Build your own wood lathe tool sharpener for precision and savings! This guide shows beginners how to create a custom sharpening machine, ensuring your tools stay razor-sharp for better woodworking.

Hey there, fellow woodworkers! Daniel Bates here from Lathe Hub. Are your wood lathe tools feeling a bit dull? It’s a common frustration, right? A dull tool doesn’t just make your work harder; it can lead to splintered cuts and even dangerous situations. But what if I told you that you don’t need to spend a fortune on fancy sharpening machines? We’re going to dive into building your very own wood lathe tool sharpening machine, right at home. It’s simpler than you might think, and I’ll walk you through every step.

Why Build Your Own Wood Lathe Tool Sharpening Machine?

Sharp tools are the heart of great woodworking. They glide through wood, leaving smooth finishes and making your turning experience more enjoyable and safe. Over time, even the best lathe chisels lose their edge. While commercial sharpening systems exist, they can be pricey. Building your own machine offers several advantages, especially for the beginner or hobbyist. You gain a deep understanding of the sharpening process, customize the machine to your specific tool shapes, and save money. Plus, there’s a fantastic sense of accomplishment in creating a tool that helps you create other beautiful things.

Understanding Your Wood Lathe Tools

Before we build a sharpening machine, let’s quickly refresh our understanding of the tools we’ll be sharpening. Knowing the basic shapes and bevel angles of your gouges, chisels, and scrapers is key to effective sharpening. This knowledge will guide how you set up your homemade machine.

Build your own wood lathe tool sharpener for precision and savings! This guide shows beginners how to create a custom sharpening machine, ensuring your tools stay razor-sharp for better woodworking.

Hey there, fellow woodworkers! Daniel Bates here from Lathe Hub. Are your wood lathe tools feeling a bit dull? It’s a common frustration, right? A dull tool doesn’t just make your work harder; it can lead to splintered cuts and even dangerous situations. But what if I told you that you don’t need to spend a fortune on fancy sharpening machines? We’re going to dive into building your very own wood lathe tool sharpening machine, right at home. It’s simpler than you might think, and I’ll walk you through every step.

Why Build Your Own Wood Lathe Tool Sharpening Machine?

Sharp tools are the heart of great woodworking. They glide through wood, leaving smooth finishes and making your turning experience more enjoyable and safe. Over time, even the best lathe chisels lose their edge. While commercial sharpening systems exist, they can be pricey. Building your own machine offers several advantages, especially for the beginner or hobbyist. You gain a deep understanding of the sharpening process, customize the machine to your specific tool shapes, and save money. Plus, there’s a fantastic sense of accomplishment in creating a tool that helps you create other beautiful things.

Understanding Your Wood Lathe Tools

Before we build a sharpening machine, let’s quickly refresh our understanding of the tools we’ll be sharpening. Knowing the basic shapes and bevel angles of your gouges, chisels, and scrapers is key to effective sharpening. This knowledge will guide how you set up your homemade machine.

Common Wood Lathe Tool Types:

Spindle Gouges: Used for shaping smaller details and coves on spindle turnings. They typically have a flute that’s deeper than it is wide.

Bowl Gouges: Designed for shaping bowls, these have a broader flute and a more rounded profile to handle the tougher grain encountered in face grain turning.

Skew Chisels: Versatile tools used for shearing cuts, scraping, and creating fine details. They have a distinctive angled cutting edge.

Scrapers: Used for smoothing surfaces, particularly end grain, scrapers have a flat edge that is “hooked” or burnished to create a cutting action rather than a slicing one.

Parting Tools: Thin, narrow tools used to cut grooves or separate pieces of wood from the workpiece.

