A 1/8 inch carbide end mill, especially with a 1/2 inch shank and long reach, offers precise G10 control for detailed milling. Properly selecting and using this tool ensures clean cuts and minimizes material damage.

Working with materials like G10 can be a bit tricky, especially when you’re just starting out. You want those clean, sharp cuts you see in projects online, but sometimes your end mill chatters, chips the material, or just doesn’t seem to cut smoothly. It’s a common hurdle for hobbyists and beginners taking on milling projects. Getting the right tool and knowing how to use it can make all the difference between frustration and fantastic results. This guide will help you understand exactly why a 1/8 inch carbide end mill is a great choice for G10, and how to achieve that coveted precise control. We’ll dive into everything you need to know to get those perfect cuts every time.

Understanding Your 1/8 Inch Carbide End Mill for G10

G10 is a fantastic, tough composite material made from layers of fiberglass cloth embedded in epoxy resin. It’s incredibly strong, rigid, and resistant to wear and electrical insulation, making it popular for knife handles, circuit boards, and custom project enclosures. However, its composite nature and hardness can present challenges for cutting tools.

This is where a high-quality 1/8 inch carbide end mill comes into its own. Carbide is a super hard material, much harder than High-Speed Steel (HSS). This hardness means it can cut through tough materials like G10 more effectively and at higher speeds without getting dull quickly. For intricate work, a 1/8 inch diameter is often perfect. It allows for fine details, sharp corners, and smaller pockets that larger bits just can’t achieve. The ability to control the cut with precision is key, and that’s what we’ll focus on for G10.

Why Carbide for G10?

- Hardness: Carbide’s superior hardness allows it to slice through the tough epoxy resin and fiberglass of G10 with less effort and less tool wear.

- Heat Resistance: Machining G10 can generate heat. Carbide holds its hardness at higher temperatures than HSS, preventing the cutting edge from softening and degrading.

- Edge Retention: Carbide tools stay sharp for much longer, providing consistent cutting performance over many projects.

- Surface Finish: When used correctly, carbide end mills can produce a very smooth finish on G10, reducing the need for post-machining cleanup.

The Importance of a 1/8 Inch Diameter

A 1/8 inch end mill is a workhorse for detailed machining. For materials like G10, its size is often ideal for:

- Intricate Designs: Creating fine patterns, small text, or detailed cutouts.

- Edge Profiling: Achieving sharp, well-defined edges without accidentally removing too much material.

- Pocketing: Milling out precise rectangular or irregular pockets for inlays or components.

- Reduced Chipping: Smaller diameter tools generally experience less cutting force, which can help reduce chipping and tear-out on delicate materials like G10.

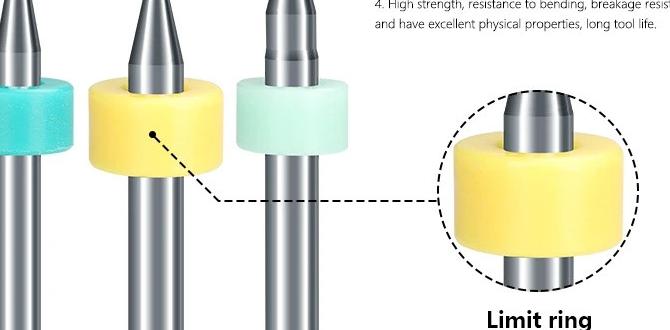

Key Features for G10 Milling: The Shank and Reach

When selecting a 1/8 inch carbide end mill for G10, a couple of specific features can make a big difference: the shank diameter and the reach (or flute length).

The 1/2 Inch Shank Advantage

While a 1/8 inch end mill will have a 1/8 inch cutting diameter, it can come with various shank diameters. A 1/2 inch shank is highly desirable for several reasons:

- Rigidity: A larger shank provides significantly more rigidity. This means less flex or deflection when the tool is under load. Reduced deflection leads to more accurate cuts and less chance of the tool breaking.

