To achieve a genius polycarbonate mirror finish, use a sharp, high-quality carbide end mill, specifically a 1/8 inch with a 1/4 inch shank and a stub length, while precisely controlling feed rate, spindle speed, and depth of cut. Careful setup and technique are key to avoiding melt and achieving a flawless surface.

Ever tried to get that super smooth, almost reflective finish on polycarbonate and ended up with a sticky, melted mess? You’re not alone! Polycarbonate is a fantastic material, tough and clear, but it can be tricky to machine. High speeds and the wrong tools often lead to melting, gumming up your end mill, and a frustratingly dull finish. But what if there was a way to get that brilliant, mirror-like surface that looks professionally done? It’s absolutely possible, and it all comes down to using the right tools and techniques. We’re going to walk through exactly how to get that dazzling finish, making polycarbonate machining less of a headache and more of a creative success. Get ready to transform your projects!

Why Polycarbonate is Tricky (and Why We Love It Anyway)

Polycarbonate’s popularity in DIY and professional projects stems from its incredible impact resistance – it’s often called “unbreakable.” It’s clearer than many plastics and can take a lot of abuse. However, this toughness also means it has a relatively low melting point and a tendency to be “gummy” when machined. This gummy nature is the main culprit behind poor surface finishes. As a tool cuts, friction generates heat. With softer plastics like polycarbonate, this heat can quickly exceed the material’s melting point, causing it to deform, stick to the cutting tool, and clog up flutes. The result is chatter, rough surfaces, and bits of plastic welded onto your end mill.

The Secret Weapon: The Right Carbide End Mill

When you’re aiming for a mirror finish on polycarbonate, the choice of cutting tool is paramount. Forget those generic, all-purpose end mills. For this specific task, we need a specialized tool. The keywords here are “carbide end mill,” “1/8 inch,” “1/4 inch shank,” and “stub length.” Let’s break down why each of these features is critical:

Carbide vs. High-Speed Steel (HSS)

- Carbide: Carbide end mills are significantly harder and more rigid than HSS. This means they can withstand higher cutting speeds and temperatures without deforming or losing their sharp edge as quickly. For gummy materials like polycarbonate, carbide’s hardness is essential for a clean cut, reducing melting and chip welding.

- HSS: High-Speed Steel is more ductile and less brittle than carbide. While good for many general machining tasks and some plastics, it tends to heat up more easily and can dull faster when encountering the challenges of machining polycarbonate at speeds needed for a good finish.

The Importance of Size: 1/8 Inch Diameter

A 1/8 inch diameter end mill is often ideal for achieving fine details and smooth passes. Smaller diameter tools can operate at higher spindle speeds more effectively (within machine limits) and are less prone to generating excessive heat per flute pass compared to larger tools. This smaller size allows for more delicate control over the cutting process, which is crucial when chasing a mirror finish. It also helps in achieving tighter tolerances and finer features in your polycarbonate parts.

The Shank: 1/4 Inch for Stability

The 1/4 inch shank provides a good balance of rigidity and compatibility with most common milling machine collets and tool holders. A stout shank reduces tool deflection, ensuring the cutting edges engage the material consistently. Less deflection means a smoother cut and a more uniform surface finish. While smaller shanks exist, a 1/4 inch shank offers the robustness needed for stable machining of polycarbonate without being overly bulky.

Stub Length: Minimizing Tool Deflection

A “stub length” end mill has a shorter flute length and overall length compared to standard end mills. This design offers superior rigidity, which is paramount when dealing with potentially wobbly cuts in plastic. Shorter tools are stiffer and less prone to vibration, chatter, and deflection. When you’re trying to achieve a flawless mirror finish, minimizing any tool movement or vibration is key. The stub length helps ensure that the cutting edge stays precisely where you want it, cutting cleanly rather than dragging or melting.

Specific Recommendations: Chip Breakers and Flute Count

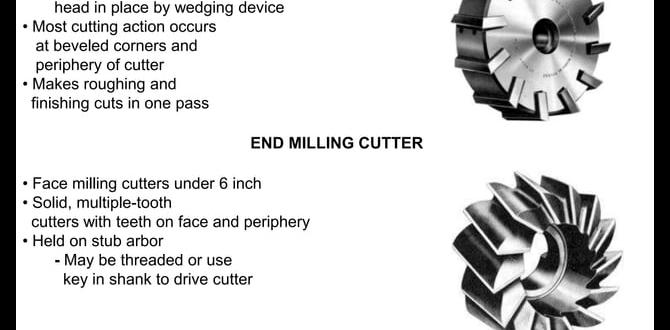

For polycarbonate, tools designed for plastics or non-ferrous metals are usually best. Look for:

- 2-Flute End Mills: These are generally preferred for plastics. More flutes can lead to chip-packing issues. A 2-flute design allows for efficient chip evacuation, which is critical to prevent melting.

- Polished Flutes: End mills with polished flutes reduce friction and help chips slide away more easily, further minimizing heat buildup and material adhesion.