Understanding Bevel Angles:

Different tools require different bevel angles for optimal performance. A steeper angle creates a sharper, more delicate point, good for fine detail work, but it can also be more prone to chipping. A shallower angle is more robust and better for heavy cuts, but may not leave as fine a finish. For beginners, common angles are:

Tool Type Recommended Bevel Angle Purpose

Spindle Gouge 30-45 degrees Detailing, general spindle work

Bowl Gouge 40-55 degrees Roughing, shaping bowls, face grain

Skew Chisel 40-45 degrees (flat grind), ~60 degrees (swept back grind) Shearing cuts, smoothing, detailing

Scraper 90 degrees (for the square nose), with a highly burnished nose Smoothing end grain, flat surfaces

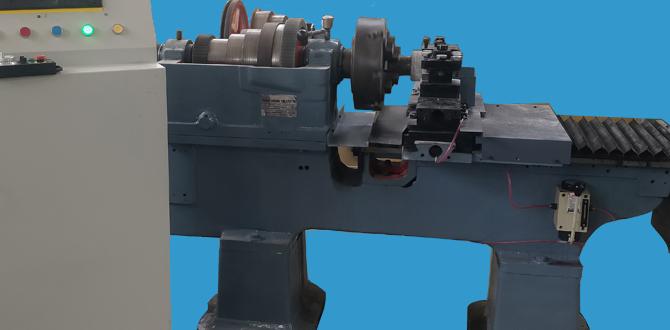

The Core Concept: Your Homemade Sharpening Machine

At its heart, a wood lathe tool sharpening machine is a system that holds an abrasive (like a grinding wheel or sharpening stone) at a consistent angle to your tool for repeatable sharpening. We’re going to create a jig that guides your tool accurately. The most common and effective type for beginners to build uses a bench grinder or a dedicated sharpening wheel. The key is repeatable accuracy. This means the machine needs to hold the abrasive and guide your tool in a way that removes minimal metal while creating the correct bevel angle every single time.

Essential Components and Materials

Let’s gather what you’ll need. Simplicity is key for a homemade build, so we’ll focus on readily available materials. Your goal is to create a stable platform and an adjustable guide that can hold your tools at precise angles.

For the Grinding Station (Option 1: Bench Grinder)

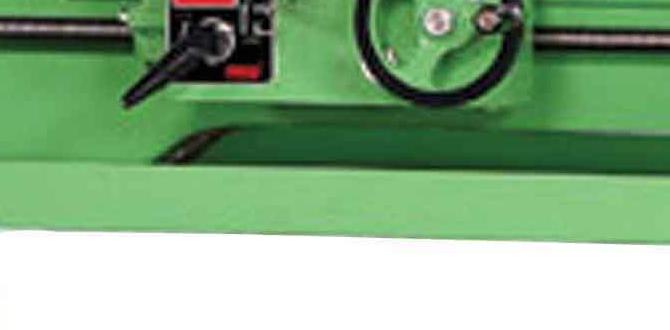

bench grinder: A standard bench grinder with a coarse and fine grinding wheel is ideal. Ensure it has a solid base. Wood Magazine has a great overview of selecting bench grinders.)

Tool Rest: Most bench grinders come with a tool rest. We’ll look at modifying or replacing this for better stability and angle adjustment.

Water Trough (Optional but Recommended): To cool the tool and prevent overheating, a small water trough or a water-soaked sponge placed near the wheel is great.

For the Sharpening Jig:

Wood (Hardwood is best): Scraps of 3/4-inch or 1-inch thick hardwood like oak, maple, or birch are perfect. You’ll need pieces for the base, fence, and tool rest arm.

Metal Angle Bracket: A few sturdy metal angle brackets to join wooden pieces securely.

Threaded Rod or Bolt: A medium-length threaded rod or a long bolt (e.g., 1/2-inch diameter) with nuts and washers. This will act as the pivot for angle adjustment.

Wood Screws: Various lengths for assembling the wooden parts.

Hinges (Optional): Small, sturdy hinges can be used for an adjustable angle base.

Non-Slip Material: A piece of rubber matting or cork to place under the jig base for stability.

Measuring Tools: Tape measure, ruler, angle finder or protractor.

Marking Tools: Pencil.

Tools for Construction:

Saw: A table saw, miter saw, or even a hand saw will work for cutting the wood pieces.

Drill and Drill Bits: For pilot holes and creating the pivot point.

Screwdriver: To drive screws.

Sandpaper: To smooth any rough edges.

Clamps: To hold pieces together while gluing or screwing.

