1/8 inch carbide end mills, especially those designed for titanium and high-precision work, offer exceptional durability and accuracy for demanding machining tasks. Choosing the right one ensures clean cuts, extended tool life, and impressive results, even for beginners.

Welcome to Lathe Hub! Ever stared at a tiny, gleaming tool and wondered if it can really handle tough materials like titanium? Specifically, that 1/8 inch carbide end mill. It looks so delicate, but trust me, it’s a powerhouse when used correctly. Many beginners get a bit hesitant, worrying about breaking such a small tool or not getting a good finish. It’s a common concern, but with the right knowledge, you’ll be confidently milling titanium in no time. This guide will break down everything you need to know about these specialized end mills, from what makes them tick to how to get the best performance out of them. Get ready to unlock some serious machining power for your projects!

What is a 1/8 Inch Carbide End Mill?

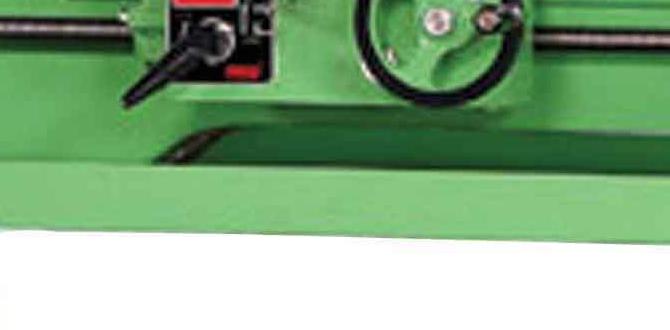

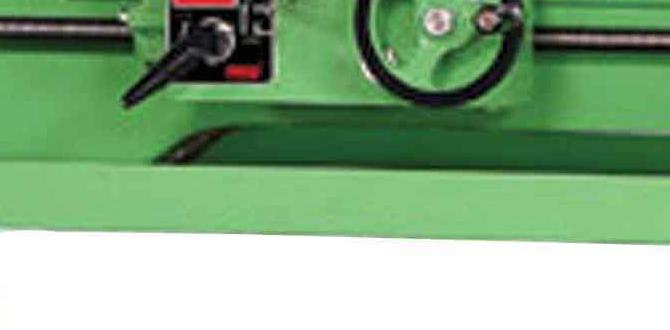

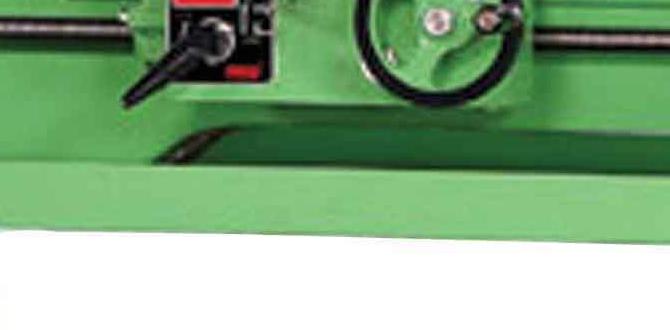

At its heart, a 1/8 inch carbide end mill is a cutting tool used in milling machines to create slots, pockets, and contours in various materials. The “1/8 inch” refers to its cutting diameter, meaning it can create cuts that are precisely 1/8 of an inch wide. “Carbide” signifies the material it’s made from – tungsten carbide. This is a super-hard, man-made material prized for its ability to withstand high temperatures and wear, making it ideal for cutting tough metals. An “end mill” is distinguished from a drill bit because it can cut sideways (laterally) as well as downwards.

The term “shank” refers to the part of the tool that fits into the milling machine’s collet or tool holder. A “reduced neck” is a design feature where the shank below the cutting flutes is slightly smaller in diameter. This design helps prevent the tool from rubbing against the workpiece in deep cuts, improving performance and accuracy.

When we talk about “titanium performance” and specific grades like “titanium grade 5,” we’re focusing on end mills engineered to tackle this exceptionally strong and heat-resistant metal. These end mills often feature special coatings and geometries to handle titanium’s unique challenges. Finally, “low runout” is crucial for precision. Runout is how much the tool wobbles when it spins. Low runout means the tool spins very true, leading to cleaner cuts, better surface finish, and longer tool life.

