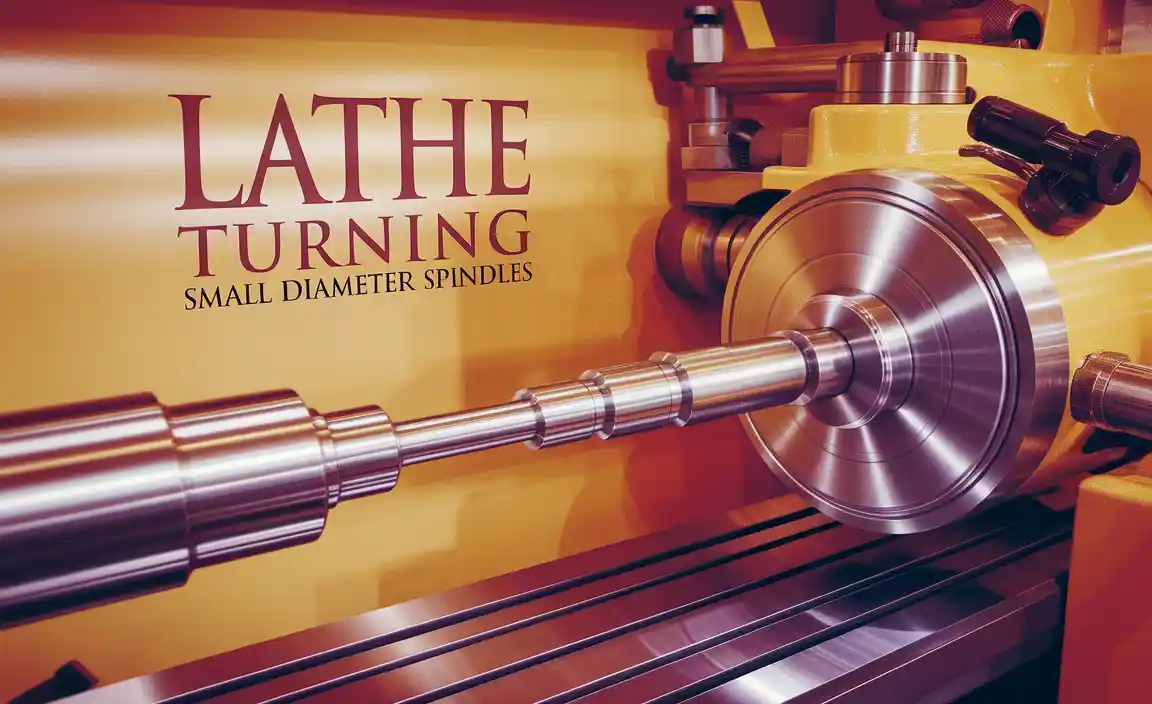

Have you ever watched a wood lathe in action? It’s almost like magic! A simple piece of wood transforms into a beautiful object right before your eyes. But to achieve that magic, you need the right tools. One important tool is the wood lathe chuck. Proper installation of this chuck can make all the difference in your woodturning adventures.

Imagine you’re excited to create a stunning bowl or vase. You have the wood, but what about the chuck? Many beginners feel confused about how to install it correctly. This confusion can lead to mistakes, wasted materials, or worse, injuries. With the right tips, you can avoid these problems and enjoy a smooth turning experience.

In this article, we’ll dive into essential wood lathe chuck installation tips. These tips will help you get a firm grip on your projects and turn wood like a pro. So, are you ready to unlock the secrets of a great installation?

Wood Lathe Chuck Installation Tips For A Perfect Fit

Wood Lathe Chuck Installation Tips

Installing a wood lathe chuck can seem tricky, but it’s easier than you think! Start by cleaning the threads on both the chuck and the lathe. Use a wrench to tighten the chuck securely. Did you know that checking the alignment is essential? A misaligned chuck can lead to wood wobbling and unsafe cuts. Always double-check your setup before starting. With these simple tips, you’ll have your wood lathe chuck ready in no time!Preparing for Installation

Necessary tools and materials for installation. Safety precautions to take before starting.Before starting your installation, gather your tools and materials. You need the following:

- A wood lathe

- A suitable chuck

- Wrenches

- Safety goggles

- Dust mask

- Ear protection

Safety is key! Always wear safety goggles to protect your eyes. A dust mask keeps harmful particles away. Use ear protection to guard against loud noises from the lathe. Following these steps will help protect you during installation.