Design Concept: The Bench Grinder Sharpening Jig

Our homemade sharpening machine will consist of a stable base that clamps or wedges onto your bench grinder’s tool rest. This base will have an adjustable fence or arm that guides your tool. The fence will have multiple slots or adjustable guides to accommodate different tool profiles and bevel angles. The key is that the distance from the pivot point of the tool to the grinding wheel remains constant, ensuring a consistent bevel as you move the tool. This is a proven method that many woodturners use.

Step-by-Step: Building Your Jig

Let’s get building! We’ll focus on a popular and effective design that uses your existing bench grinder. This jig is designed to be simple, robust, and accurate. We’ll use common lumber and hardware.

Step 1: Prepare Your Bench Grinder Setup

First, ensure your bench grinder is securely mounted. If it’s a benchtop model, consider bolting it to a sturdy workbench. The standard tool rests that come with grinders are often not ideal for precise sharpening. You may need to remove the existing rest and plan to attach your new jig directly to the grinder’s frame or modify the existing mounting point. Safety first: always unplug the grinder before making any modifications.

Step 2: Construct the Base Platform

Cut a piece of your hardwood (e.g., 1-inch thick) to serve as the base of your jig. A good starting size might be 6 inches wide by 8 inches long. This base will sit on your grinder’s tool rest or be mounted to the grinder’s frame. On the underside of this base, attach a strip of wood or a metal bracket that will securely fit over or around your grinder’s tool rest post. This ensures the jig doesn’t move during sharpening. If mounting directly to the grinder, drill holes through the base that match the mounting holes on your grinder’s support arm and secure with bolts.

Step 3: Create the Adjustable Fence and Pivot

This is the most crucial part. You need an arm that pivots to set your sharpening angle and a fence to guide the tool.

Main Arm: Cut a sturdy piece of hardwood for the main arm (e.g., 1.5 inches thick, 3 inches wide, and about 10-12 inches long). This arm will extend over the grinding wheel.

Pivot Point: Drill a hole through the back of the main arm, about 2 inches from one end. This will be the pivot. Drill a corresponding hole in the base platform, ensuring the arm can pivot freely. Insert a sturdy bolt or threaded rod through these holes, securing it with nuts and washers. This pivot allows you to adjust the angle of the arm relative to the grinding wheel. For better angle adjustment, you can create a series of holes in the base where the pivot bolt passes through, allowing you to select different angles. Another approach is to use a robust hinge connecting the arm to the base, with a way to lock that angle.

Fence: Attach a vertical fence to the top surface of the main arm. This fence will be where you rest your tool. The fence should be about 3-4 inches high. You can build it from two pieces of wood or a single solid piece. The critical aspect is creating a flat, stable surface for your tool to slide against.

Step 4: Incorporate Angle Adjustment and Locking

To set and lock your sharpening angle, you need a mechanism.

Angle Marking: On the base platform, adjacent to the pivot, mark degrees using an angle finder. This helps you set consistent angles.

Locking Mechanism: This could be as simple as tightening the pivot bolt firmly. For more robust locking, add a wing nut or a second bolt that clamps the arm to the base once the desired angle is set. If you’ve made a series of holes for the pivot bolt, the bolt itself acts as the locking mechanism at each selected angle setup.

Step 5: Add Tool Guides and Refinements

The fence needs to guide your tools accurately over the grinding wheel.

Slots for Tools: Cut slots into the fence. These slots will position your tool at the correct angle relative to the grinding wheel. For instance, you might cut a slot at 45 degrees for your spindle gouge and another at 55 degrees for a bowl gouge. The width of the slot should be just enough for your tool to fit snugly.

Adjustable Guide (Optional yet Recommended): For even more versatility, you can make the fence itself adjustable or create a sliding guide block that attaches to the fence rail. This block can be moved in or out to control the depth of cut and provide a stable rest for different tool shapes. A common method involves a sliding carriage with a fence attached, which moves along a track on the main arm. This allows you to precisely control the position of the tool on the grinding wheel.

