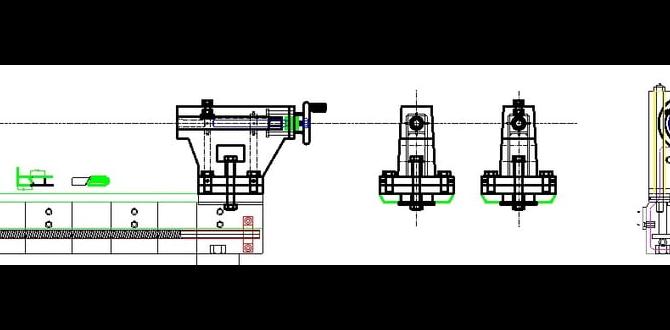

Carbide end mills with optimized flute geometry make cutting PVC smooth by efficiently clearing plastic chips, preventing melting and cutter damage.

Working with plastic on a mill can sometimes feel like wrestling a gummy bear – sticky, frustrating, and if you’re not careful, a real mess. One of the biggest headaches is when the cut material, called chips, melts and re-welds itself around your cutting tool. This is especially common with plastics like PVC. Melted chips can gum up your end mill, leading to poor surface finish, increased cutting forces, and even tool breakage. But there’s a really effective solution: using the right kind of carbide end mill designed for excellent chip evacuation. Let’s dive into what that means and how it can make your PVC machining projects so much easier and cleaner.

Why PVC Chip Evacuation is Tricky

PVC, or Polyvinyl Chloride, is a very popular plastic for many projects. It’s affordable, easy to work with, and offers good performance. However, it has a relatively low melting point. When you machine PVC, the friction from the cutting edge generates heat. If this heat isn’t carried away effectively, the PVC can soften and melt.

These melted chips then stick to the cutting flutes of your end mill. As the tool continues to cut, more melted plastic builds up. This creates a vicious cycle:

Poor Surface Finish: The melted plastic smears rather than being cleanly cut.

Increased Cutting Forces: The enlarged, softened material requires more force to push through.

Tool Wear: Chips clinging to the tool can cause premature dulling and chipping of the cutting edges.

Melting the Workpiece: The accumulated heat can start to melt the surrounding PVC material.

Tool Breakage: In severe cases, the cutter can get completely jammed, leading to breakage.

The Solution: Carbide End Mills Designed for Chip Evacuation

So, how do we combat this sticky situation? The answer lies in the design of the carbide end mill itself, specifically its flutes and geometry. For PVC and other sticky plastics, we need end mills that excel at getting the chips out of the cut and away from the tool as quickly as possible.

What Makes an End Mill Good at Evacuation?

Several design features contribute to superior chip evacuation:

Helix Angle: This is the angle of the cutting edges as they spiral around the tool. For materials that tend to produce long, stringy chips (like many plastics), a steeper helix angle (often 45 degrees or more) is beneficial. A steeper helix “pulls” the chip up the flute more effectively, helping to lift it out of the workpiece.

Flute Count: The number of cutting edges. For plastics, fewer flutes are often better.

2-Flute End Mills: These offer ample chip room. The wider space between the two flutes allows larger chips to pass through easily without clogging. They are often the go-to for plastic machining.

3-Flute End Mills: Can offer a good balance between chip removal and surface finish, but might be more prone to clogging with very soft or gummy plastics than 2-flute.

4-Flute End Mills: Typically better for metals, as they provide more cutting edges for smoother finishes and faster material removal in harder materials. They generally offer less chip room, making them less ideal for sticky plastics.

Chip Breakers: Some end mills have small notches or teeth along the cutting edge designed to break up long chips into smaller, more manageable pieces. While these are common in metalcutting, they are less frequently seen on standard plastic-specific end mills, where maximizing chip escape is the primary goal.

Polished Flutes: A highly polished surface within the flutes reduces friction between the chip and the tool. This makes it easier for chips to slide out, further preventing them from sticking and melting.

Coating: Certain coatings can improve chip evacuation. While not as common for PVC as for some metals, coatings like TiCN can offer some lubricity. However, for PVC, the base tool geometry is usually more critical than the coating.

Focusing on PVC: The Ideal End Mill

For PVC, the key is maximizing chip clearance. This generally means favoring:

2-flute end mills

Aggressive helix angles (often 30-45 degrees or steeper)

A design specifically labeled for plastics or general non-ferrous materials

Polished flutes

The exact dimensions you need (like shank diameter and length) will depend on your specific project, but the goal is to find the right geometry within those dimensions. For instance, you might be looking for a carbide end mill 1/8 inch 1/4 shank standard length for PVC chip evacuation. The “1/8 inch” refers to the cutting diameter, “1/4 shank” is the diameter of the tool holder, and “standard length” describes its overall reach. The critical part is ensuring the flute design is optimized for plastics.

Setting Up for Success: Speed, Feed, and Depth of Cut

Even with the perfect end mill, how you use it is crucial. Proper cutting parameters will significantly impact chip evacuation and prevent melting.

