

Question: Why should I use wood lathe centering jig ideas?

Answer: Wood lathe centering jig ideas help you create customized jigs. They inspire creativity and problem-solving skills. A good jig improves turning accuracy and safety. Exploring different ideas can lead to better woodworking results.

Question: What materials work best for making jigs?

Answer: Common materials include wood, metal, and plastic. Wood is easy to work with and modify. Metal offers durability, while plastic provides flexibility. Mixing materials can offer unique benefits, depending on your project’s needs.

Question: Can I buy a wood lathe centering jig instead of making one?

Answer: Yes, you can purchase a jig from woodworking or hardware stores. Store-bought jigs are often made from durable materials and offer specific features. They are ideal if you prefer a ready-to-use solution without the need for customization.

Question: How do I maintain my wood lathe centering jig?

Answer: Regular maintenance is key. Clean your jig after each use. Store it in a dry, safe place. Check for loose parts and tighten them as needed. Proper care ensures your jig remains functional for many projects.