Non-Slip Base: Glue a piece of rubber matting or cork to the underside of the jig’s base. This prevents it from sliding on the grinder’s tool rest during operation.

<li>

Common Wood Lathe Tool Types:

- Spindle Gouges: Used for shaping smaller details and coves on spindle turnings. They typically have a flute that’s deeper than it is wide.

- Bowl Gouges: Designed for shaping bowls, these have a broader flute and a more rounded profile to handle the tougher grain encountered in face grain turning.

- Skew Chisels: Versatile tools used for shearing cuts, scraping, and creating fine details. They have a distinctive angled cutting edge.

- Scrapers: Used for smoothing surfaces, particularly end grain, scrapers have a flat edge that is “hooked” or burnished to create a cutting action rather than a slicing one.

- Parting Tools: Thin, narrow tools used to cut grooves or separate pieces of wood from the workpiece.

Understanding Bevel Angles:

Different tools require different bevel angles for optimal performance. A steeper angle creates a sharper, more delicate point, good for fine detail work, but it can also be more prone to chipping. A shallower angle is more robust and better for heavy cuts, but may not leave as fine a finish. For beginners, common angles are:

| Tool Type | Recommended Bevel Angle | Purpose |

|---|---|---|

| Spindle Gouge | 30-45 degrees | Detailing, general spindle work |

| Bowl Gouge | 40-55 degrees | Roughing, shaping bowls, face grain |

| Skew Chisel | 40-45 degrees (flat grind), ~60 degrees (swept back grind) | Shearing cuts, smoothing, detailing |

| Scraper | 90 degrees (for the square nose), with a highly burnished nose | Smoothing end grain, flat surfaces |

The Core Concept: Your Homemade Sharpening Machine

At its heart, a wood lathe tool sharpening machine is a system that holds an abrasive (like a grinding wheel or sharpening stone) at a consistent angle to your tool for repeatable sharpening. We’re going to create a jig that guides your tool accurately. The most common and effective type for beginners to build uses a bench grinder or a dedicated sharpening wheel. The key is repeatable accuracy. This means the machine needs to hold the abrasive and guide your tool in a way that removes minimal metal while creating the correct bevel angle every single time.

Essential Components and Materials

Let’s gather what you’ll need. Simplicity is key for a homemade build, so we’ll focus on readily available materials. Your goal is to create a stable platform and an adjustable guide that can hold your tools at precise angles.

For the Grinding Station (Option 1: Bench Grinder)

- Bench Grinder: A standard bench grinder with a coarse and fine grinding wheel is ideal. Ensure it has a solid base. Wood Magazine has a great overview of selecting bench grinders.)

- Tool Rest: Most bench grinders come with a tool rest. We’ll look at modifying or replacing this for better stability and angle adjustment.

- Water Trough (Optional but Recommended): To cool the tool and prevent overheating, a small water trough or a water-soaked sponge placed near the wheel is great.

For the Sharpening Jig:

- Wood (Hardwood is best): Scraps of 3/4-inch or 1-inch thick hardwood like oak, maple, or birch are perfect. You’ll need pieces for the base, fence, and tool rest arm.

- Metal Angle Bracket: A few sturdy metal angle brackets to join wooden pieces securely.

- Threaded Rod or Bolt: A medium-length threaded rod or a long bolt (e.g., 1/2-inch diameter) with nuts and washers. This will act as the pivot for angle adjustment.

- Wood Screws: Various lengths for assembling the wooden parts.

- Hinges (Optional): Small, sturdy hinges can be used for an adjustable angle base.

- Non-Slip Material: A piece of rubber matting or cork to place under the jig base for stability.

- Measuring Tools: Tape measure, ruler, angle finder or protractor.

- Marking Tools: Pencil.

Tools for Construction:

- Saw: A table saw, miter saw, or even a hand saw will work for cutting the wood pieces.

- Drill and Drill Bits: For pilot holes and creating the pivot point.

- Screwdriver: To drive screws.

- Sandpaper: To smooth any rough edges.

- Clamps: To hold pieces together while gluing or screwing.