Speeds and Feeds: The Balancing Act

spindle speed (RPM): Generally, for plastics like PVC, you want to run at a faster spindle speed than you would for many metals. This allows the tool to cut efficiently and generate heat that is quickly dissipated by the rapid movement. However, too fast can overheat the plastic.

Feed Rate (IPM or mm/min): This is how fast the mill moves the cutter through the material. For chip evacuation, you typically want a good chip load. A chip load is the thickness of the material being removed by each cutting edge per revolution. A sufficient chip load ensures that a decent chip is formed and that this chip is efficiently cleared.

If your feed rate is too slow, you won’t form substantial chips, and the friction can build up heat.

If your feed rate is too fast, you can overload the tool or create excessive heat and stress.

A good starting point for 1/8 inch and 1/4 inch end mills in PVC might be:

Spindle Speed: 10,000 – 25,000 RPM (This will vary greatly depending on your machine’s capabilities and rigidity)

Chip Load per Tooth: Start small, around 0.001 – 0.003 inches (0.025 – 0.076 mm). This will translate to a feed rate. For a 2-flute end mill, it would be roughly 20,000 – 50,000 IPM (though your machine likely won’t achieve these speeds). A more practical approach is to calculate feed rate: Feed Rate (IPM) = RPM Number of Flutes Chip Load per Tooth.

Example: 15,000 RPM 2 flutes 0.002 inch chip load = 60 IPM.

Always consult your end mill manufacturer’s recommendations or machining calculators for specific starting points. It’s better to start conservatively and increase as you observe the material removal.

Depth of Cut and Stepover

Depth of Cut (DOC): This is how deep the end mill cuts into the material in a single pass. For PVC, using a shallower depth of cut is often better. This reduces the amount of material the tool has to clear at once, making it easier for the flutes to do their job. A common recommendation is to keep the DOC no more than 1-2 times the diameter of the end mill. For a 1/4 inch end mill, this would be 1/4 inch or less.

Stepover: This is the distance the tool moves sideways between passes (for profiling or pocketing). A moderate stepover is usually fine, but very large stepovers can sometimes lead to chips getting re-cut or packed into corners.

The Role of Lubrication (or Lack Thereof)

When machining metals, coolant or lubricant is almost always used to reduce heat and friction. For PVC, the situation is different.

Avoid Liquid Coolants: Most liquid coolants and lubricants will not work well with PVC. They can react with the plastic, making it even gummier, or simply won’t provide the necessary cooling effect without creating a mess.

Air Blast is Your Friend: The best practice for PVC is to use a strong blast of compressed air directed at the cutting zone. This air stream helps to:

Cool the cutting edge.

“Blow” the chips away from the cut and out of the flutes.

Prevent the plastic from melting.

A directed air nozzle, often attached to your machine’s spindle or a flexible coolant hose, is a must-have accessory for machining plastics.

Step-by-Step: Achieving Clean PVC Cuts

Let’s put this all together. Here’s how you can approach machining PVC with a carbide end mill for optimal chip evacuation:

- Choose the Right End Mill:

- Select a 2-flute carbide end mill.

- Look for one with a steeper helix angle (30-45 degrees or more).

- Ensure it’s designed for plastics or non-ferrous materials and has polished flutes.

- Confirm the diameter and shank size (e.g., 1/4 inch diameter, 1/4 inch shank).

- Secure Your Workpiece:

- Use a reliable method to hold your PVC firmly. Clamps, a vise, or double-sided tape (for thinner stock) can work. Ensure the PVC won’t move during the cut.

- Set Up Your Machine:

- Mount your chosen end mill securely in your collet or chuck.

- Ensure your workpiece is properly indicated and aligned.

- Configure Cutting Parameters:

- Start with conservative speeds and feeds, aiming for a good chip load. Use the calculated values as a starting point (e.g., 15,000 RPM, 60 IPM for a 1/4″ 2-flute).

- Set a shallow depth of cut (e.g., 0.125″ for a 1/4″ end mill).

- Set a reasonable stepover (e.g., 40-60% of the end mill diameter).

- Apply Air Blast:

- Turn on your compressed air directed at the cutting zone before you start cutting and keep it on throughout the operation.

- Perform a Test Cut (Optional but Recommended):

- If possible, make a small test cut on a scrap piece of the same PVC material. Check the chips being produced – they should be relatively small, dusty, or short strands, not long, stringy, melted masses.

- Execute the Machining Operation:

- Start the spindle and then engage the feed.

- Listen to the tool and watch the chip evacuation.

- If you see melting or excessive chip buildup, you may need to:

- Increase feed rate slightly.

- Decrease depth of cut.

- Ensure your air blast is strong and well-aimed.

- Reduce spindle speed if the plastic is truly melting from excessive friction (less common with good geometry, more common with poor speed/feed choices).

- Inspect Your Results:

- After the cut, check the workpiece for a clean finish and the end mill for any signs of melted plastic buildup. A clean flute is a sign of success!