Why Choose Carbide for Tough Materials?

Carbide, specifically tungsten carbide, is a game-changer in machining. It’s far harder and more rigid than high-speed steel (HSS), meaning it can cut faster, last longer, and handle higher temperatures. This is especially critical when machining materials like titanium.

- Hardness: Carbide is incredibly hard, allowing it to cut through very tough materials that would quickly dull or deform HSS tools.

- Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS before losing its hardness or shape. This is vital for materials like titanium, which get very hot during cutting.

- Rigidity: Carbide is stiffer than HSS. This means less flex and vibration during cutting, leading to more accurate dimensions and a better surface finish.

- Tool Life: Due to its hardness and heat resistance, carbide end mills typically last significantly longer than HSS tools, especially in demanding applications. This means fewer tool changes and lower overall costs.

Understanding Titanium Grade 5

When milling “titanium grade 5,” we’re talking about a specific alloy that is the workhorse of the titanium world. Also known as Ti-6Al-4V, it’s an alpha-beta titanium alloy containing approximately 6% aluminum and 4% vanadium. This composition gives it an excellent balance of strength, light weight, corrosion resistance, and weldability.

Titanium Grade 5 is widely used in:

- Aerospace components (aircraft frames, engine parts)

- Medical implants (hip and knee replacements)

- High-performance automotive parts

- Sporting goods

- Chemical processing equipment

However, its excellent properties also make it notoriously difficult to machine. It has a low thermal conductivity, meaning heat generated during cutting tends to stay at the cutting edge. It also has a high strength-to-weight ratio and a tendency to work-harden, meaning it gets harder the more you cut it. These factors require specialized tooling and machining strategies.

What Makes a 1/8 Inch Carbide End Mill “Proven Titanium Performance”?

For an end mill to deliver “proven titanium performance,” especially at the 1/8 inch size, it needs several key features and design considerations:

- High-Performance Carbide Grade: Not all carbide is the same. End mills designed for titanium often use specialized sub-micron or micro-grain carbide formulations for superior strength and wear resistance.

- Advanced Coatings: A thin, hard coating applied to the surface of the end mill is crucial. For titanium, coatings like Titanium Aluminum Nitride (TiAlN) or Aluminum Chromium Nitride (AlCrN) are common. These coatings add extreme hardness, reduce friction, and provide a thermal barrier, allowing for higher cutting speeds and feed rates.

- Optimized Flute Geometry: The shape of the cutting edges (flutes) is critical. For titanium, this often means a higher helix angle (typically 30-45 degrees) to help evacuate chips more efficiently and reduce cutting forces. Variables like the number of flutes (often 3 or 4 for titanium to balance rigidity and chip clearance) and the depth of the flute are carefully engineered.

- Reduced Neck Design: As mentioned, the reduced neck provides clearance in deeper pockets, preventing tool-on-workpiece contact and allowing for more aggressive machining passes.

- Precise Manufacturing and Low Runout: This is non-negotiable for small tools. Low runout (typically under 0.0005 inches or 0.01mm) ensures the tool cuts a true profile. When the tool wobbles, it effectively takes wider, inconsistent cuts, leading to poor finish, increased tool wear, and potential breakage. High-quality end mills undergo rigorous manufacturing processes to achieve this precision.

- Through-Coolant Capability (Optional but Beneficial): Some high-performance end mills have small channels that allow coolant to be delivered directly to the cutting edge through the tool itself. This is incredibly effective for managing heat in difficult-to-machine materials like titanium.

Key Specifications to Look For

When shopping for a 1/8 inch carbide end mill for titanium, keep these specs in mind:

Material & Grade

Look for “Tungsten Carbide,” often with specific mentions of “sub-micron grain” or “micro-grain” for enhanced toughness.

Coating

TiAlN or AlCrN are excellent choices for titanium. Some might even use advanced multilayer coatings.

Flute Count

- 2-Flute: Generally offers the best chip clearance, good for softer materials or less aggressive cuts in titanium.

