Wood lathe torque issues can be frustrating, but most are easily fixed with simple adjustments and a few common tools. This guide provides clear, proven solutions to get your lathe running smoothly and powerfully again.

Hey folks, Daniel Bates here from Lathe Hub! If you’re working on your wood lathe and it feels like it’s struggling, especially when you’re turning larger pieces or using certain tools, you’re not alone. It’s a common hiccup, and it can really take the fun out of your project. A lack of torque, or power, from your wood lathe can make turning feel like a battle instead of a joy. But don’t worry, this isn’t a problem that requires a whole new machine! In many cases, we can pinpoint the issue with some simple checks and make your lathe ready to tackle any project. Let’s get that power back and make your turning smooth and satisfying again. We’ll walk through the most likely culprits and how to fix them, step by step.

Understanding Wood Lathe Torque

Before we dive into fixes, let’s quickly talk about what torque really means for your wood lathe. Think of torque as the twisting force your lathe’s motor delivers to the spindle. It’s what allows you to remove material efficiently and smoothly, especially when you’re working with dense hardwoods or turning large diameter stock. High torque means your lathe can maintain speed and power even under load. When torque is low, the spindle can slow down significantly or even stop when you apply pressure with a cutting tool. This not only makes for a frustrating and inefficient turning experience but can also be a safety hazard.

For beginners, it’s easy to confuse power (measured in horsepower or watts) with torque. While related, a powerful motor doesn’t automatically guarantee high torque at the spindle, especially at lower speeds. The design of the motor, the drive system (belt, gears, or direct drive), and the control electronics all play a role in delivering usable twisting force to your workpiece. For most wood lathes, especially those found in home workshops, maximizing and maintaining this torque is key to enjoyable and productive woodworking.

Common Causes of Wood Lathe Torque Issues

Most wood lathe torque problems stem from a few common sources. Identifying the root cause is the first step to a quick and effective fix. Let’s break down the most frequent culprits:

- Belt Slippage: This is by far the most common reason for perceived power loss. When the belt connecting the motor to the headstock drive pulley is loose, worn, or dirty, it can’t effectively transfer the motor’s power to the spindle.

- Motor Issues: The motor itself might not be performing optimally. This could be due to overheating, internal electrical problems, or issues with the motor controller (especially on variable-speed lathes).

- Drive System Problems: Beyond the belt, other parts of the drive system like worn pulleys, seized bearings in the motor or headstock, or even a poor connection between components can reduce torque.

- Incorrect Speed Settings: While not a “fix,” sometimes users encounter torque issues because they are trying to turn too fast for the size of the workpiece or the type of wood.

- Power Supply Issues: An inadequate or unstable power supply to the lathe can limit its ability to deliver full power and torque.

We’ll tackle each of these in detail, providing clear steps to diagnose and resolve them so you can get back to turning with confidence. Understanding these points will help you become a more intuitive woodworker, able to troubleshoot your tools effectively.

Fixing Wood Lathe Torque Issues: A Step-by-Step Guide

Let’s roll up our sleeves and get your wood lathe running with the power it should have. We’ll start with the easiest and most common fixes and move towards more involved diagnostics.

Step 1: Inspect and Adjust the Drive Belt

This is the number one suspect for torque loss. A loose or worn belt simply can’t grip the pulleys well enough to transmit power effectively. Think of it like a bicycle chain that’s too slack – it slips and doesn’t transfer your pedaling force efficiently.

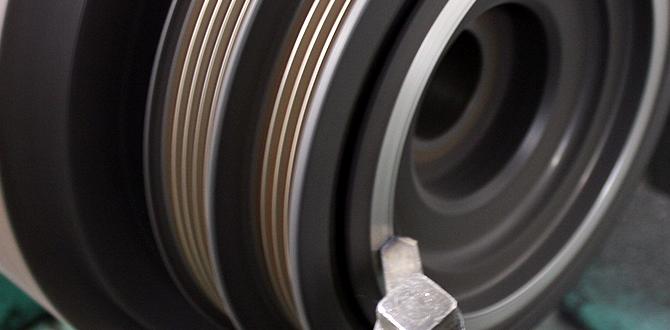

What to Look For:

- Belt Tension: With the lathe unplugged, press on the belt midway between the two pulleys. It should have a little give, maybe about half an inch to an inch, but it shouldn’t feel excessively loose or floppy. If it feels really slack, it needs tightening.