Tools and Accessories for Success

Beyond the end mill itself, a few other items can greatly aid in successful PVC machining:

Collets and Holders: High-quality collets ensure the end mill is held securely and runs concentrically. Runout can exacerbate chip evacuation problems. For smaller diameters like 1/8 inch, precision collets are essential.

Rigid Machine: A sturdy milling machine with minimal play in its axes will provide the most consistent results and prevent chatter, which can also lead to poor chip formation.

Chip Vac or Dust Collection: While air blast is primary for evacuation during cutting, a chip vac or dust collection system is vital for managing the loose chips and dust afterward, especially for health and safety.

Indicator and Square: For good alignment and setup, these are standard but crucial for any machining.

Material Considerations: Different Types of PVC

It’s worth noting that not all PVC is the same.

Rigid PVC (uPVC): This is common for pipes and profiles. It machines well with the techniques described.

* Flexible PVC: This contains plasticizers and is much gummier. It’s significantly harder to machine cleanly and may require even more cautious speeds and feeds, possibly specialized tooling if large quantities are involved.

For most hobbyist and DIY applications, you’ll likely be working with rigid PVC.

Troubleshooting Common Issues

| Problem | Likely Cause | Solution |

| :——————————- | :————————————————- | :————————————————————————————————————————————- |

| Melting Plastic on Tool | Insufficient chip evacuation, high friction | Use a 2-flute end mill with aggressive helix, ensure strong air blast, increase chip load (feed rate), decrease depth of cut. |

| Poor Surface Finish | Dull tool, insufficient chip removal, wrong tool | Sharpen or replace end mill, check speeds/feeds for correct chip load, verify end mill geometry is suitable for plastics. |

| Chip Buildup in Flutes | Too much material packed, poor flute design | Increase air blast intensity/aim, reduce depth of cut, ensure flutes are clean and polished, consider a less aggressive stepover. |

| Tool Chatter/Vibration | Machine rigidity, dull tool, incorrect speeds/feeds | Ensure machine is rigid, use sharp tool, adjust RPM and Feed Rate to avoid resonant frequencies, reduce depth of cut. |

| End Mill Breakage | Excessive force, jamming, thermal shock, dull tool | Start with conservative parameters, ensure excellent chip evacuation, use sharp tooling, avoid sudden movements. |

External Resources for Machining Plastics

When diving into machining new materials, consulting authoritative guides is always wise. The Association for Manufacturing Technology (AMT) provides valuable resources on machining practices. For understanding materials and their properties, resources like the Plastics Industry Association can offer in-depth information on different polymer types. For general machining safety, the Occupational Safety and Health Administration (OSHA) has extensive guidelines that apply to any workshop environment.

Frequently Asked Questions

What is the best type of end mill for cutting PVC?

For PVC, the best end mill is typically a 2-flute carbide end mill with a steep helix angle (30-45 degrees or more) and polished flutes. This design maximizes chip clearance and helps prevent melting.

Why does PVC plastic melt when I machine it?

PVC has a low melting point. The friction generated during machining causes heat. If the chips are not efficiently cleared away from the cutting zone, they can melt and stick to the end mill, leading to a mess and poor results.

Should I use coolant when machining PVC?

No, liquid coolants are generally not recommended for PVC. They can react with the plastic, making it gummier. A strong blast of compressed air directed at the cutting zone is the preferred method for cooling and chip evacuation.

What speeds and feeds should I use for PVC?

For a 1/4 inch 2-flute end mill, starting around 15,000 RPM and an IPM feed rate that provides a chip load of 0.001-0.003 inches per tooth is a good ballpark. Always consult manufacturer recommendations and adjust based on observation.

Can I use a 4-flute end mill for PVC?

While technically possible for very shallow cuts or specific applications, 4-flute end mills are generally not ideal for PVC. Their tighter flutes offer less chip room, making them much more prone to clogging and melting with this material.

How deep should I cut PVC in one pass?

It’s best to use a shallow depth of cut, typically no more than 1-2 times the diameter of the end mill. For a 1/4 inch end mill, this means cutting no deeper than 1/4 inch per pass. This helps ensure efficient chip evacuation.

What’s the difference between machining PVC and aluminum?

Aluminum is a metal and requires different cutting parameters, often slower speeds, more aggressive depths of cut, and liquid coolants. PVC is a plastic with a low melting point, necessitating faster surface speeds, shallower depths of cut, and air cooling for optimal chip evacuation.

Conclusion

Tackling PVC on your milling machine doesn’t have to be a sticky mess. By understanding the challenges of chip evacuation and choosing the right tools and techniques, you can achieve clean, precise cuts every time. The key is to select a 2-flute, steep-helix carbide end mill designed for plastics, use a strong blast of compressed air, and maintain appropriate speeds and feeds that promote good chip formation and clearance. With a little attention to these details, you’ll be smoothly machining PVC projects and enjoying the confidence that comes from knowing your tools and techniques are working for you, not against you. Happy milling!