- 3-Flute: A good balance, providing better rigidity and chip load capacity than 2-flute while still offering decent chip evacuation for many titanium applications.

- 4-Flute: Offers maximum rigidity and a smoother finish, best suited for finishing passes or less demanding titanium alloys where chip evacuation isn’t the primary concern. For 1/8 inch tools milling titanium, 3 flutes are often a very effective compromise.

Helix Angle

A higher helix angle (30° to 45°) is typically preferred for titanium. It helps with chip evacuation and reduces the effective rake angle at the cutting edge, lowering cutting forces.

Shank Type

Ensure it’s a standard cylindrical shank, often with a Weldon flat (a groove machined into the side of the shank for a set screw in tool holders) for secure clamping. A reduced neck is a bonus for deeper cuts.

Overall Length (OAL) and Reach

Consider how deep you need to cut. A longer reach might be necessary for some pockets, but always remember that longer tools are less rigid and more prone to vibration.

Tolerances

Specifically, look for “low runout” or a specific runout tolerance (e.g., <0.0005″). This is a hallmark of precision tooling.

Carbide End Mill Performance in Titanium: A Comparison

Let’s look at how different features impact performance when milling Titanium Grade 5 with a 1/8 inch carbide end mill.

| Feature | Impact on Titanium Machining Performance | Why it Matters |

|---|---|---|

| Carbide Grade (Sub-micron) | Much higher wear resistance, improved toughness at high temperatures. | Prevents premature chipping and wear, allowing the tool to cut for longer. |

| TiAlN/AlCrN Coating | Reduces friction and heat at the edge, resists cratering, and enhances surface hardness. | Keeps the cutting edge cooler and sharper, enabling faster speeds and feeds with less tool degradation. |

| High Helix Angle (30-45°) | Better chip evacuation, reduced cutting forces, less tendency for the chip to re-weld to the workpiece. | Prevents chip packing, which can cause tool breakage and poor surface finish in sticky materials like titanium. |

| Reduced Neck | Allows for deeper slotting and pocketing without the shank dragging. | Enables more versatile machining operations and prevents surface damage in deeper features. |

| Low Runout | Extremely consistent cut diameter and surface finish, reduced vibration. | Critical for precision parts and preventing tool breakage due to uneven cutting load. A wobbly 1/8″ tool is a recipe for disaster. |

| Lubrication/Coolant Management | Effective cooling and chip removal. | Titanium cutting generates significant heat. Proper cooling is essential to prevent tool damage and workpiece distortion. Using a good cutting fluid or MQL (Minimum Quantity Lubrication) is key. |

For optimal results, aim for an end mill that incorporates as many of these features as possible, especially when dealing with challenging materials like Grade 5 Titanium. Cutting fluids can be applied using various cutting fluid guidelines to ensure proper lubrication and cooling, greatly enhancing tool life and surface finish.

How to Use a 1/8 Inch Carbide End Mill for Titanium (Step-by-Step)

Milling titanium requires a methodical approach. Here’s how to get started with your 1/8 inch carbide end mill:

Step 1: Machine Setup and Workpiece Fixturing

Secure Your Workpiece: Titanium is tough, and cutting forces can be significant. Ensure your workpiece is rigidly clamped. Vises with hardened jaws are common. If you’re using a metalworking vise, consider adding soft jaws or inserts to protect the workpiece surface and provide better grip. For higher precision, custom fixtures or a CNC machine with a robust clamping system are ideal.

Ensure Stability: The workpiece must not move during the operation. Any shifting will lead to inaccurate cuts, poor surface finish, and potentially tool breakage.

Step 2: Tool Holder and Collet Selection

Use a High-Quality Collet: For a 1/8 inch end mill, a precision collet is essential. Look for collets with minimal runout (e.g., ER-16 or smaller if available for your system). Cheap, worn-out collets are a primary cause of tool wobble and breakage.

Secure the Tool in the Holder: Insert the end mill shank into the collet, ensuring it’s seated correctly. Tighten the collet nut securely according to the manufacturer’s recommendations. A Weldon flat on the shank should be positioned to engage with the set screw in your tool holder for added security against pull-out, especially in milling operations.

