Have you ever wondered about the tools that make woodturning exciting? Two important tools are the wood lathe live center and the dead center. Both have unique roles in shaping wood. But what makes one better than the other?

Picture this: You’re in a workshop, surrounded by the scent of fresh wood shavings. You pick up your lathe, ready to create something amazing. But wait! Should you use a live center or a dead center? This decision can change your project.

Fun fact: Live centers allow for movement while turning. This means they help create smooth, precise shapes. On the other hand, dead centers are stable and strong but lack that movement. Which one do you think will fit your project best?

Let’s dive into the exciting world of wood lathes and discover how these centers can make or break your work. Understanding the difference between a wood lathe live center and a dead center is key to better woodturning. Are you ready to turn your ideas into reality?

Wood Lathe Live Center Vs Dead Center: Understanding The Differences

Wood Lathe Live Center vs Dead Center

When working with a wood lathe, understanding live centers and dead centers is essential. A live center spins with the workpiece, reducing friction and allowing for smoother cuts. In contrast, a dead center stays still, making it easier to maintain precise cuts over time. Wondering which is best for you? Live centers are perfect for detailed work, while dead centers shine in sturdiness. This choice can enhance your project’s quality!Understanding Lathe Centers

Definition and purpose of lathe centers. Importance of precision in woodturning.Lathe centers are essential tools in woodturning. They help hold your wood securely while you shape it. A live center spins as the wood turns, while a dead center stays still. This difference can influence how smooth your project turns out. Precision is key in crafting beautiful pieces. A small slip can mean the difference between a lovely bowl and a wobbly hat! Remember, a steady center keeps your creativity flowing.

| Type of Center | Movement | Use |

|---|---|---|

| Live Center | Spins with wood | Best for smoother finishes |

| Dead Center | Stays still | Good for basic support |

Characteristics of Live Centers

Definition and mechanics of live centers. Advantages of using live centers in woodturning.Live centers are tools that help keep wood steady while it’s turned. They have a moving tip that spins with the wood. This feature allows for smoother cuts and less friction. Here are some advantages of using live centers:

- Better support: Live centers hold wood securely.

- Reduced wear: They create less friction and heat.

- Increased precision: Cuts are cleaner and more accurate.

- Versatility: They work well with different wood types.

Using a live center can really make a difference for woodturners. Funny enough, many beginners find them easier to use!

What is a live center used for?

A live center is used to hold the wood securely while it spins, allowing for smoother cuts in woodturning projects.

Characteristics of Dead Centers

Definition and mechanics of dead centers. Advantages and limitations of dead centers in woodworking.A dead center is a tool used in lathes to hold workpieces in place. Unlike its lively counterpart, the live center, it doesn’t spin. Instead, it stays still, while the workpiece turns around it. This means it’s great for tasks like drilling and shaping!

Advantages of using dead centers include their strength and accuracy. They can support heavy workpieces without budging. Now, for the funny part—they never get tired! But they can create friction and heat if used too long, which isn’t so cool.

| Advantages | Limitations |

|---|---|

| Strong support | Friction can build up |

| Accurate positioning | Not suitable for high-speed work |

In summary, dead centers are your sturdy friends for woodworking, but remember to keep an eye on overheating—nobody likes a hot mess!

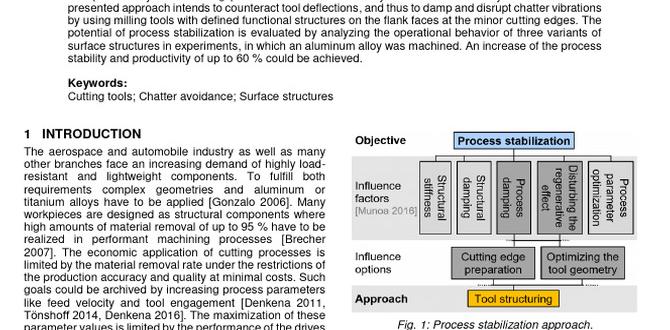

Comparative Analysis: Live Center vs Dead Center

Key differences in design and functionality. Application contexts for each type of center.Live centers and dead centers serve different purposes. A live center has a spinning part, which means it rotates with the wood. This helps make smoother cuts and saves time. On the other hand, a dead center stays still. It supports the wood but doesn’t move. This is great for heavy work but can be slow.

| Feature | Live Center | Dead Center |

|---|---|---|

| Movement | Rotates with the work | Stays fixed |

| Best For | Speedy cuts | Heavy-duty projects |

Pick a live center for quick work and a dead center for strength. Don’t worry! Whichever you choose, woodturning can still be fun—unless the wood decides to run away!

