Quick Summary: For stainless steel, a carbide end mill is your best bet. Its hardness and heat resistance cut through tough materials efficiently, especially smaller sizes like 1/8 inch with a 1/4 inch shank, and are MQL friendly for smoother, cooler machining.

Carbide End Mill: Your Best Friend for Cutting Stainless Steel

Hey everyone, Daniel Bates here from Lathe Hub! Ever stared at a block of stainless steel, wondering how to tackle it? It’s strong, tough, and can really give standard cutting tools a hard time. That’s where the right tool makes all the difference. Don’t let the stubborn nature of steel get you down. We’re going to explore why a carbide end mill is your secret weapon for this material. Think of this as your friendly guide to making stainless steel cutting feel less like a battle and more like a smooth operation. Ready to cut with confidence? Let’s dive in!

Why Stainless Steel is a Different Beast (And Why Carbide Wins)

Stainless steel, with its impressive corrosion resistance and strength, is a popular choice for many projects. But this toughness makes it a real challenge to machine. Unlike softer metals, stainless steel has a tendency to work-harden – meaning it gets harder the more you try to cut it, especially with the wrong tools. This can lead to tool breakage, poor surface finishes, and a lot of frustration. Traditional High-Speed Steel (HSS) cutters often can’t stand up to the heat and forces involved, dulling quickly or even melting on contact.

This is precisely where carbide end mills shine. Here’s why:

- Superior Hardness: Carbide is significantly harder than HSS. This allows it to cut through tough materials like stainless steel without rapidly wearing down.

- High Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS before losing its cutting edge, which is crucial for stainless steel cutting.

- Rigidity: Carbide tools are more rigid, meaning they flex less under cutting pressure. This leads to more accurate cuts and a better surface finish.

- Increased Productivity: Because they can cut faster and last longer, carbide end mills allow you to remove material more effectively, saving you time and increasing your output.

For beginners, this means less tool replacement, fewer ruined workpieces, and a much more enjoyable machining experience. It’s about using the right tool for the job to make your life easier and your results better.

Understanding Carbide End Mills: What to Look For

When you’re looking for a carbide end mill, especially for stainless steel, a few key features will make a big difference. We’re going to focus on aspects that are important for getting started and achieving good results.

Material Matters: Solid Carbide

For stainless steel, you absolutely want a solid carbide end mill. This means the entire cutting tool is made from carbide, as opposed to carbide inserts fixed into a steel body. Solid carbide offers the best combination of hardness, rigidity, and heat resistance needed for this tough material.

Geometry is Key: Flute Count

The number of flutes (the cutting edges spiraling around the end mill) is important:

- 2-Flute End Mills: These offer more chip clearance, which is excellent for materials like aluminum and softer steels. For stainless steel, they can work, but might require slower feed rates to avoid clogging.

- 3-Flute End Mills: A good all-around choice for many materials. They provide a balance of cutting performance and chip evacuation.

- 4-Flute End Mills: These are generally preferred for harder materials like stainless steel. They handle higher feed rates and provide better stability and surface finish. The increased number of flutes also helps spread the cutting load, reducing stress on each individual cutting edge.

For stainless steel, a 4-flute solid carbide end mill is often the go-to choice for a good balance of performance and chip evacuation. However, depending on your specific application and machine rigidity, a 2 or 3-flute might be used with adjustments to your cutting parameters.

Coatings: The Extra Shield

While solid carbide is great, special coatings can enhance performance even further, especially for challenging materials like stainless steel.

- TiN (Titanium Nitride): A common, general-purpose coating that adds hardness and lubricity, offering some protection against heat and wear.

- TiCN (Titanium Carbonitride): Harder and more wear-resistant than TiN, it’s excellent for tougher materials and offers better performance in dry machining.

- AlTiN (Aluminum Titanium Nitride): This is a top performer for exotic alloys and steels like stainless steel. It forms a protective aluminum oxide layer at high temperatures, allowing the tool to run hotter (within limits) without degradation. This makes it ideal for machining stainless steel where heat is a major factor.

- ZrN (Zirconium Nitride): Offers good lubricity and can be a good choice for stainless steels, often used for milling and drilling.

For milling stainless steel, AlTiN or TiCN coatings are highly recommended. They offer the best combination of hardness and heat resistance to keep your end mill cutting effectively and prolong its life.

Shank and Length: Practical Considerations

When you’re starting out, you’ll encounter common sizes. For a 1/8 inch diameter end mill, a 1/4 inch shank is standard. This provides sufficient rigidity for the size of the tool. Standard length end mills are generally good for most beginner operations. Avoid extremely long end mills unless your machining depth requires it, as they can be more prone to vibration and deflection.

So, to recap for stainless steel: Look for a solid carbide, 4-flute end mill with an AlTiN or TiCN coating. For your common needs, a 1/8 inch diameter with a 1/4 inch shank is a great starting point.