What tools do I need for wood lathe chuck installation?

You need a wood lathe, a suitable chuck, wrenches, and safety gear.Safety measures include:

- Wearing safety goggles

- Using a dust mask

- Wearing ear protection

Step-by-Step Installation Guide

Detailed steps for installing a standard chuck. Common challenges and troubleshooting tips.Installing a standard chuck can be fun and easy. First, gather your tools: a wrench and your lathe. Follow these steps:

- Turn off the lathe and unplug it for safety.

- Remove the old chuck by loosening its screws.

- Clean the spindle to avoid dirt.

- Align the new chuck on the spindle and tighten it firmly.

- Double-check the tightness before using.

Sometimes, the chuck might wobble or not fit. If this happens:

- Check for dirt on the spindle.

- Ensure it’s aligned correctly.

- Try tightening it more.

With a bit of care, you’ll have a great setup!

What tools do I need for installation?

You will need a wrench and a clean cloth for this process.

Common challenges and how to fix them?

- Wobbling chuck: Check for dirt or misalignment.

- Chuck won’t fit: Make sure you have the correct size.

Aligning the Chuck Properly

Importance of alignment for accuracy. Techniques for ensuring proper alignment during installation.Getting the alignment just right is key for a wood lathe chuck. If it’s off, your project may end up looking wobbly, like a table with three legs! To ensure proper alignment, make sure the jaws of the chuck are parallel to the lathe’s axis. Use a dial indicator for precision—it’s like a tiny referee for your setup!

| Technique | Description |

|---|---|

| Check for Level | Confirm the lathe itself is level. A little tilt can spell trouble. |

| Use a Centering Tool | A centering tool helps guide your installation. Think of it as a GPS! |

Proper alignment leads to smoother cutting. A chuck that’s not aligned can ruin pieces like a typo in a bestseller. Remember, even the best craftspeople need to double-check their work!

Securing the Chuck

Best practices for securing the chuck to avoid slippage. Tips for checking the stability of the installation.First, lock that chuck down tight. Use the right tool to give it a solid twist; think of it like giving it a big hug! You want it to feel secure and loved, not scared and wobbly. After securing it, shake it a bit to check if it stays put—don’t want it sliding away like a shy puppy! The table below shows some quick checks to keep your chuck stable:

| Check | What to Do |

|---|---|

| Tool Tightness | Use a wrench to ensure it’s snug. |

| Wobble Test | Rotate the lathe slowly and observe for any shake. |

| Visual Inspection | Look for any gaps or misalignment. |

Following these simple steps will help keep your chuck stable and your projects chipper!

Maintaining Your Wood Lathe Chuck

Routine maintenance tips to extend chuck lifespan. Signs that indicate maintenance or replacement is needed.To keep your wood lathe chuck in good shape, regular care is key. Simple tasks can help it last longer. For example, clean your chuck after each use. Check for dirt and chips. Grease the moving parts lightly. This keeps everything working smoothly. Also, look for signs that it’s time for maintenance or replacement:

- Visible cracks or chips

- Difficulty tightening or loosening

- Unusual noises during use

These signs could mean your chuck needs help. Don’t ignore them to avoid bigger problems!

How can I tell if my wood lathe chuck needs maintenance?

Keep an eye out for cracks, strange noises, or tough movement. Regular checks can save you time and keep your work safe.

Upgrading Your Chuck

When to consider upgrading your wood lathe chuck. Popular advanced chuck options for enhanced performance.When your wood lathe chuck no longer meets your needs, it’s time to think about an upgrade. New chucks can improve your work. Popular choices include:

- Four-jaw chucks for precision gripping.

- Quick-release chucks for faster changes.

- Scroll chucks for easy operation.

When should I upgrade my wood lathe chuck?