- Sharp, High-Quality Edges: This cannot be stressed enough. A dull or chipped end mill is the enemy of a good finish. Invest in a reputable brand known for producing sharp, precise carbide tools.

Setting Up for Success: Your Polycarbonate Mirror Finish Workflow

Achieving a genius mirror finish on polycarbonate isn’t just about the tool; it’s about the entire setup and process. Precision and control are your best friends here.

Material Preparation

Before you even touch the mill, ensure your polycarbonate sheet is clean and free from any dirt, oils, or protective films that could interfere with the cut or melt onto the tool. If you’ve cut the polycarbonate with a coarse saw or router, consider a light pass with a finer tool or a deburring tool to remove any large imperfections on the edge that will be machined.

Workholding: Keep it Stable!

Secure your polycarbonate firmly. Any movement will lead to inconsistent cuts and a poor finish. Use clamps, a vise, or double-sided tape specifically designed for machining applications to ensure the material doesn’t shift during the operation. Ensure your clamping doesn’t create stress points that could cause the polycarbonate to crack, especially around thin sections. For very thin sheets, consider using a sacrificial backing board or a hold-down system that distributes pressure evenly.

Machine Setup: The Foundation of Precision

This is where the magic happens. Your machine needs to be set up correctly to execute the clean cut required for that mirror finish.

- Rigidity: Ensure your milling machine, Z-axis, and tool holder are all as rigid as possible. Any play or looseness will translate into a poor finish.

- Cleanliness: Make sure your spindle is clean and your collet is free of debris. A well-seated tool is crucial.

- Coolant/Lubrication (Optional but Recommended): While not always necessary for polycarbonate, a minimal amount of a specialized plastic cutting fluid or even a blast of compressed air can help manage heat and chip evacuation. Avoid water-based coolants that can cause thermal shock or crazing in some plastics. A light mist of a suitable lubricant can make a huge difference.

For guidance on coolants and lubricants, reputable sources like https://www.machinerylubricants.com/ offer valuable industry insights.

The Cutting Parameters: Finding the Sweet Spot

This is arguably the most critical part of achieving a mirror finish. Polycarbonate is sensitive to heat and speed. Too fast, and it melts; too slow, and it can chatter. The goal is the cleanest possible chip removal.

Spindle Speed (RPM):

For a 1/8 inch carbide end mill in polycarbonate, you’ll generally want to operate at a moderate to high spindle speed. This helps the tool cut efficiently rather than rub. A good starting point might be between 8,000 and 15,000 RPM, but this can vary depending on the specific end mill geometry, machine capability, and material thickness. The key is that the tool is spinning fast enough to shear the material cleanly.

Feed Rate (IPM – Inches Per Minute or mm/min):

The feed rate determines how quickly the end mill moves through the material. You want a feed rate that works in conjunction with your spindle speed to create a proper chip. Too slow a feed rate at high RPM will lead to rubbing and melting. Too fast a feed rate will overload the tool and potentially cause chatter or breakage. A good starting point for a 1/8 inch carbide end mill might be between 15 to 40 inches per minute (approx. 380-1000 mm/min). This will likely require some fine-tuning. The aim is to produce small, consistent chips, not dust or stringy melted material.

Depth of Cut (DOC – Axial and Radial):

This is where stubbing your toe can happen! For a mirror finish, you’ll typically want to take light cuts.

- Axial Depth of Cut (How deep you plunge or cut down): Keep this shallow. For finishing passes, aim for 0.010″ to 0.030″ (0.25mm to 0.75mm). For roughing, you can go deeper (0.100″ – 0.200″ or 2.5mm – 5mm), but remember you’ll need a dedicated finishing pass.

- Radial Depth of Cut (How wide a cut it takes across the surface, often called Stepover): For a smooth surface finish, a small radial stepover is essential. Aim for 20% to 50% of the tool diameter. For a 1/8 inch end mill, this means a stepover of 0.025″ to 0.060″ (0.6mm to 1.5mm). A smaller stepover results in a finer surface texture, closer to a mirror finish.

Cutting Strategy: Climb Milling vs. Conventional Milling

Climb Milling: In climb milling, the cutter rotation direction is the same as the feed direction. This generally results in a cleaner cut, less tool pressure, and better surface finish, especially in plastics. It’s often the preferred method for achieving a mirror finish. The cutting edge engages the material at its thickest point and exits at its thinnest, reducing friction and the tendency to “drag.”

Conventional Milling: In conventional milling, the cutter rotation direction is opposite to the feed direction. This creates more tool pressure and friction and is more prone to chatter, making it less ideal for achieving a mirror finish on polycarbonate.

Always prioritize climb milling for polycarbonate finishing passes if your machine setup allows for it.

