Have you ever seen an old lathe and wondered about its history? Antique treadle wood lathes hold secrets of craftsmanship from long ago. These machines helped create beautiful pieces of woodwork, from furniture to toys.

Restoring an antique treadle wood lathe can be a thrilling adventure. Imagine bringing a forgotten tool back to life! You could make it shine just like it did in its prime. Isn’t it exciting to think about all the stories the lathe could tell?

In this article, we will explore the steps to restore an antique treadle wood lathe. You’ll learn helpful tips and tricks along the way. Whether you are a beginner or have some experience, there is something here for everyone. Let’s dive into this rewarding journey of craftsmanship!

Antique Treadle Wood Lathe Restoration: A Step-By-Step Guide

Antique Treadle Wood Lathe Restoration

Restoring an antique treadle wood lathe is like bringing history back to life. You learn how to assess its parts and identify what needs fixing. This process often requires patience and creativity. Did you know that many lathes were used by skillful craftsmen? They shaped wood into amazing designs. By restoring one, you can revive those old stories. Enjoy the satisfaction of transforming rusty pieces into a functioning piece of art!

Understanding Antique Treadle Wood Lathes

Definition and historical significance. Common types and manufacturers.

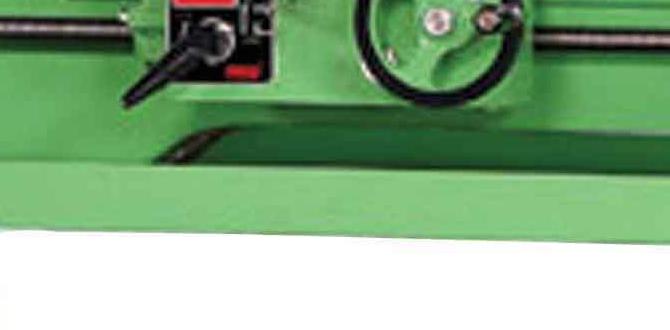

Antique treadle wood lathes are fascinating tools used for shaping wood. These machines use a foot pedal to turn wood, allowing artisans to create beautiful pieces. They date back to the 19th century, marking an important time in woodworking history. Key types include the American and European models, made by various makers like Delta and Rockwell. Restoring these lathes connects us to past craftsmen, showing us their skills and artistry.

What are some common types of antique treadle wood lathes?

- American Treadle Lathes: Known for their sturdy design and reliable performance.

- European Treadle Lathes: Often more intricate, showcasing fine craftsmanship.

- Manufacturers: Popular brands include Delta, Rockwell, and Craftsman.

Assessing the Condition of Your Lathe

Signs of wear and damage to look for. Evaluating metal versus wood components.

Before starting your project, check your lathe carefully. Look for signs of wear and damage. Here are some things to notice:

- Cracks or chips in the wood.

- Rust or corrosion on metal parts.

- Loose screws and bolts.

- Worn-down bearings.

Next, think about the materials. Wood parts can wear out over time, while metal components might last longer. Compare both to see which needs more attention. This will help you plan your restoration better.

What are common signs of damage on a lathe?

Common signs include visible cracks, rust, or loose parts. Always check both wood and metal components closely.

Essential Tools for Restoration

Musthave hand tools for lathe restoration. Recommended power tools for efficiency.

Restoring an antique treadle wood lathe is exciting! First, you need hand tools like chisels, a mallet, and a measuring tape. They’re your trusty sidekicks. Next, power tools can speed things up—think of a drill or a sander. They’re like your superhero partners in crime. Check out the must-have tools below:

| Hand Tools | Power Tools |

|---|---|

| Chisels | Drill |

| Wood Mallet | Sander |

| Measuring Tape | Jigsaw |

With the right tools, you can turn that old lathe into a masterpiece. Remember, always measure twice and cut once—unless you’re looking for a new coffee table design!

Step-by-Step Restoration Process

Disassembly and cleaning techniques. Repairing or replacing damaged parts. Refinishing wood components for aesthetics and durability.

First, take your wood lathe apart. Label each piece. This will save you from playing the guessing game later! Next, clean everything. Use a soft cloth and some soapy water. You want to shine like a new penny! If you find any damaged parts, it’s time to either repair or replace them. Remember, patching things up is like putting a band-aid on a boo-boo. Finally, give the wood a facelift. Sand it down and apply a fresh coat of finish. Think of it as a spa day for your lathe!

| Step | Action |

|---|---|

| 1 | Disassemble parts and label them. |

| 2 | Clean with soap and cloth. |

| 3 | Repair or replace damaged parts. |

| 4 | Refinish the wood for a new look. |

Preservation Techniques for Longevity

Best practices for maintaining the lathe. Tips for applying protective finishes.

To keep your antique treadle wood lathe in tip-top shape, regular maintenance is key. First, keep it clean and dust-free. A swipe with a cloth can do wonders. Next, use a good quality wood oil to enhance the shine and protect the wood. It’s like sunscreen for your lathe! For extra protection, consider applying a finish. It’s not just about looks; it guards against moisture too.

| Technique | Description |

|---|---|

| Dusting | Wipe surfaces regularly to prevent grime buildup. |

| Wood Oil | Apply oil for shine and to protect the wood. |

| Protective Finish | Use a finish to shield against moisture and wear. |

Remember, a little care goes a long way! A lathe that looks happy will make happy projects. So, treat it right, and it will treat you right back!

Common Challenges and Solutions

Dealing with rust and corrosion. Addressing worn bearings and pulleys.

Rust can look scary, but fear not! You can scrub it away with some elbow grease and rust remover. Corrosion loves to creep up, so keep things dry and oiled. Now, about those worn bearings and pulleys — think of them like tired shoes. They might need replacing to keep your lathe spinning smoothly. Don’t fret, finding new parts is easier than finding a needle in a haystack!

| Challenge | Solution |

|---|---|

| Rust | Use rust remover and keep dry. |

| Worn Bearings | Replace with new parts. |

| Corrosion | Oil and store properly. |

Resources for Antique Lathe Enthusiasts

Recommended books and online forums. Where to find spare parts and materials.

Many antique lathe lovers seek great resources. Books can provide deep knowledge. Check out titles like “The Lathe Book” for guidance. Online forums are also helpful. Here, enthusiasts share tips and stories. Don’t forget about places to find parts! Local hardware stores often stock what you need. Websites like eBay or specialized shops sell spare parts too.

- Books to Explore:

- “The Lathe Book”

- “The Complete Guide to Woodturning”

- Helpful Online Forums:

- Woodworking Talk

- Lathe Users Group

Where can I find spare parts for antique lathes?

You can find spare parts at local hardware stores or online platforms like eBay. Specialized woodworking sites also offer various components for restoration.

Showcasing Your Restored Lathe

Ideas for display and usage. Joining local woodworking clubs or exhibitions.

After you restore your lathe, it’s time to show it off! You could place it in your workshop or home as a beautiful display piece. Why not join local woodworking clubs or exhibitions? This is a great way to share your work and meet other woodworkers. You can even show how your lathe works!

- Host a mini workshop at your house to demonstrate your lathe.

- Participate in local fairs to gain new friends and ideas.

- Share photos of your projects on social media.

How can I share my lathe restoration?

You can share your restoration journey by posting online and talking with others at local clubs. Consider making a video about your lathe use. This attracts attention and inspires others!

Conclusion

In conclusion, restoring an antique treadle wood lathe can be a fun and rewarding project. You learn woodworking skills while preserving history. Take your time and gather the right tools. For more tips, check out resources on woodworking restoration. We can keep these beautiful machines alive together! Happy restoring!

FAQs

What Are The Essential Tools And Materials Needed For Restoring An Antique Treadle Wood Lathe?

To restore an antique treadle wood lathe, you need some basic tools. First, get a screwdriver to take it apart. You’ll also need sandpaper to smooth the wood. A wood finish or varnish will help protect it. Lastly, have some oil ready to keep the moving parts working smoothly.

