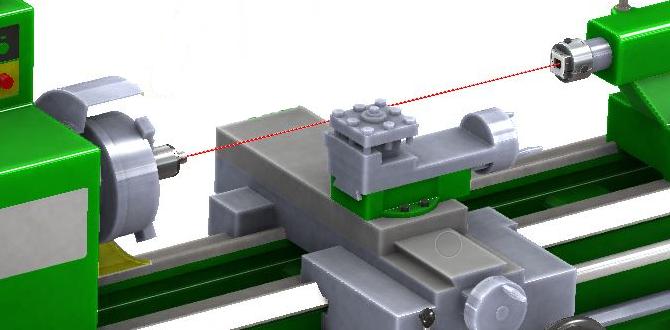

Don’t let dull tools ruin your woodturning! This guide reveals common wood lathe tool sharpening mistakes and how to fix them, ensuring clean cuts and satisfying projects every time. Master sharpening for better results and safer operation.

Welcome to Lathe Hub! As a fellow enthusiast and lifelong machinist, I know that getting a clean cut on your wood lathe can be frustrating, especially when your tools aren’t performing at their best. One of the biggest culprits is dull tools, and figuring out how to sharpen them properly can seem like a puzzle. Many beginners stumble over the same few mistakes when sharpening their wood lathe tools, leading to poor finishes, torn grain, and even dangerous situations. But don’t worry! We’re going to break down these common pitfalls and show you exactly how to avoid them. Get ready to transform your turning experience with perfectly sharp tools.

Why Sharp Tools Matter on Your Wood Lathe

Imagine trying to carve butter with a blunt knife – it’s messy, requires a lot of force, and the result is far from pretty. The same principle applies to your wood lathe tools. Sharp chisels and gouges glide through wood, removing material cleanly and efficiently. Dull tools, on the other hand, require more pressure, causing friction heat, tear-out, and uneven surfaces. This not only makes your work harder but also increases the risk of the tool catching and kicking back, which is a serious safety concern.

For us hobbyists and makers, the goal is to create beautiful pieces with a professional finish. Sharp tools are the foundation of good woodworking. They allow for precise control, beautiful detail, and a much more enjoyable turning experience. Thinking about sharpening as an “oops” moment you can fix later is not the way to go; it’s a core skill that directly impacts every single cut you make.

Common Wood Lathe Tool Sharpening Mistakes Beginners Make

We’ve all been there, staring at a sharpening stone or grinder, wondering if we’re doing it right. The good news is that most sharpening mistakes are easily identifiable and correctable. Let’s walk through the most frequent offenders.

Mistake 1: Not Sharpening Often Enough

This is probably the most common mistake. You might think a tool is still sharp enough because it’s cutting something, but it’s likely not cutting cleanly. A truly sharp tool feels effortless. If you’re finding yourself pushing hard, or the shavings are wispy instead of curling off nicely, it’s time to sharpen. Regular touch-ups are far better than waiting until a tool is completely blunt.

Best Practice: Develop a habit of checking and touching up your tools after a set amount of turning time or when you notice a slight decrease in cutting performance. A diamond-coated file or a few passes on a sharpening stone can make a world of difference in seconds.

Mistake 2: Overheating the Tool Edge

Using a grinder too aggressively can burn the temper out of your tool steel. When steel gets too hot, it loses its hardness, meaning your edge won’t hold up to use, no matter how sharp you get it initially. You’ll know you’ve overheated it if the edge turns blue or if you see smoke. A gentle, brief touch to the grinding wheel is all that’s needed.

Best Practice: Use a grinder with a cool running system (like a water-cooled grinder) or employ a light touch and cool the tool frequently in water. For bench grinders, take short passes and dip the tool in water every few seconds to prevent heat buildup.

Mistake 3: Incorrect Grinding Angle

Every wood lathe tool has an optimal bevel angle for cutting. If you grind at too steep an angle, the edge becomes too fine and brittle, prone to chipping. If the angle is too shallow, the edge won’t be aggressive enough for clean cuts and will dull quickly. The exact angle depends on the tool type (e.g., skew chisel, scraper, gouge) and the type of wood you’re working with. A general range for most turning tools is between 35 and 55 degrees.

Why It’s Tricky: Holding a consistent angle while grinding, especially freehand, is challenging. Many beginners rely on jigs, which is a great way to maintain accuracy.

Resources: For detailed recommendations on bevel angles for specific tools, the American Association of Woodturners (AAW) offers excellent technical resources for its members and the wider community.

Mistake 4: Losing the Tool’s Original Geometry

When you sharpen, you’re essentially removing metal to re-establish the cutting edge. If you remove too much metal, or grind unevenly, you can alter the tool’s original shape. For example, grinding away too much from the flute of a bowl gouge can change its sweeping action, making it harder to control. This often happens when trying to remove a chip or a heavily damaged edge too quickly.

