A wood lathe spins a workpiece to shape it with cutting tools, creating round objects like bowls and spindles. A router uses a spinning bit to cut material away, ideal for decorative edges, dados, and inlays. Choosing between them depends on your project goals and desired woodworking results.

Woodworking can feel like a puzzle sometimes, especially when you’re starting out. You see all these amazing projects – from elegant bowls to intricately carved furniture – and you wonder, “How did they do that?” Often, the tools at the heart of these crafts are a wood lathe and a router. But what’s the real difference, and which one should you pick up first? Many beginners find themselves scratching their heads, trying to figure out which tool is best for their specific needs. Is a wood lathe for turning, or can a router do similar magic? Don’t worry, it’s a common question, and by the end of this guide, you’ll have a clear picture. We’ll break down the wood lathe vs. router debate, look at what each tool excels at, and help you make an informed decision for your workshop. Get ready to demystify these essential woodworking machines!

Wood Lathe VS Router: Understanding the Core Differences

The first step to understanding which tool is right for you is to grasp what each one fundamentally does. Think of it this way: a wood lathe turns the wood, while a router carves into it. This simple distinction opens up entirely different creative pathways.

What is a Wood Lathe?

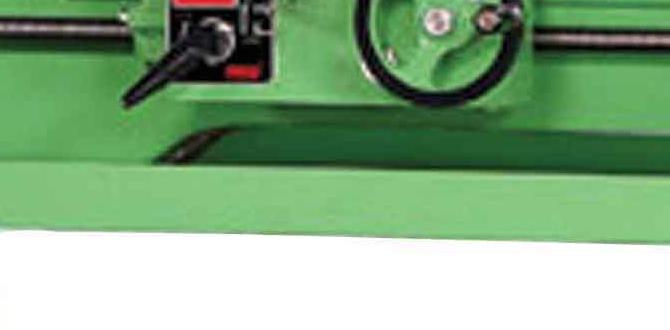

A wood lathe is a woodworking machine that rotates a piece of wood between two centers or between a spur and a faceplate. You then use various sharp cutting tools to shape the wood as it spins. It’s the classic tool for creating symmetrical, round objects. If you dream of crafting bowls, vases, pens, table legs, or spindles, the wood lathe is your go-to machine.

How it works: The wood is mounted and spins at a controlled speed. The woodturner then applies specialized chisels and gouges to gradually remove material and form the desired shape.

Primary function: Shaping wood into round, symmetrical forms.

Key outputs: Bowls, platters, spindles, pens, pepper mills, baseball bats, tool handles.

What is a Router?

A router is a power tool with a spinning cutting bit used to hollow out or shape hard materials, most commonly wood. Unlike a lathe that spins the workpiece, a router holds the cutting bit stationary (in relation to the router body) and moves it across or into the material. Routers come in various types, including handheld and table-mounted versions (router tables).

How it works: A high-speed motor spins a cutting bit. The user guides the router to make cuts, such as creating edges, grooves (dados), mortises, inlay designs, or decorative patterns.

Primary function: Cutting, shaping edges, creating joinery, engraving, and decorative work.

Key outputs: Decorative edges on tabletops, dados for shelves, mortises for hinges, inlay patterns, signs, rabbets for cabinet backs.

The Wood Lathe: Crafting Round Wonders

When you think of a wood lathe, imagine a sculptor’s wheel for wood. It’s all about bringing perfectly balanced, flowing shapes to life from a stationary blank of wood that’s spinning at your command.

What Can You Make with a Wood Lathe?

The possibilities for a wood lathe are vast, especially for anyone interested in traditional woodworking and creating functional art pieces.

Bowls and Platters: From small trinket dishes to large serving bowls, the lathe is essential for creating these iconic shapes. You’ll learn techniques for hollowing, shaping the exterior, and creating a smooth rim.

Spindles and Legs: Whether for furniture like chairs and tables, or decorative elements for banisters, the lathe excels at producing uniform, turned components. You can create intricate patterns and tapers with practice.

Pens and Small Gifts: Mini-lathes are perfect for hobbyists who want to make personalized pens, bottle stoppers, or small decorative items. These projects are great for practicing basic turning skills.

Vases and Hollow Forms: More advanced techniques allow for the creation of hollow forms, which can be incredibly beautiful and complex.

Tool Handles and Custom Grips: Create ergonomic and perfectly fitted handles for your handmade tools.