Example Cutting Parameters Table

These are starting points. Always test on scrap material first!

| Operation | End Mill | Spindle Speed (RPM) | Feed Rate (IPM) | Axial DOC (inches) | Radial DOC (Stepover – inches) | Direction | Notes |

|---|---|---|---|---|---|---|---|

| Roughing (Optional) | 1/8″ 2-Flute Carbide Stub | 8,000 – 10,000 | 20 – 30 | 0.100 – 0.200 | 40% (0.050) | Climb Milling | Remove bulk material. Leave ~0.010″ for finishing. |

| Finishing Pass (for Mirror Finish) | 1/8″ 2-Flute Carbide Stub (Polished Flutes Recommended) | 10,000 – 15,000+ | 25 – 40 | 0.010 – 0.025 | 20% – 30% (0.025 – 0.040) | Climb Milling | Light, high-speed pass to achieve smooth surface. |

Remember, the specific RPM and feed rate values are heavily dependent on your machine’s rigidity, the exact geometry of the end mill, and the clamping force. A more rigid machine can handle higher speeds and feeds. For more information on cutting parameters and tool selection for plastics, industry resources like https://www.plasticstoday.com/ offer valuable insights into material properties and machining best practices.

Troubleshooting Common Mirror Finish Issues

Even with the best setup, you might encounter problems. Here’s how to tackle them:

- Melting/Gummy Chips:

- Cause: Too much heat. This could be due to feed rate being too slow for the RPM, not enough chip load, or a dull tool.

- Solution: Increase feed rate slightly, decrease axial DOC, increase spindle RPM, or use a sharper/higher-quality end mill. Compressed air blast can also help evacuate chips and heat.

- Chatter/Vibration:

- Cause: Tool deflection, loose workholding, machine rigidity issues, or incorrect cutting parameters (feed rate too slow, DOC too aggressive).

- Solution: Use a more rigid tool (stub length is good for this), improve workholding, slow down feed rate slightly or reduce DOC. Ensure Z-axis is locked down. Try using a slower spindle speed if you hear rapid squealing.

- Rough Surface Texture (Not Reflective):

- Cause: Stepover too large, dull tool, insufficient spindle speed, or feed rate too fast.

- Solution: Decrease the radial stepover (e.g., down to 20%), ensure your tool is razor-sharp, increase spindle RPM, or slightly decrease feed rate.

- Edge Chipping/Cracking:

- Cause: Tool engagement issues, material stress, or aggressive feed rates/DOC.

- Solution: Ensure climb milling. Reduce DOC and feed rate. Check workholding for any over-tightening that could induce stress. Make sure the polycarbonate is supported properly.

Beyond the Cut: Post-Machining Polishing

Sometimes, even with perfect machining, there might be microscopic marks that prevent a true mirror finish. A light post-machining polish can elevate your results.

Manual Polishing:

Use a progressively finer grit abrasive. Start with a 400-grit wet-dry sandpaper (used wet), then move to 800, 1200, and even 2000 grit. Always sand in one direction, then switch to the perpendicular direction for the next grit to ensure you’re removing the scratches from the previous step. After sanding, a plastic polish compound (available at most auto parts or plastics suppliers) with a soft, lint-free cloth can bring out an incredible shine. Be patient and use light, even pressure.

Rotary Polishing Tools:

A Dremel or a similar rotary tool with a polishing felt or cotton buffing wheel and a plastic polish compound can also be very effective. Use a low-to-medium speed setting to avoid generating too much heat, and keep the tool moving constantly to prevent melting or creating distortion. This method can be faster but requires a steady hand.

For further understanding of abrasive technologies and polishing compounds, resources from organizations like the NASA (in their materials science sections) or various industrial abrasives manufacturers can provide deep dives into their application and effectiveness.

Safety First: Always

Machining, even plastics, requires respect for the tools and materials. Always:

- Wear safety glasses or a full face shield.

- When possible, use dust extraction to manage plastic chips.

- Keep hands and loose clothing away from rotating machinery.

- Know your machine and its limits.

- If using a lubricant or coolant, ensure it’s rated for use with plastics and ventilation is adequate.

Frequently Asked Questions

Q1: What is the best type of end mill for polycarbonate?

The best end mill for polycarbonate is a sharp, high-quality carbide end mill. For a mirror finish, specifically look for a 1/8 inch diameter, stub length, 2-flute end mill with polished flutes, designed for plastics or non-ferrous metals.

Q2: Can I use a regular end mill for polycarbonate mirror finish?

While you can use a regular end mill, achieving a true mirror finish will be significantly more challenging. Specialized end mills with specific geometries and coatings are designed to perform better, reducing heat and preventing melting, which is crucial for a high-quality finish.

Q3: What spindle speed (RPM) should I use for cutting polycarbonate with a 1/8 inch end mill?

A good starting range for RPM is between 8,000 and 15,000 RPM, but it often works better on the higher end for a clean cut. Always start lower and increase gradually while observing chip formation and listening to the cut. Higher RPMs help the tool shear the material cleanly rather than rub and melt it.

Q4: Is climb milling or conventional milling better for polycarbonate?

Climb milling is generally better for