MQL (Minimum Quantity Lubrication): A Friendly Approach to Cooling

Machining stainless steel generates significant heat. Traditional flood coolant systems can be messy and expensive for home workshops. This is where MQL comes in. MQL systems deliver a fine mist of lubricant and air directly to the cutting zone. This effectively cools the tool and workpiece, lubricates the cut, and helps evacuate chips without excessive fluid use.

For stainless steel, MQL is:

- Effective Cooling: Reduces heat buildup, preventing tool damage and work hardening.

- Improved Lubrication: Reduces friction, leading to a smoother cut and better surface finish.

- Cleaner Operation: Uses minimal fluid, making cleanup much easier.

- Chip Evacuation: The air mist helps blow chips away from the cutting area.

Many modern carbide end mills, especially those designed for stainless steel, are MQL friendly. Using MQL with your carbide end mill and stainless steel is a winning combination for a cleaner, cooler, and more efficient cut. You’ll want to use a cutting fluid specifically designed for MQL applications and compatible with stainless steel.

Choosing the Right Carbide End Mill for Stainless Steel: A Quick Guide

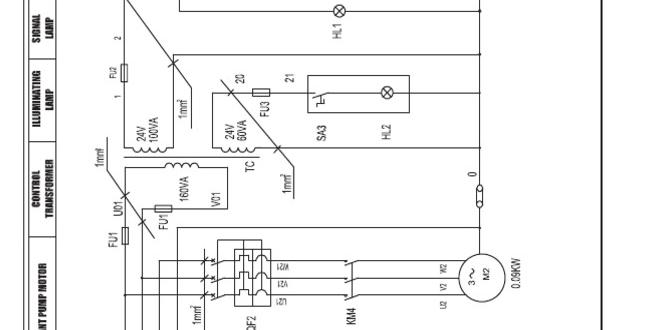

Let’s put it all together when you’re shopping. Here’s a handy table to guide your selection:

| Feature | Recommendation for Stainless Steel | Why It Helps |

|---|---|---|

| Material | Solid Carbide | Hardness and heat resistance to cut tough steel. |

| Flute Count | 4-Flute (preferred) | Good chip clearance, stability, and surface finish for harder materials. |

| Coating | AlTiN or TiCN | Superior heat resistance and wear resistance for aggressive cutting. |

| Diameter/Shank | e.g., 1/8″ Diameter, 1/4″ Shank (Standard) | Appropriate rigidity for the tool size. |

| Lubrication | MQL Friendly Tooling, appropriate cutting fluid | Keeps cutting zone cool and lubricated, aids chip evacuation. |

When you see descriptions like “Carbide End Mill 1/8 inch 1/4 shank standard length for stainless steel 316 MQL friendly,” you know you’re looking at a tool designed for exactly what we’re talking about. SS 316 is a common, harder grade of stainless steel, so tools specified for it will generally perform well on others, too.

Basic Machining Parameters for Stainless Steel

Getting the right tool is only half the battle. Setting your machine speeds and feeds correctly is crucial for success and preventing tool breakage. These are starting points and may need adjustment based on your specific machine, the exact grade of stainless steel, and the rigidity of your setup. Always start conservatively!

For a 1/8 inch diameter, 4-flute solid carbide end mill with an AlTiN coating, when milling stainless steel, consider these general guidelines:

- Spindle Speed (RPM): Start between 1,500 – 3,000 RPM. Stainless steel doesn’t like to be spun too fast, as it can lead to work hardening and overheating.

- Feed Rate (IPM – Inches Per Minute): Aim for 0.001 – 0.002 inches per tooth. With a 4-flute end mill, this translates to roughly 6-24 IPM. A good starting point for a 1/8″ end mill might be around 8-12 IPM.

- Depth of Cut (DOC): This depends heavily on your machine’s rigidity and the total width of cut. For lighter cuts, start with a radial depth of cut (how much side of the end mill is engaged) of 0.010 – 0.020 inches and an axial depth of cut (how deep it cuts into the material) of 0.060 – 0.090 inches. It’s often better to take shallower cuts more frequently.

- Lubrication: Use MQL with a suitable cutting fluid.

Remember, these are just starting points. A good rule of thumb is to listen to your machine and the tool. If you hear squealing or chattering, adjust your speeds and feeds. If the chips are coming off as fine powder, you might be cutting too dry or too fast. If they are long and stringy, you might be feeding too slowly or have too much heat.

For more detailed information and resources on machining parameters, you can often find helpful charts and calculators from tool manufacturers or educational institutions like MetalMachining.com or university engineering departments often have publicly available guides on machining practices.

Step-by-Step: Milling Stainless Steel with Your Carbide End Mill

Let’s walk through a basic milling operation. This assumes you have your workpiece securely fixtured to your milling machine.

- Secure Your Workpiece: Ensure your stainless steel piece is firmly clamped to the milling machine bed or vise. For stainless steel, a strong grip is essential as it can exert significant force.