- Vibration Dampening: The larger mass of a 1/2 inch shank can help dampen vibrations that often occur when milling composites. Less vibration means a smoother cut and a better surface finish.

- Tool Holder Compatibility: Many milling machines and CNC routers use collets or tool holders designed for common shank sizes like 1/2 inch. This ensures a secure and precise fit, reducing runout.

Long Reach for Versatility

The “reach” or “flute length” of an end mill refers to how far down the cutting flutes extend from the shank. A “long reach” end mill offers more versatility:

- Deeper Cuts: It allows you to mill deeper pockets or profiles in a single pass, although for G10, shallower passes are usually recommended for best results.

- Accessing Difficult Areas: A longer reach enables you to mill into areas of a workpiece that might be otherwise inaccessible, especially if there are raised features or contours.

- Considerations for G10: While long reach is useful, it’s crucial to remember that longer tools are generally less rigid. For G10, it’s a balance. A longer reach is great for access, but you must still manage your cutting parameters (like cutting depth and feed rate) to prevent chatter and tool breakage. For most common G10 projects involving panels or handles, a moderate reach will suffice, but if you need to get into a deep recess, a long reach is the way to go.

G10 Control: Achieving Precision with Your End Mill

The term “G10 Control” refers to your ability to precisely guide the end mill to create accurate shapes and features in G10. This control comes from a combination of machinery, fixturing, tool selection, and machining technique.

Understanding Runout

Runout is the wobble or deviation of a rotating tool from its intended true path. Low runout is critical for precise machining, especially with small tools and hard materials. High runout can cause:

- Poor Surface Finish: The tool will cut unevenly, leaving marks.

- Increased Tool Wear: The cutting edges will be subjected to uneven forces, dulling them faster.

- Chatter and Vibration: Leading to audible noise and a rough cut.

- Inaccurate Dimensions: The part will not be the size or shape you intended.

A 1/8 inch carbide end mill, especially one designed for low runout (often achieved through precise manufacturing, balanced design, and a good collet system), is essential for tight tolerances. A tool with a high-quality coating can also contribute to better performance and longevity.

Feeds and Speeds: The Heart of G10 Machining

This is often the most intimidating part for beginners, but it’s crucial for success. Getting the right feed rate (how fast the tool moves through the material) and spindle speed (how fast the tool spins) prevents issues like G10 melting, chipping, or the tool breaking.

General Guidelines for 1/8 Inch Carbide End Mills on G10

These are starting points. Always consult the tool manufacturer’s recommendations if available, and be prepared to adjust based on your specific machine and setup.

Spindle Speed (RPM): For a 1/8 inch carbide end mill, a common range for composites like G10 is often between 12,000 and 24,000 RPM. Lower speeds might be used with slower feed rates or on less rigid machines. Higher speeds are generally preferred to keep the cutting chips small and to efficiently clear material.

Feed Rate (IPM or mm/min): This is heavily dependent on spindle speed, the number of flutes on your end mill, and the depth of cut. A general starting point might be anywhere from 10 to 40 inches per minute (IPM). For optimal control and to avoid overheating or chipping G10, it’s often better to run a shallower depth of cut and a slightly higher feed rate. This ensures the chips are cleared effectively.

Chip Load

Chip load is the thickness of the material removed by each cutting edge of the end mill with each rotation. A good target chip load helps prevent tool wear and chatter. For a 1/8 inch carbide end mill in G10, a chip load might range from 0.001 to 0.003 inches per flute. You can calculate feed rate using the formula:

Feed Rate (IPM) = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches/flute)

Depth of Cut (DOC)

For G10, it’s crucial to use shallow depths of cut, especially with a 1/8 inch bit. This minimizes the cutting force and prevents the material from chipping. A conservative DOC might be 0.010 to 0.050 inches. For finer detail or very hard G10, you might use even less.

Avoiding Melting

G10 can melt or become gummy if too much heat is generated. This is usually caused by:

- Too slow a spindle speed.

- Too fast a feed rate (rubbing instead of cutting).

- Too deep a cut.

- Poor chip evacuation.