Upgrade your chuck if you want better grip or quicker changes. Also, look for upgrades if your current chuck feels old or hard to use.Better tools make better projects!

Common Mistakes to Avoid

Top errors during installation and how to prevent them. Tips for troubleshooting after installation issues arise.Installing a wood lathe chuck can be tricky! Many common errors pop up during this process. For example, forgetting to tighten the chuck can lead to wobbly workpieces. Always check that everything is snug before starting. If problems arise later, like vibration, don’t panic. Check that the chuck is mounted correctly and isn’t crooked—like a tree trying to dance! Here’s a handy table of common mistakes and how to fix them:

| Error | Solution |

|---|---|

| Loose Chuck | Tighten all screws and ensure it’s secure. |

| Incorrect Alignment | Recheck positioning and adjust as needed. |

| Excess Vibration | Inspect for even placement and balance. |

By being careful and checking these details, you’ll enjoy a smoother and more fun woodworking journey! After all, nobody wants their projects to go “off-chuck!”

Additional Resources and References

Recommended books, websites, and forums for further learning. Manufacturer manuals and specifications for different chuck models.If you’re eager to dive deeper into wood lathe chuck installation, there are plenty of resources to help! Grab a good book like “The Woodworker’s Bible” for tips that feel like a chat with a buddy. Websites like WoodworkingTalk and forums like Lumberjocks offer fresh ideas and advice from fellow woodworkers. Don’t forget to check out the manufacturer’s manuals for your chuck. They’re filled with golden nuggets of wisdom specific to your model!

| Resource Type | Recommended Resource |

|---|---|

| Book | The Woodworker’s Bible |

| Website | WoodworkingTalk.com |

| Forum | Lumberjocks.com |

| Manual | Manufacturer’s Manual |

With these tools in hand, you’ll install like a pro. Remember, every expert was once a beginner—so go ahead, make those chucks rock! Wishing you smooth spinning and little splinters!

Conclusion

In conclusion, installing a wood lathe chuck is easy with the right tips. Always choose the right size chuck for your lathe. Make sure to secure it tightly to avoid accidents. Remember to check for alignment and balance. Don’t forget to practice safety while working. Now, you can dive in and start your woodturning projects! Happy turning!FAQs

What Are The Key Steps To Properly Install A Wood Lathe Chuck?To install a wood lathe chuck, start by turning off the lathe. Next, clean the spindle where the chuck will go. Then, place the chuck on the spindle. Make sure it fits snugly. Finally, tighten the screws or bolts to hold it in place. You’re ready to use your lathe!

How Can I Ensure My Wood Lathe Chuck Is Aligned Correctly During Installation?To make sure your wood lathe chuck is aligned right, first clean the lathe’s spindle. Next, gently slide the chuck onto the spindle. Tighten it securely but not too tight. You can use a dial indicator to check if it spins straight. If it wobbles, adjust it until it sits perfectly.

What Types Of Wood Lathe Chucks Are Available, And How Do Their Installation Processes Differ?There are three main types of wood lathe chucks: scroll chucks, collet chucks, and faceplates. Scroll chucks have moving jaws and hold different shapes well. Collet chucks grip smaller pieces tightly. Faceplates are flat plates used for larger pieces. To install a scroll chuck, you usually screw it onto the lathe. For a collet chuck, you slide your piece in and lock it. Faceplates attach by screwing them into the workpiece. Each type is easy to use but has its own way to set up.

What Tools Are Necessary For Installing A Wood Lathe Chuck Securely?To install a wood lathe chuck securely, you need a few simple tools. First, grab a chuck key, which helps tighten the chuck. You’ll also need a wrench to help turn bolts or nuts. Lastly, a cloth can help you clean the area and make sure everything is safe. With these tools, you can install your chuck easily!

How Do I Maintain And Troubleshoot My Wood Lathe Chuck After Installation?To keep your wood lathe chuck working well, clean it regularly. Wipe it down with a soft cloth to remove dust and wood shavings. Check for any loose screws and tighten them if needed. If the chuck doesn’t grip tightly, make sure the jaws are clean and don’t have chips stuck in them. If something seems broken, ask for help from an adult who knows about tools.