- Install the End Mill: Insert your chosen carbide end mill into the collet or tool holder. Make sure it’s seated correctly and tightened securely.

- Set Up Your MQL System: Connect your MQL system and ensure it’s ready to deliver mist to the cutting zone. Verify that the nozzle is positioned correctly to spray directly onto the cutting area.

- Set Zero and Zero Out Axes: Using your machine’s control or indicator, find the top surface of your workpiece and set your Z-axis zero. Traverse to the edge of your workpiece and set your X and Y axes zero (or establish your work offset).

- Program or Manually Enter Toolpath: For simple operations, you might manually jog the machine. For more complex shapes, you’ll use CAM software or enter G-code.

- Enter Cutting Parameters: Input your chosen spindle speed (RPM) and feed rate (IPM) into the machine controller. Ensure your depth of cut and radial step-over (for contouring) are set correctly.

- Start the MQL System: Turn on your MQL system before you start cutting.

- Start the Spindle: Bring the spindle up to the programmed RPM.

- Engage the Cut: Slowly feed the end mill into the material. Listen for any unusual noises and observe chip formation.

- Monitor the Cut: Keep an eye on chip evacuation, surface finish, and any signs of vibration or chatter. Adjust feed rate or spindle speed if necessary, but always make small, incremental changes.

- Complete the Operation: Allow the machine to complete the programmed toolpath.

- Retract and Stop: Once the operation is finished, retract the end mill from the workpiece and stop the spindle. Turn off the MQL system.

- Inspect and Clean: Inspect the resulting cut for accuracy and finish, and clean up any residual coolant.

Safety first! Always wear safety glasses and appropriate personal protective equipment (PPE). Ensure guards are in place and be mindful of rotating machinery and sharp tools.

Benefits of Using Specialized End Mills for Stainless Steel

Investing in the right tool pays off. Here’s a look at the advantages:

- Reduced Tool Wear: Carbide’s hardness and heat resistance mean end mills last much longer compared to HSS.

- Improved Surface Finish: When used correctly, carbide end mills leave a smoother, more accurate surface on stainless steel.

- Faster Material Removal: You can cut faster and deeper (with a rigid setup), saving significant time.

- Less Work Hardening: Proper cutting parameters with carbide help prevent the stainless steel from hardening as much during the machining process.

- Increased Precision: The rigidity of carbide tools leads to more precise and repeatable results.

- Cost-Effectiveness (Long Term): While carbide end mills may have a higher upfront cost, their longevity and efficiency often make them more cost-effective over time, especially for production or frequent use.

Common Beginner Mistakes to Avoid

We all start somewhere, and making mistakes is part of learning. Here are a few common pitfalls when machining stainless steel with end mills:

- Using the Wrong Tool: Trying to mill stainless steel with an HSS end mill will likely lead to rapid dulling, overheating, and poor results.

- Inadequate Lubrication/Cooling: Not using enough (or any) coolant or MQL for stainless steel is a fast track to overheating and tool failure.

- Incorrect Speeds and Feeds: Too fast a spindle speed or too slow a feed rate can cause work hardening and chip welding. Too fast a feed rate can overload the tool.

- Taking Too Deep of a Cut: Especially when starting, it’s tempting to try and hog out material quickly. This can overload small end mills and lead to breakage.

- Insufficient Workpiece Clamping: Stainless steel is strong. A loosely held workpiece can shift, leading to inaccurate cuts or dangerous situations.

- Not Engaging MQL Properly: If the mist isn’t hitting the cutting edge, it’s not doing its job. Ensure proper nozzle placement.

By being aware of these common issues, you can focus on mastering the basics and achieving great results from the start.

FAQ: Your Carbide End Mill Questions Answered

Q1: Can I use a regular end mill for stainless steel?

For best results, it’s highly recommended to use a carbide end mill. Traditional High-Speed Steel (HSS) end mills will dull very quickly and struggle to cut stainless steel effectively due to its hardness and tendency to work-harden.

Q2: What’s the difference between a 2-flute and 4-flute carbide end mill for stainless steel?

A 4-flute end mill is generally preferred for stainless steel. It offers better stability and chip evacuation for harder materials, leading to smoother finishes and less risk of chip recutting. A 2-flute can work but often requires slower feed rates and more care with chip management.

Q3: Is MQL necessary for milling stainless steel?

While not strictly mandatory, MQL (Minimum Quantity Lubrication) is highly beneficial. It provides essential cooling and lubrication to combat the high heat generated when cutting stainless steel, prolonging tool life and improving cut quality. It’s also much cleaner than flood coolant for home workshops.

Q4: How do I know if my end mill is MQL friendly?

Most modern solid carbide end mills designed for working with challenging materials like stainless steel are manufactured with internal coolant channels or are designed to perform well with external MQL application. Look for product descriptions that mention MQL compatibility or suitability for your specific material.

Q5: What happens if I use too much heat when milling stainless steel?

Excessive heat causes the cutting edge of your end mill to