Using the correct high spindle speeds, appropriate feed rates, and shallow depths of cut, combined with good chip clearing, will prevent G10 from melting.

Tool Selection: What to Look For

Not all 1/8 inch carbide end mills are created equal. Here’s what to consider for optimal G10 control:

Types of End Mills

For G10, you’ll typically want a square end mill (for sharp corners) with a geometry suited for composites or plastics. Some end mills are specifically designed for high-performance materials:

- Uncoated Carbide: A good general-purpose option.

- Coated Carbide: Coatings like AlTiN (Aluminum Titanium Nitride) or TiCN (Titanium Carbonitride) can improve hardness, reduce friction, and extend tool life, which is beneficial for tougher materials like G10.

- Compression End Mills: While more common in woodworking for a clean finish on plywood, they are less common for milling hard composites like G10 from raw stock.

- “O” Flute or “Single Flute” End Mills: These are often used for plastics and composites because they have excellent chip evacuation and can run at higher speeds, reducing heat buildup. A single flute can be a great choice for G10 if your machine can handle the higher feed rates.

- Standard Two-Flute End Mills: These are versatile and will work well, especially if they are high-quality. Ensure they are designed for milling harder materials.

Number of Flutes

- 1-Flute: Excellent for chip evacuation and higher speeds, often ideal for composites and plastics like G10. Requires higher feed rates.

- 2-Flute: A good all-around choice, balancing chip evacuation with holding power. Will work well for G10.

- 3+ Flutes: Provide a smoother finish but can struggle with chip evacuation in softer materials or when taking deep cuts. May not be the best choice for G10 unless at very shallow depths.

For G10, a 1-flute or 2-flute end mill is generally recommended.

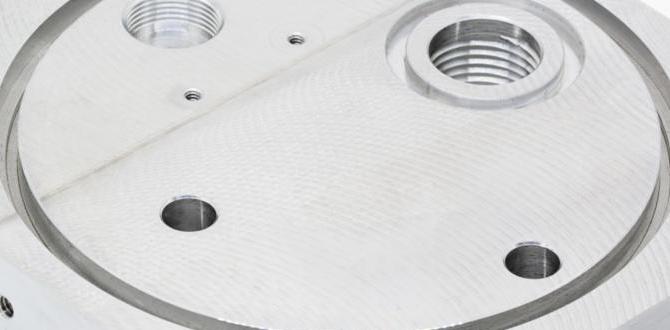

Tool Holder and Collet Quality

Even the best end mill won’t perform well with a poor tool holder or collet. A high-quality collet chuck system will:

- Minimize Runout: Ensure the end mill runs true.

- Provide Secure Clamping: Prevent the tool from slipping.

- Allow for Accurate Centering: Essential for precise cuts.

Look for ER collet systems (like ER16, ER20) which are widely available and offer good precision for their cost.

Practical Steps for Milling G10 with a 1/8 Inch Carbide End Mill

Now, let’s get practical. Here’s how to set up and run your G10 milling project:

1. Secure Your Workpiece

G10 can be slippery and tough, so secure it firmly. Use clamps, a vise, or vacuum hold-down. Ensure the clamps are positioned so they don’t interfere with the cutting path. For detailed work, a jig or fixture can provide extra stability and support.

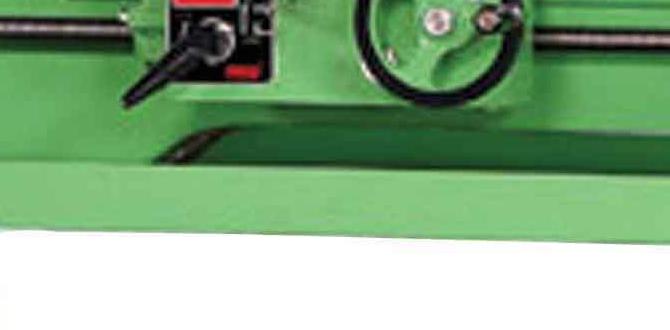

2. Set Up Your Machine and Tool

- Install the End Mill: Insert the 1/8 inch carbide end mill into a clean collet and tighten it securely in your spindle or router. Ensure it’s seated properly to minimize runout.