Best Practice: For significant repairs, use a coarser grit wheel or stone and focus on restoring the basic shape and bevel. For regular sharpening, use finer grits and only remove enough metal to re-establish the sharp edge. Tools like the Oneway Vari-Grind jig can help maintain the original shape of bowl gouges.

Mistake 5: Relying Solely on a Grinder

Grinding is essential for reshaping or repairing a dull edge, but it shouldn’t be the only sharpening step. Grinding can leave microscopic tears and a somewhat rough edge. For a truly keen, long-lasting edge, you need to hone or strop the tool after grinding. This process refines the edge, removes any burrs, and makes the tool perform significantly better.

Honing and Stropping: Honing typically involves using finer grit sharpening stones (like water stones or diamond plates) to further sharpen and refine the edge. Stropping uses a leather strop, often with a polishing compound, to remove any last imperfections and create an incredibly sharp, razor-like edge.

Mistake 6: Improper Use of Sharpening Jigs

While jigs are fantastic for consistency, they need to be set up correctly. If a jig isn’t properly aligned, or if you’re using the wrong jig for a particular tool, you can end up grinding at the wrong angle or unevenly. Always read the instructions for your specific jig.

Common Jig Issues:

- Incorrect distance from the grinding wheel.

- Jig not held firmly against the tool rest.

- Using a jig designed for one tool on a different tool type.

Mistake 7: Not Checking for a Burry Edge

When you grind or hone a tool, a small “burr” or wire edge forms on the very tip of the cutting edge. This burr is often the sharpest part right after sharpening. However, if you don’t remove or refine this burr properly, it can break off during the first few cuts, leaving you with a seemingly dull tool almost immediately. You should be able to feel a slight wire edge with your fingertip (carefully!) or see it under magnification.

How to Fix: Stropping is the key to refining this burr. It bends the burr over and then shaves it off, leaving a clean, strong edge.

Essential Tools for Sharpening Wood Lathe Tools

To avoid these mistakes, you’ll need a few key items. Don’t feel like you need the most expensive gear to start; functional tools are the priority.

- Grinding Wheel: A bench grinder (ideally 8-inch, 1750 RPM for slower, cooler grinding) is the most common. Slow speed grinders are preferred to minimize heat.

- Sharpening Stones: Water stones (e.g., Japanese water stones) or diamond plates are excellent for honing. They come in various grits, from coarse for repair to very fine for polishing.

- Strop: A leather strop (can be mounted on wood or a board) with a honing compound like CBN or diamond paste is crucial for the final edge refinement.

- Sharpening Jigs: Essential for consistent bevel angles, especially for bowl gouges and scrapers. Common types include the Oneway Vari-Grind, various Wolverine™ Grinding Jigs, or simpler angle guides.

- Water Bath/Coolant: A bucket of water for cooling the tool during grinding, or a dedicated grinder coolant system.

- Safety Gear: Safety glasses are a MUST. Gloves are optional but can help with grip.

Sharpening Techniques: A Step-by-Step Approach

Let’s break down the common sharpening process, which often involves grinding and then honing/stropping. We’ll focus on a typical bowl gouge as an example.

Step 1: Assess Your Tool and Grinding Needs

Is the tool just slightly dull from regular use, or is it significantly damaged with nicks and chips?

- Slightly Dull: You’ll likely only need a light touch-up on the grinder, followed by honing and stropping.

- Damaged/Very Dull: You might need to reshape the tool first. This requires more time on the grinder, focusing on restoring the basic geometry and bevel before refining the edge.

Step 2: Set Up Your Grinding Station

Ensure your grinder is stable. Have your water bucket ready. If using a jig, set it up according to the manufacturer’s instructions. For a bowl gouge, you’ll typically set the jig so the tool rest makes contact with the jig, guiding the gouge into the wheel at the correct angle.

Step 3: Grinding the Bevel

Hold the tool firmly against the jig or tool rest. For a bowl gouge, you’ll typically rotate the tool as you move it across the grinding wheel to form the “wings” and the cutting edge.

- Angle: Aim for your desired bevel angle (around 30-40 degrees for a swept-back bowl gouge is common, leading to about a 55-60 degree cutting edge angle).

- Pressure: Use light pressure. Keep the tool moving across the wheel.

- Cooling: Dip the tool in water frequently to prevent overheating. A blue discoloration means you’ve overheated it.

- Consistency: Grind both sides of the bevel evenly.

Step 4: Check for the Burr

Carefully feel the edge with your fingertip. You should feel a slight wire edge on the opposite side of where you were grinding. If you don’t feel a burr after grinding, you haven’t ground enough to create one, or you’ve burned the edge.