Essential Wood Lathe Tools and Accessories

To get started with a wood lathe, you’ll need a few key items beyond the lathe itself. These are your basic toolkit for turning:

| Tool | Description | Use |

|---|---|---|

| Spindle Gouge | A versatile tool with a hollow, scooped flute. | Roughing out shapes, creating coves and beads, general turning. |

| Roughing Gouge | A larger, heavier gouge for quickly removing material and establishing basic cylinder shapes. | Efficiently turning square stock into a rough cylinder. |

| Skew Chisel | A flat blade with an angled cutting edge. | Shearing cuts for smoothing, creating details, and finishing curved surfaces. |

| Scraper | A flat tool with a sharpened edge that scrapes rather than cuts. | Finishing and smoothing, especially for end grain or difficult woods. |

| Parting Tool | A narrow, straight blade. | Cutting grooves and separating finished pieces from the stock. |

| Faceplate | A flat disc that screws onto the lathe spindle. | Mounting larger, flatter pieces like bowls. |

| Chuck | A device that grips the workpiece from the inside or outside. | Holding work securely for turning, essential for most bowl turning. |

Safety First with a Wood Lathe

Woodturning involves spinning wood at high speeds, so safety is paramount. Always wear safety glasses or a full face shield. Avoid loose clothing, jewelry, or long hair that could get caught. Ensure your workpiece is securely mounted and balanced. Read your lathe’s manual thoroughly before operating. For more detailed safety guidelines, the Occupational Safety and Health Administration (OSHA) provides valuable insights into machine guarding and safe operating procedures applicable to any workshop equipment.

The Router: Versatility in Shaping and Detail

If the wood lathe is about symmetry and form, a router is your master of customization, pattern-making, and adding fine details. It’s a tool that can transform flat boards into functional items with elegant touches or precise joinery.

What Can You Make with a Router?

The sheer versatility of a router is what makes it indispensable in many workshops. It can perform a wide array of tasks that go far beyond simple cutting.

Decorative Edges: Create beautifully profiled edges on tabletops, shelves, picture frames, and cabinet doors using various router bits.

Joinery: Cut dados (grooves for shelves), rabbets (grooves for cabinet backs or panel insertion), mortises (rectangular holes for tenons), and dovetails with the right jigs.

Inlays and Engraving: With precision, you can cut out shapes to inlay different woods or materials, or create detailed lettering and designs.

Sign Making: Routers are perfect for carving out lettering and graphics for custom signs.

Pocket Holes and Recesses: Create clean, precise pockets for hardware or to recess electrical boxes.

Shaping Components: While not for turning round items, a router can shape curved components or flatten rough surfaces.

Essential Router Jigs and Accessories

To unlock the full potential of a router, especially for precise and repeatable tasks, certain jigs and accessories are a must.

Router Bits: This is your “brush” for the router. Bits come in countless profiles (straight, roundover, chamfer, cove, ogee, flush trim, etc.) and varying shank sizes. Always buy good quality bits for clean cuts and safety.

Router Table: Attaching your router to a table allows for greater control and precision for many tasks, especially edge profiling and smaller cuts. It essentially turns your router into a stationary shaper.

Straight Edge Guide: Essential for making perfectly straight cuts, especially when creating dados or rabbets.

Circle Cutting Jig: Allows you to cut perfect circles or arcs, useful for routing out a dish shape if you don’t have a lathe, or creating circular inlays.

Dovetail Jig/Template: For making precise dovetail joints, a staple in fine furniture construction.

Dust Collection: Routers produce a lot of fine dust. A good dust collection system or vacuum attachment is crucial for a clean and healthy workspace. For safe and effective dust management, consulting resources from the Environmental Protection Agency (EPA) on dust and air quality is a good practice for any workshop.

Safety First with a Router

Routers spin at very high speeds and can easily cause severe accidents if not used properly. Always wear safety glasses or a face shield. Use hearing protection, as routers are loud. Never force the router; let the bit do the work. Keep your hands well away from the spinning bit. Pay attention to kickback, which can happen when the bit binds in the wood. For router table safety, ensure you’re using push sticks and featherboards to keep your hands away from the bit.

Wood Lathe vs. Router: Direct Comparison

To crystallize the differences, let’s put them side-by-side. This comparison highlights their primary strengths and the types of projects they are best suited for.

| Feature | Wood Lathe | Router |

|---|---|---|

| Primary Action | Spins the workpiece; user shapes it with cutting tools. | Holds a spinning cutter; user moves the cutter over/into the workpiece. |

| Output Shape | Primarily round, symmetrical objects (bowls, spindles). | Flat surfaces with profiles, edges, dados, mortises, inlays, engraving. |

| Common Projects | Bowls, platters, pens, table legs, custom handles, small decorative items. | Decorative edges, joinery (dados, rabbets, mortises), signs, inlays, flattening surfaces. |

| Learning Curve | Steep for advanced techniques (bowl hollowing, spindle turning) but basic turning can be learned relatively quickly. Requires specific tool control. | Moderate; handheld use requires practice for stability and precision. Router table use is generally more controlled. |

| Tooling | Gouges, chisels, scrapers designed for shaping spinning wood. | A wide variety of router bits with different profiles and cutting actions. |

| Versatility | Specialized for round work. | Extremely versatile for edge detailing, joinery, and surface work. |

| Space Requirements | Requires clear space around it for safe operation and tool access. | Can be handheld or mounted on a table; table setups require dedicated space. |

| Dust Generation | Significant dust and chips. | Creates fine dust, often more of a particulate issue. |

Can a Router Replace a Wood Lathe (and Vice Versa)?

This is where the nuance comes in. While they are different tools, there are some overlapping capabilities and workarounds.

Can a Router Make Round Things?

Yes, to a degree, but with significant limitations and differences.

Using a Circle Cutting Jig: A router with a circle cutting jig can create perfectly round discs or rings. You can also hollow out the center of a disc to create a basic bowl-like shape or a platter. The surface finish will depend on your technique and the quality of the jig. It won’t inherently give you the hollowed-out shape of a bowl turned on a lathe.

Making Cylinders/Spindles: It’s extremely difficult and impractical to use a router to create a true cylinder or spindle like you would on a lathe. You could technically route flat sides onto a square stock to make it octagonal or hexagonal, but achieving a consistent roundness and a smooth finish is nearly impossible. You’d be far better off using a lathe for this.

Can a Wood Lathe Make Edges or Dados?

Not directly. The fundamental design of a lathe means the wood spins, making it impossible to use a router bit to cleanly cut a straight dado or a profiled edge on stationary wood. You can use specialized turning tools to create decorative rings, beads, and chamfers on a turning piece, but this is different from the flat-plane edge treatments a router excels at.

In essence:

If you want to make bowls, spindles, or anything with rotational symmetry, you need a wood lathe.

If you want to add decorative edges, cut joinery, engrave signs, or perform detailed surface work, you need a router.

Choosing Your First Essential Tool: Lathe or Router?

The decision often boils down to what kind of projects you are most excited about creating.

When to Choose a Wood Lathe First:

You are captivated by the idea of creating bowls, vases, or other hollow forms.

You envision making furniture with turned legs or spindles.

You want to craft small, turned items like pens or pepper mills.

You appreciate the art of removing material with sharp tools to reveal form.

When to Choose a Router First:

Your primary interest is in furniture making, cabinet making, or adding decorative touches to existing projects.

You want to create custom signage or decorative panels.

You need to cut precise joinery such as dados, rabbets, or mortises.

You plan to work with smaller projects like picture frames or cutting boards and want to add nice edges.

You are looking for a highly versatile tool that can do many different tasks.

Many woodworkers eventually own both. They are complementary tools that enable a much wider range of projects than either could alone. Think of them as different chapters in your woodworking journey.

Exploring Advanced Techniques and Applications

Once you’ve mastered the basics of your chosen tool, there’s a whole world of advanced techniques waiting for you.

Advanced Wood Lathe Techniques:

Multi-axis Turning: This involves offsetting the workpiece or using specialized chucks to create asymmetrical or abstract forms.

Segmented Turning: Building up bowls and other forms from many small, precisely cut pieces of wood glued together. This allows for complex patterns and color designs.

Texturing: Using specialized tools or methods to add texture to turned surfaces.

Finishing: Learning techniques for sanding, applying finishes, and polishing turned pieces to a high sheen. A great resource for finishing wood can be found in guides from the Wood Magazine, a trusted authority in woodworking techniques.

Advanced Router Techniques:

Using Templates and Jigs: Beyond the basics, custom jigs can allow for highly repeatable and complex operations like creating custom profiles or precise inlay work.

Inlay Work: Combining different woods, metals, or even plastics to create stunning decorative effects.

Sign Making with CNC: While not strictly traditional router work, many hobbyists use CNC machines (which are essentially automated routers) to create intricate signs and decorative panels with incredible detail.

Edge Routing with Guides: Using plunge routers and guide systems to create clean, straight edges on large panels or to route precisely along existing edges.

Both tools offer a lifetime of learning and creativity. Starting with one and then adding the other as your skills and interests grow is a common and very rewarding path for woodworkers.

Frequently Asked Questions (FAQs)

Q1: Can I turn wood on a drill press?

While a drill press can spin wood, it’s not designed for turning and lacks the stability, tool rest, and safety features of a proper wood lathe. It’s extremely dangerous to attempt turning on a drill press. Stick to dedicated lathes for turning.

Q2: What’s the difference between a handheld router and a router table?

A handheld router is portable and versatile for moving around the workpiece. A router table mounts the router upside down, offering more stability and control for repetitive cuts, edge profiling, and joinery. Many tasks are safer and easier on a router table.

Q3: Is woodturning safe for beginners?

Woodturning has a learning curve and requires respect for the tools and machinery. Basic spindle turning can be learned relatively safely with proper instruction and safety gear. Bowl turning, with its larger forces, often requires more experience. Always prioritize safety.

Q4: Can a router cut circles accurately enough for a bowl?

A router with a good circle jig can cut a precise circle for the outside of a bowl or platter. It can also be used to hollow out the center. However, it won’t achieve the smooth, hollow