How Can I Identify The Age And Historical Significance Of My Antique Treadle Wood Lathe?

To find out the age of your treadle wood lathe, you can look for any labels or stamps on it. These often show when it was made. You can also search online to find pictures of similar lathes and see when they were used. For historical significance, think about how it was used in woodworking and its role in making furniture. You can ask experts or visit museums for more information too!

What Are The Common Issues That Arise When Restoring An Antique Treadle Lathe, And How Can They Be Addressed?

When restoring an antique treadle lathe, you might find rust on the metal parts. You can clean this off using a rust remover or sandpaper. Sometimes, the wood can be broken or rotting. You can fix this by replacing the bad wood with new pieces. Lastly, the belts may be worn out, so you should buy new belts to replace them.

Are There Specific Techniques For Preserving The Original Finish And Patina Of The Wood While Restoring The Lathe?

Yes, there are ways to keep the wood’s finish and look while fixing the lathe. First, we can clean it gently with a soft cloth. Avoid using water or strong cleaners. We can also use special wood oils to protect it without changing its color. Lastly, if there are scratches, we can lightly sand the area and add wax to help it shine again.

What Safety Precautions Should I Take When Working On The Restoration Of A Treadle Wood Lathe?

When working on a treadle wood lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and avoid loose clothing to stay safe from moving parts. Make sure your tools are in good shape so they don’t break while you work. Use a clean workspace to avoid accidents, and never rush. If you’re unsure about something, ask an adult for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Antique Treadle Wood Lathe Restoration:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are answers to five questions about restoring an antique treadle wood lathe. 1. **What tools do you need?** You need basic tools like wrenches, screwdrivers, and sandpaper. These help you fix and clean the lathe. 2. **How do you clean it?** First, remove dirt and rust with soapy water or a wire brush. Then, dry it well. 3. **How do you fix broken parts?** You can often replace them with new ones. If you can’t find the part, you may need to make it! 4. **What kind of paint should you use?** Use paint that’s safe for wood and looks nice. Try using colors like green or blue, which were popular long ago. 5. **Why should you restore it?** Restoring it keeps history alive. It lets us use and enjoy a cool old tool!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Materials Needed For Restoring An Antique Treadle Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore an antique treadle wood lathe, you need some basic tools. First, get a screwdriver to take it apart. You’ll also need sandpaper to smooth the wood. A wood finish or varnish will help protect it. Lastly, have some oil ready to keep the moving parts working smoothly.”}},{“@type”: “Question”,”name”: “How Can I Identify The Age And Historical Significance Of My Antique Treadle Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find out the age of your treadle wood lathe, you can look for any labels or stamps on it. These often show when it was made. You can also search online to find pictures of similar lathes and see when they were used. For historical significance, think about how it was used in woodworking and its role in making furniture. You can ask experts or visit museums for more information too!”}},{“@type”: “Question”,”name”: “What Are The Common Issues That Arise When Restoring An Antique Treadle Lathe, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When restoring an antique treadle lathe, you might find rust on the metal parts. You can clean this off using a rust remover or sandpaper. Sometimes, the wood can be broken or rotting. You can fix this by replacing the bad wood with new pieces. Lastly, the belts may be worn out, so you should buy new belts to replace them.”}},{“@type”: “Question”,”name”: “Are There Specific Techniques For Preserving The Original Finish And Patina Of The Wood While Restoring The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are ways to keep the wood’s finish and look while fixing the lathe. First, we can clean it gently with a soft cloth. Avoid using water or strong cleaners. We can also use special wood oils to protect it without changing its color. Lastly, if there are scratches, we can lightly sand the area and add wax to help it shine again.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Working On The Restoration Of A Treadle Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working on a treadle wood lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and avoid loose clothing to stay safe from moving parts. Make sure your tools are in good shape so they don’t break while you work. Use a clean workspace to avoid accidents, and never rush. If you’re unsure about something, ask an adult for help.”}}]}