Minimize Tool Stick-out: Keep the amount of end mill extending from the collet nose as short as possible. This maximizes rigidity and minimizes vibration. For a 1/8 inch tool, excessive stick-out is highly detrimental.

Step 3: Setting Up Your Milling Machine

Zero the Z-Axis: Carefully indicate the tip of the end mill to the top surface of your workpiece and set your machine’s Z-axis zero. You can use an edge finder, a dial indicator, or for CNC, a touch probe.

Set the X/Y Origin: Similarly, establish your X and Y starting points using an edge finder or probe.

Step 4: Applying Cutting Parameters

Consult Machining Data: This is crucial for titanium. Always refer to machining handbooks, tool manufacturer recommendations, or online calculators. Milling titanium often requires slower spindle speeds (RPM) and feed rates than you might expect for steel.

Recommended Starting Points for 1/8″ Carbide End Mill in Titanium Grade 5 (Adjust as needed):

- Spindle Speed (RPM): Often in the range of 1,000 – 3,000 RPM. This depends heavily on the specific tool, coating, and machine rigidity.

- Feed Rate (IPM or mm/min): This is calculated based on chip load. Chip load is the thickness of material removed by each cutting edge per revolution. For a 1/8 inch, 3-flute end mill in titanium, a chip load might be around 0.001″ – 0.002″ per tooth. So, RPM x Flutes x Chip Load = Feed Rate. (e.g., 2000 RPM x 3 Flutes x 0.0015″ = 9 IPM).

- Depth of Cut (DOC): For roughing, start conservatively. A radial depth of cut (how much of the tool’s diameter is engaged across the width of the cut) and axial depth of cut (how deep the tool cuts into the material vertically) are important. For a 1/8 inch tool in titanium, you might start with an axial DOC of 0.010″ – 0.020″ and adjust based on results. Radial DOC will depend on your operation (e.g., full slotting vs. contouring).

- Ramping/Plunging: Titanium is tough to plunge straight down into. If you need to plunge, use a very slow feed rate and consider specialized drilling cycles or helical interpolation.

Step 5: Machining Process

Use Coolant/Lubrication: Either a flood coolant system, a mist system (MQL), or a high-quality cutting fluid applied manually is essential. Titanium cutting generates extreme heat, which can damage the tool and the workpiece. Use a fluid specifically designed for titanium or stainless steel machining.

Employ Climb Milling: Wherever possible, use climb milling (also known as conventional milling). In climb milling, the cutter rotates in the same direction as the workpiece material is moving past it. This results in a thinner chip at the start of the cut and a thicker chip at the end, which is generally better for tool life and surface finish, reducing the risk of the tool “digging in” and breaking.

Chip Evacuation: Pay close attention to chip formation. Chips should be a consistent, manageable size and appear bright or light grey. If they are dark, stringy, or packing up in the flutes, your feed rate might be too high, your DOC too deep, your speed too fast, or you may have inadequate cooling.

Listen to Your Machine: Unusual noises like chattering or high-pitched squealing often indicate problems. Back off the feed rate, reduce DOC, or check your tool setup.

Peck Drilling (for Plunging): If plunging is unavoidable, use a “peck” cycle. This involves drilling down a small amount, retracting to clear chips, then drilling down again. This is crucial for preventing chip buildup and tool failure.

Step 6: Inspection and Finishing Passes

Inspect Often: Periodically stop the machine and inspect the tool for wear or chipping, and check the workpiece for surface finish and dimensional accuracy.

Finishing Pass: For critical dimensions or a mirror finish, a final light “clean-up” pass with a very shallow depth of cut (e.g., 0.001″ – 0.003″) at a slightly higher feed rate can improve the surface finish significantly.

Common Problems and Troubleshooting

Even with the best tools, you might encounter issues. Here’s how to troubleshoot:

- Tool Breakage:

- Cause: Too much feed, too much depth of cut, inadequate cooling, chips packing in flutes, low runout, excessive tool stick-out, improper clamping.

- Solution: