A 1/8 inch carbide end mill is an indispensable tool for detailed woodworking, offering precision for carving, engraving, and small cuts. It’s ideal for hobbyists and professionals alike for intricate projects requiring accuracy and smooth finishes.

Hey everyone, Daniel Bates here from Lathe Hub! If you’ve ever looked at a finely detailed wooden carving or a perfectly etched design and thought, “How did they do that?” chances are, a tiny but mighty tool was involved. We’re talking about carbide end mills, and specifically, the popular 1/8 inch size. For us woodworkers, especially those just starting out, tackling intricate projects can feel a bit daunting. You might be wondering if there’s a secret tool that unlocks that level of detail. Well, good news! That 1/8 inch carbide end mill might just be your new best friend. It’s designed to give you amazing control and beautiful results, even on your first try. In this guide, we’ll break down exactly why this tool is so essential and how you can start using it to bring your creative visions to life. Get ready to elevate your woodworking game!

The Mighty Minis: Understanding the 1/8 Inch Carbide End Mill

When you first start exploring the world of CNC routing and detailed woodworking, you’ll encounter a whole toolbox of bits. Among them, the carbide end mill stands out, and the 1/8 inch shank version is particularly noteworthy for wood. But what exactly is it, and why is it so special for wood applications? Let’s break it down.

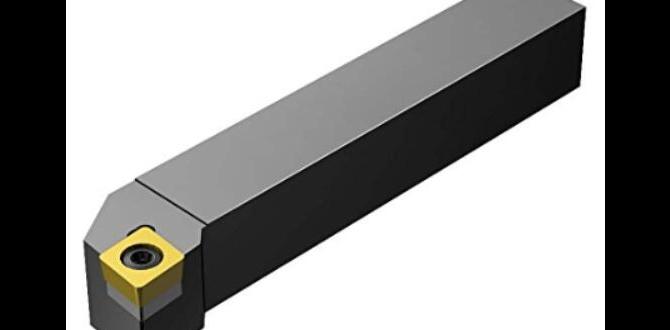

What is a Carbide End Mill?

An end mill is a type of milling cutter. It’s designed to cut on its periphery and in its flutes. Think of it like a drill bit that can also cut sideways. This capability makes it incredibly versatile for shaping materials. The “carbide” part refers to the material it’s made from – tungsten carbide. This super-hard material is much more durable and resistant to wear and heat than standard high-speed steel (HSS). This means carbide end mills can cut faster, last longer, and create cleaner cuts, especially in tougher materials or when performing demanding operations.

Why 1/8 Inch Shank for Wood?

The shank is the part of the tool that fits into your machine’s collet or chuck. For wood, a 1/8 inch shank end mill offers several key advantages:

- Precision and Detail: The small diameter allows for extremely fine detail work. Think intricate engravings, delicate scrollwork, or creating tiny channels.

- Maneuverability: In CNC routing, a smaller bit can navigate tighter curves and corners with greater ease.

- Less Material Removal: If you’re doing precise cuts or shallow engraving, a smaller bit removes material more predictably.

- Versatility in Collets: Most common CNC routers and handheld trim routers are readily equipped with collets that can accept a 1/8 inch shank, making it a widely accessible size.

While larger end mills are great for fast material removal, the 1/8 inch carbide end mill is your go-to for finesse and intricate designs in wood. It’s the precision instrument of the woodworking world.

Key Features to Look For in a 1/8 Inch Carbide End Mill

Not all 1/8 inch end mills are created equal. To get the best results for your wood projects, you’ll want to pay attention to a few specific features. These details can make a big difference in cut quality, tool life, and overall ease of use.

Material: Solid Carbide is King

As mentioned, solid carbide is the standard for high-performance end mills. For wood carving and detailing, ensure you are selecting a “solid carbide” end mill. This means the entire fluted portion of the tool is made from a solid piece of tungsten carbide, offering the best strength and edge retention.

Number of Flutes: Performance Through the Plies

Flutes are the spiral grooves that run along the cutting edge of the end mill. The number of flutes affects how it cuts and how it clears chips:

- 2-Flute: These are generally preferred for wood. They offer more aggressive chip evacuation, which is great for softer materials like wood, preventing clogging and overheating. They also tend to cut cleaner with less burning.

- 4-Flute: While often used for harder materials or finishing passes in metal, 4-flute end mills can be used for wood. However, they can clog more easily with wood dust and may require slower feed rates to prevent burn marks.

For most 1/8 inch woodworking applications, a 2-flute end mill is usually the best choice for a balance of cutting performance and chip management.

Flute Type: Up-cut, Down-cut, and Straight

The direction the flutes are angled can impact the surface finish and chip flow:

- Up-cut: The flutes spiral upwards. This pulls chips out of the cut and away from the workpiece, which is excellent for clearing material and preventing dust buildup. This is a very common and effective type for general wood routing.

- Down-cut: The flutes spiral downwards. This pushes chips down onto the surface. It’s great for achieving a very clean top surface finish because it holds the material down, but it can cause chips to pack into the cut.

- Straight Flute: Less common for CNC, these are typically used for manual machining or specific applications.

For most CNC woodworking tasks with a 1/8 inch end mill, an up-cut spiral flute is the most versatile and commonly recommended. It helps keep the workpiece clear of dust and debris.

Coating: Enhancing Durability and Performance

Some end mills come with special coatings. While less common for standard woodworking end mills compared to metal cutting, coatings like TiN (Titanium Nitride) can offer:

- Increased hardness and wear resistance.

- Reduced friction, which can help prevent burning and sticking.

- Improved chip flow.

For wood, a coating isn’t always essential, as the natural properties of carbide and the correct flute design often suffice. However, if you are working with very abrasive woods or performing high-volume production, a coated end mill might extend its life.

Length: Standard vs. Extended

The length of the fluted section (cutting length) is also important. For a 1/8 inch shank, you’ll commonly find end mills with standard cutting lengths, perhaps around 1/4 inch to 1/2 inch. For most detailed woodworking, this is more than enough. Extended length bits are usually for deeper pocketing operations, which might not be the primary use for a tiny 1/8 inch bit.

When shopping, look for terms like “carbide end mill 1/8 inch 1/4 shank standard length” to find commonly available and suitable options for detailed wood projects.

Applications of the 1/8 Inch Carbide End Mill in Woodworking

This little bit punches way above its weight class! The 1/8 inch carbide end mill is incredibly versatile, allowing you to perform a range of detailed tasks that larger bits simply can’t handle. Whether you’re using a CNC router or a handheld trim router, here are some of the key applications where this tool shines:

Intricate Carving and Engraving

This is where the 1/8 inch end mill truly excels. Its small diameter is perfect for:

- Lettering and Text: Cutting crisp, clean text into plaques, signs, or personalized items.

- Scrollwork and Patterns: Creating delicate interlacing designs or complex artistic patterns.

- Detailing Miniature Models: Adding fine textures, panel lines, or architectural details to small wooden models.

- Embossing and Debossing: Creating raised or recessed designs on surfaces.

V-Carving and Letter Routing

When paired with V-carving bits or used by programming with specific depth settings, an end mill can create beautiful beveled edges for lettering and designs. A 1/8 inch end mill allows for very fine V-carving, producing sharp, detailed lines for sign-making or decorative panels.

Creating Small Joinery and Channels

While not for heavy-duty joinery, the 1/8 inch end mill can be used for:

- Small Dadoes and Rabbets: For thin material or detailed cabinet doors.

- Grooves for Splines or Inlays: Precisely cutting slots for decorative wood splines or small inlay work.

- Wire Channels: Creating discreet channels on the back of plaques for mounting or for routing small wires.

Edge Profiling and Detail Work

Even for edge treatments, this small bit can be useful:

- Chamfers and Fillets: Adding small decorative bevels or rounded edges to specific areas of a project.

- Creating Depth: By making shallow passes, you can create multi-layered designs where elements appear to float or inset.

3D Carving

For CNC users, a 1/8 inch end mill is often the primary tool for 3D carving projects. Its ability to detail fine contours and smooth transitions is essential for creating realistic textures, reliefs, and sculpted shapes in wood.

The key is that the 1/8 inch carbide end mill allows you to work with precision on a smaller scale, opening up a world of detailed craftsmanship that might otherwise be unachievable.

Using Your 1/8 Inch Carbide End Mill Safely and Effectively

Having the right tool is only half the battle; knowing how to use it safely and effectively is crucial for both the quality of your work and your well-being. Here’s how to get the most out of your 1/8 inch carbide end mill.

Safety First! Always.

Working with spinning cutting tools requires respect. Before you even turn on your machine:

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Use Hearing Protection: Routing can be loud.

- Keep Hands Clear: Never place your hands directly in the path of the bit. Use push sticks or jigs when working with a handheld router.

- Secure Your Workpiece: Ensure your wood is firmly clamped or held down.

- Know Your Machine: Understand the controls and limitations of your CNC or handheld router.

- Dust Collection: Wood dust can be harmful and a fire hazard. Use a dust collection system whenever possible. You can find great resources on dust control for workshops from organizations like OSHA (Occupational Safety and Health Administration) at osha.gov.

Setting Up for Success

Proper setup minimizes vibration, improves cut quality, and extends tool life:

- Securely Install the End Mill: Ensure the end mill is fully seated in the collet and the collet nut is tightened correctly. You want the shank to be well-supported.

- Minimize Spindle Stickout: Only let the necessary amount of the end mill extend from the collet. Too much overhang creates vibration and reduces rigidity.

- Calibrate Your Machine: If using CNC, ensure your machine’s bed is level and your Z-axis is properly calibrated.

Speed and Feed Rate: The Sweet Spot

This is often the trickiest part for beginners. These settings dictate how fast the tool spins (RPM or speed) and how fast it moves through the material (feed rate). These are highly dependent on your material, the type of end mill, and the depth of cut.

As a general starting point for a 1/8 inch 2-flute carbide end mill in common softwoods (like pine or poplar):

- Speed (RPM): Start around 18,000 – 24,000 RPM.

- Feed Rate: Begin with something slow, maybe 20-40 inches per minute (IPM) for CNC. For handheld routers, this is more about feeling the resistance.

- Depth of Cut: For detail work, shallow passes are key. Don’t try to cut the full depth in one go. Make multiple passes, each removing a small amount of material (e.g., 0.020 – 0.060 inches per pass).

Crucial Tip: Always perform a test cut on scrap material first. Listen to the sound the cutter makes – a smooth hum is good, a chattering or screaming sound indicates problems. Visually inspect the cut for burning or tear-out. Adjust speed and feed rates incrementally until you achieve a clean, efficient cut.

Resources like the Woodworker’s Journal often provide helpful charts for router bit speeds, though direct end mill settings for CNC might require more experimentation or specific manufacturer recommendations.

Clearing Chips and Preventing Burns

Wood dust and chips can clog the flutes, leading to heat buildup and burning. Here’s how to combat it:

- Use Up-Cut Flutes: As discussed, up-cut bits help pull chips out.

- Adequate Chip Load: The feed rate and depth of cut must be balanced to create a proper “chip load.” This means the bit is actually cutting material, not just rubbing. If you use very shallow passes with a fast feed rate, you might not be creating enough chip load, leading to burning.

- Dust Collection: A good dust collection system is your best friend for keeping the cutting area clear.

- MQL (Minimum Quantity Lubrication): For some advanced users working with very dense or resinous woods, or for very fine detail where dust is a major issue, a mist coolant system (MQL) can be considered. This sprays a tiny amount of lubricant and air. It helps cool the bit and evacuate dust. Ensure your machine is compatible and that you use a wood-friendly lubricant if opting for this.

When to Replace Your End Mill

Carbide is tough, but not indestructible. Signs that your 1/8 inch end mill might be worn out include:

- Increased burning or scorching of the wood.

- Rougher cut surfaces than usual.

- More vibration or chatter during cuts.

- Difficulty in achieving crisp details.

A worn-out bit can produce poor results and also put extra strain on your machine. Because 1/8 inch end mills are relatively inexpensive, it’s often more economical to replace them when they show signs of wear rather than try to push them too far.

Comparing Router Bits vs. End Mills for Woodworking

This is a common point of confusion for beginners: When should I use a router bit, and when should I reach for an end mill, especially when working with a CNC or a trim router?

Standard Router Bits

These are the bits you typically see in a standard plunge or fixed-base router. They are designed primarily for edge profiling, dadoes, rabbets, and general shaping. Common types include:

- Straight bits: For cutting dados, rabbets, and mortises.

- Roundover and Chamfer bits: For softening edges.

- Flush Trim bits: For following a template.

- Cove and Ogee bits: For decorative edging.

Key Characteristics:

- Often made of High-Speed Steel (HSS) or have carbide cutters brazed onto a steel body.

- Designed to leave a smooth surface without needing complex toolpath programming.

- Limited ability to cut internal corners (they always leave a radius) or plunge into the material to create pockets.

- Limited directional cutting (primarily cut on the periphery).

Carbide End Mills

As we’ve been discussing, these are specialized cutting tools, commonly used in milling machines and CNC routers.

Key Characteristics:

- Usually made of solid carbide for superior hardness and edge retention.

- Designed to cut on both the end (tip) and the side (periphery).

- Can cut internal square corners by plunging straight down.

- Extremely versatile for pocketing, contouring, engraving, and 3D carving.

- Require programmed toolpaths for CNC operations.

- Available in a wide variety of geometries (single flute, double flute, up-cut, down-cut, compression, ball nose, etc.).

When to Choose Which for Wood?

Here’s a simple breakdown:

- Use Standard Router Bits for:

- Decorative edge profiles (roundover, Ogee, chamfer).

- Cutting dados and rabbets with a fence or guide