- Set Zero: Accurately set your X, Y, and Z zero points on the workpiece. This is critical for dimensional accuracy.

- Measure Tool Engagement: If using a probe or edge finder, be precise when measuring the tool diameter to set your offsets correctly.

3. Program Your Tool Paths (if CNC) or Plan Your Manual Cuts

For CNC users, input your design into CAM software. For manual machining, plan your cuts carefully. Remember:

- Climb Milling vs. Conventional Milling: For G10, climb milling is often preferred as it puts less stress on the tool and can result in a smoother finish. However, conventional milling can sometimes be more stable on very light machines. Experiment to see what works best.

- Stepover: For pocketing or contouring, the stepover is the distance between adjacent cutting passes. A smaller stepover (e.g., 30-50% of the tool diameter) will give a smoother finish but take longer.

4. Machine the G10 with Proper Parameters

- Depth of Cut: Start shallow. For a 1/8 inch end mill, a depth of cut of 0.010″ to 0.030″ is a good starting point. Increase only if your machine is very rigid and you’re monitoring for chatter.

- Feed Rate: Begin with a conservative feed rate. If you’re using a 2-flute carbide bit at 18,000 RPM and want a chip load of 0.002″, your feed rate would be 18000 2 0.002 = 72 IPM.

- Spindle Speed: Aim for the higher end of the recommended range, around 15,000-20,000 RPM or more if your machine allows.

- Cooling/Lubrication: While not always necessary for G10, a blast of compressed air can help clear chips and keep the tool and material cool, reducing the risk of melting. Some machinists use a light mist of cutting fluid, but be aware that this can make G10 dust messy.

5. Monitor and Listen

Pay close attention throughout the process. Listen for any signs of chatter or struggling. Look for:

- Smooth Cutting Sound: A consistent, light “hiss” or “chip” sound is good.

- Visible Chips: Fine, powdery chips are typical for G10. If they start melting or clumping, your feeds/speeds are off.

- Tool Condition: Check the end mill periodically for signs of wear or damage.

6. Post-Machining Cleanup

G10 dust can be fine and clingy. Wear appropriate safety gear, including an N95 mask, to avoid inhaling it. Use a brush, vacuum, or compressed air to clean your workpiece and machine.

Safety First!

Machining G10, especially with power tools, generates dust that can be harmful. Always wear:

- Safety Glasses: To protect your eyes from flying debris.

- Hearing Protection: Especially if your machine is loud.

- Dust Mask (N95 or better): G10 dust can be an irritant.

- Gloves: To protect your hands.

Always understand the safety features of your machine and follow all operating guidelines.

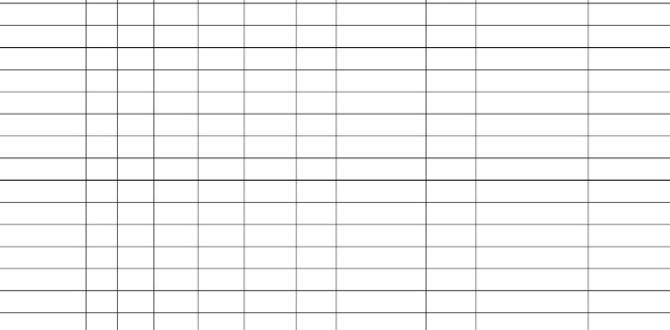

Table: Recommended Starting Parameters for 1/8″ Carbide End Mill on G10

These are starting points. Always adjust based on your specific machine, tool, and material. A good reference for milling hard composites can be found at CME Votech’s Plastics Machining Guide which covers composites generally.

| Parameter | Starting Value (Imperial) | Starting Value (Metric) | Notes |

|---|---|---|---|

| Spindle Speed (RPM) | 15,000 – 20,000 RPM | 15,000 – 20,000 RPM | Higher is often better if possible to maintain chip load and reduce heat. |

| Feed

|