- Belt Condition: Examine the belt for any signs of wear, such as glazing (a shiny, smooth surface), fraying, cracking, or missing chunks. A worn belt will often have reduced grip.

- Belt Cleanliness: Over time, belts can accumulate dust, resin build-up, or even oil. This film can significantly reduce friction.

- Pulley Condition: Check the pulleys themselves for wear or damage. If the grooves in the pulleys are worn out, they won’t properly seat the belt.

How to Adjust/Fix:

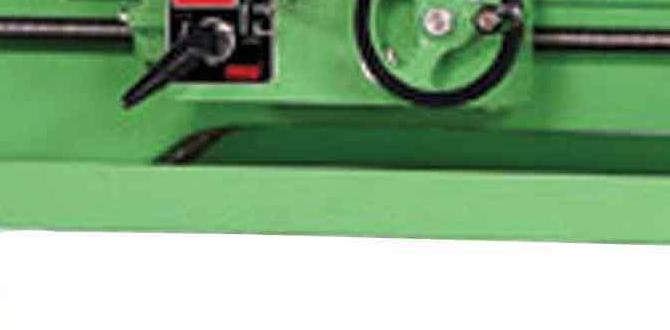

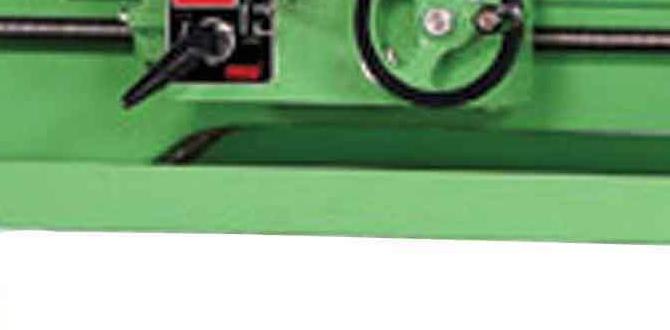

The method for adjusting belt tension varies by lathe model. Many lathes have the motor mounted on a sliding rail, allowing you to pull the motor away from the headstock to tighten the belt. Some might have an adjustment screw.

- Unplug the Lathe: Always ensure the machine is completely disconnected from power before making any adjustments.

- Locate the Belt Guard: You’ll typically need to remove a cover or guard to access the belt and pulleys.

- Adjust Motor Position: If your lathe has a sliding motor mount, loosen the bolts or clamps that hold the motor in place. Gently pull the motor away from the headstock until the belt has the correct tension.

- Tighten Motor Mount: Once the tension is right, firmly retighten the motor mounting bolts.

- Check Pulley Alignment: Ensure the motor pulley and headstock pulley are perfectly aligned. Misalignment can cause premature belt wear and slippage. You can often check this by lining up a straight edge against the pulleys.

- Clean the Belt and Pulleys: If the belt and pulleys are dirty, a good cleaning with isopropyl alcohol or a mild degreaser can improve grip. Avoid using lubricants on the belt itself, as this will cause excessive slippage.

- Replace Worn Belts: If the belt is visibly worn, damaged, or glazed, the best solution is to replace it. Make sure to get the correct size and type for your specific lathe model. Manufacturer websites or good woodworking supply stores can help you find the right replacement.

Tip: For variable-speed lathes, ensure the belt is set to the correct groove for the desired speed range. Using a different pulley groove might affect torque characteristics. You can find specifications on belt tension and maintenance in your lathe’s user manual. For example, Wood Magazine provides excellent general advice on keeping lathes in top shape, which often includes belt maintenance sections.

Step 2: Check the Motor and Electrical Connections

If the belt seems fine, the next step is to look at the motor and its power delivery. An inefficient motor or loose connection can rob your lathe of precious torque.

What to Look For:

- Motor Overheating: Does the motor feel excessively hot to the touch after short periods of use? Overheating can cause a motor to lose power. Ensure ventilation openings are clear.

- Strange Noises: Listen for unusual grinding, buzzing, or humming noises from the motor. These can indicate bearing issues or internal motor problems.

- Loose Wires: With the lathe unplugged, visually inspect all electrical connections going to and within the motor housing and the control switch. Look for any wires that appear loose, frayed, or burnt.

- Variable Speed Control: If you have a variable-speed lathe, the electronic speed control box might be malfunctioning. Does the speed fluctuate oddly, or is it difficult to achieve lower speeds?

How to Check/Fix:

- Unplug Lathe: Safety first! Always disconnect power.

- Inspect Motor Ventilation: Make sure the vents on the motor housing are free of dust and debris. Use compressed air to clean them out.

- Tighten Electrical Connections: Carefully open the motor housing or control box (refer to your manual) and check that all wire terminals are securely fastened. Gently wiggle wires to ensure they are not loose. Burnt or discolored connections indicate a problem that may require professional attention or replacement of parts.

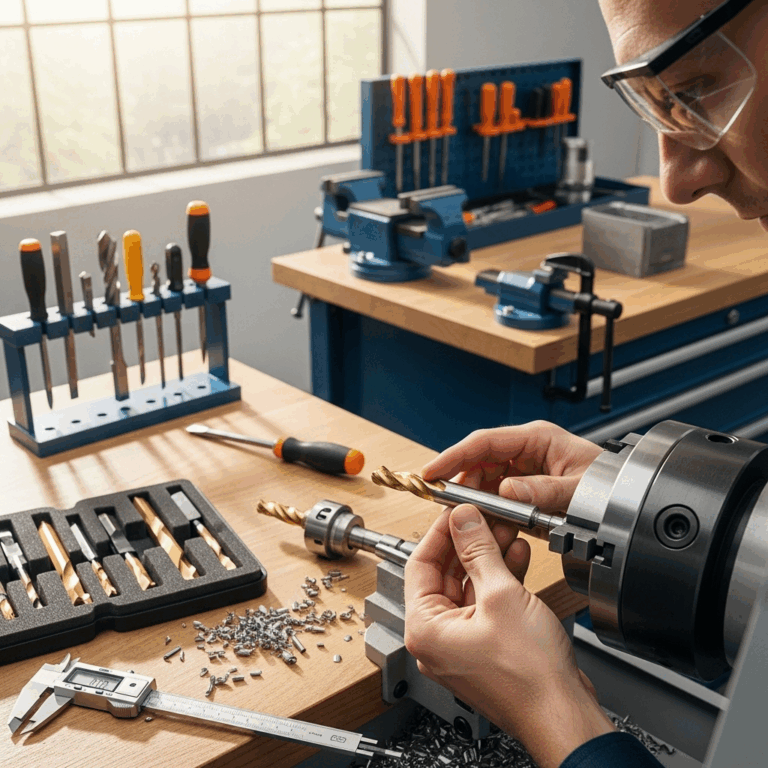

- Test Motor Bearings: With the belt removed, try spinning the motor shaft by hand. It should spin freely and quietly. If it feels rough, noisy, or seized, the motor bearings may need replacement. This is often a job for a professional or an experienced DIYer, as motor bearings can be tricky.

- Variable Speed Control Troubleshooting: For variable speed issues, sometimes a simple reset of the control unit (unplugging for a few minutes and plugging back in) can help. If problems persist, it might indicate a faulty capacitor or control board. Consult your manual or the manufacturer for specific troubleshooting steps for your model. You might find resources at sites like OSHA that detail safe power tool operation and electrical safety in workshops, reinforcing best practices.

Step 3: Examine Headstock and Tailstock Bearings

Friction in the spinning parts of the lathe itself – the headstock (where the motor drives the spindle) and tailstock (the non-driven end) – can also sap torque. If these bearings are worn or not properly lubricated, they create resistance that the motor has to fight against.

What to Look For:

- Rough Rotation: With the belt removed, try spinning the headstock spindle (where the drive pulley is) and the tailstock spindle by hand. Do they feel smooth, or is there roughness, grinding, or excessive resistance?

- Wobble or Play: Does the spindle have noticeable side-to-side or up-and-down play? This could indicate worn bearings.

- Noise: Listen for any grinding or rumbling noises when turning the spindles.

How to Check/Fix:

- Unplug Lathe: Always disconnect power.

- Remove Belt: Take the drive belt off to isolate the spindle rotation.

- Spin Spindles Manually: Grasp the spindle (usually at the drive end) and rotate it. Feel for smoothness.

- Check for Play: Try to wiggle the spindle. A small amount of movement might be normal on some lathes, but excessive wobble definitely points to worn bearings.

- Lubrication: Many headstock and tailstock spindles have grease ports that require periodic lubrication. Consult your lathe’s manual for the correct type of lubricant and the recommended intervals.

- Bearing Replacement: If the bearings are rough, noisy, or have excessive play, they will likely need to be replaced. This is a more involved repair. For some benchtop lathes, you might be able to access and replace the bearings yourself by safely disassembling the headstock or tailstock assembly. For larger or more complex lathes, it’s often best to consult a qualified technician or your lathe’s manufacturer for guidance. Identifying the correct bearing specifications (e.g., Conrad type ball bearings, taper roller bearings) is crucial for replacement.

Step 4: Consider Workpiece Size and Wood Type

Sometimes, the “torque issue” isn’t with the machine but with the demands placed upon it. Trying to turn a large, dense piece of hardwood at high speed with an underpowered lathe will always feel like a struggle.

When to Adjust Your Expectations:

- Workpiece Diameter: Larger diameter pieces require significantly more torque to turn smoothly. As the diameter increases, the load on the motor increases exponentially.

- Wood Density: Dense hardwoods (like oak, maple, or exotic hardwoods) require more torque than softer woods (like pine or poplar) to cut effectively.

- Tool Choice and Technique: Using a very aggressive cut with a large gouge or parting tool will also demand more torque than lighter cuts with a skew or scraping tools.

How to Mitigate:

- Reduce Speed: For larger or denser workpieces, simply reducing the lathe’s speed can make a huge difference. Many variable-speed lathes allow you to dial down the RPMs significantly. Aim for a speed where the lathe doesn’t bog down. For example, turning a 10-inch diameter bowl blank might require speeds under 300 RPM, while a small spindle project could be turned at 1000 RPM or more.

- Make Lighter Cuts: Instead of trying to remove a lot of material at once, take shallower, more frequent cuts. This puts less strain on the motor and results in a smoother finish.

- Rough Turning: For large bowl blanks, consider roughing out the basic shape at a very low speed, then re-speeding the lathe for final shaping and finishing.

- Use Appropriate Tools: Ensure your cutting tools are sharp. Dull tools require more force to cut, dramatically increasing the load on the lathe and reducing perceived torque.

Tool Sharpening and Maintenance: This is non-negotiable. Sharp tools cut easily and efficiently, reducing strain on both you and your lathe. Organizations like the American Association of Woodturners (AAW) offer great resources and advice on tool sharpening techniques for woodturners.

Step 5: Address Power Supply Issues

A healthy motor needs healthy power. An insufficient or inconsistent power supply can mimic the symptoms of a weak motor or drive system.

What to Look For:

- Extension Cord Usage: Are you using a thin, long extension cord? These can create significant voltage drop, reducing power to the motor.

- Circuit Load: Is the lathe plugged into a circuit that is already heavily loaded with other tools or appliances?

- Home Wiring: Older home wiring may not be adequate to supply the consistent power needed for some motors, especially those with higher draw.

How to Check/Fix:

- Use Recommended Extension Cords: If you must use an extension cord, ensure it’s a heavy-duty gauge (e.g., 12-gauge or 10-gauge) and as short as possible. Consult your lathe’s manual for specific power requirements. Never use a “household” light-duty cord.

- Dedicated Circuit: Ideally, a larger wood lathe should be on its own dedicated circuit. If you’re experiencing frequent tripping or dimming lights when the lathe kicks on, this is a strong indicator. You might need an electrician to install a new circuit.

- Test Voltage: If you have a multimeter, you can test the voltage at the outlet with the lathe idle and under load. A significant drop in voltage when the lathe is running can indicate a power supply problem or an inadequate circuit.

- Plug Directly into Wall: When troubleshooting, try plugging the lathe directly into a wall outlet (without any extension cords or power strips) to rule out issues with those accessories.

Safety Note: Working with electrical systems can be dangerous. If you are unsure about any electrical testing or modifications, always consult a qualified electrician. For information on safe electrical practices, the National Fire Protection Association (NFPA) offers valuable resources.

Troubleshooting Table: Common Torque Issues and Solutions

Here’s a quick reference to help you diagnose and fix your wood lathe’s torque problems:

| Symptom | Likely Cause | Primary Fix | Secondary Fix |

|---|---|---|---|

| Lathe bogs down easily when cutting | Loose or worn drive belt | Adjust belt tension / Replace belt | Clean belt and pulleys |

| Lathe feels weak, even with new belt | Motor overheating / Electrical connection issue | Ensure motor ventilation is clear / Tighten connections | Check motor bearings / Variable speed control |

| Spindle is rough when turned by hand (belt off) | Worn headstock/tailstock bearings | Lubricate bearings / Replace bearings | Check for proper spindle alignment |

| Lathe struggles with large or dense wood | Attempting too aggressive a cut or too high a speed | Reduce speed and depth of cut | Use sharper tools |

| Lathe loses power when tool is applied, especially at low speeds |