Design Concept: The Bench Grinder Sharpening Jig

Our homemade sharpening machine will consist of a stable base that clamps or wedges onto your bench grinder’s tool rest. This base will have an adjustable fence or arm that guides your tool. The fence will have multiple slots or adjustable guides to accommodate different tool profiles and bevel angles. The key is that the distance from the pivot point of the tool to the grinding wheel remains constant, ensuring a consistent bevel as you move the tool. This is a proven method that many woodturners use.

Step-by-Step: Building Your Jig

Let’s get building! We’ll focus on a popular and effective design that uses your existing bench grinder. This jig is designed to be simple, robust, and accurate. We’ll use common lumber and hardware.

Step 1: Prepare Your Bench Grinder Setup

First, ensure your bench grinder is securely mounted. If it’s a benchtop model, consider bolting it to a sturdy workbench. The standard tool rests that come with grinders are often not ideal for precise sharpening. You may need to remove the existing rest and plan to attach your new jig directly to the grinder’s frame or modify the existing mounting point. Safety first: always unplug the grinder before making any modifications.

Step 2: Construct the Base Platform

Cut a piece of your hardwood (e.g., 1-inch thick) to serve as the base of your jig. A good starting size might be 6 inches wide by 8 inches long. This base will sit on your grinder’s tool rest or be mounted to the grinder’s frame. On the underside of this base, attach a strip of wood or a metal bracket that will securely fit over or around your grinder’s tool rest post. This ensures the jig doesn’t move during sharpening. If mounting directly to the grinder, drill holes through the base that match the mounting holes on your grinder’s support arm and secure with bolts.

Step 3: Create the Adjustable Fence and Pivot

This is the most crucial part. You need an arm that pivots to set your sharpening angle and a fence to guide the tool.

- Main Arm: Cut a sturdy piece of hardwood for the main arm (e.g., 1.5 inches thick, 3 inches wide, and about 10-12 inches long). This arm will extend over the grinding wheel.

- Pivot Point: Drill a hole through the back of the main arm, about 2 inches from one end. This will be the pivot. Drill a corresponding hole in the base platform, ensuring the arm can pivot freely. Insert a sturdy bolt or threaded rod through these holes, securing it with nuts and washers. This pivot allows you to adjust the angle of the arm relative to the grinding wheel. For better angle adjustment, you can create a series of holes in the base where the pivot bolt passes through, allowing you to select different angles. Another approach is to use a robust hinge connecting the arm to the base, with a way to lock that angle.

- Fence: Attach a vertical fence to the top surface of the main arm. This fence will be where you rest your tool. The fence should be about 3-4 inches high. You can build it from two pieces of wood or a single solid piece. The critical aspect is creating a flat, stable surface for your tool to slide against.

Step 4: Incorporate Angle Adjustment and Locking

To set and lock your sharpening angle, you need a mechanism.

- Angle Marking: On the base platform, adjacent to the pivot, mark degrees using an angle finder. This helps you set consistent angles.

- Locking Mechanism: This could be as simple as tightening the pivot bolt firmly. For more robust locking, add a wing nut or a second bolt that clamps the arm to the base once the desired angle is set. If you’ve made a series of holes for the pivot bolt, the bolt itself acts as the locking mechanism at each selected angle setup.

Step 5: Add Tool Guides and Refinements

The fence needs to guide your tools accurately over the grinding wheel.

-

- Slots for Tools: Cut slots into the fence. These slots will position your tool at the correct angle relative to the grinding wheel. For instance, you might cut a slot at 45 degrees for your spindle gouge and another at 55 degrees for a bowl gouge. The width of the slot should be just enough for your tool to fit snugly.

- Adjustable Guide (Optional yet Recommended): For even more versatility, you can make the fence itself adjustable or create a sliding guide block that attaches to the fence rail. This block can be moved in or out to control the depth of cut and provide a stable rest for different tool shapes. A common method involves a sliding carriage with a fence attached, which moves along a track on the main arm. This allows you to precisely control the position of the tool on the grinding wheel.

- Non-Slip Base: Glue a piece of rubber matting or cork to the underside of the jig’s base. This prevents it from sliding on the grinder’s tool rest during operation.