Have you ever wondered how woodworkers create those perfect threads on external tenons? It’s all about the wood lathe for threading external tenons. This powerful tool helps transform simple wood into beautifully threaded pieces. Imagine fitting those threads into your projects with ease!

Using a wood lathe can feel like magic. Just picture this: you start with a plain block of wood. Soon, with some skill and a lathe, it turns into a piece that fits perfectly with others. You can make furniture, toys, or even gifts!

Here’s a fun fact: threading on external tenons dates back centuries. Craftsmen have used these techniques to create strong, lasting joints. Today, you can learn to do the same with a wood lathe.

Isn’t it exciting to think about all the things you can make? Let’s dive deeper into how a wood lathe for threading external tenons can change your woodworking experience!

Wood Lathe For Threading External Tenons: A Complete Guide

Understanding Wood Lathes

Definition and basic components of a wood lathe.. Types of wood lathes suitable for threading external tenons..

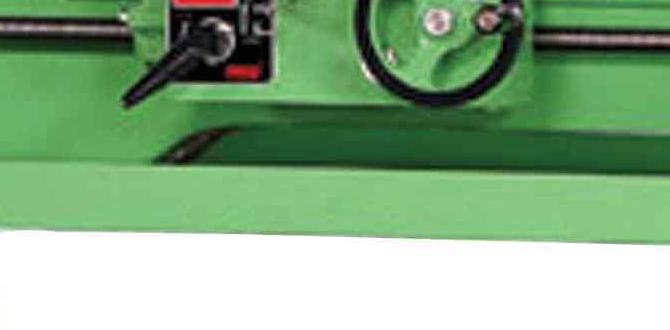

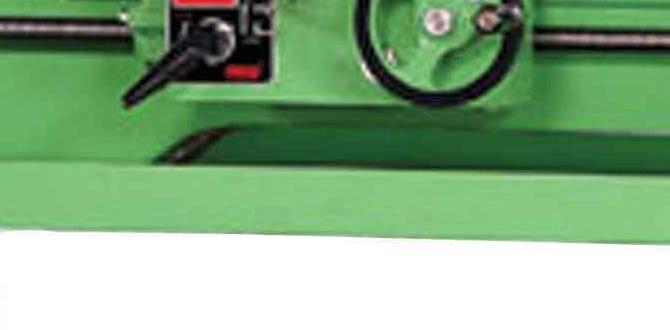

A wood lathe is a machine that shapes wood into round pieces. It spins the wood while tools cut and smooth the surface. Some basic parts include the bed, headstock, tailstock, and tool rest. Each part helps to hold and control the wood.

There are different types of wood lathes, each suitable for specific projects. For threading external tenons, you can use:

- Mini lathes: Great for small projects and tight spaces.

- Full-size lathes: More powerful and ideal for larger pieces.

- Variable speed lathes: Allow you to adjust speed for better control.

What Are External Tenons?

Explanation of external tenons and their purpose in woodworking.. Common applications of external tenons in furniture and woodworking projects..

External tenons are the little heroes in woodworking. They stick out from a piece of wood like a tiny thumb, making strong connections between two wooden parts. Their main job is to hold pieces together securely, especially in furniture and various projects. Think of them as the superheroes of joints! You might find them in items like chairs, tables, and cabinets. They help ensure everything stays put, even during wild dance parties!

| Application | Example |

|---|---|

| Tables | Dining tables often use external tenons for strong support. |

| Chairs | They help keep the legs stable, even when wobbly friends sit down! |

| Cabinets | Cabinet doors may use them for lasting durability. |

Selecting the Right Wood Lathe for Threading

Key features to look for in a wood lathe for threading tenons.. Comparison of popular wood lathe brands and models for threading tasks..

Choosing the best wood lathe for threading external tenons can make a big difference in your projects. Look for key features like stability, variable speed control, and easy adjustments. Popular brands include Jet, Grizzly, and Shopsmith. Each offers different models with unique features. Compare their strengths:

- Jet: Known for smooth operation and durability.

- Grizzly: Offers great value with a strong motor.

- Shopsmith: Versatile with multiple functions.

Your choice can help you create amazing threads!

What makes a wood lathe great for threading?

Good features include a strong motor, smooth turning, and easy setup.

Key points:

- Sturdy frame

- Precision control

- Attachment options

Step-by-Step Guide to Threading External Tenons

Detailed process for setting up the wood lathe for threading.. Techniques for creating precise external tenons..

Setting up your wood lathe is like getting ready for a fun adventure! First, make sure your lathe is safe and secure. Check that everything is tight and in place. Next, choose your correct cutting tool. A sharp tool is your best buddy here!

Now, let’s dive into creating those precise external tenons. Start by measuring the diameter of your tenon. Don’t forget: measure twice, turn once! Mark where you want to cut, and slowly shape your wood. It’s all about patience and control. If you slip, remember it’s wood, not a rock—you can always fix it!

| Steps | Tips |

|---|---|

| Check Lathe Setup | Stay Safe! |

| Choose Cutting Tool | Keep it Sharp! |

| Measure Tenon Diameter | Measure Twice! |

| Shape Wood Carefully | Be Patient! |

With these steps, you’ll turn your wood into works of art, one tenon at a time! Who knew threading could be so fun?

Common Mistakes and Troubleshooting

Typical errors to avoid when threading external tenons.. Solutions to common problems encountered during the process..

Threading external tenons can be tricky, and mistakes sure love to sneak in! One common error is not holding the wood steady, which can lead to uneven threads. Solution? Make sure your wood is firmly clamped and won’t do a wiggly dance. Another typical mistake is using the wrong tool speed. It’s like trying to cook chicken on low heat—it won’t work! Experiment with speeds for the best results.

| Common Mistakes | Solutions |

|---|---|

| Unsteady wood | Clamp securely to avoid movement. |

| Wrong tool speed | Adjust speed for smooth cutting. |

These tips can help you avoid those pesky errors and help you thread like a pro. Remember, everyone makes mistakes—so laugh it off and keep spinning!

Maintenance Tips for Wood Lathes

Routine maintenance practices for prolonging the lifespan of a wood lathe.. Specific care for components involved in threading tenons..

Keeping your wood lathe happy is key to a long life! Regular check-ups can save you lots of headaches. Lubricate moving parts to keep them smooth and whisper quiet. Dust can be a wood lathe’s worst enemy, so use a soft cloth to wipe it down after each project. For threading tenons, pay special attention to your tailstock and spindle. A little love goes a long way! Here’s a quick care table:

| Action | Frequency |

|---|---|

| Clean and Dust | After Each Use |

| Lubricate Parts | Weekly |

| Check for Damage | Monthly |

Remember, a happy lathe means smooth projects and fewer mistakes. So, treat it well, and it will reward you with fine tenons and maybe even a smile—or a chirp! Who knew wood lathes could be so cheerful?

Project Ideas Using Threaded External Tenons

Examples of projects that effectively utilize threaded external tenons.. Design inspiration and complexity levels for various skill sets..

Creating with threaded external tenons opens up a world of fun projects! How about making a stylish lamp or a playful wall shelf? Both of these projects use tenons to keep pieces together, so they’re strong and stable. Even beginners can try their hands at simple designs, while experts might design intricate furniture pieces. Want to impress your friends? Try crafting a unique wine rack. It’s even a great conversation starter!

| Project Idea | Skill Level | Design Complexity |

|---|---|---|

| Stylish Lamp | Beginner | Simple |

| Wall Shelf | Beginner | Moderate |

| Wine Rack | Intermediate | Complex |

Resources and Further Learning

Recommended books, videos, and online courses for mastering wood lathe threading.. Online forums and communities for woodturners seeking advice and inspiration..

Looking to up your wood lathe game? There are plenty of exciting resources to explore! Grab some recommended books that dive deep into threading techniques. YouTube has amazing tutorials that’ll make you laugh and learn at the same time. Want to connect with fellow woodturners? Join online communities where sharing advice is as common as sharing snacks!

| Type | Recommendations |

|---|---|

| Books | “The Woodturner’s Bible” by Percy Blandford |

| Videos | YouTube Channels: “The Wood Whisperer”, “Carl Jacobson” |

| Online Courses | Craftsy or Udemy courses on woodturning |

| Forums | Woodturners Anonymous, Reddit: r/WoodTurning |

With these tools, you’ll thread like a pro in no time! Plus, remember: every expert was once a beginner, probably carving wobbly tenons. So, keep learning and don’t take it too seriously – woodworking should be fun!

Conclusion

In conclusion, using a wood lathe for threading external tenons is a useful skill. It helps you create strong joints in your projects. You can achieve precise threads with practice. Remember to choose the right tools and materials. Now, try threading on a scrap piece of wood. For more tips, check out beginner woodworking guides. Happy crafting!

FAQs

What Features Should I Look For In A Wood Lathe To Effectively Thread External Tenons?

When choosing a wood lathe for threading external tenons, look for a few key features. First, ensure it has adjustable speeds. This helps you work with different materials easily. Next, find one with a reliable tailstock. This keeps your wood steady and safe. Lastly, check if it comes with good tools for cutting threads. That way, you can make strong tenons without any trouble.

How Do I Properly Set Up A Wood Lathe For Threading External Tenons?

To set up a wood lathe for threading external tenons, start by making sure the lathe is clean and working well. Next, choose the right cutting tool for the job. Adjust the tool rest to the right height so it’s comfortable for you. Use a ruler or caliper to measure your tenon size before you start cutting. Finally, run the lathe at the right speed and carefully cut the threads.

What Tools And Accessories Are Essential For Threading External Tenons On A Wood Lathe?

To thread external tenons on a wood lathe, you need a few important tools. First, get a good lathe with a threading attachment. You also need a sharp threading tool to make the threads. A tool rest will help keep your hands steady while you work. Finally, have a caliper to measure the threads accurately.

Can You Provide Tips Or Techniques For Achieving Precise Threads On External Tenons Using A Wood Lathe?

To make precise threads on external tenons with a wood lathe, start by using a sharp tool. This helps create clean cuts. Next, measure carefully. You want the tenon to fit perfectly. Move slowly and check your work often. This way, you can fix mistakes before they become big problems.

What Common Mistakes Should I Avoid When Threading External Tenons On A Wood Lathe?

When threading external tenons on a wood lathe, avoid rushing the process. Take your time to make smooth cuts. Always check your measurements before you start. Keep the tool steady and don’t push too hard. Also, make sure your wood is properly secured to avoid accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Features Should I Look For In A Wood Lathe To Effectively Thread External Tenons? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a wood lathe for threading external tenons, look for a few key features. First, ensure it has adjustable speeds. This helps you work with different materials easily. Next, find one with a reliable tailstock. This keeps your wood steady and safe. Lastly, check if it comes with good tools for cutting threads. That way, you can make strong tenons without any trouble.”}},{“@type”: “Question”,”name”: “How Do I Properly Set Up A Wood Lathe For Threading External Tenons? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a wood lathe for threading external tenons, start by making sure the lathe is clean and working well. Next, choose the right cutting tool for the job. Adjust the tool rest to the right height so it’s comfortable for you. Use a ruler or caliper to measure your tenon size before you start cutting. Finally, run the lathe at the right speed and carefully cut the threads.”}},{“@type”: “Question”,”name”: “What Tools And Accessories Are Essential For Threading External Tenons On A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To thread external tenons on a wood lathe, you need a few important tools. First, get a good lathe with a threading attachment. You also need a sharp threading tool to make the threads. A tool rest will help keep your hands steady while you work. Finally, have a caliper to measure the threads accurately.”}},{“@type”: “Question”,”name”: “Can You Provide Tips Or Techniques For Achieving Precise Threads On External Tenons Using A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make precise threads on external tenons with a wood lathe, start by using a sharp tool. This helps create clean cuts. Next, measure carefully. You want the tenon to fit perfectly. Move slowly and check your work often. This way, you can fix mistakes before they become big problems.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should I Avoid When Threading External Tenons On A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When threading external tenons on a wood lathe, avoid rushing the process. Take your time to make smooth cuts. Always check your measurements before you start. Keep the tool steady and don’t push too hard. Also, make sure your wood is properly secured to avoid accidents.”}}]}