Step 5: Transition to Honing (Optional but Recommended)

If you have sharpening stones or diamond plates, this is where you refine the edge.

- Stone Grit: Start with a medium grit stone (around 1000) if your grinder left a somewhat rough edge.

- Technique: Glide the bevel of the tool across the stone, maintaining the same angle you used on the grinder. Move from the heel of the bevel to the toe.

- Progression: Move to finer grits (e.g., 4000-8000 grit stones) to polish the edge.

Step 6: Stropping for the Final Edge

This is the secret weapon for a razor-sharp edge that lasts.

- Compound: Apply a honing compound to the leather strop.

- Technique: Hold the tool at a slightly shallower angle than your grinding bevel. Alternate sides, moving the tool from heel to toe, trailing the edge. The goal is to push the burr back and forth until it’s removed, leaving a polished, keen edge.

- Safety: Be very careful; a stropped edge is incredibly sharp.

Sharpening Angles and Tool Types: A Quick Guide

Different tools require different approaches. Here’s a general overview of common angles. Remember, these are starting points, and personal preference and material can influence the ideal angle.

| Tool Type | Typical Bevel Angle (degrees) | Primary Grinding Method | Key Consideration |

|---|---|---|---|

| Bowl Gouge (Swept Back) | 30-40 (for flute grind) | Grinder with jig, honing, stropping | Maintain flute shape & wing integrity. Swept back grinds offer maneuverability. |

| Spindle Gouge | 30-35 | Grinder with jig, honing, stropping | Less swept back than bowl gouges, more focused on fine spindle work. |

| Skew Chisel | 35-45 | Grinder, honing, careful stropping | Maintain accurate cutting edge geometry; very easy to overgrind. |

| Scrapers (e.g., Round, Square) | 90 (flat edge), then turn slight burr | Grinder (briefly), honing stones | Creating a burr is critical for scraping action. Lubricants can help. |

| Parting Tool | 55-60 (primary bevel for clearance) | Grinder, honing | Primary bevel is steep; secondary relief bevel is minimal. |

| Roughing Gouge | 20-25 | Grinder, honing, stropping | A more aggressive, robust edge for initial shaping of blanks. |

Troubleshooting Common Sharpening Problems

Even with the best intentions, you might run into snags. Here’s how to tackle them.

Problem: The edge dulls almost immediately after sharpening.

Possible Causes:

- Overheating: The edge lost its temper. It will feel sharp but crumble with the slightest use.

- Improper Burr Removal: The burr was too large and broke off, taking a thin layer of metal with it.

- Using Low-Quality Steel: Some cheaper tools are made from softer steel that won’t hold an edge.

- Grinding Too Much Material: You might be removing too much metal, leaving a very thin, weak edge.

Solutions:

- Re-grind carefully, ensuring no overheating.

- Focus on proper stropping to refine, not remove, the burr.

- Consider investing in higher-quality tools for critical work.

- Use minimal pressure when sharpening and only remove what’s necessary to restore the edge.

Problem: The tool is tearing the wood, not cutting cleanly.

Possible Causes:

- Dull Edge: The most common reason.

- Incorrect Bevel Angle: Too steep an angle may lead to rubbing rather than cutting.

- Too Much Clearance: The back of the bevel is rubbing on the wood, preventing the cutting edge from engaging properly.

Solutions:

- Sharpen the tool thoroughly.

- Ensure your bevel angle is appropriate for the tool and wood.

- Check the clearance angle behind the bevel; it should be sufficient for the tool to cut freely.

Problem: I can’t get a consistent bevel angle.

Possible Causes:

- Freehand Grinding: Holding a consistent angle without a jig is very difficult.

- Jig Not Set Correctly: The jig itself might be misaligned or not properly secured.

- Tool Slipping: The tool might be slipping in your hand or against the jig.

Solutions:

- Invest in a Jig: This is often the best solution for consistency.

- Practice: Even with a jig, a little practice on scrap metal or wood can help you get a feel for it.

- Ensure Stability: Make sure your tool rest and jig are firmly in place.

Learning to sharpen effectively is a continuous process. Don’t get discouraged if your first few attempts aren’t perfect. The Woodturners’ Guild of America often has local chapters that offer workshops or advice from experienced turners, which can be invaluable.

FAQ: Your Wood Lathe Tool Sharpening Questions Answered

Q1: How often should I sharpen my wood lathe tools?

A1 for beginners: Sharpen whenever you notice the tool is not cutting cleanly or requires extra effort. For more experienced turners, a quick touch-up might be needed every 15-30 minutes of heavy use, or even less for light work. Regular checks are key!