Choosing the Right Center for Your Project

Factors to consider when selecting a center type. Common woodworking projects suited for each center.Picking the right center for your wood project is important. The center affects how well your project will turn out. Here are some factors to think about:

- Project size: Bigger projects might need a live center.

- Wood type: Soft woods work well with dead centers.

- Cutting needs: Live centers help with details.

Common projects for live centers include bowls and vases. Dead centers are great for simple items like spindles and legs. Always choose what suits your project best!

What factors should I consider when choosing a center?

Consider project size, wood type, and cutting needs.Which projects are best for each center?

- Live centers: Bowls and vases.

- Dead centers: Simple items like spindles.

Maintenance Tips for Lathe Centers

Best practices for maintaining live and dead centers. Importance of upkeep for tool longevity and performance.Keeping your lathe centers in good shape is very important. Well-maintained centers help your tools last longer and work better. Here are some simple tips:

- Clean centers after each use to remove dust and debris.

- Lubricate moving parts regularly for smooth operation.

- Store centers in a dry place to prevent rust.

- Inspect for wear and tear often to catch problems early.

Following these tips can help your wood lathe live center and dead center stay sharp and ready to work!

Why is maintenance so important?

Regular upkeep ensures tool longevity and keeps performance high. Neglect can lead to wear, making work harder and less safe.

Common Problems and Troubleshooting

Typical issues encountered with live and dead centers. Solutions and tips for resolving common problems.Many users face problems with live and dead centers. Common issues include poor alignment, uneven wear, or vibrations during use. These problems can lead to inaccurate cuts or damaged materials.

Here are some simple tips to solve these issues:

- Check alignment regularly.

- Inspect for wear and tear.

- Tighten all connections to reduce vibrations.

- Use proper lubrication for smoother operation.

By following these steps, you can ensure better performance and longer life for your wood lathe centers.

What are common problems with wood lathe centers?

Common issues include misalignment, excessive wear, and vibrations. Fixing these problems involves regular maintenance and careful checks.

Expert Opinions and Recommendations

Insights from experienced woodturners. Reviews of popular live and dead centers on the market.Many skilled woodturners agree on the value of choosing the right center for your lathe. They share insights and recommendations based on real experiences. Here’s what they say:

- Live centers offer better precision and reduce friction.

- Dead centers are cheaper and simpler for basic tasks.

- Both types vary in quality, so read reviews carefully.

A popular choice is the PSI Woodworking Live Center for its durability. For budget options, the Woodturner’s Catalog Dead Center gets good feedback.

What do experts recommend for beginners?

Experts suggest starting with a live center. It helps create smoother finishes, making projects more enjoyable!

Choosing the right center can lead to better results. Listen to experienced woodturners, and explore options carefully. Happy turning!

Conclusion

In summary, a wood lathe live center spins with your wood, offering better accuracy. A dead center stays still but may limit options. Choose live centers for detailed work, and dead centers for simpler tasks. Explore both types to see what fits your projects best. Happy turning, and consider reading more to discover tips about using wood lathes!FAQs

What Are The Main Differences Between A Live Center And A Dead Center In Wood Lathe Applications?A live center spins with the wood while you work. It has a special part inside that allows it to move. A dead center stays still and doesn’t turn at all. You use a live center for smoother cuts and a dead center for simple tasks. Both help hold the wood in place on the lathe.

When Should I Choose To Use A Live Center Over A Dead Center For Turning Projects?You should use a live center when you need to turn a long piece of wood or metal. A live center has a spinning tip that helps reduce friction. This makes your project smoother and helps it last longer. If you want to turn faster and more easily, choose a live center. Use a dead center for shorter pieces or when perfect accuracy is needed.

How Do Live Centers Improve Accuracy And Finish When Compared To Dead Centers During The Lathe Process?Live centers help us make better shapes when using a lathe. They spin with the piece we are working on. This makes our cuts smoother and more accurate. Dead centers don’t move, so they can cause extra friction. With less friction, we get a nicer finish!

What Maintenance Or Care Is Required For Live Centers Versus Dead Centers In A Wood Lathe?Live centers have moving parts, so you need to keep them lubricated with oil. This helps them spin smoothly. Dead centers don’t have moving parts, so they need less care. You should clean them to remove dust and wood shavings. Checking both types regularly is important to keep them working well.

Are There Specific Types Of Projects Or Materials That Are Better Suited For Either Live Centers Or Dead Centers?Yes, some projects do better with live centers, while others are better with dead centers. Live centers have moving parts, so they work well with long or heavy pieces of wood. This helps them spin without getting stuck. Dead centers are good for smaller, lighter pieces since they don’t move. You can choose based on what you’re working on!